Scrapped vehicle detachment flexible turnover machine

A turning machine and flexible technology, applied in the direction of hoisting device, hoisting device, etc., can solve problems such as unreliable clamping, potential safety hazards, and depression of the car roof, so as to achieve firm and reliable clamping, improve production efficiency, and broaden the application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

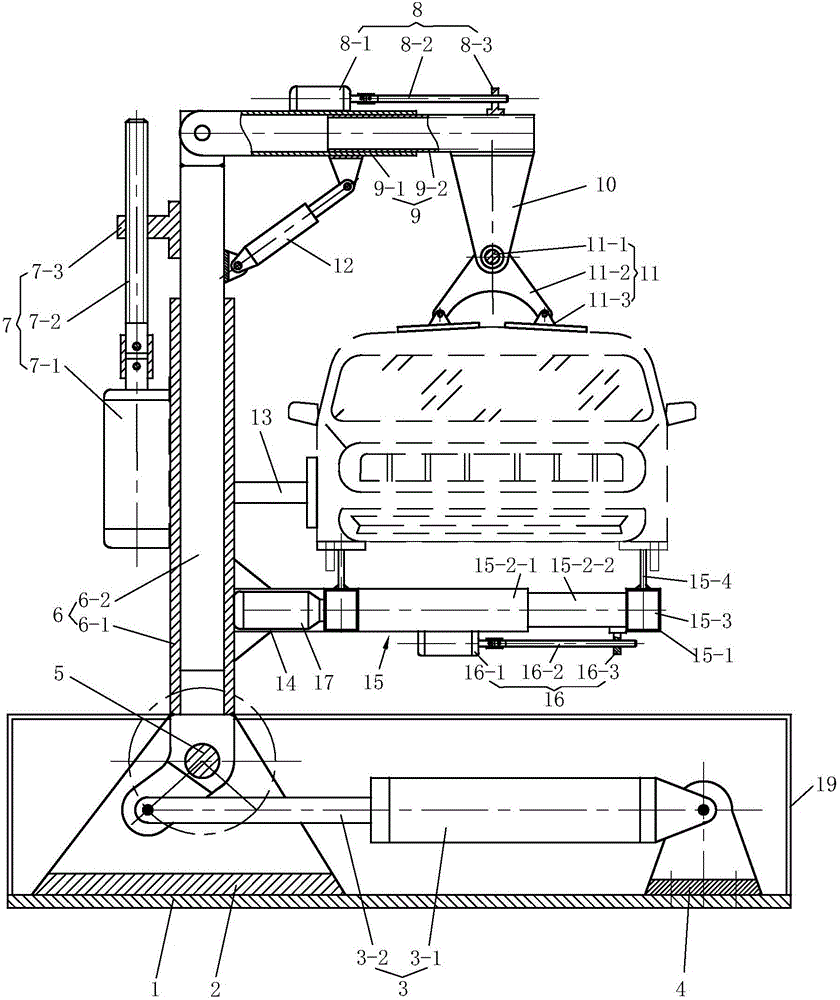

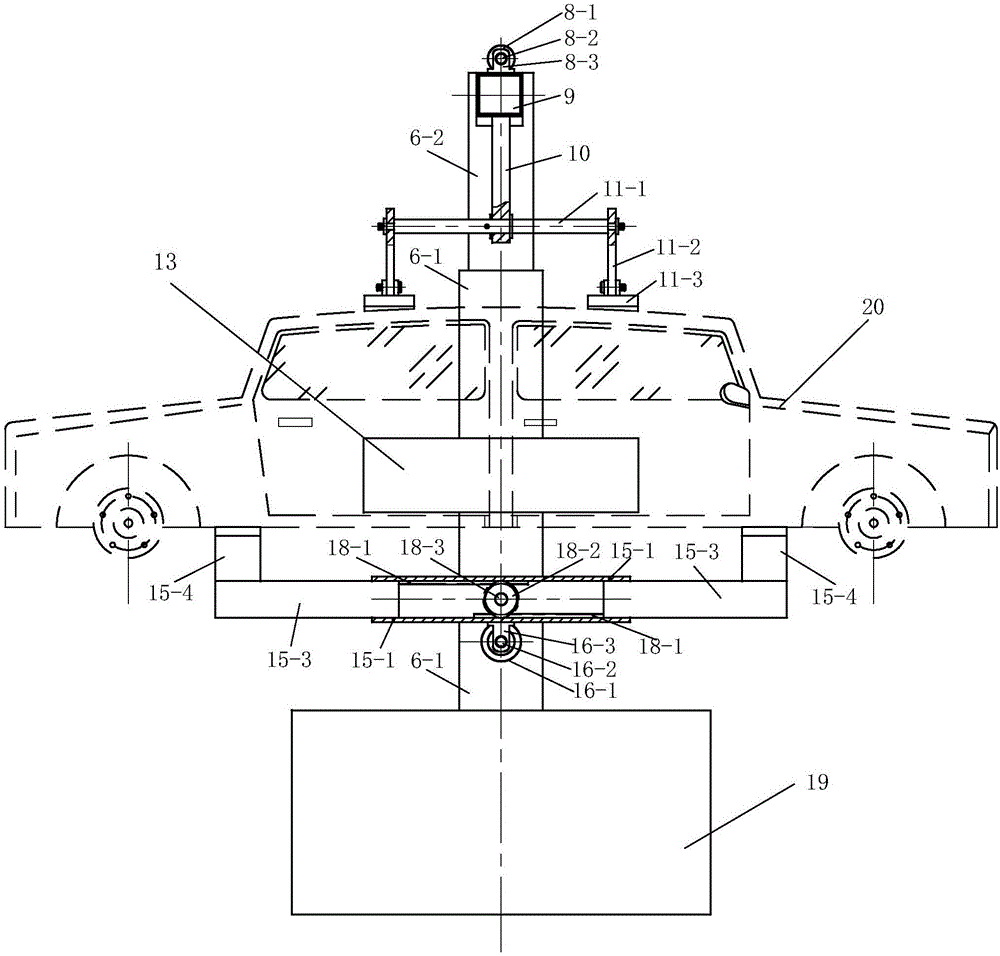

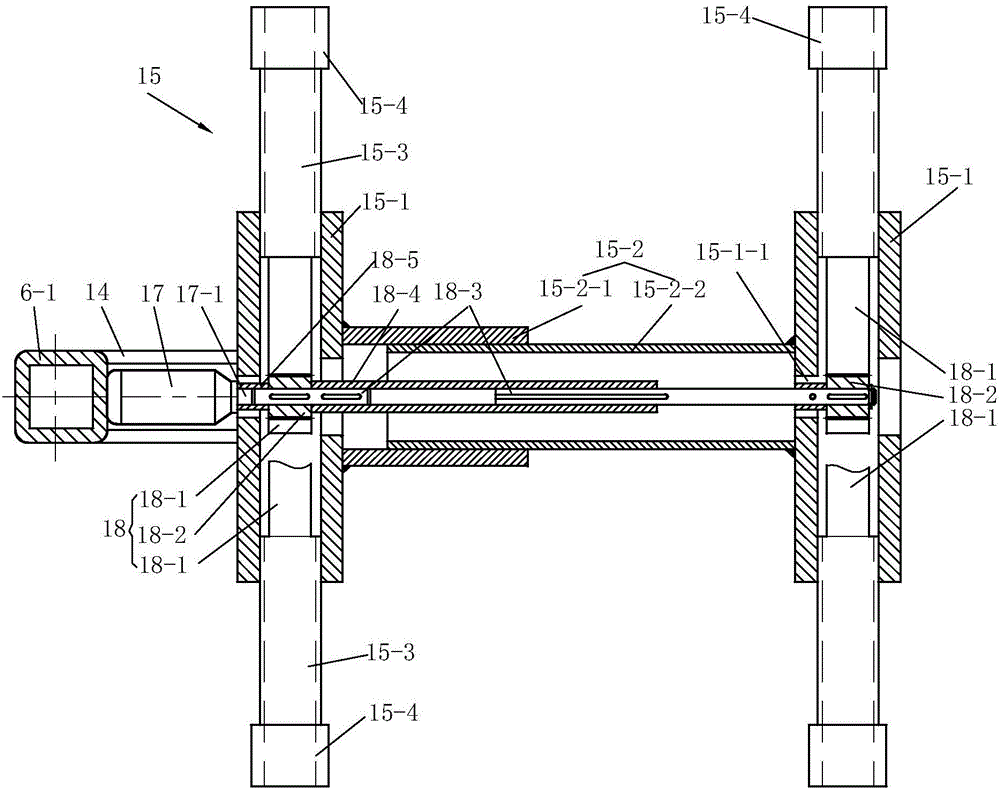

[0015] See Figure 1 to Figure 3 , the present embodiment has a base 1 , a column 6 , a beam 9 , a carrier frame 15 , an overturning hydraulic cylinder 3 and a clamping hydraulic cylinder 12 . The base 1 is provided with a first hinge seat 2 and a second hinge seat 4 distributed left and right.

[0016] The column 6 is composed of a square hollow column 6-1 and a square lifting column 6-2 dynamically matched with the hollow column 6-1. The lower end of the hollow column 6-1 is hinged on the first hinge seat 6 through the first pin shaft 5 , the lifting mechanism 6-17 supported by the hollow column 6-1 drives the lifting column 6-2 to lift. The lifting mechanism can be a hydraulic cylinder, and the lifting mechanism 7 of the present embodiment is driven by a motor. The lifting mechanism 7 includes a lifting motor 7-1 fixed on the hollow column 6-1, and a lifting wire connected to the main shaft of the lifting motor 7-1. Bar 7-2 and the lifting nut 7-3 that is fixed on the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com