Wood chipper tooth head

A chipper and tooth head technology, applied in grain processing, etc., can solve problems affecting work efficiency, impact of tooth head materials, damage to tooth head structure, etc., to reduce use cost, improve work efficiency, and easy to use and install Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

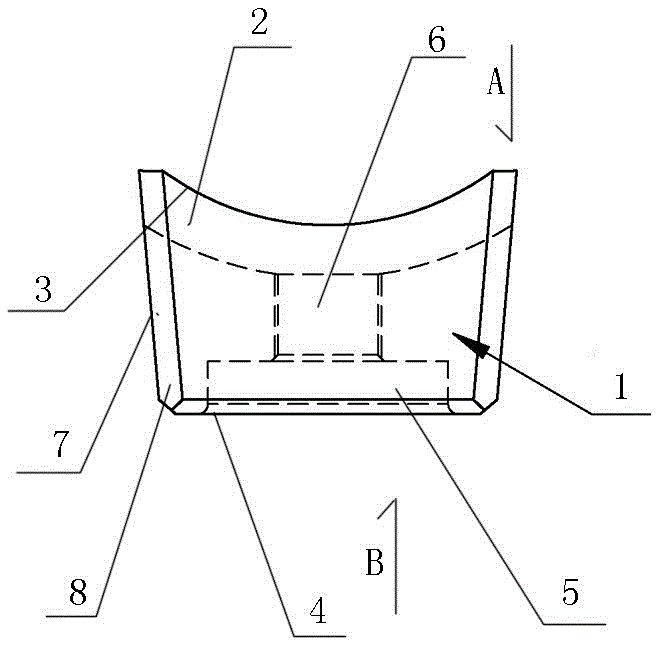

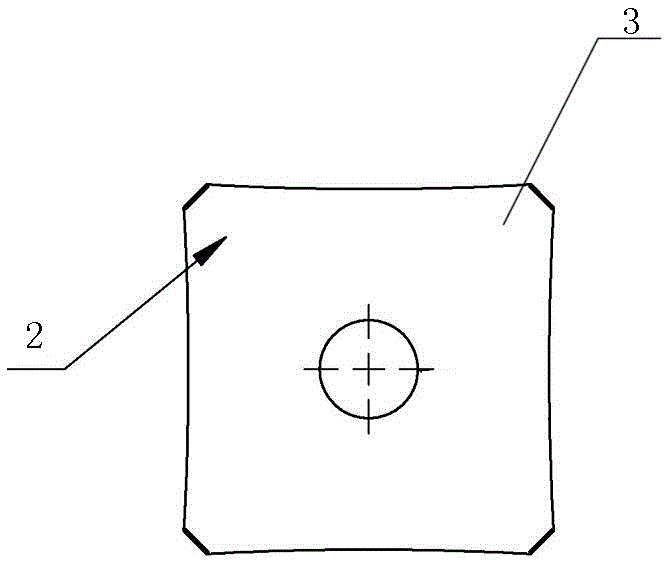

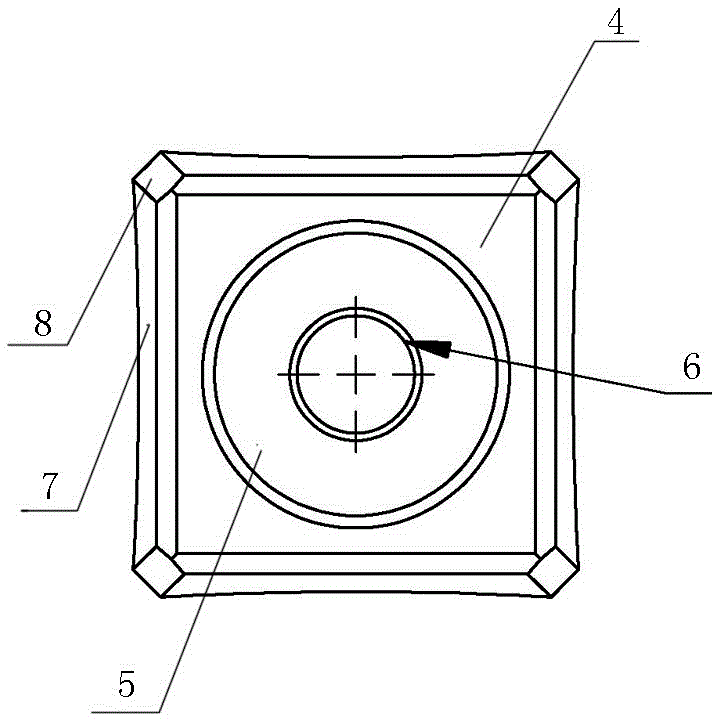

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a tooth head of a branch breaker according to the present invention includes a square block tooth head body 1, the upper end surface of the tooth head body 1 is a working surface 2, and the working surface 2 is formed by a spherical body The upper end surface of the tooth head body 1 is formed by a circular arc end face tangentially formed, and the four corners form an upwardly convex sharp knife angle 3; the lower end surface of the tooth head body 1 is an assembly surface 4, and the middle of the assembly surface 4 is set A countersunk hole 5 is provided, and a vertically upward positioning threaded through hole 6 is arranged in the middle of the countersunk hole 5 .

[0011] As shown in the figure, the four sides of the tooth head body 1 are slopes 7 retracted from top to bottom, forming a quadri-conical body whose upper area is larger than the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com