Branch crusher tooth

A technology of chipping machine and machine teeth, applied in grain processing and other directions, can solve problems such as affecting work efficiency, impact of tooth head materials, increasing use cost, etc., and achieves the effect of reducing use cost, convenient use and installation, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

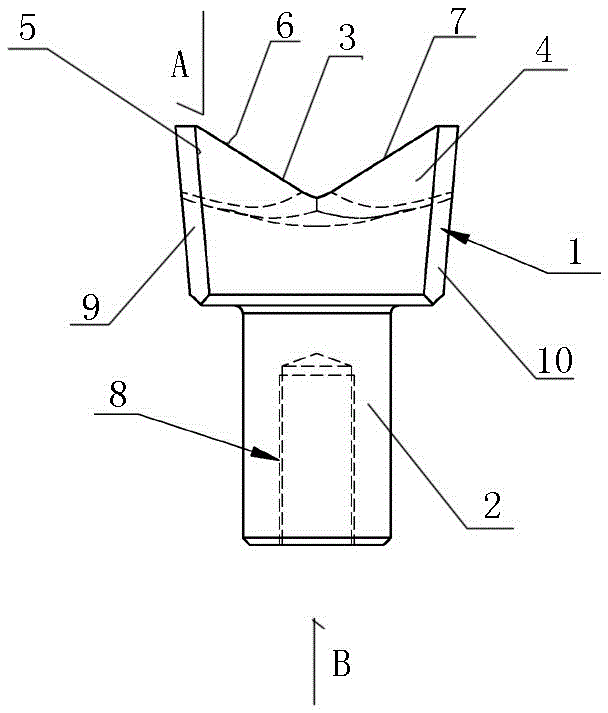

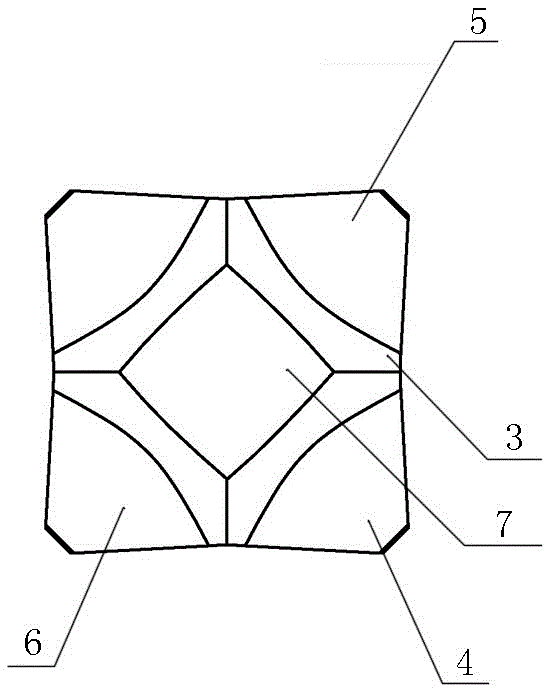

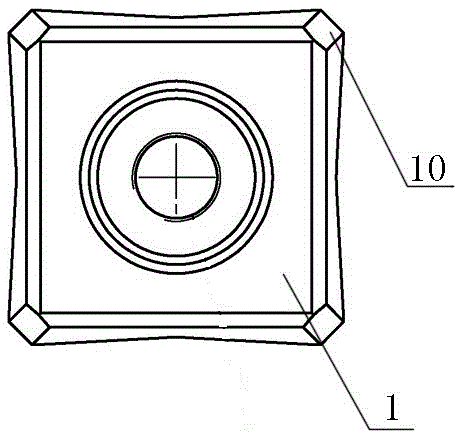

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a shredder tooth according to the present invention includes a square block machine tooth body 1 , and a vertically downward connecting column 2 is connected in the middle of the lower end surface of the machine tooth body 1 . The upper end surface of the machine tooth body 1 is a working surface 3, and the four corners on the working surface 3 are respectively provided with a triangular block tooth head end 4 integrally formed with the machine tooth body, and each tooth head end 4 is The outer corner protrudes into a sharp corner 5, and transitions from the outer sharp corner 5 to the inner slope 6 downward or arc-shaped downward to the working surface, and forms a V-shaped groove 7 on the top of the four sides; The cylindrical surface of the connecting column 2 is an assembly surface, and the lower end surface of the connecting column 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com