Nanometer cement grout and application thereof

A technology of cement slurry and slurry liquid, which is applied in the field of nano-cement slurry, which can solve the problems of poor adhesion performance, anchor bolt erosion, and poor anchor bolt protection effect, and achieve high adhesion performance, not easy to rust, and high protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

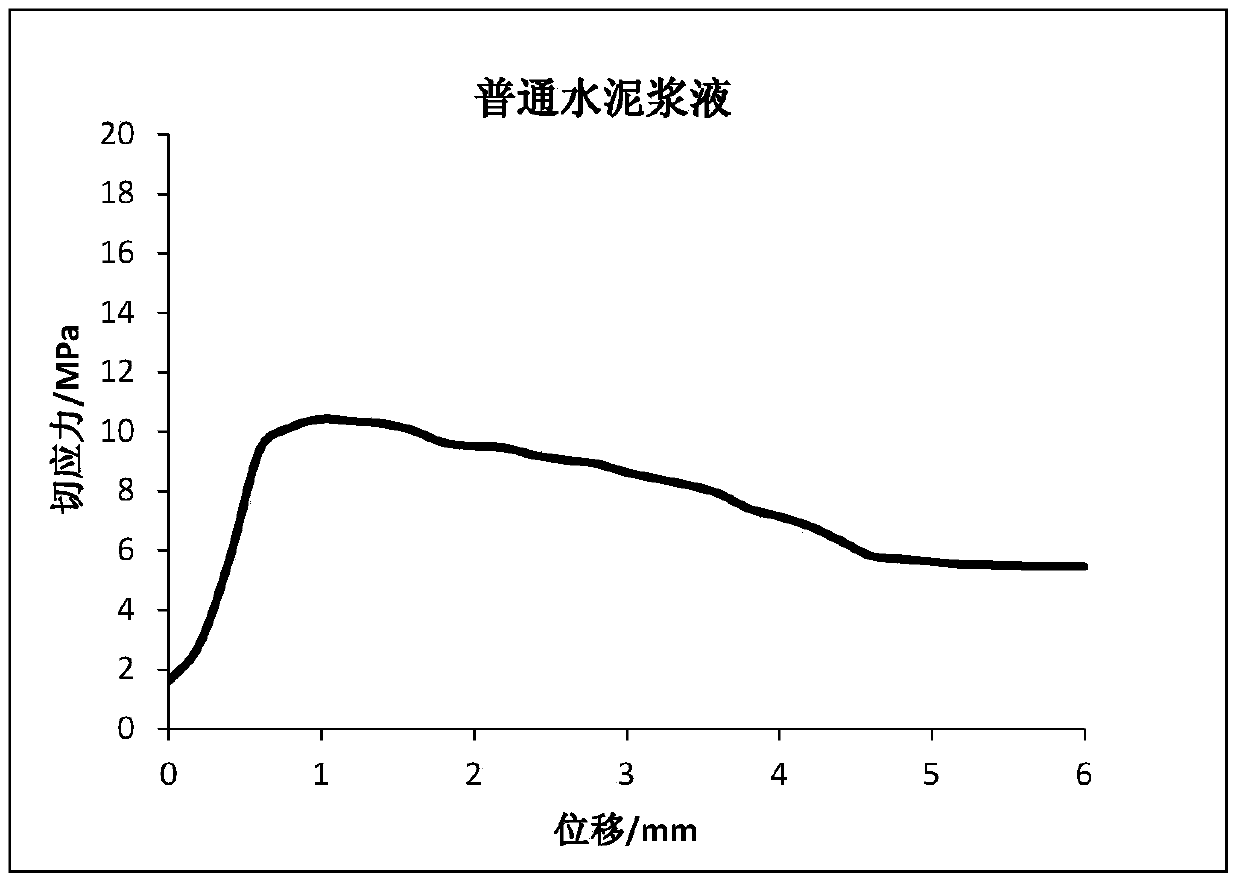

Embodiment 1

[0036] The raw materials are ordinary Portland cement 15.1302kg, water 7.5651kg, non-hydrophilic nano-silica and UNF-5 naphthalene-based water reducing agent, mixed uniformly to obtain cement slurry.

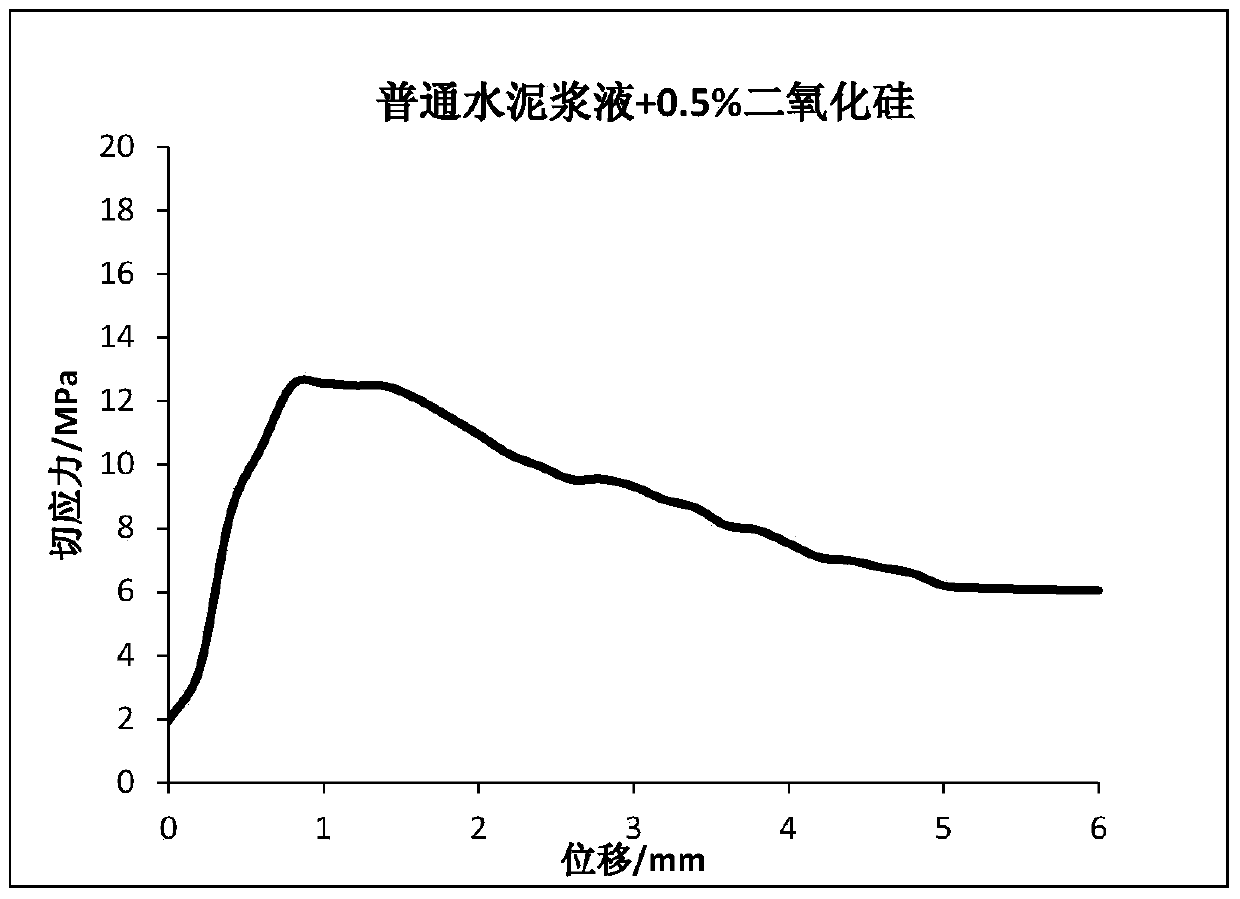

Embodiment 2

[0038] The raw materials are ordinary Portland cement 15.1302kg, water 7.5651kg, 0.5% of the total mass of ordinary Portland cement and water, hydrophilic nano-silica, and no UNF-5 naphthalene-based water reducing agent, mixed uniformly to obtain cement Slurry.

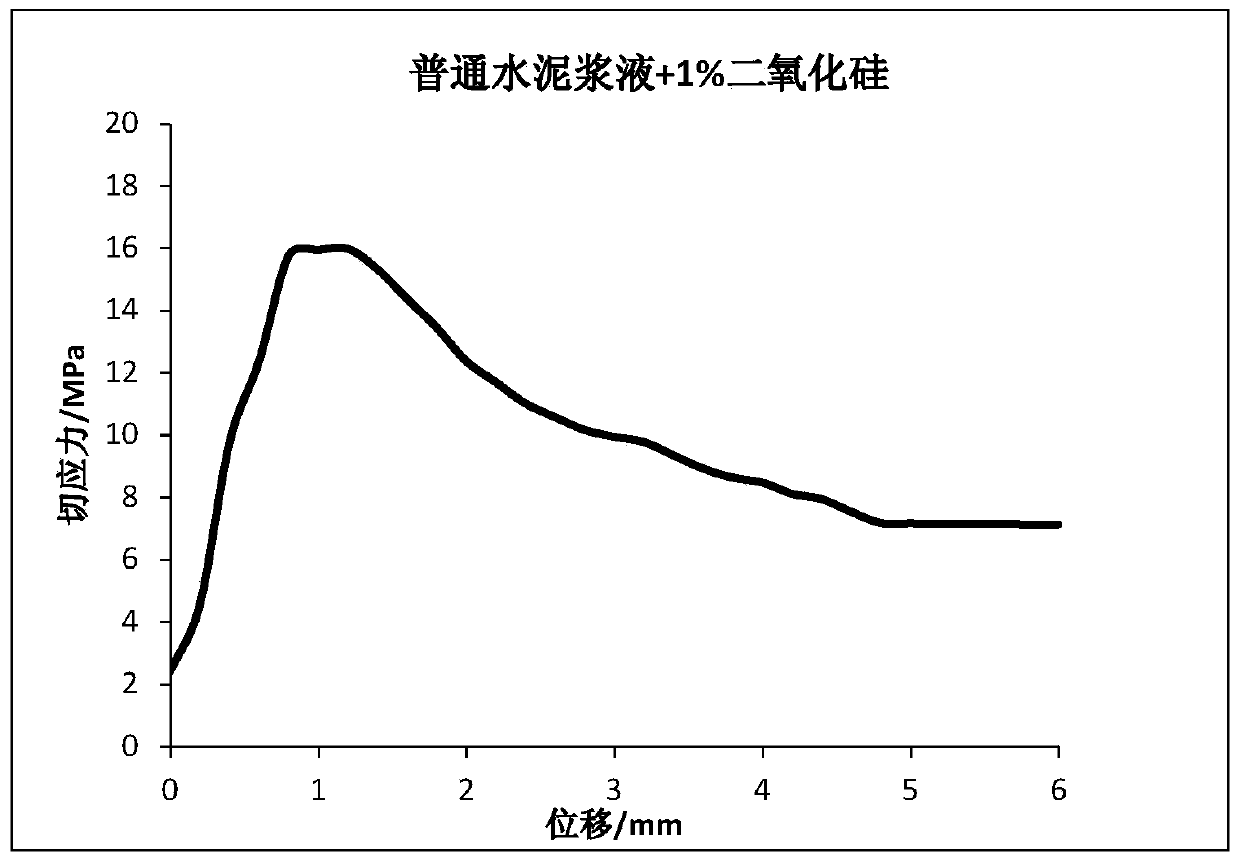

Embodiment 3

[0040] The raw materials are ordinary Portland cement 15.1302kg, water 7.5651kg, hydrophilic nano-silica accounting for 1% of the total mass of ordinary Portland cement and water, and no UNF-5 naphthalene-based water-reducing agent. Mix uniformly to obtain cement Slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com