Special transmission device with flexible shock absorption structure for magnetic latching relay

A technology of magnetic latching relay and transmission device, applied in the direction of non-pole relay, etc., to achieve the effect of improving effective driving force, maintaining long-term working stability and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

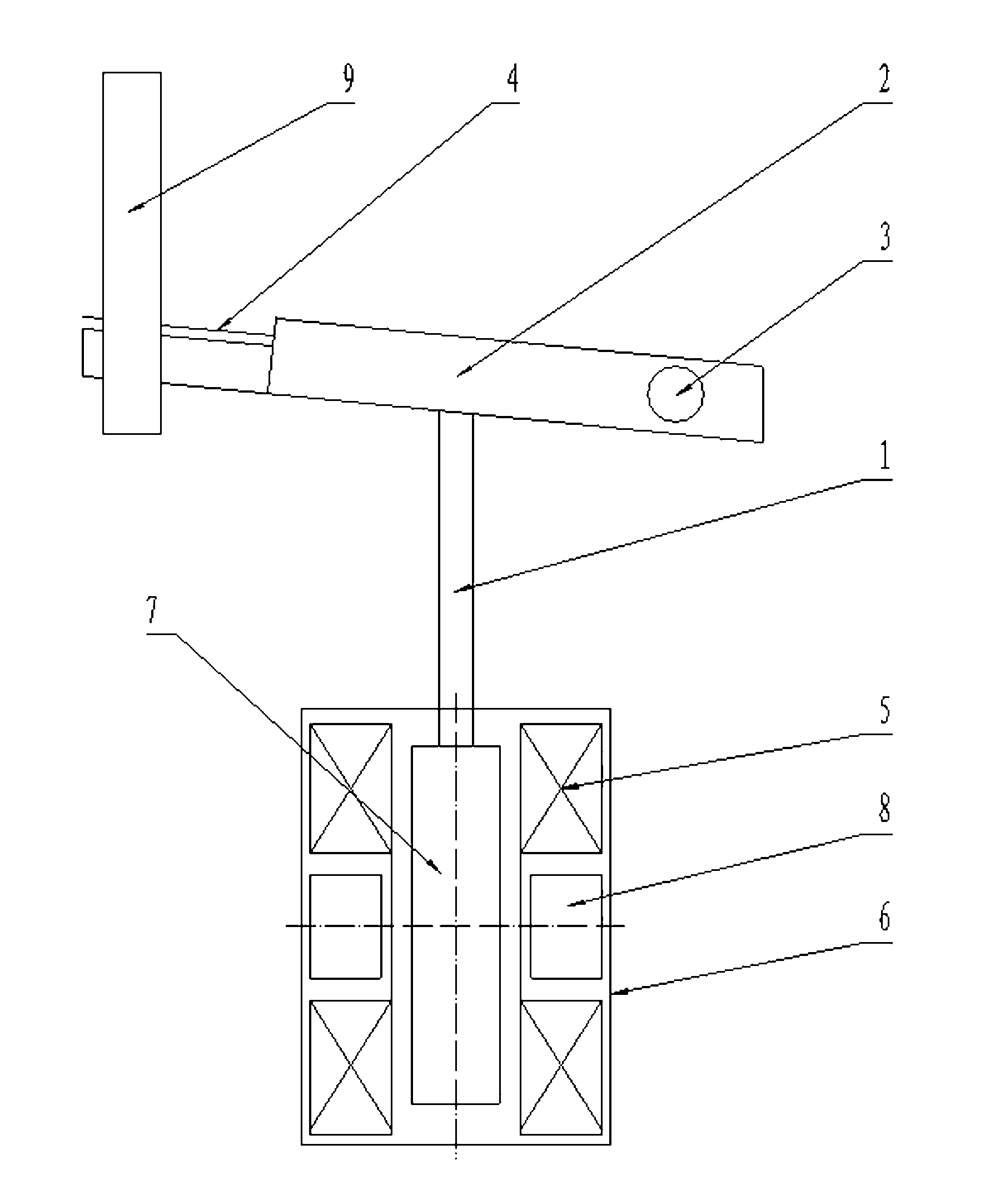

[0021] Such as figure 1 It can be seen that the transmission device with a flexible damping structure for magnetic latching relays of the present invention includes an insulating transmission rod 1, and one end of the insulating transmission rod 1 is provided with a rocker arm 2, and the other end is connected with a magnetic drive device; one end of the rocker arm 2 is provided with a rotating shaft 3. The other end is provided with an overtravel piece 4, and the overtravel piece 4 is arranged above the rocker arm 2 in parallel, and there is a stroke space between the end of the overtravel piece 4 and the end of the rocker arm 2 that can make the overtravel piece 4 yield, so that the overtravel piece 4 The process sheet 4 can play the role of flexible shock absorption.

[0022] When working, the position of the rotating shaft 3 is fixed, and the insulating transmission rod 1 is pushed to be displaced by the magnetic driving device, thereby causing the rocker arm 2 to rotate a...

Embodiment 2

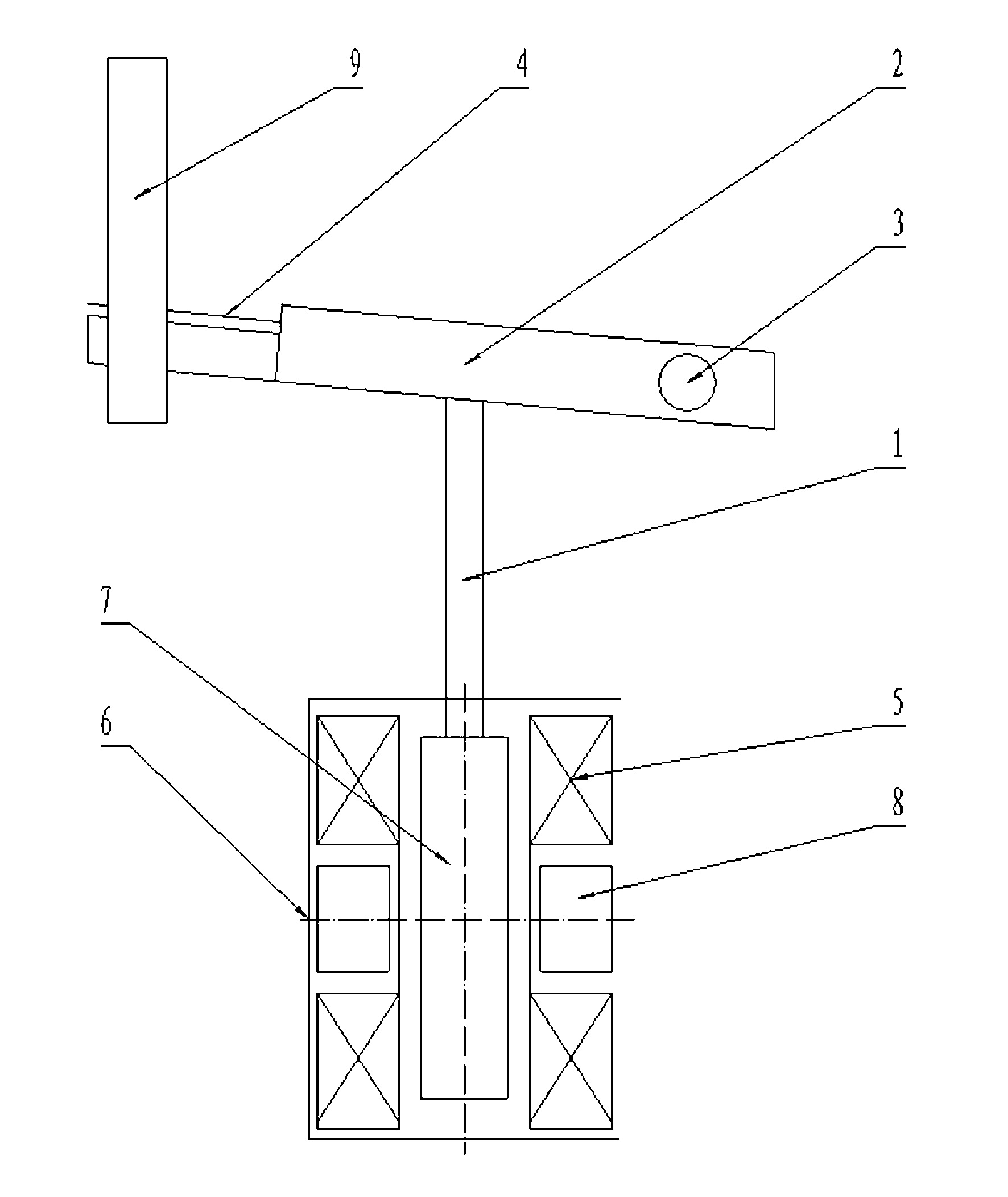

[0028] Such as figure 2 It can be seen that the difference between this embodiment and Embodiment 1 is that in the magnetic drive device, the static iron core 6 is a half-wrapped structure, that is to say, one side of the static iron core 6 is provided with an opening to facilitate the installation of other components. Wind the electromagnetic coil on the coil frame 5, connect the insulating transmission rod 1 to the upper end of the moving iron core 7, install the permanent magnet 8 into one side of the coil frame 5, and then attach the corresponding static iron core 6 to the other magnetic pole of the permanent magnet 8 It is fixed on the end faces of both ends of the coil frame 5 . With this structure, the purpose of transmission and shock absorption can also be achieved, and at the same time, it still has the characteristics of preventing external magnetic field interference.

[0029] The transmission device with a flexible damping structure dedicated to the magnetic lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com