Movable electro-hydraulic composite drive spraying robot with large working space

A spraying robot and electro-hydraulic composite technology, applied in the field of robots, can solve problems such as the limitation of the running space by the track, the interference of the spraying process, and the limitation of the working space, so as to improve the spraying accuracy and dynamic performance, improve the motion stability, and improve the applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The specific embodiments of the present invention are given below, and will be described in conjunction with the accompanying drawings.

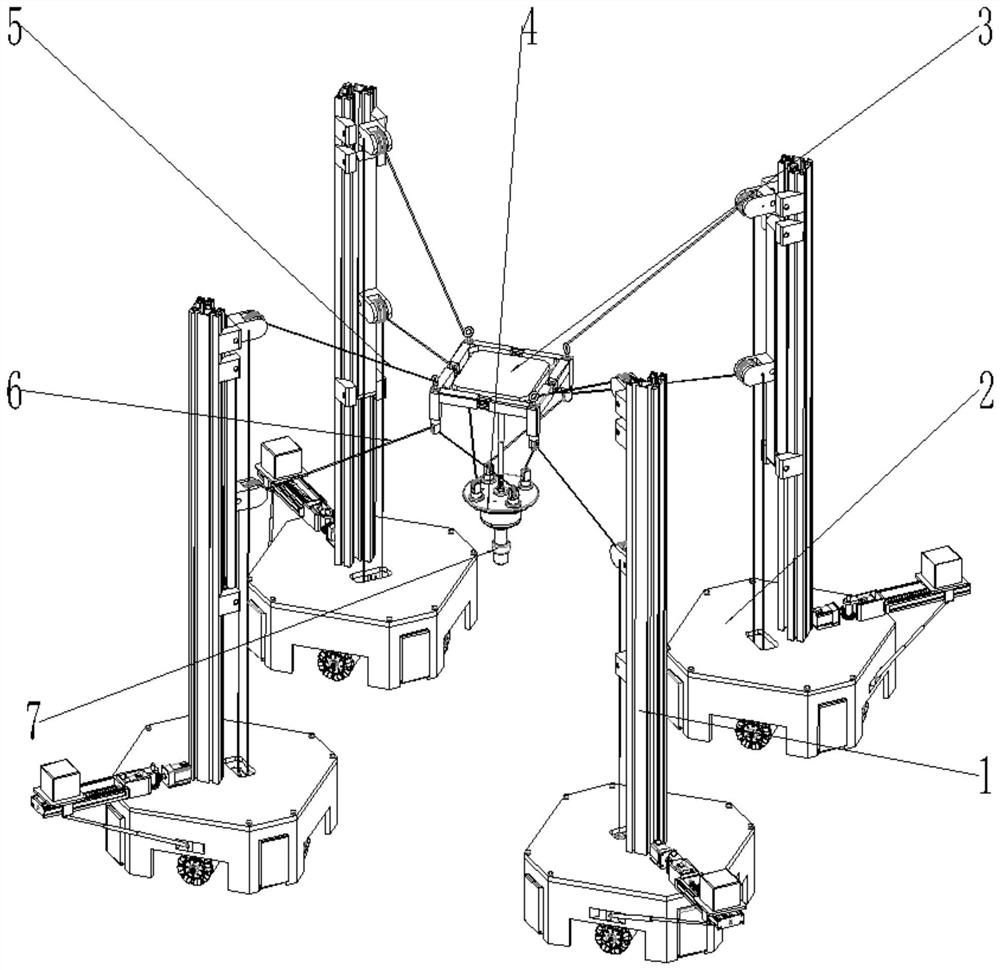

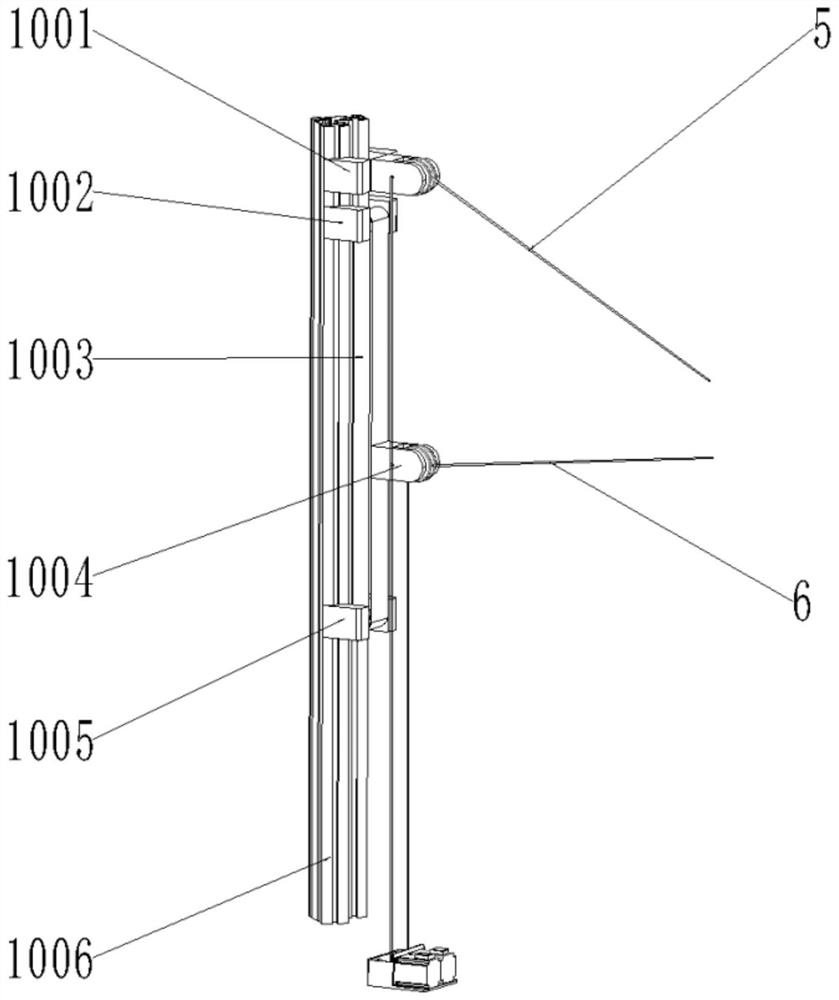

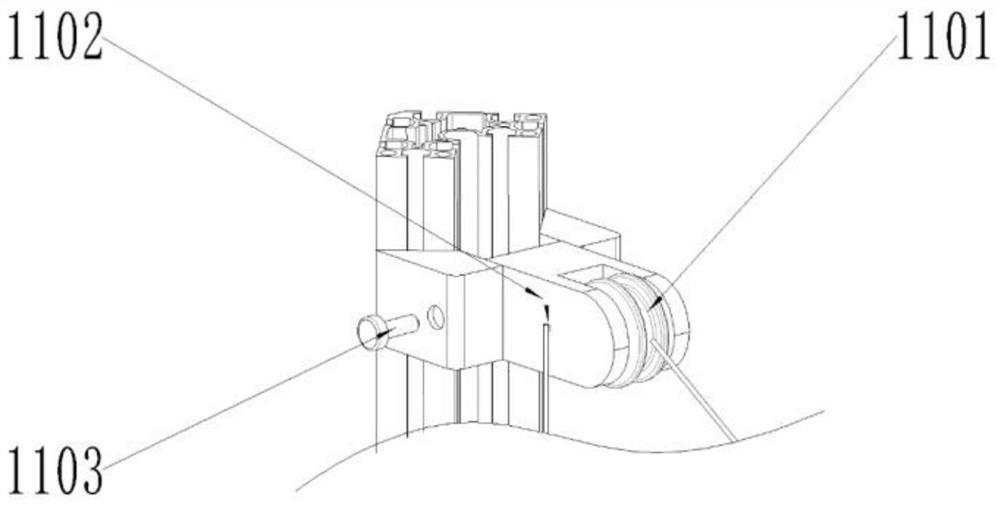

[0078] Combine figure 1 The spray robot with large working space removable electro-hydraulic composite drive is adjusted by four identical drive rope position adjustment modules 1, four exact same mobile base 2, adjustable auxiliary sports platform 3, rotary moving platform 4 , Four adjustable auxiliary sports platforms drive rope 5, four swivel moving platforms drive rope 6, and the gun 7 is composed.

[0079] Further, four mobile base 2 is responsible for carrying other mechanisms, securing the corresponding four drive rope adjustment modules 1, the corresponding four drive rope adjustment module 1 is fixed to the mobile base 2 by the mounting holes reserved on the mobile base 2. On, thereby realizing a large-range movement of the robot's overall movement; the adjustable auxiliary motion platform drive rope 5 is driven by one motor in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com