Patents

Literature

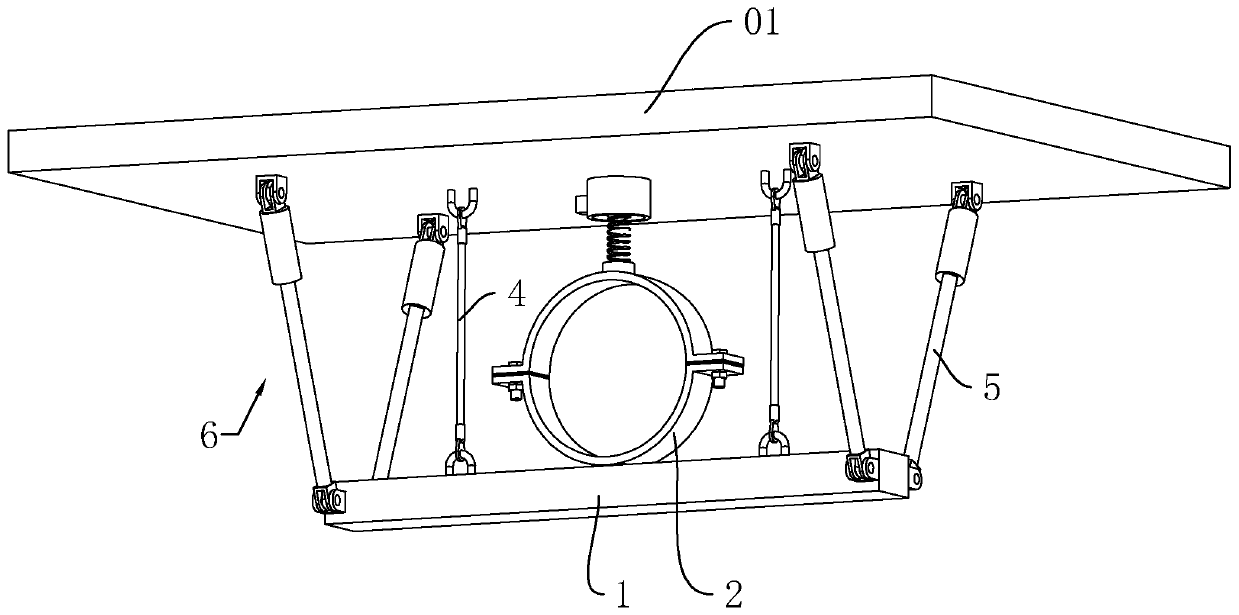

381results about How to "Reduce the likelihood of breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing low temperature solder sheets

ActiveCN107486651AImprove uniformityHigh strengthWelding/cutting media/materialsSoldering mediaLiquid stateMixed states

The invention discloses a method for preparing low temperature solder sheets. The method comprises the following steps: firstly, carrying out chemical cleaning on stains and oxide films on the surface of a foam metal skeleton; filling metal foam with low-melting point solder in an infiltration way; and finally heating the metal foam filled with the low-melting point solder to a solid-liquid mixed state and rolling to obtain composite sheets with certain thicknesses. According to the method disclosed by the invention; the foam metal-reinforced solder is rolled in the solid-liquid mixed state, so that the problems that the foam metal skeleton is stretched to form a thin strip-type fiber structure and is fractured during normal temperature rolling are effectively solved; meanwhile, during rolling in the solid-liquid mixed state, low-melting point metal which is in a liquid state is good in fluidity and can be uniformly filled in the foam metal skeleton, so that the mass percentage of the foam metal skeleton can be increased, the porosity of the foam metal is reduced and the uniformity and the strength of the foam metal-reinforced low melting point solder are increased.

Owner:CHINA NAT ELECTRIC APP RES INST

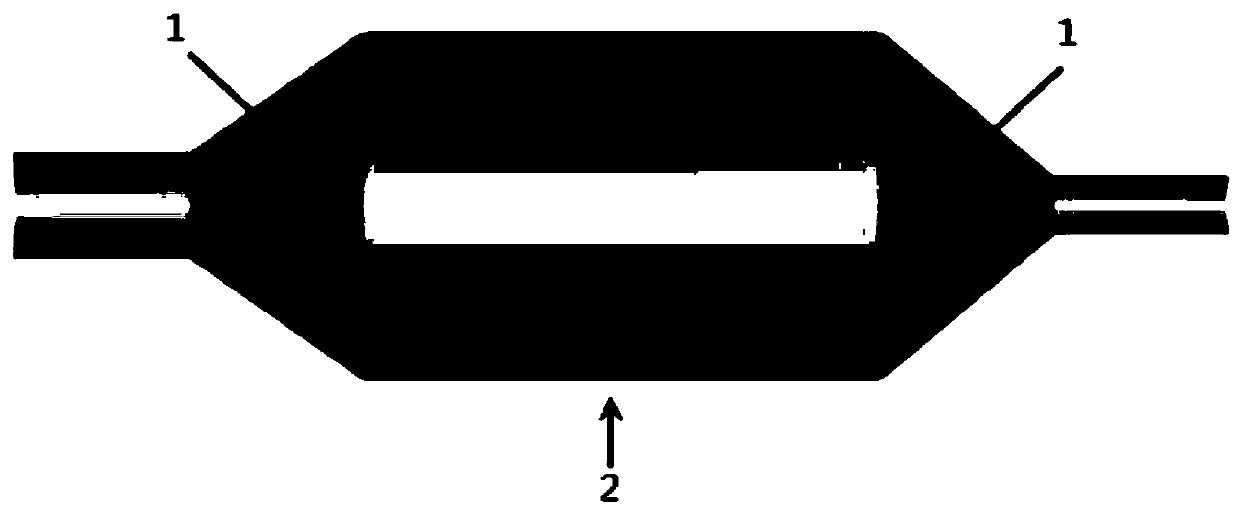

Tailor welded blank integral drawing forming device and method for large-scale curved surface part

The invention discloses a tailor welded blank integral drawing forming device and a method for a large-scale curved surface part, relates to the tailor welded blank integral forming device and method, and the problem that in the prior art, fractures exist in tailor welded blank integral forming is solved. The tailor welded blank integral drawing forming device comprises a male die, a blank holder, a female die and a liquid filling chamber; the portion between the blank holder and the female die is used for containing an unequal thickness tailor welded blank; the profile of the male die is provided with a male die groove which is consistent with the shape of a thick wall area where a sheet metal weld joint is located, blank holder grooves which are consistent with the shape of the thick wall area where the sheet metal weld joint is located are formed in an inner hole of the blank holder and the lower surface of the blank holder simultaneously, and the male die groove and the blank holder grooves are used for preventing the portion, perpendicular to the direction of the weld joint, of the thick wall area from deforming; or female die grooves which are consistent with the shape of the thick wall area where the sheet metal weld joint is located are formed in the upper surface of the female die and an inner hole of the female die and used for preventing the portion, perpendicular to the direction of the weld joint, of the thick wall area from deforming. The invention further provides a tailor welded blank integral drawing forming method of the large-scale curved surface part through using the tailor welded blank integral drawing forming device. The tailor welded blank integral drawing forming device and the method for the large-scale curved surface part are used for filling liquid, drawing and forming for the unequal thickness and symmetrical tailor welded blank through adopting uniform strength bearing design.

Owner:HARBIN INST OF TECH

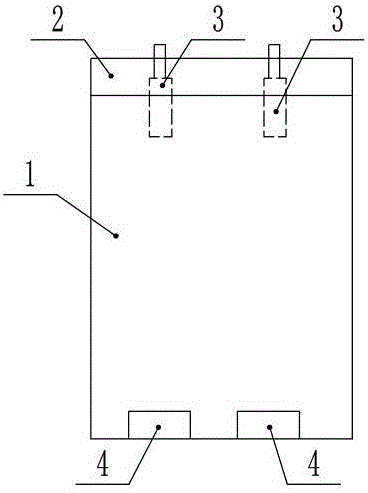

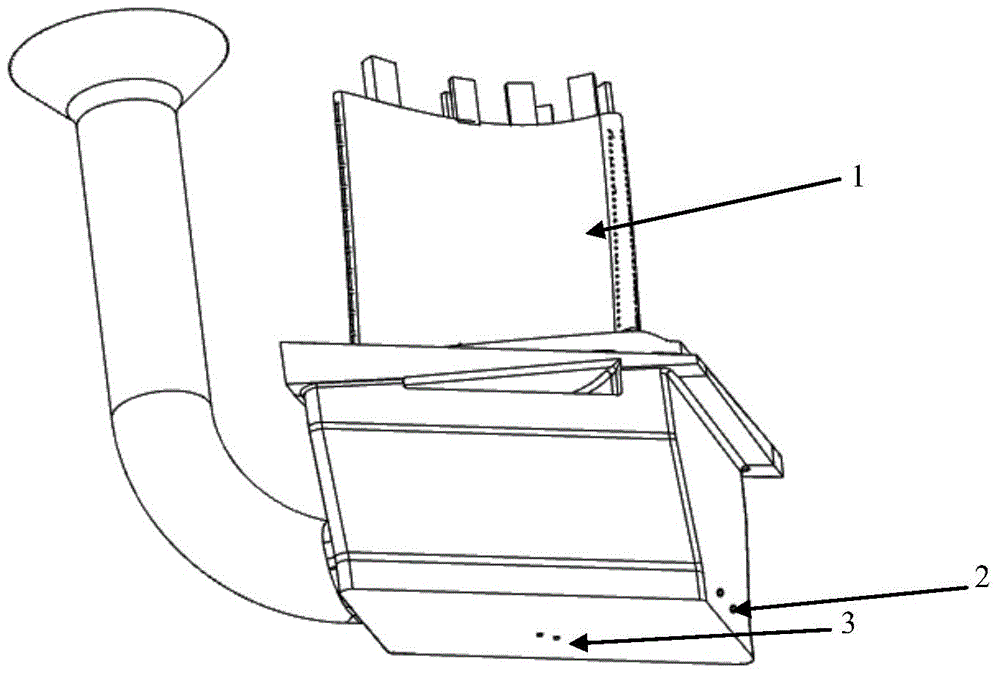

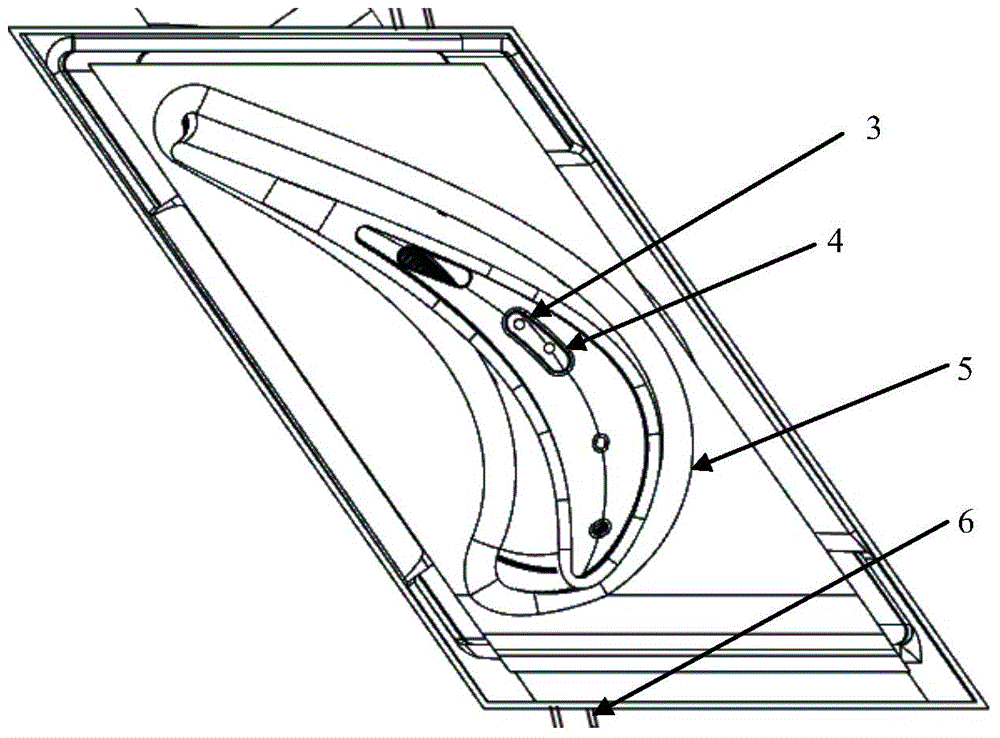

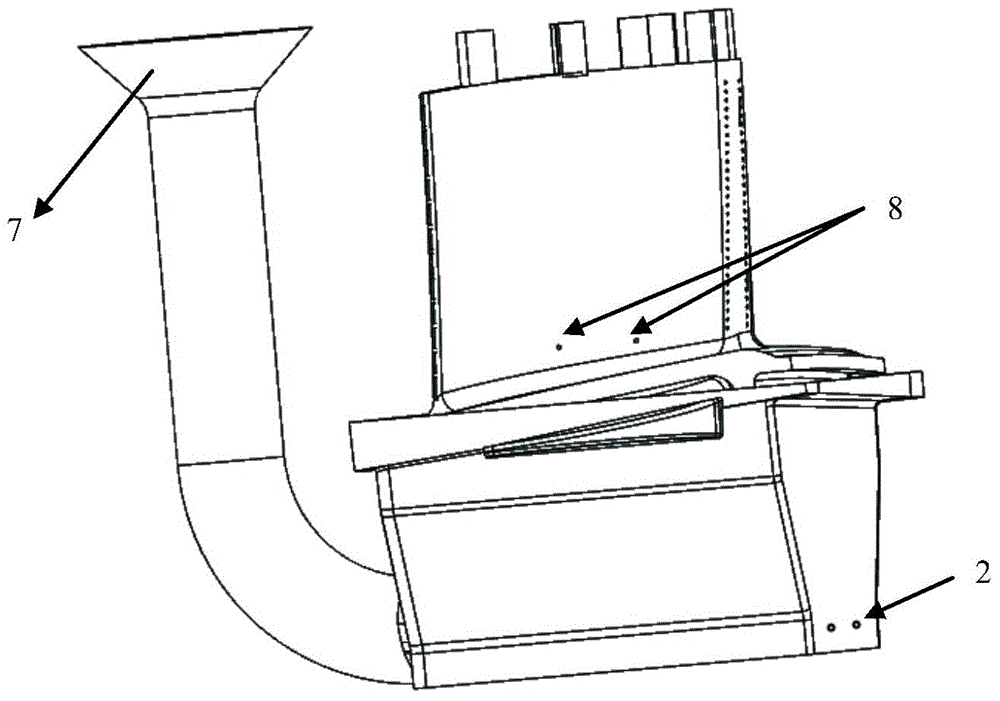

Synchronous spraying device for large machine

InactiveCN105772293ARealize simultaneous sprayingEnsure consistencySpraying apparatusArthrobotrysMechanical engineering

The invention provides a synchronous spraying device for a large machine. The synchronous spraying device comprises a plurality of movable bases (1), wherein a six-axis joint robot is installed on each movable base (1), and a spray gun is installed at the tail end of each six-axis joint robot; a steel plate (2) is arranged at the front end of each movable base (1), a piston cylinder (3) is further horizontally arranged at the front end of each movable base (1), the outer end of a piston rod of each piston cylinder (3) is level with the outer side of the corresponding steel plate (2) while retracting, and an electrically-controlled magnetic attraction device (4) is arranged at the rear end of each movable base (1); and the movable bases (1) attract the electrically-controlled magnetic attraction devices (4) through the steel plates (2) and are sequentially connected in series to form an integrated movable platform. According to the synchronous spraying device provided by the invention, the integrated movable platform formed by sequentially connecting the plurality of movable bases (1) in series is provided, and synchronous spraying of all the six-axis joint robots can be realized; and moreover, the problem of interference is avoided, and the consistency of the spraying quality of parts of the large machine can be ensured.

Owner:李富平

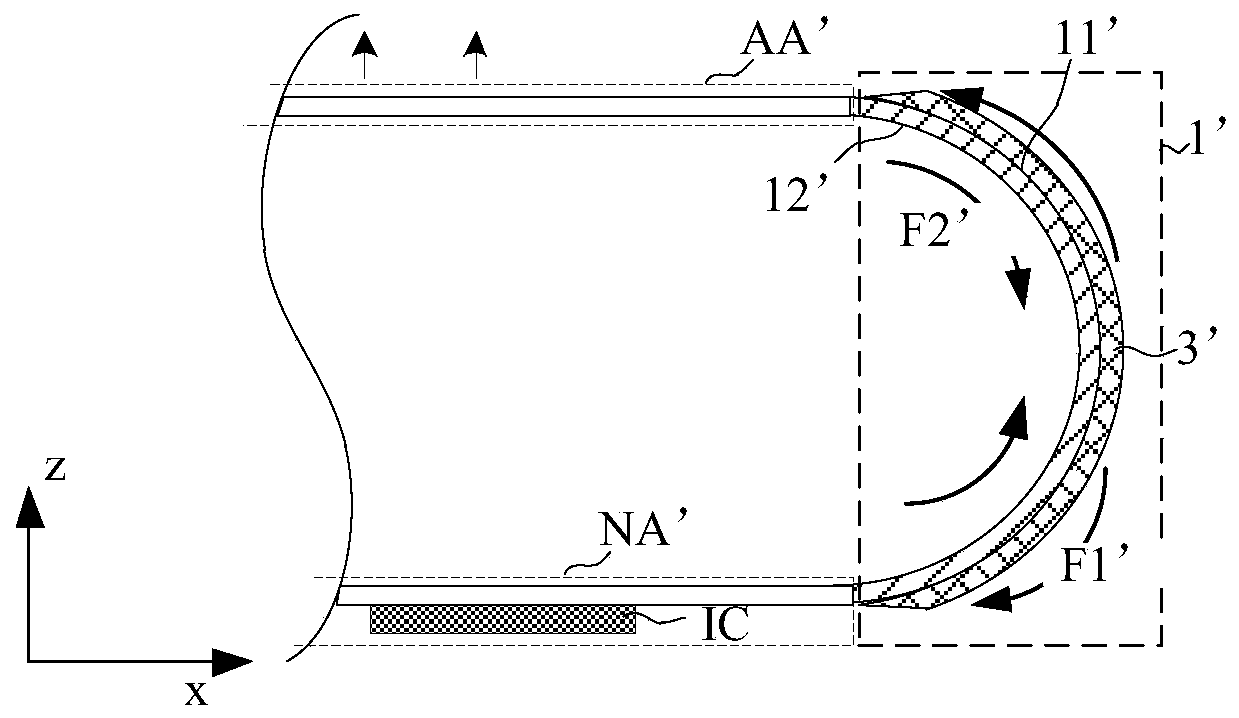

Display panel and display device

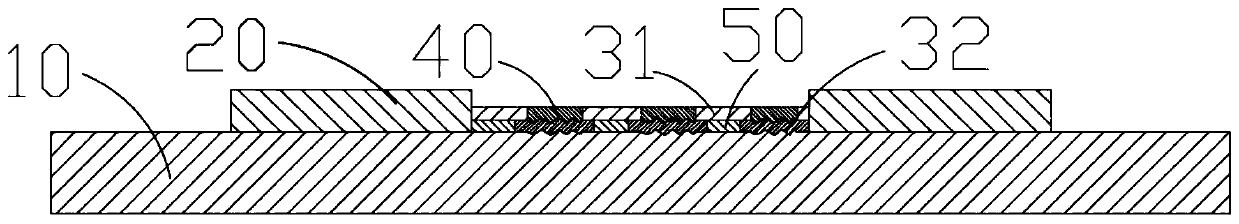

ActiveCN110085649AIncreasing the thicknessReduce the likelihood of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention provides a display panel and a display device, which relates to the technical field of display and used for improving the bending reliability of each film layer in a bending area of the display panel. The display panel comprises a flexible substrate, a light emitting device and a support layer, wherein the flexible substrate includes a display area and a bending area which are arranged in the first direction; the bending area includes a first edge and a second edge which are arranged in the second direction; the first direction interests with the second direction; the bending area includes a bending axis, and the bending axis extends in the second direction; the light emitting device is located in the display area; the support layer and the light emitting device are located at the same side of the flexible substrate; the support layer includes a first support layer, the first support layer is overlapped with the bending area, and the first support layercovers the first edge; and the minimum distance from the first support layer to the second edge in the second direction is greater than zero.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Preparation method of addition type liquid fluorinated silicone rubber

The invention relates to a preparation method of addition type liquid fluorinated silicone rubber. D3F, ViD4 and MM with the purity larger than 99.5% are adopted as raw materials and evenly mixed according to a certain ratio, and vinyl fluorosilicone oil is obtained; the vinyl fluorosilicone oil is used as base gum, a reinforcement agent, a cross-linking agent and a catalyst are added in the vinyl fluorosilicone oil, kneading, grinding, tabletting and other technologies are performed, and the liquid fluorinated silicone rubber (FSR) is obtained; the insulation performance, hydrophobic property, the high-temperature resistance and the like of the LSR are better than that of liquid silicone rubber (LSR) with the same technology and formula. The preparation method is short in production period, the product has the good heat tear resistance, demolding is convenient, various machining ways of mold pressing, extrusion, injection molding and the like can be achieved, and automatic production materials can be achieved.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

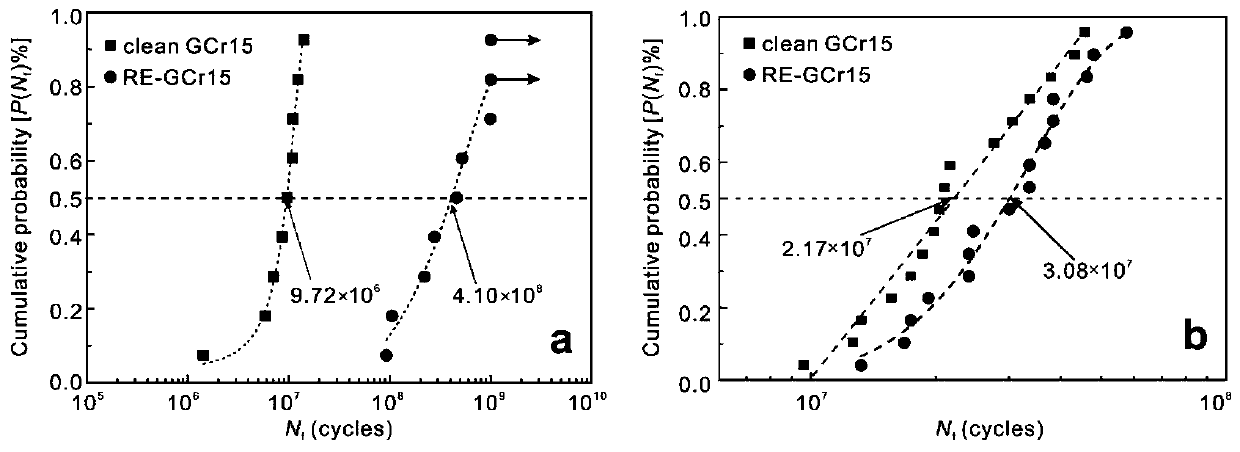

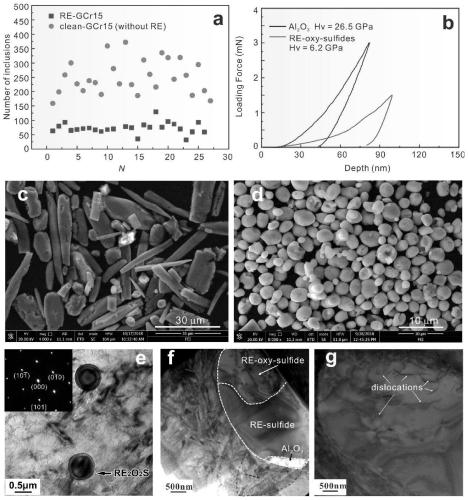

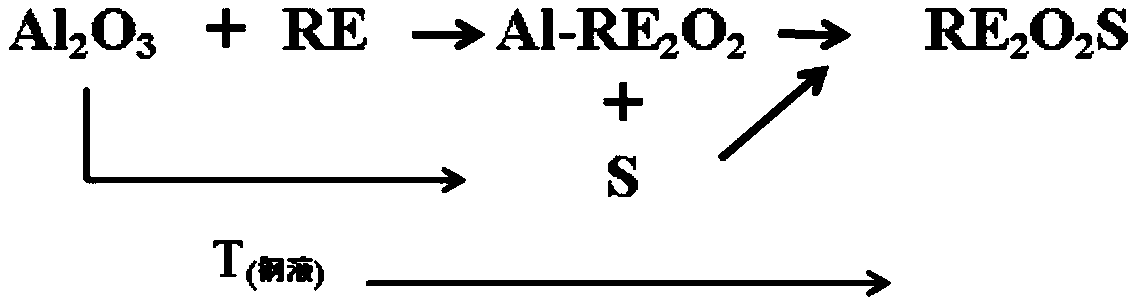

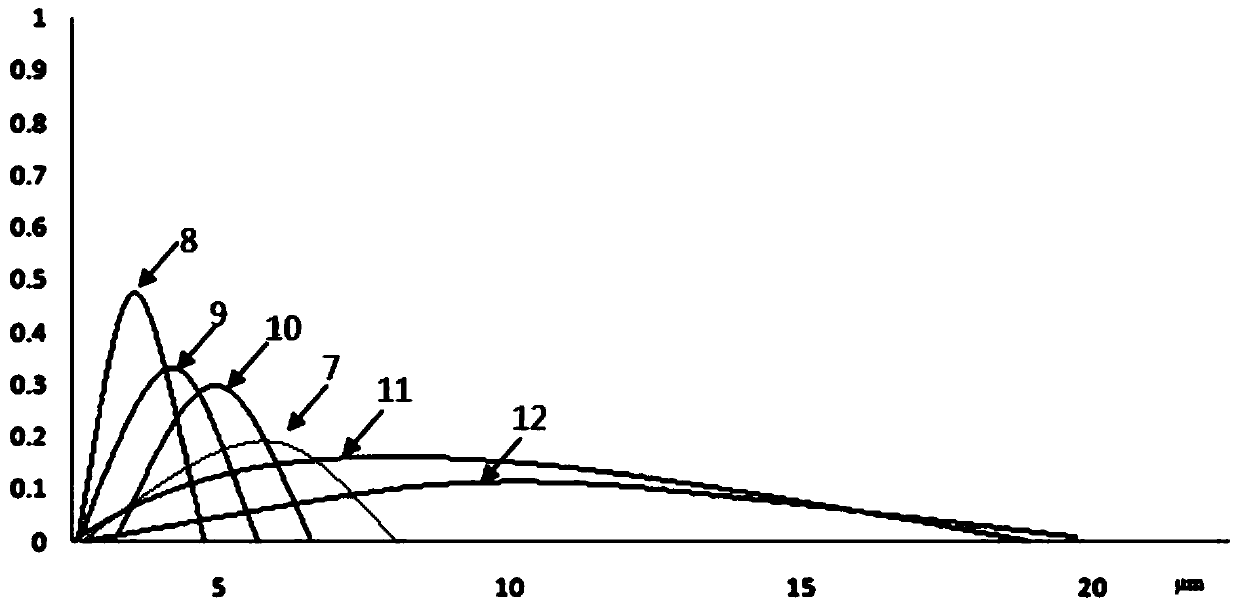

Ultra-clean rare earth steel and occluded foreign substance modification control method

ActiveCN110484811AReduce hardnessImprove fatigue lifeProcess efficiency improvementRare-earth elementMicrometer

The invention provides ultra-clean earth steel and an occluded foreign substance modification control method. 10-200 ppm of rare earth elements are included in the steel, and 50% or more occluded foreign substances in the steel are dispersed RE-oxygen-sulfide with the average equivalent diameter Dmean ranging from 1 micrometer to 5 micrometers in a spherical shape or a spheroidal shape or a granular shape. According to the method, at least 80%, preferably at least 90%, of Al2O3 occluded foreign substances in the steel are modified into RE-oxygen-sulfide, compared with steel with the same components without rare earth, the total amount of the occluded foreign substances in the steel is reduced by 18% or higher, the cracking probability caused by occluded foreign substances such as Al2O3 intraditional pure steel is reduced, the mechanical and chemical performance such as the fatigue life of the steel is remarkably improved, precise control over the modification type, distribution and dimension of the occluded foreign substances in the steel is achieved, and the method is suitable for researching and producing of high-performance steel in more varieties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

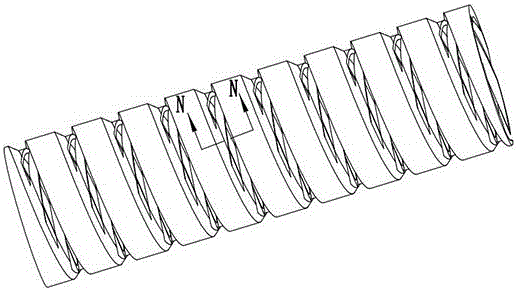

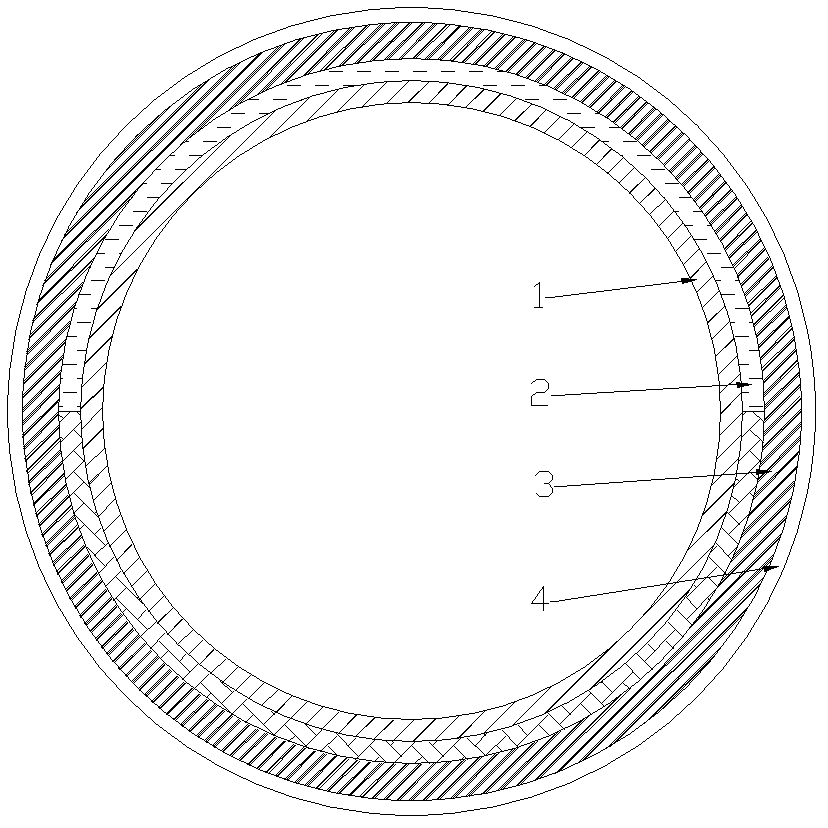

Carbon fiber composite, preparation method thereof and tank

ActiveCN103009716ALose weightHigh mechanical strengthSynthetic resin layered productsLarge containersProtection layerFilament winding

The invention discloses a carbon fiber composite. The carbon fiber composite comprises a metal inner layer, a local reinforcement layer, a reinforcement layer and an outer protection layer in sequence, wherein the reinforcement layer is formed by preferably winding large-tow carbon fibers. The invention also discloses a preparation method of the carbon fiber composite. The invention further discloses a tank prepared from the carbon fiber composite. The tank can be used for carrying liquid, powder, gases, pulp and other substances. The carbon fiber composite and the tank have the beneficial effects that compared with the traditional metal tanks, the tank prepared from the carbon fiber composite is lightened by more than 50%; the carrying capacity of a tank car can be obviously improved, and fuel consumption and carbon dioxide emission can be reduced; and the tank has the double effects of increasing the operating profits and reducing the environmental pollution.

Owner:北京蓝星清洗有限公司

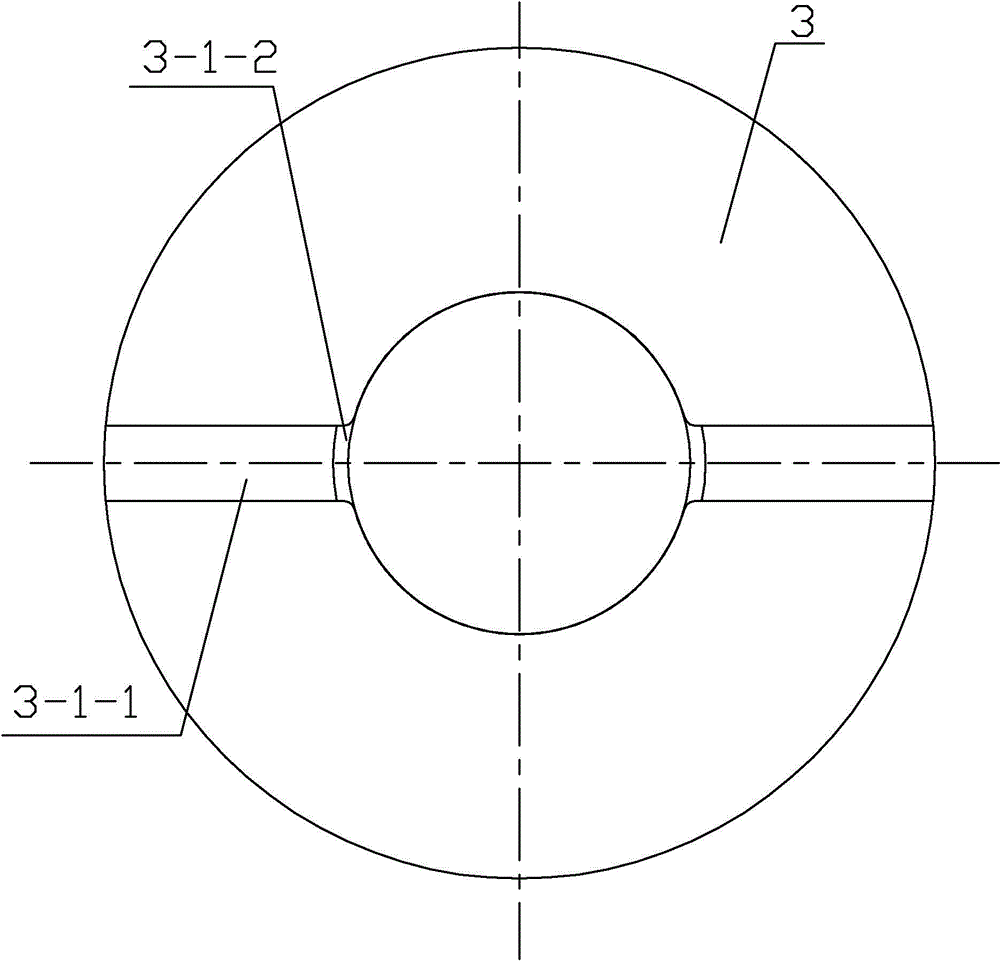

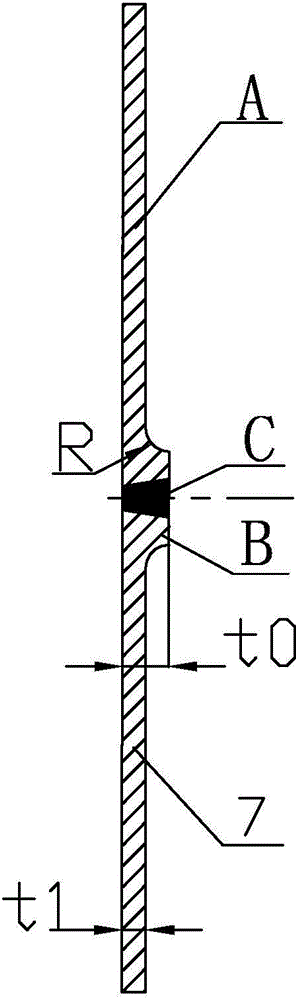

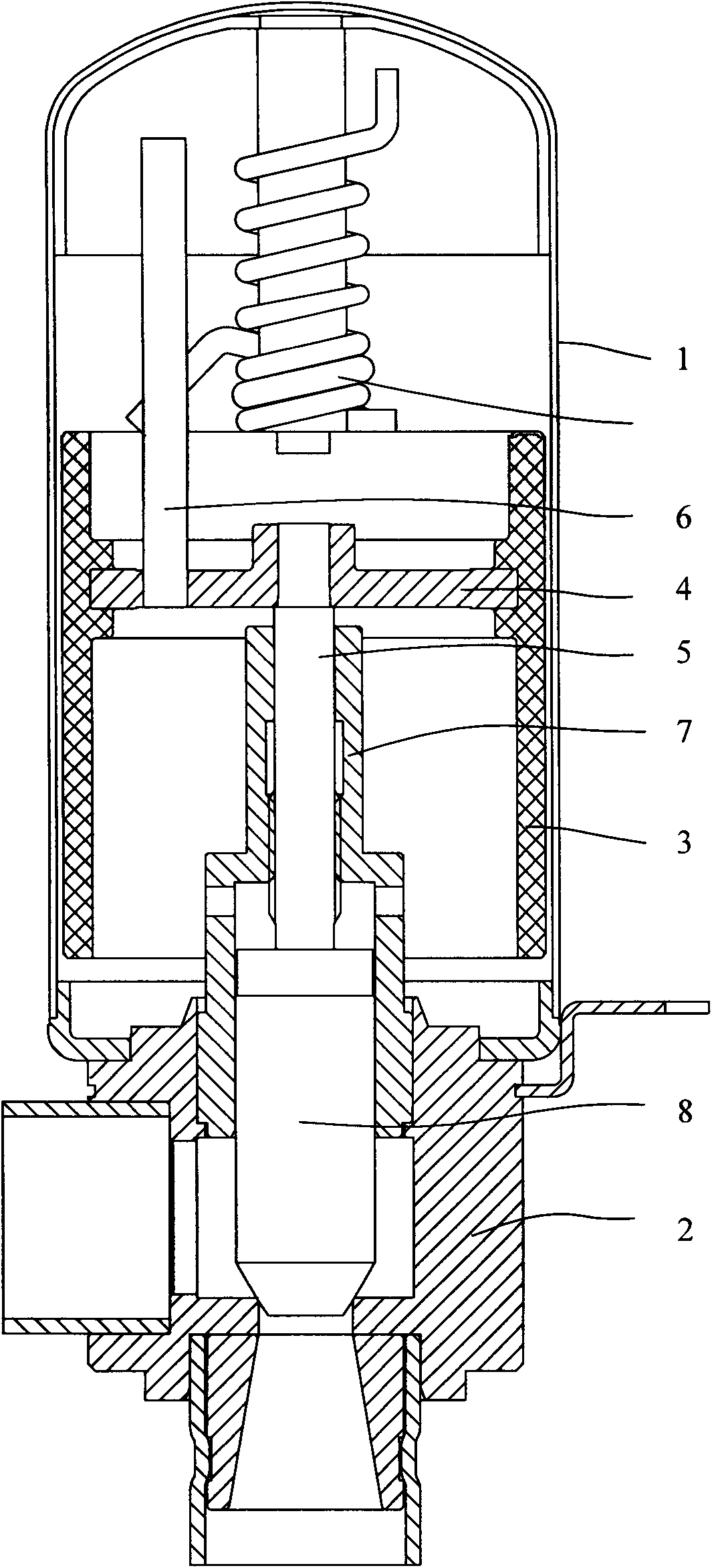

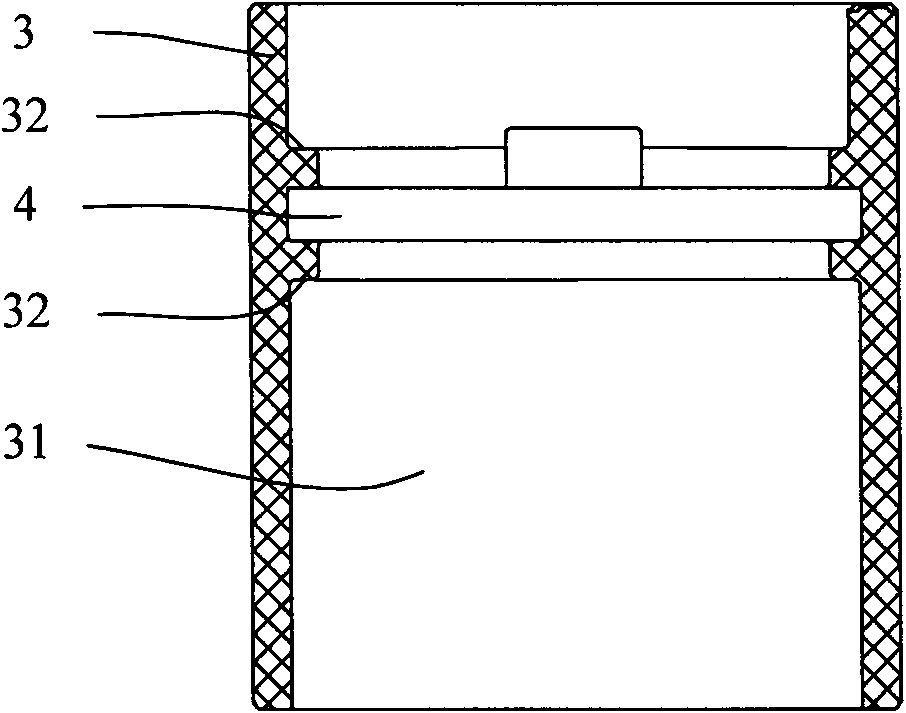

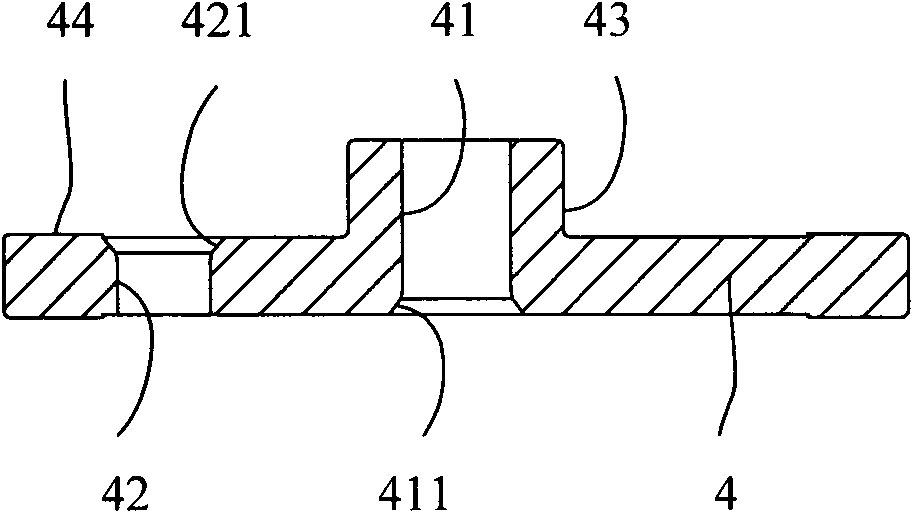

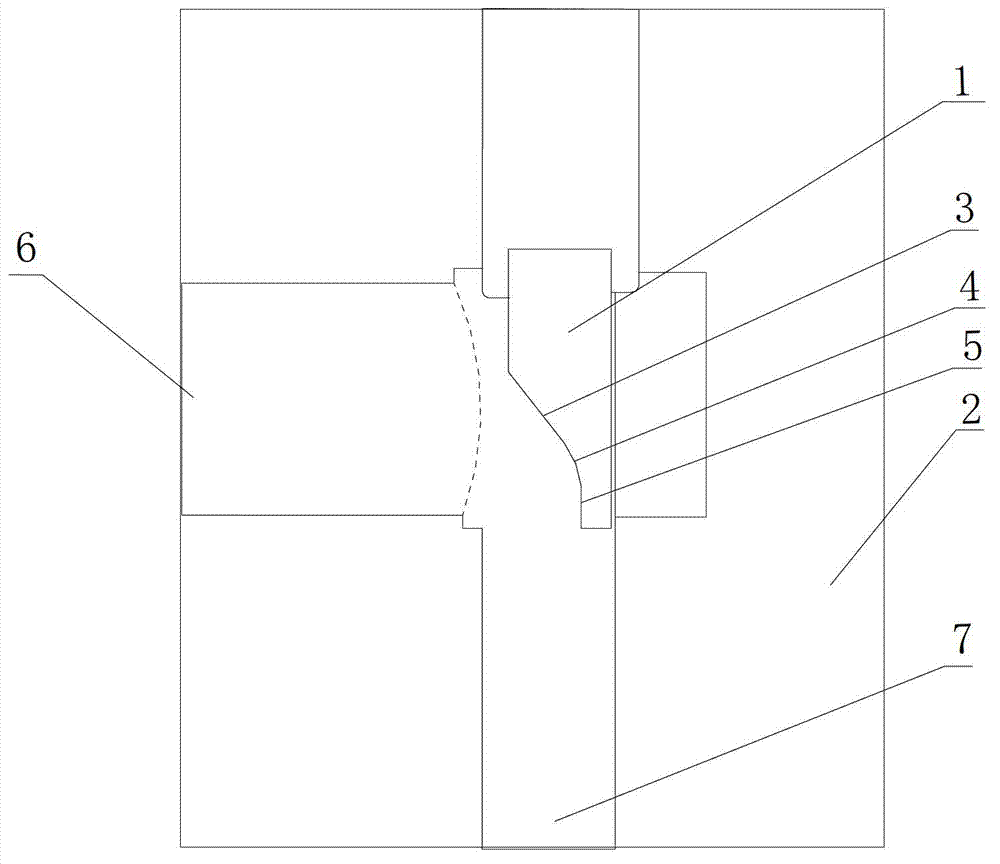

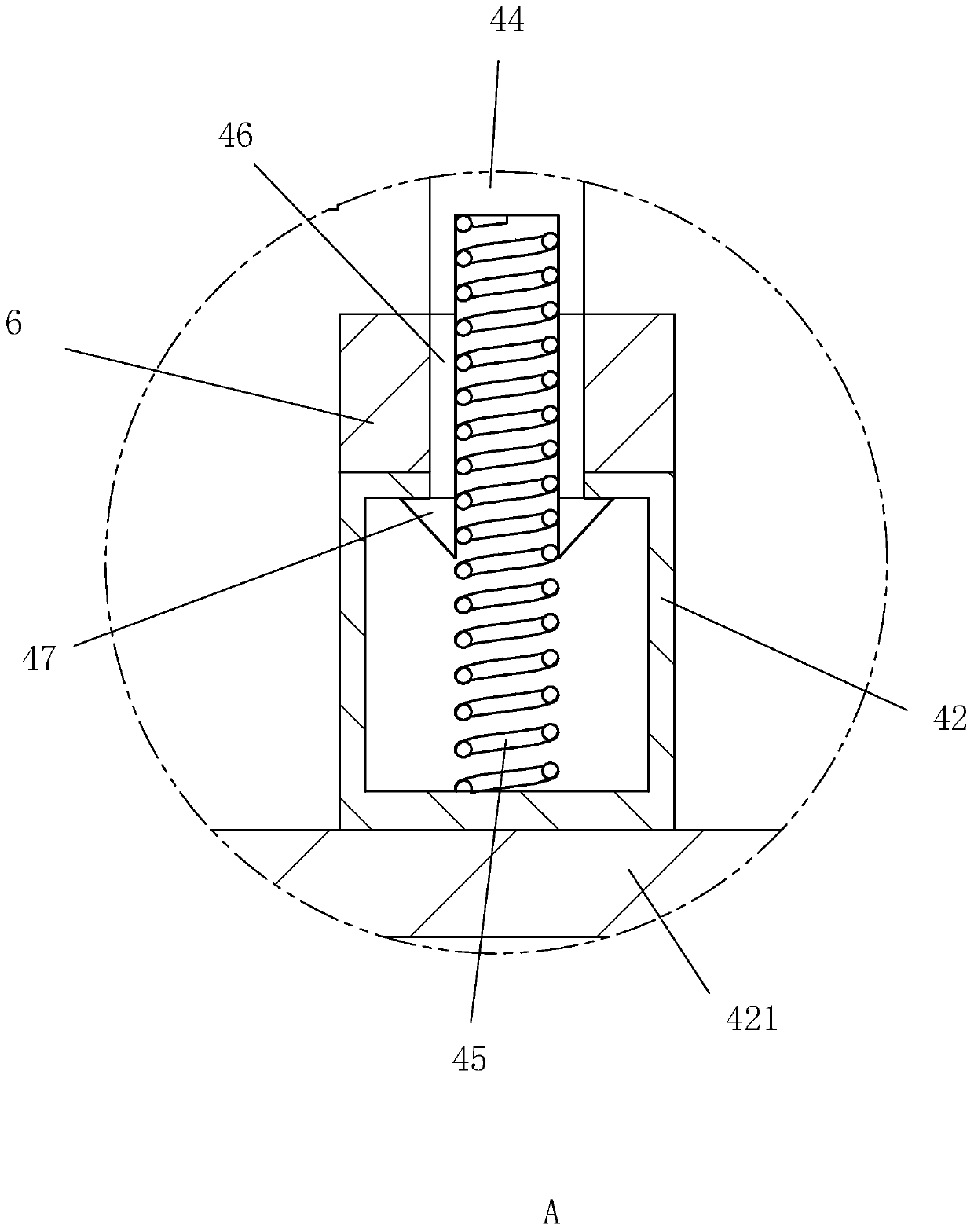

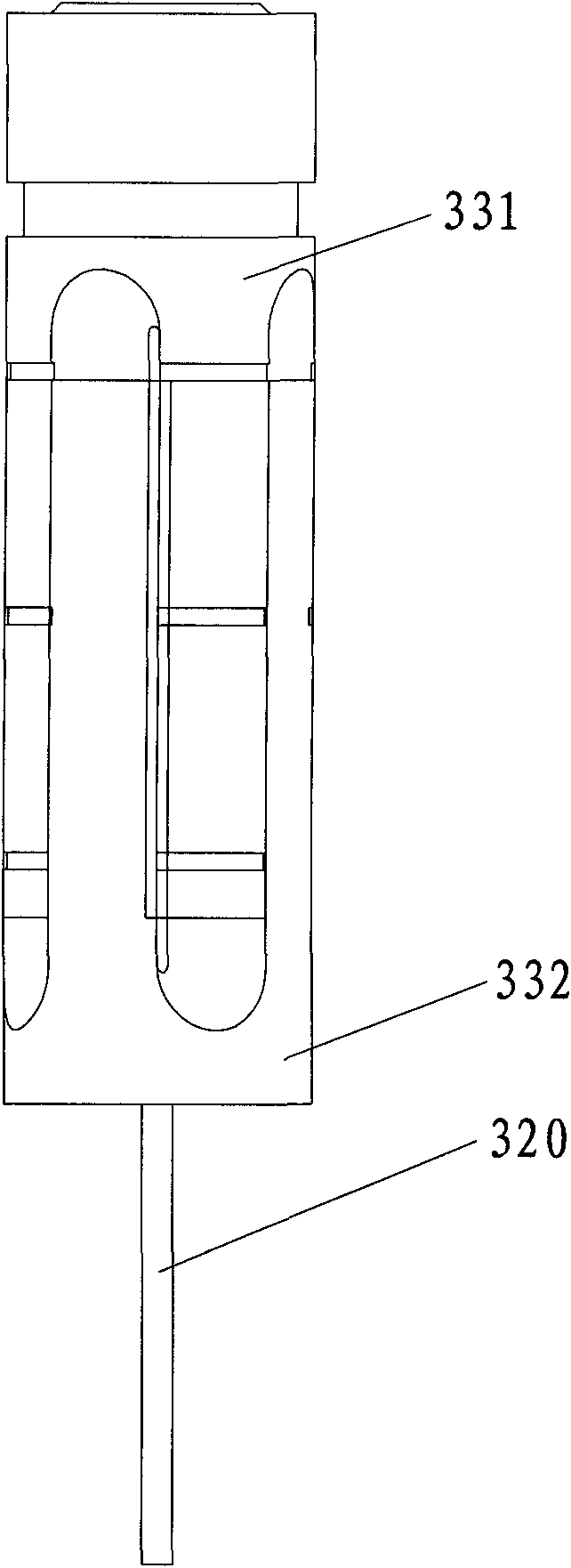

Electronic expansion valve

InactiveCN102032380AImprove reliabilityReduce the likelihood of breakageOperating means/releasing devices for valvesLift valveEngineeringElectronic expansion valve

The embodiment of the invention provides an electronic expansion valve, comprising a magnetic rotor, a stop rod and a screw rod, wherein the axis of the screw rod is coincided with the axis of the magnetic rotor. The electronic expansion valve further comprises a connecting plate which is fixedly arranged in a through hole of the magnetic rotor, a first fixing hole is arranged at the center of the connecting plate, and the upper end part of the screw rod is fixedly arranged in the first fixing hole; a second fixing hole for fixing the stop rod is arranged on the connecting plate, and the lower end part of the stop rod is fixedly arranged in the second fixing hole; and the magnetic rotor drives the screw rod and the stop rod to rotate by the connecting plate. The stop rod, the screw rod and the magnetic rotor are firmly connected by the connecting plate which is fixedly arranged on the magnetic rotor, and the magnetic rotor is not influenced by the radial force of the connecting plate in the process that the stop rod and the screw rod are arranged on the magnetic rotor by the connecting plate, so as to reduce the possibility of cracking of the magnetic rotor owning to high radial force and improve the reliability of the electronic expansion valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

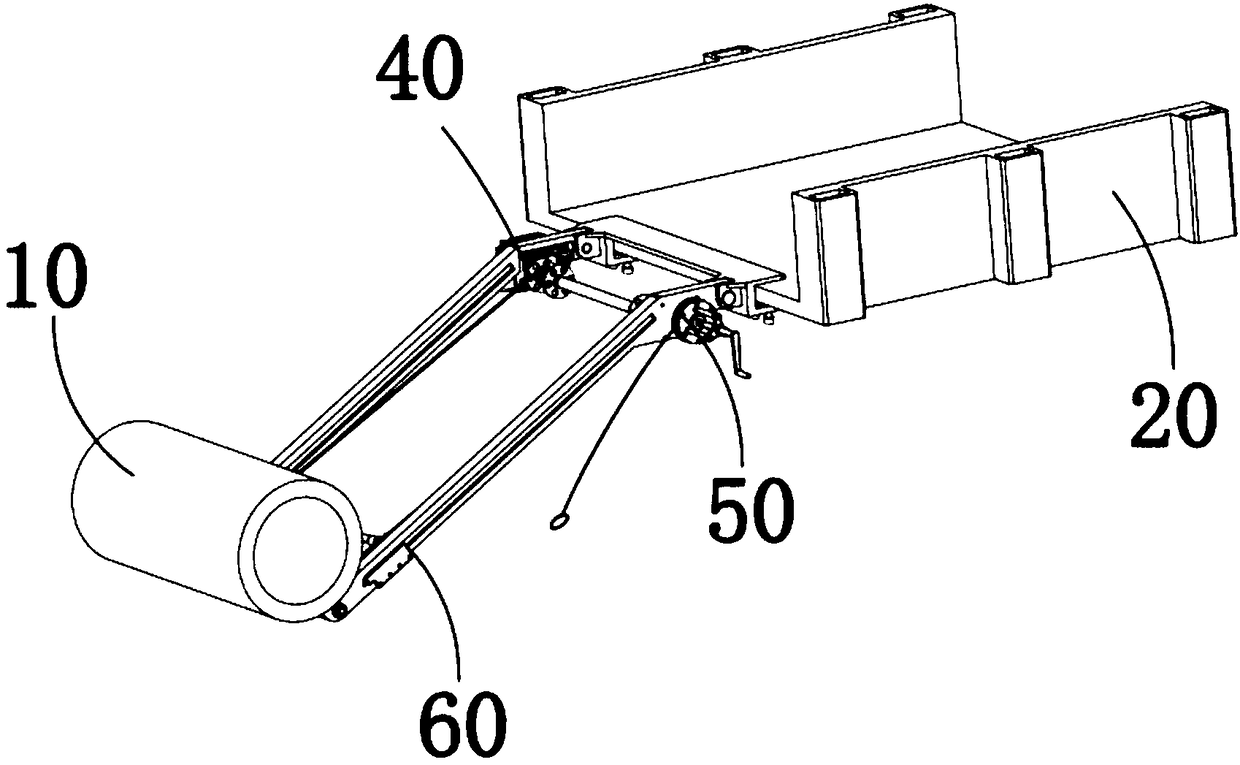

Safe slow descent control and loading method applied to cement pipeline

ActiveCN109051887AReduce the likelihood of breakageInhibit sheddingConveyorsLoading/unloadingContact pressureEngineering

The invention discloses a safe slow descent control and loading method applied to a cement pipeline. The method is characterized in that a clamping mechanism is connected on a discharging end of a carriage in a clamped mode, one end of a low-position sliding mechanism in the length direction is connected with the clamping mechanism, and the other end of the low-position sliding mechanism extends to the ground; when the clamping mechanism is installed, the opening port of a clamping frame is matched with an unloading end of the carriage, and the top of the unloading end of the carriage is in contact with the top of the opening port of the clamping frame; at the moment, a bolt is rotated, and a contact pressure is enabled to be generated between the big face facing upwards of the clamping plate and the bottom of the unloading end of the carriage, a contact pressure is generated between the top of the unloading end of the carriage and the top of the opening port of the clamping frame, a slow descent control rope winds round a rope winding groove of a rope winding cylinder and is tied on a hook of a rope tying mechanism in a gentle tying mode after being guided by the rope winding groove, and whether a slow descent control device and a slow lifting control device are intact or not are checked.

Owner:阜阳市华顺水泥制品有限公司

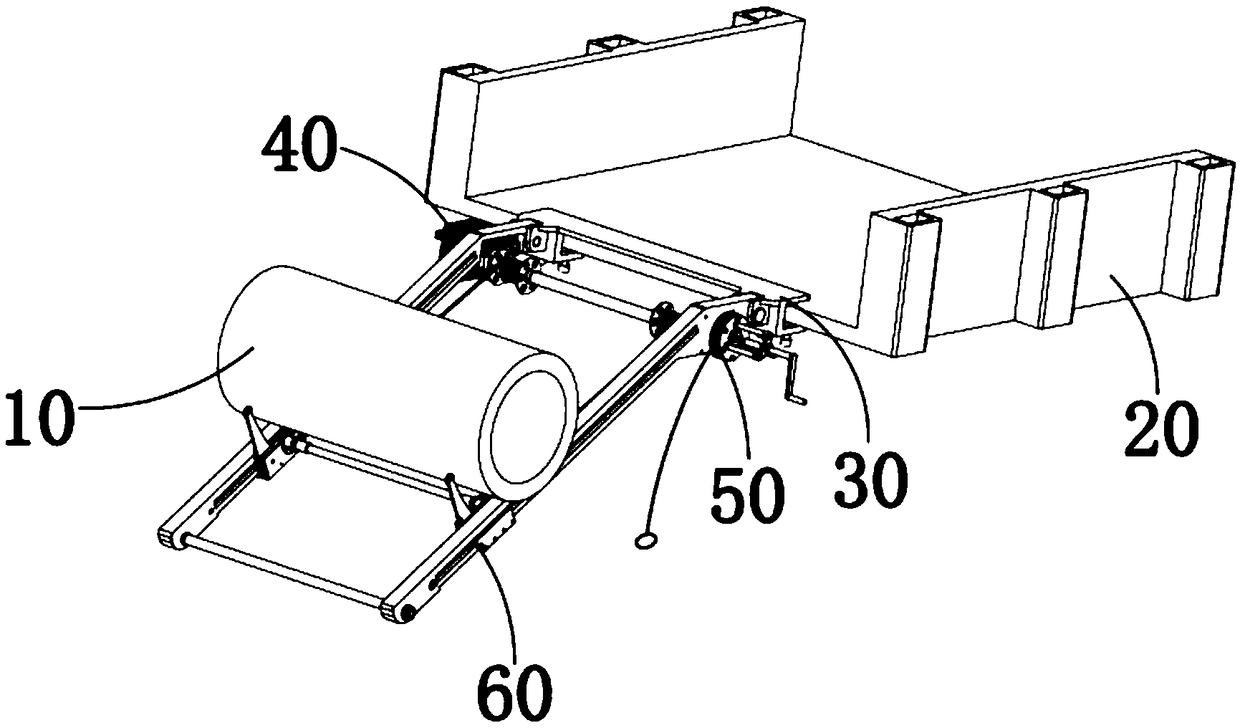

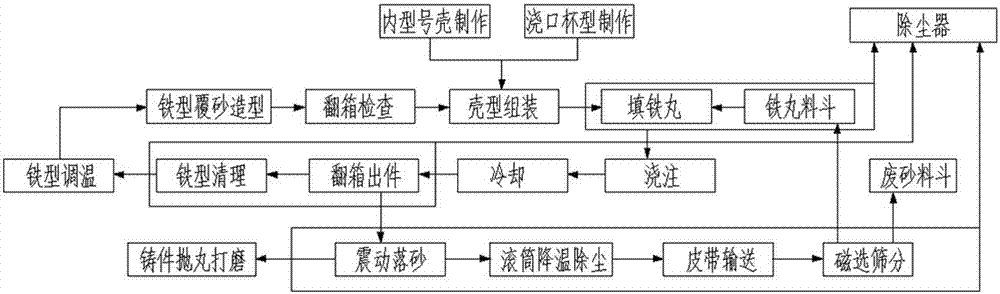

Novel casting technique of semitrailer brake drum

InactiveCN103286279AGuaranteed not to deformBack-off guaranteeCasting plantsFoundry mouldsBrakeDust control

The invention relates to a novel casting technique of a semitrailer brake drum. The novel casting technique of the semitrailer brake drum comprises the following steps of: manufacturing an inner mold shell and a pouring cup; regulating the temperature of an iron mold, covering with sands, and modeling; checking by turning over a mold; assembling a shell mold; filling iron shots; pouring and cooling; turning over the mold, discharging elements, assembling the elements, and recovering; carrying out magnetic separation, and screening; dedusting and cleaning. No deformation of the brake drum is ensured fully; the steel shots are filled in an internal mold sand shell; poured steel liquids generate pressure inward; firstly, because of the 'arch bridge principle', the internal mold sand shell has great support force; and then the steel shots also can block the pressure by steel liquids, and the internal mold sand shell cannot be cracked or deformed absolutely. Before cast elements are condensed and contracted, the internal mold sand shell is scattered, the filled steel shots are at the scattered state, the deformability of the cast elements in contraction is ensured fully, so that free contraction instead of hindered contraction is formed; a bottom-pouring-type pouring mode is adopted, air is discharged smoothly; the cracking possibility at the crossed part is reduced; air holes of the cast elements caused by dampness of a sand mold are prevented; the novel casting technique of the semitrailer brake drum is an environment-friendly casting technique.

Owner:FUDI PRECISION CASTING

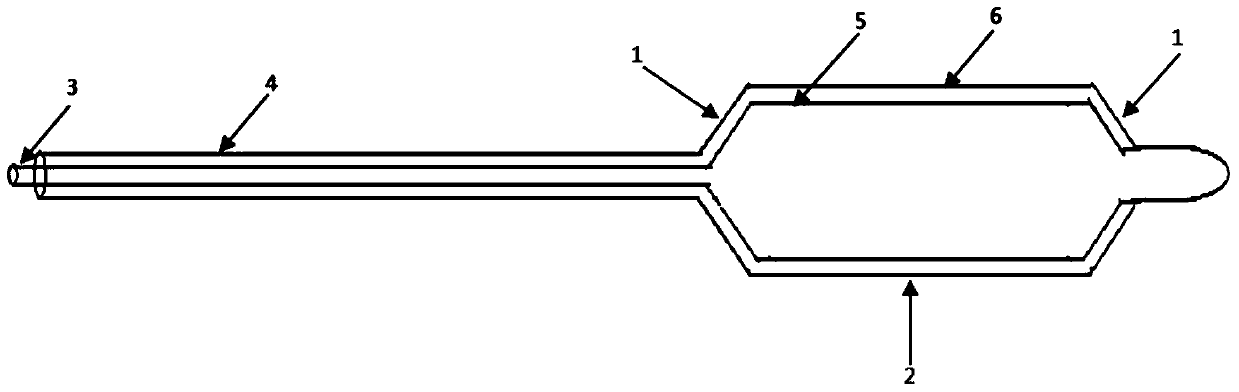

Drug delivery balloon dilating catheter

ActiveCN103623497ASatisfied with repeated expansionMeet shrinking needsSurgeryDilatorsPorosityBalloon dilatation catheter

The invention provides a drug delivery balloon dilating catheter of a double-layer balloon structure. The drug delivery balloon dilating catheter comprises a pressurizing hole-free inner balloon body and an outer balloon body with a drug-permeable micro-hole permeable membrane. Compared with the prior art, the hole diameter of the drug delivery balloon dilating catheter is even, and the high porosity and the high mechanical strength are achieved. The invention further discloses a manufacturing method of the drug delivery balloon dilating catheter of the double-layer balloon structure, the drug delivery balloon dilating catheter is made of materials such as polyethylene or nylon 12, the micro-hole permeable membrane is manufactured with a thermally induced phase separation method, and the drug delivery balloon dilating catheter has the advantages of being simple in manufacturing process, suitable for large-scale production, low in manufacturing cost and the like.

Owner:SHENZHEN SALUBRIS BIOMEDICAL ENG CO LTD

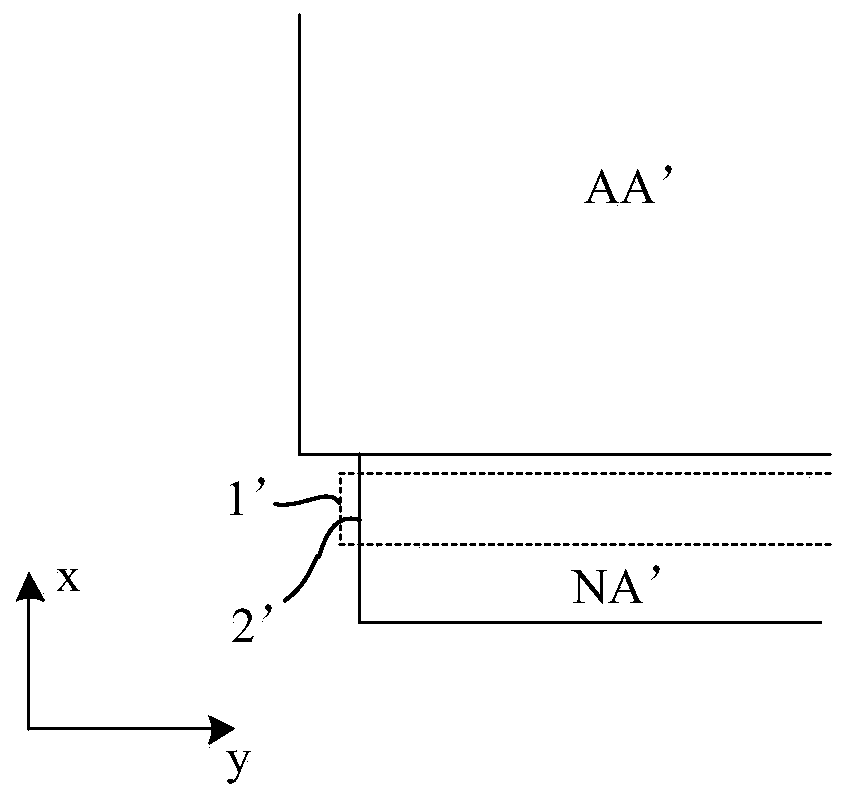

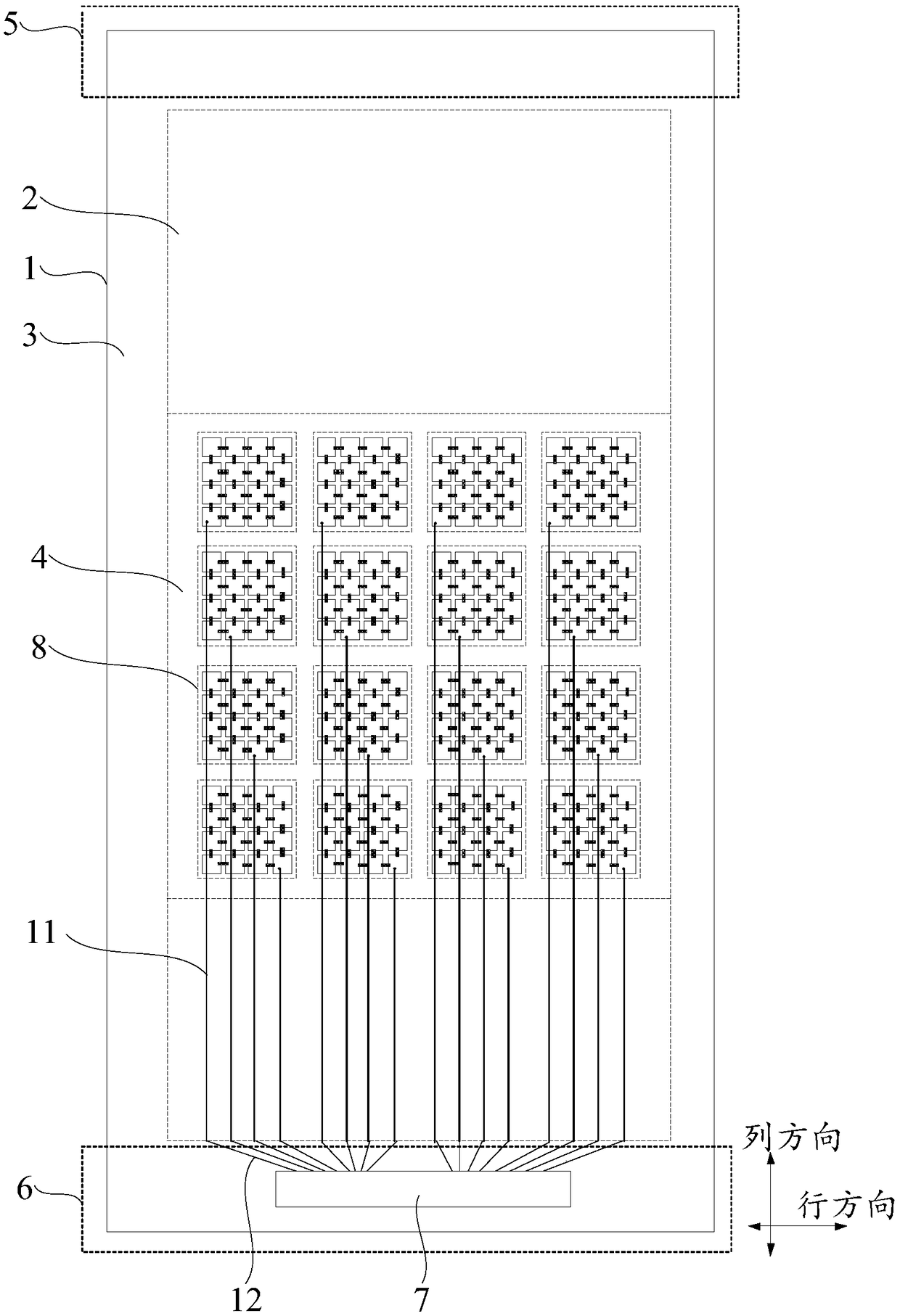

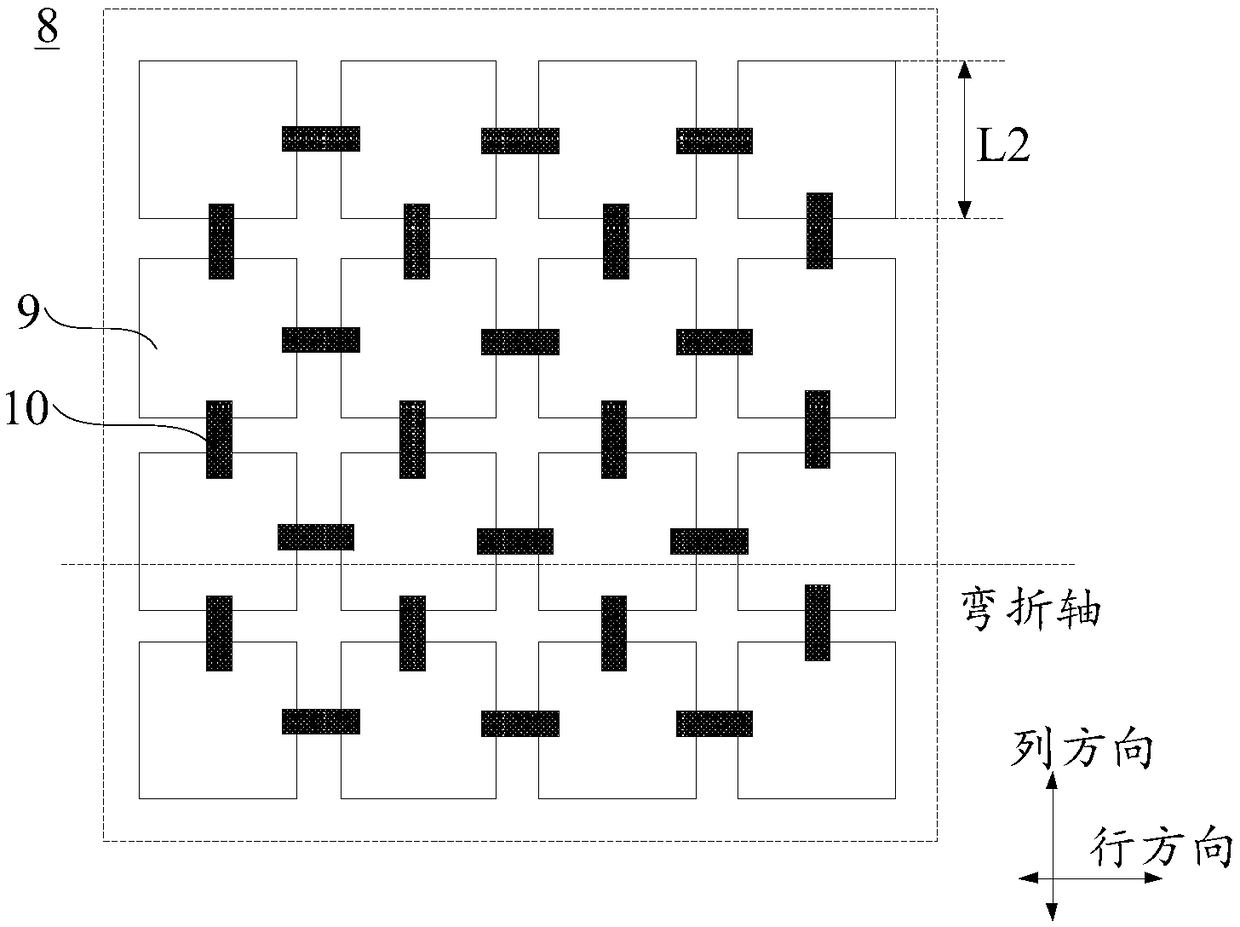

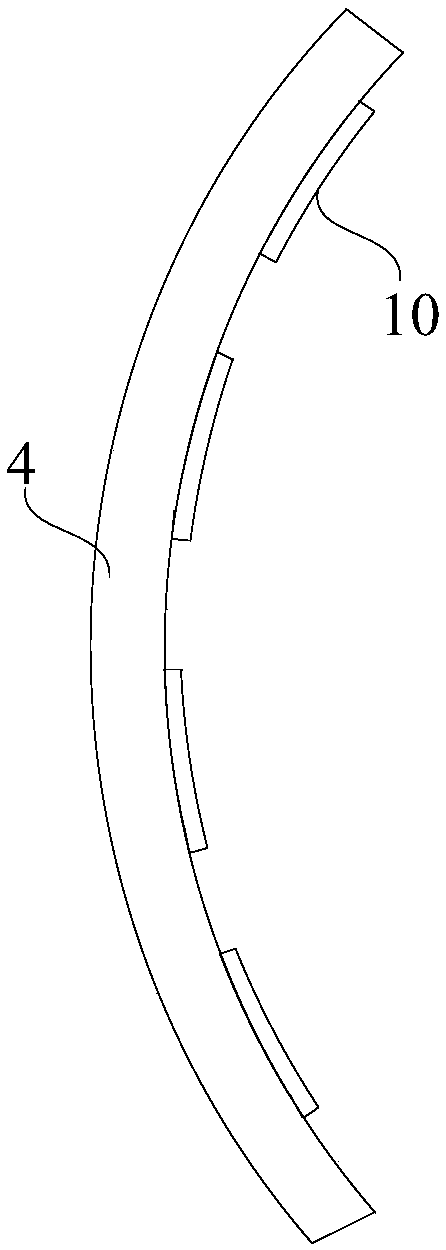

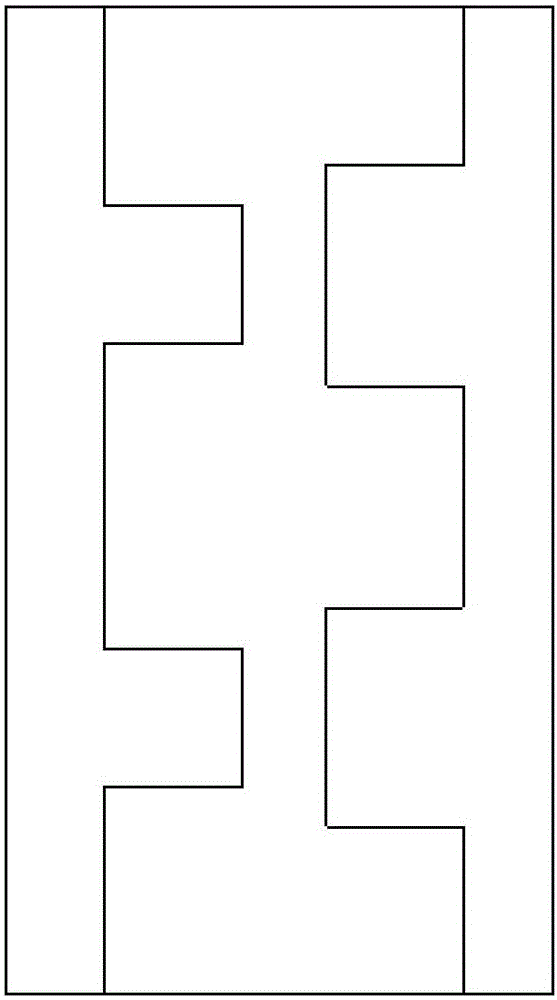

A touch display panel and a touch display device

ActiveCN108958539AImprove bending resistanceReduce the likelihood of breakageInput/output processes for data processingDisplay deviceHuman–computer interaction

The embodiment of the invention provides a touch display panel and a touch display device, which relate to the technical field of display and are used for improving the bending performance of touch electrodes and further improving the working stability of the touch display panel. The touch display panel comprises a substrate, wherein the substrate comprises a display region and a non-display region, the display region comprises a bent region, the non-display region comprises an upper non-display region and a lower non-display region, and the lower non-display region is provided with a chip binding region. The bending area is provided with touch electrodes, and each touch electrode comprises a plurality of touch electrode blocks. In one touch electrode, two adjacent touch electrode blocks are electrically connected through a connection part. The display area is provided with a plurality of first touch signal lines, and at least part of the touch electrodes are connected with the first touch signal lines. The lower non-display area is provided with a plurality of second touch signal lines one-to-one correspondingly connected with a plurality of first touch signal lines, and the second touch signal lines are also connected with the chip binding area. The touch display panel is used for realizing screen display.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

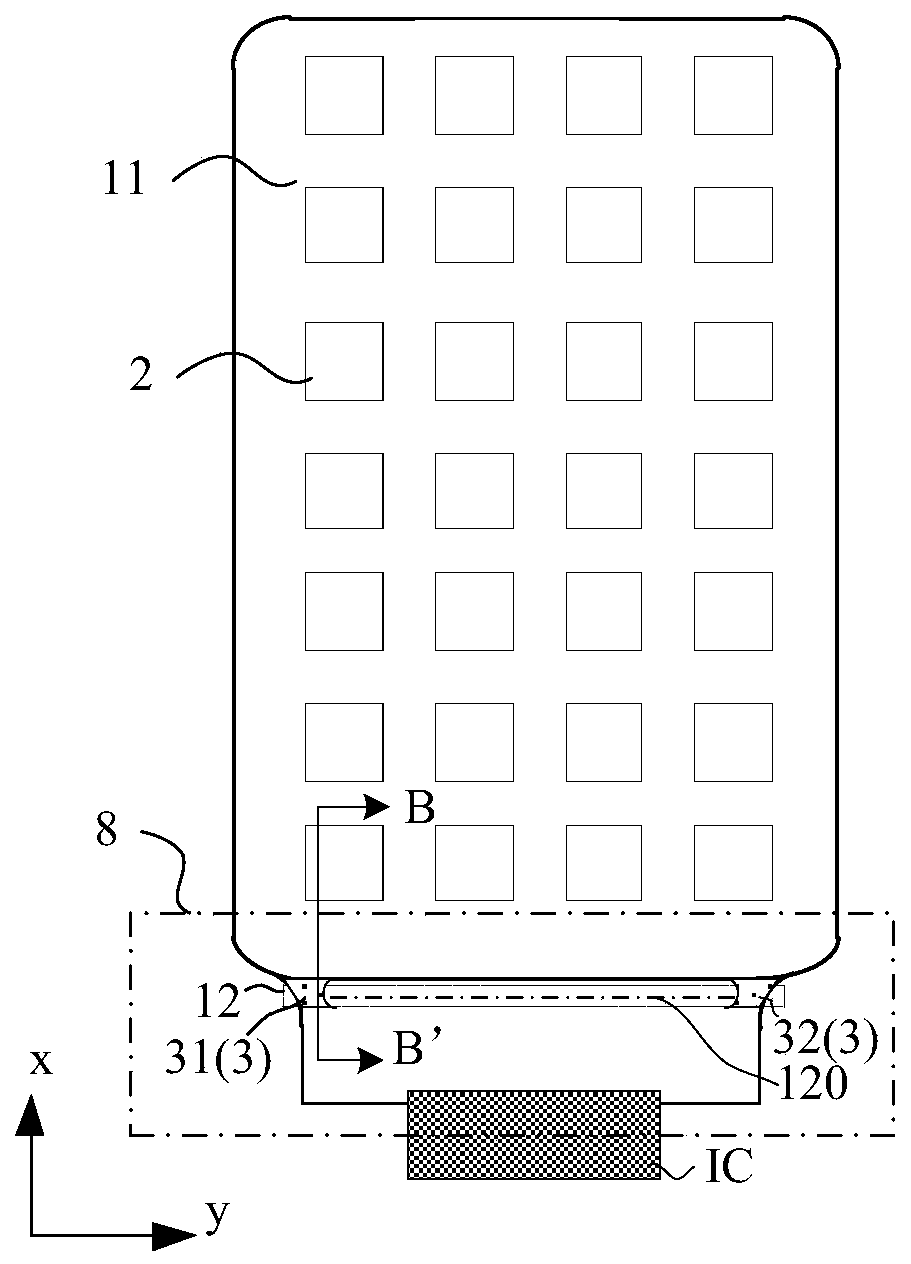

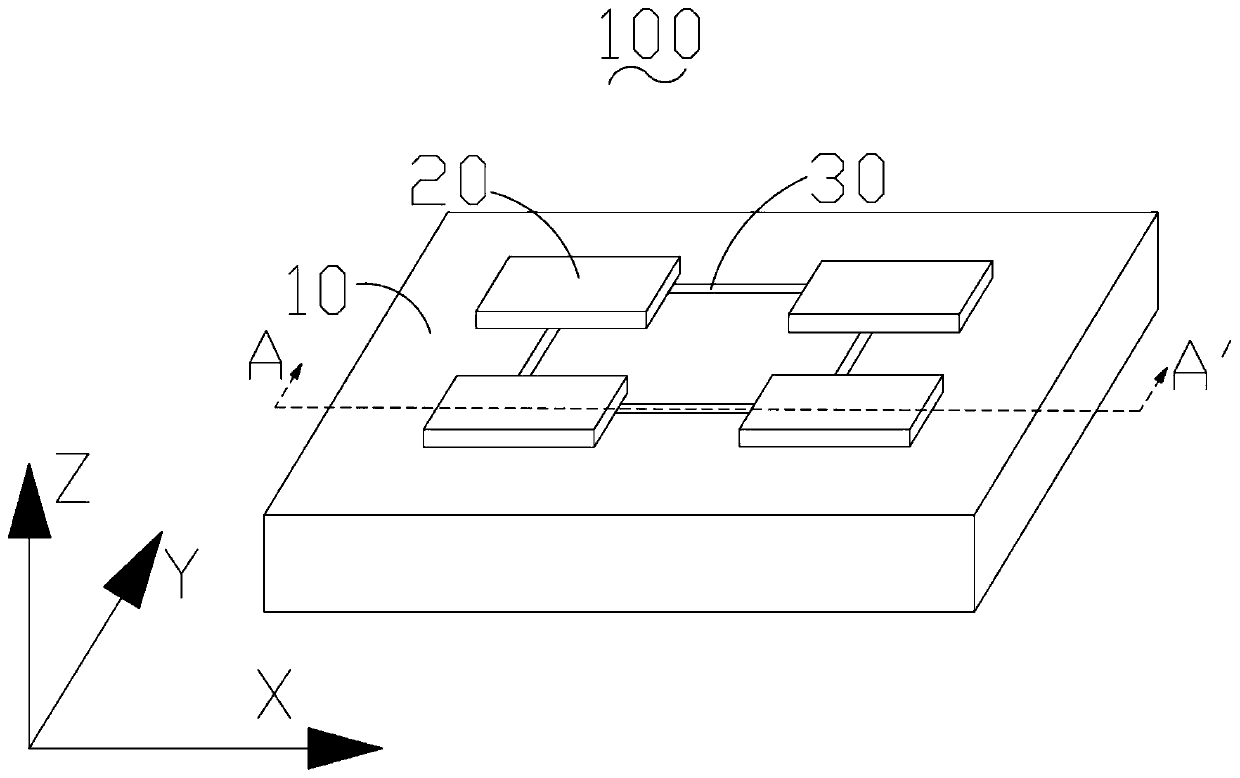

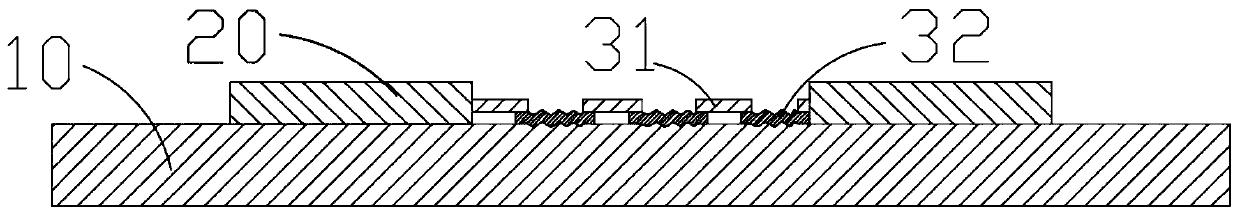

Stretchable display panel and display device

ActiveCN109830510AReduce the likelihood of breakageSolid-state devicesSemiconductor devicesEngineeringSurface plate

The invention relates to the display technology field and discloses a stretchable display panel and a display device. The stretchable display panel comprises a flexible substrate, a plurality of pixelislands arranged on the flexible substrate and a lead electrically connected to the pixel islands. The lead comprises the multiple sections of top metal wires arranged above the flexible substrate atintervals, and the multiple sections of bridging metal wires which are arranged below the top metal wires at the thickness direction of the flexible substrate and are arranged at intervals. Each section of bridging metal wires directly faces an interval between the two adjacent sections of the top metal wires, the two adjacent sections of the top metal wires are conducted, and the bridging metalwires are bended and extended towards the other one from one of the two adjacent sections of the top metal wires. By using the stretchable display panel and the display device, the possibility of leadfracture is reduced.

Owner:YUNGU GUAN TECH CO LTD

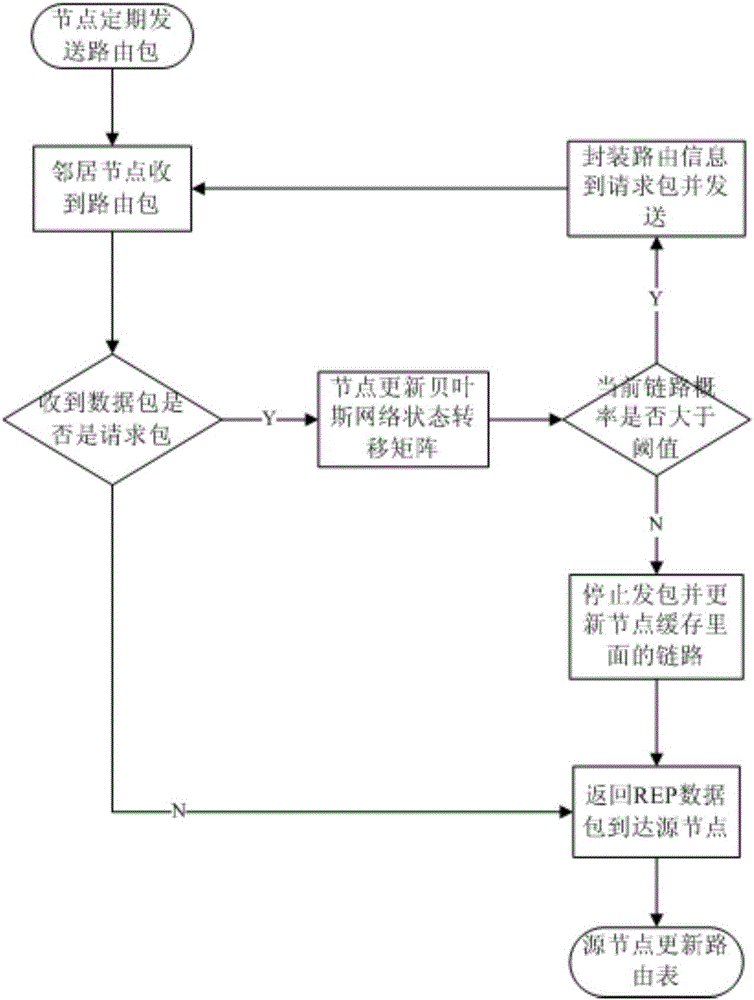

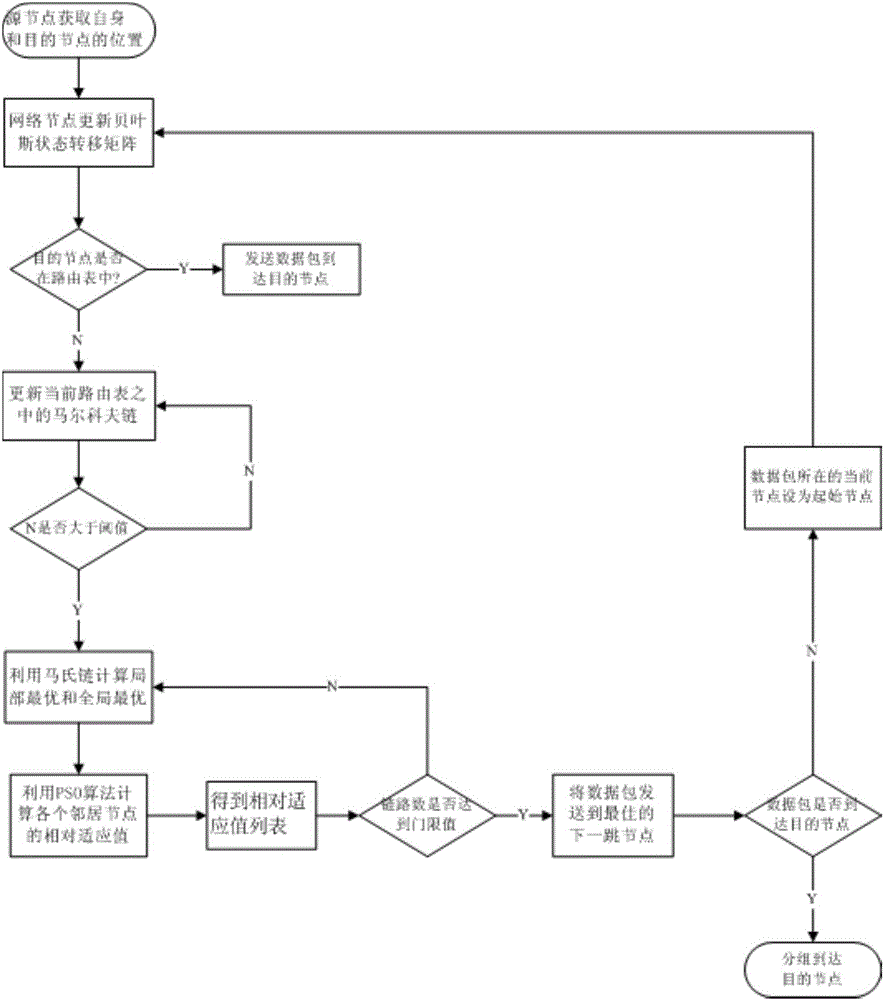

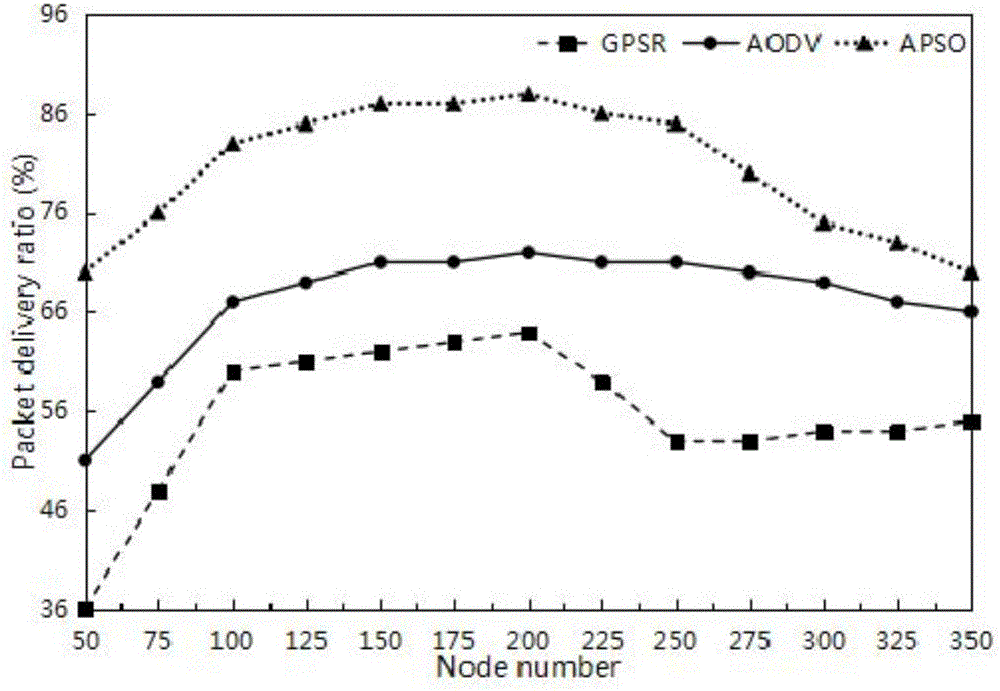

Vehicular Ad Hoc network self-adaption routing protocol method

InactiveCN105848247ASolve instabilityReduce conflictNetwork topologiesTelecommunications linkCommunication link

The invention relates to the field of vehicle self-organizing network, and particularly relates to a vehicular Ad Hoc network self-adaption routing protocol method. The protocol method comprises the step of routing node network and link state monitoring. The step of monitoring comprises the steps that A1. a node in a network periodically sends a route request packet REQ, and a Bayesian network is used to calculate the probability of packet sending of nodes and neighbor nodes to establish a network state probability transition matrix; A2. other nodes in the network receives the REQ, and the network state probability transition matrix is updated to acquire a Markov chain; A3. the network state probability transition of the nodes is used to calculate the connectivity of links in the Markov chain, and an REQ or REP data packet is selected and sent. According to the monitoring mechanism provided by the invention, the problem of unstable communication link in a VANET network is effectively solved; the probability of data packet conflict is reduced; and a good way is provided for data traffic model prediction.

Owner:SUN YAT SEN UNIV

Method for improving position accuracy of mold core of integrated type ceramic mold

InactiveCN104526856AHigh positioning accuracyReduce the possibility of deformationCeramic shaping mandrelsCeramic shaping coresFiberLithographic artist

The invention discloses a method for improving the position accuracy of a mold core of an integrated type ceramic mold, and belongs to the field of rapid costing based on stereo-lithography technologies. The method comprises the steps that (1) three-dimensional software is utilized to design a resin mold, and a resin mold prototype with a positioning hole is manufactured by utilizing a stereo-lithography method; (2) a ceramic fiber or a ceramic bar penetrates into the positioning hole according needs; (3) ceramic slurry is poured into the resin mold prototype of turbine blades through a gel casting method to obtain a mold blank; (4) vacuum freeze drying and sintering are carried out on the mold blank to obtain the integrated type ceramic mold of the turbine blades. The position accuracy of the mold core of the integrated type ceramic mold can be effectively improved through the vertically through or non-through mold core, and the method is reasonable in design, is easy and convenient to operate, greatly improves the manufacturing integrity and accuracy of the mold and is suitable for practical production.

Owner:XI AN JIAOTONG UNIV +1

High-linearity electromagnetic type semi-active vibration absorber

ActiveCN105909713AImprove linearityReduce the likelihood of breakageVibration dampersMagnetic springsSemi activeLinear region

The invention provides a high-linearity electromagnetic type semi-active vibration absorber. The high-linearity electromagnetic type semi-active vibration absorber comprises a magnetic conductive outer barrel, an upper end cover, a lower end cover, an armature and a central shaft, wherein the upper end cover and the lower end cover are mounted at the two ends of the magnetic conductive outer barrel correspondingly; and the armature and the central shaft are arranged in the magnetic conductive outer barrel. The inner surface of the magnetic conductive outer barrel and the outer surface of the armature are provided with gear rings. A first spring is arranged between the upper end of the armature and the upper end cover, and a second spring is arranged between the lower end of the armature and the lower end cover. The central shaft sequentially penetrates through the upper end cover and the armature from top to bottom and then is fixedly connected with the lower end cover through an inside hexagonal bolt. A linear bearing is arranged between the central shaft and the armature. A groove is formed in the middle of the armature. A coil is wound in the groove. A wire of the coil penetrates through a wire hole formed in the armature, then bypasses the central shaft, and extends out of the lower end cover along a wiring trough formed in the lower end cover. The vibration absorber has quite high linearity, and the linearity range of the vibration absorber is wider through achievement of high-linearity electromagnetic stiffness, so that the allowable stroke of the armature of the vibration absorber is increased.

Owner:HARBIN ENG UNIV

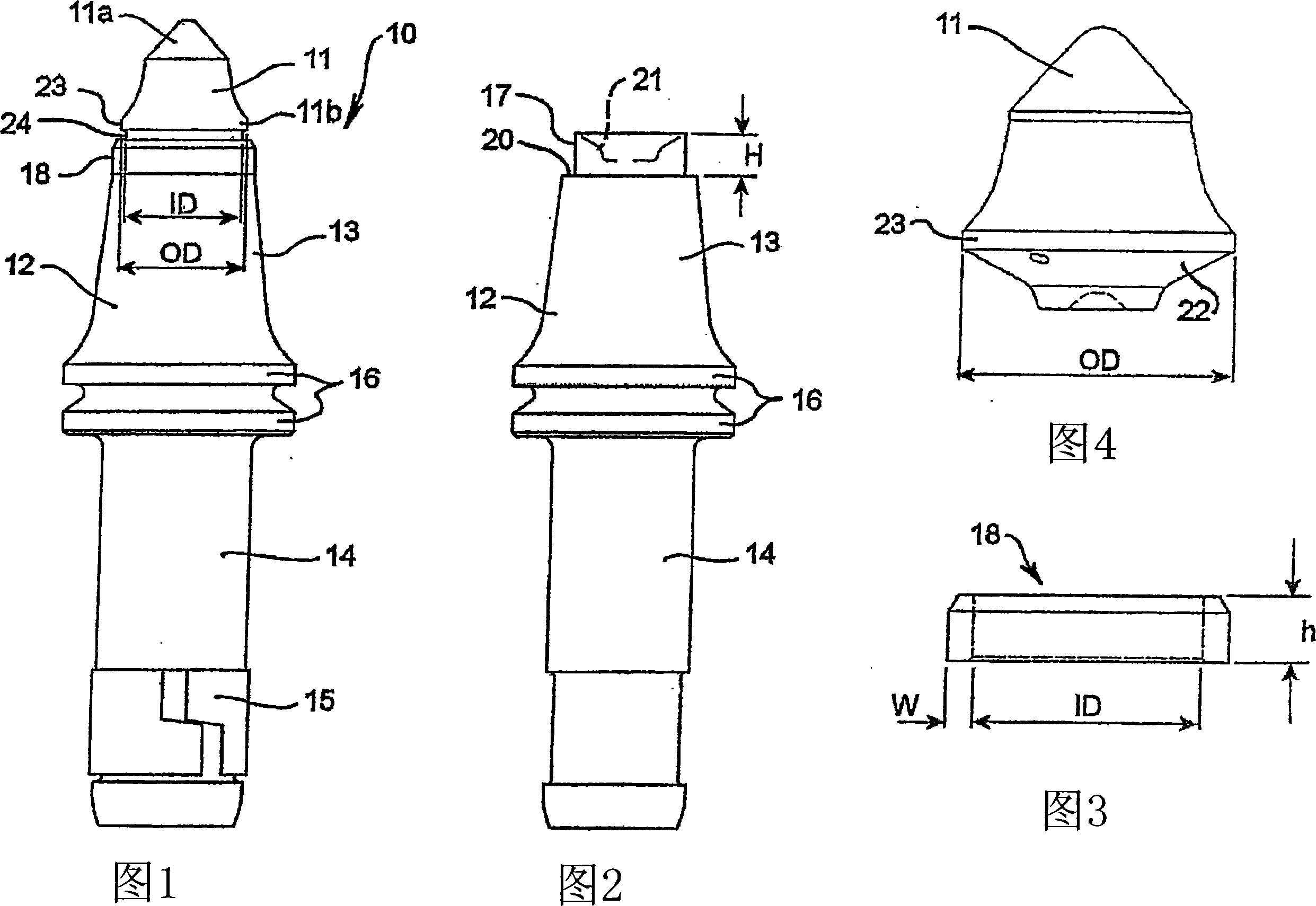

Rotary cutting pick and method of using a cutting pick for mining

InactiveCN101248251AReduce basic functionsReduce exposureConstructionsSlitting machinesMaximum diameterEngineering

A rotary pick (10) includes an elongated shank (12) and a cutting tip (11) mounted to one end of the shank (12). The cutting tip 11 has a front end (11a), a tail end (11b) and a mounting portion (22) for mounting to a shank (12). The tip (11) has a shape diverging outwards up to a maximum diameter portion in the direction from the leading end (11a) to the trailing end (11b). An annular sleeve (18) is attached around the shank (12) and is adjacent and in non-contacting relationship to the trailing end (11b) of the cutting tip (11). The maximum diameter (23) of the cutting tip (11) is greater than the diameter of the inner diameter of the annular sleeve (18), such that the maximum diameter portion (23) radially overlaps the sleeve (18).

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Even speed tube of flow sensor

InactiveCN1696617AHigh strengthReduce impactVolume/mass flow by differential pressureTransducerEngineering

A uniform velocity tube of flow rate transducer consists of high pressure sampling hole at flow receiving surface, low pressure sampling hole at side surface between flow receiving surface and flow departing surface which are built on tube wall of the uniform velocity tube . It features that the said tube section is prepared to be a bullet head form so fluid is splited along two side surfaces of said tube section formed as bullet head to make a flow coefficient relatively stable when fluid flows through the tube.

Owner:熊辉

Manual wedge-shaped throttle valve

InactiveCN102853094AReduce lateral forceReduce the likelihood of breakageValve members for absorbing fluid energyLift valveTransverse forceShuttle valve

The invention provides a manual wedge-shaped throttle valve, belongs to the field of oil well pressure control and aims to enhance the transverse force bearing capacity of a valve core and increase the safety coefficient of the throttle valve. The technical scheme includes that the manual wedge-shaped throttle valve comprises a valve seat, a valve core and a shell, the valve core is a cylinder with one side edge clinging to the inner wall of the valve seat, and flow guide buffer surfaces are arranged on the front section of the valve core. Since one side of the valve core clings to the inner wall of the valve seat, the valve core cannot vibrate after being impacted by fluid, the transverse force of the fluid on the valve core is reduced by the aid of the flow guide surfaces, possibility of breakage of the valve core is greatly decreased, oil well blowout is avoided, and safety of oil well operation is improved; by the aid of a concave cambered surface arranged between the inclined flow guide surface and the axial flow guide surface, anti-erosion capability of the valve core is enhanced, and service life of the valve core is prolonged.

Owner:CHONGQING XINTAI MASCH CO LTD

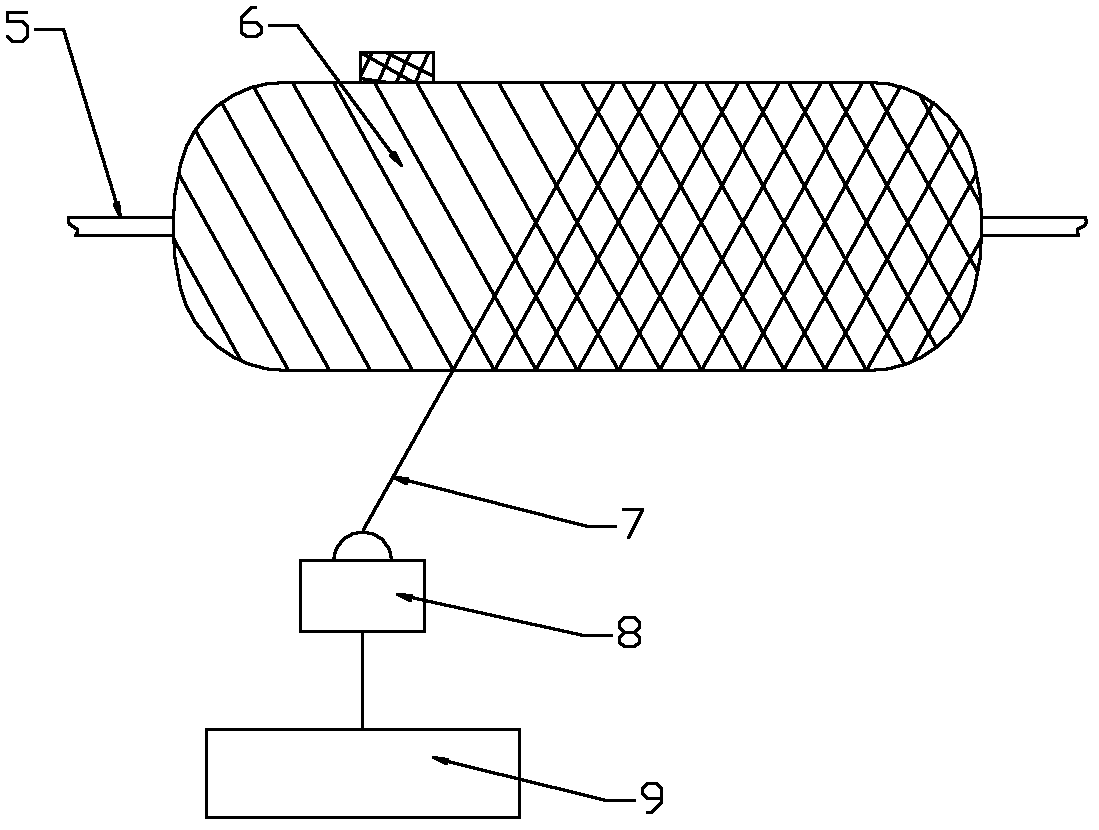

Method and device for reducing oil and gas well annulus belt pressure

InactiveCN105298445ASlow down a sharp rise or fallReduce maintenance timesBorehole/well accessoriesWellheadProduction string

The invention provides a method and device for reducing oil and gas well annulus belt pressure. The method for reducing the oil and gas well annulus belt pressure comprises the following steps that a gas storage tank is provided, and the gas storage tank is communicated with an oil and gas annulus through a pipeline; a preset volume of inert gas is fed into the gas storage tank. By means of the method and device for reducing the oil and gas well annulus belt pressure, sharp increase or decrease of the oil and gas well annulus pressure can be reduced, and the possibility of seal failure leakage and breakage of a production pipe column, a sleeve pipe, a packer and wellhead equipment can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

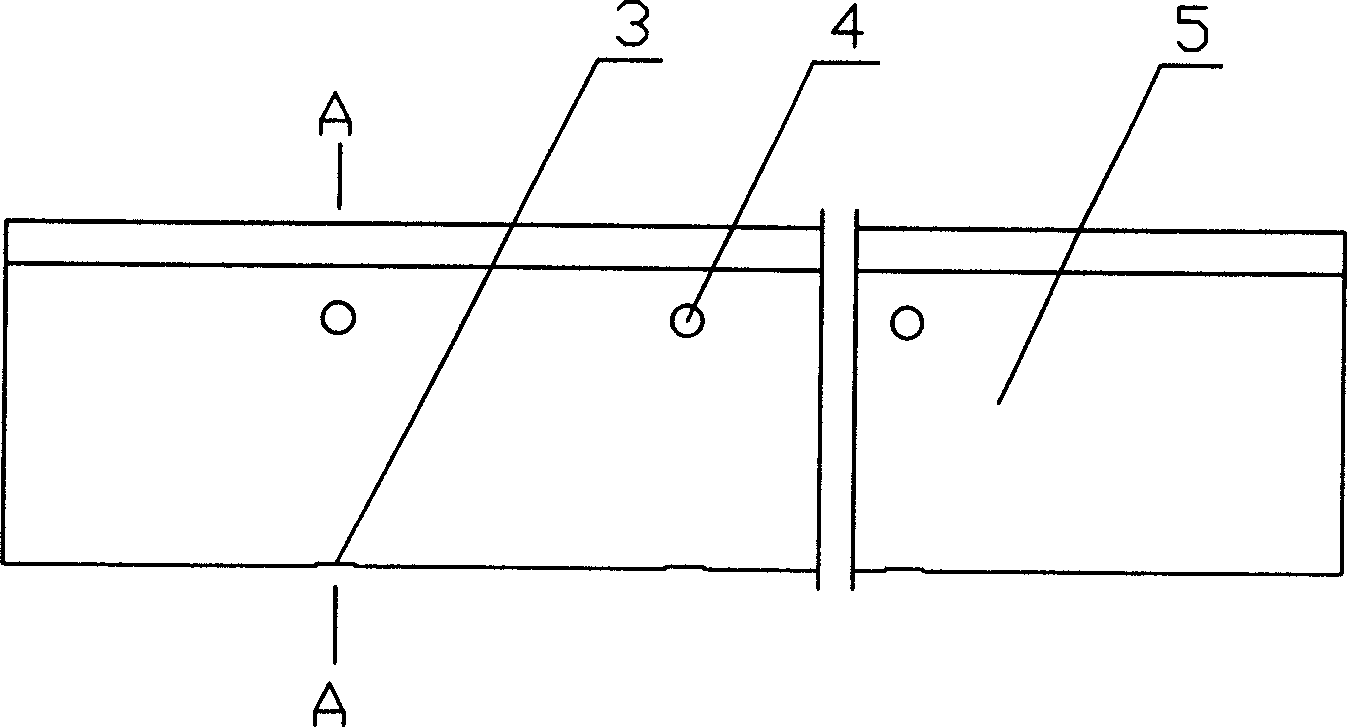

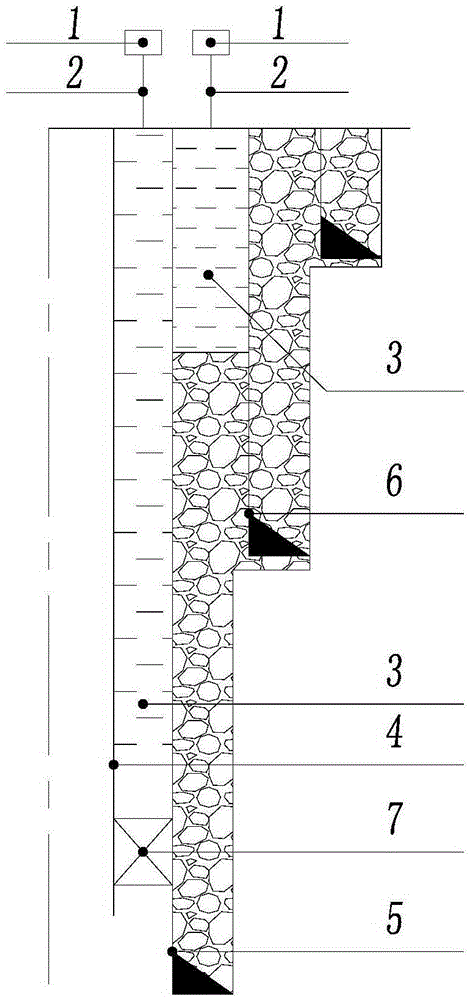

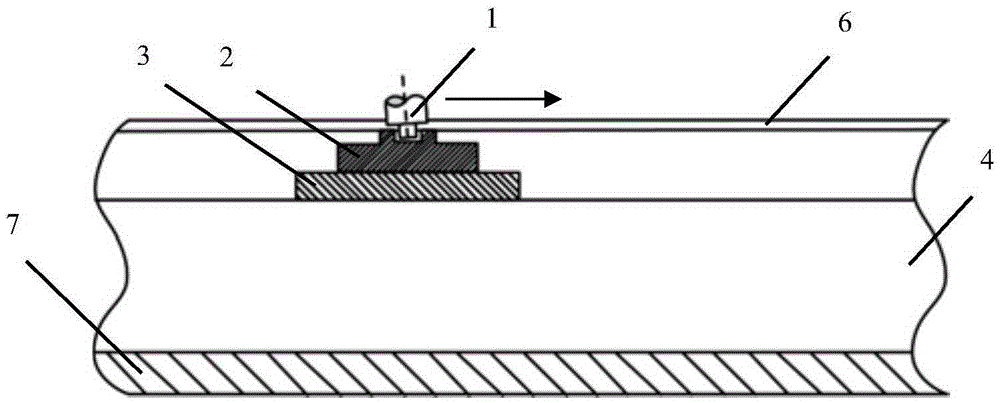

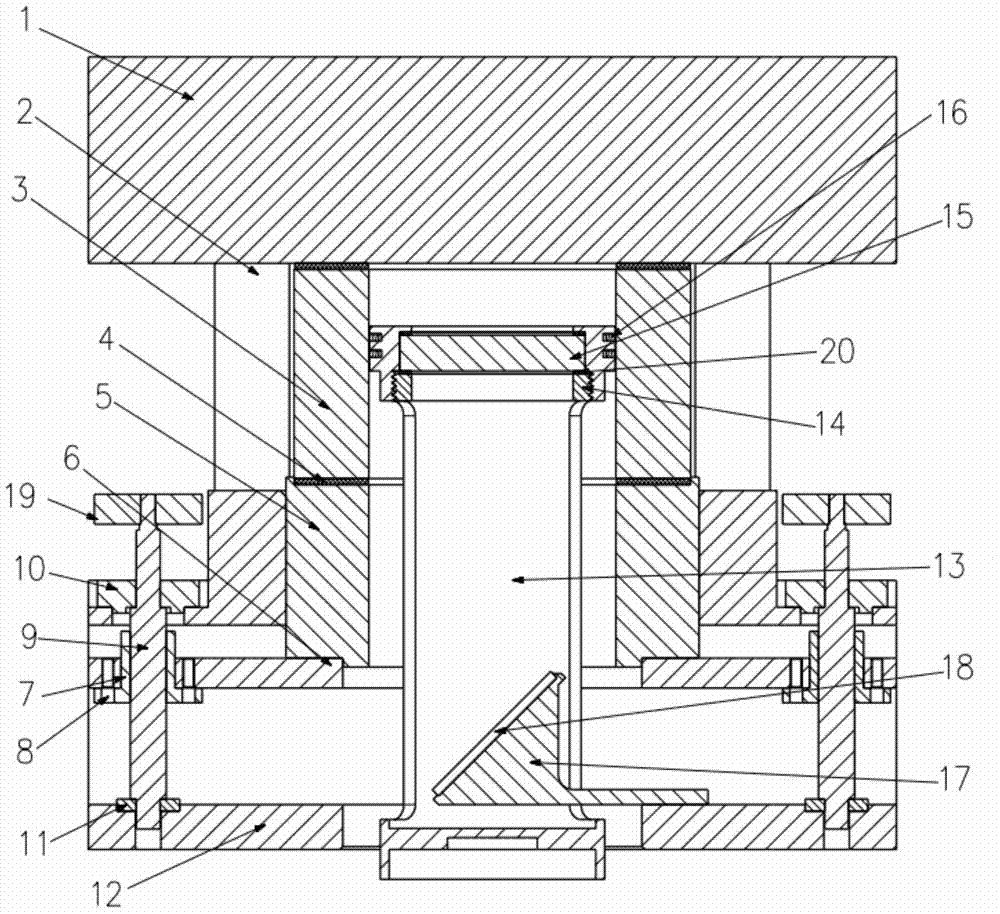

Stationary shaft shoulder assistant supporting inclined penetration friction-stir welding device and method

ActiveCN105382405AReduce the likelihood of breakageAvoid problems prone to void defectsNon-electric welding apparatusFriction weldingEngineering

The invention discloses a stationary shaft shoulder assistant supporting inclined penetration friction-stir welding device and method, relates to a friction-stir welding device and method, and aims at solving the problem that an existing friction-stir welding method is difficult in avoiding a non-welding-on defect, or the problem that although the non-welding-on defect can be avoided, overlarge thermal input and other defects are caused. The friction-stir welding device provided by the invention comprises a long-needle stirring head, a stationary shaft shoulder with a blind hole, a translation sliding block, a linear guideway and a positioning clamping apparatus. During welding, the liner guideway, a welded workpiece and the positioning clamping apparatus are stationary, and the long-needle stirring head, the stationary shaft shoulder and the translation sliding block move along a welding direction, so as to realize a welding process. The stationary shaft shoulder assistant supporting inclined penetration friction-stir welding method provided by the invention comprises the following steps: 1, assembly of the device; 2, fixing of the long-needle stirring head and the stationary shaft shoulder; 3, friction-stir welding. The device and the method, provided by the invention are used for friction-stir welding.

Owner:HARBIN INST OF TECH

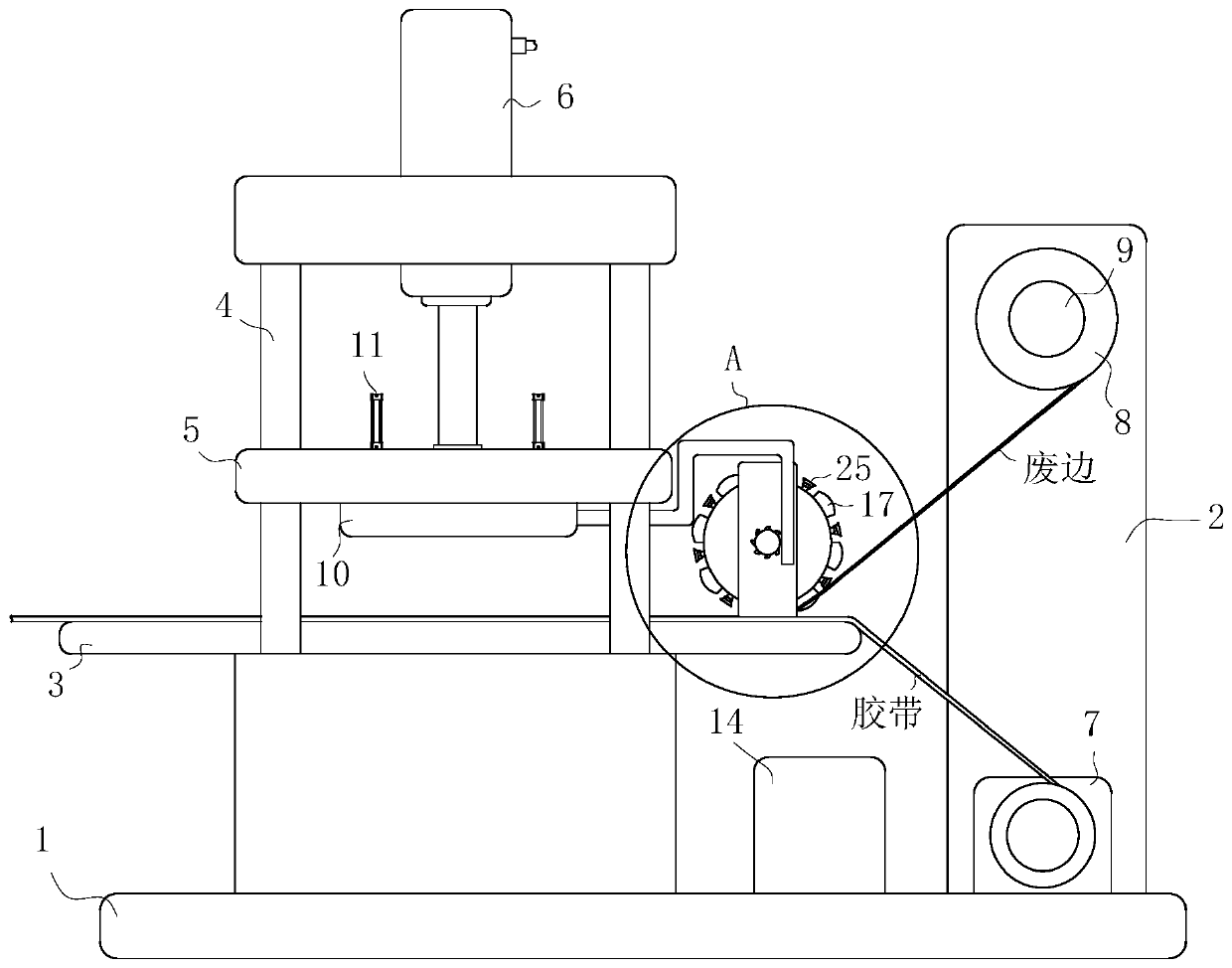

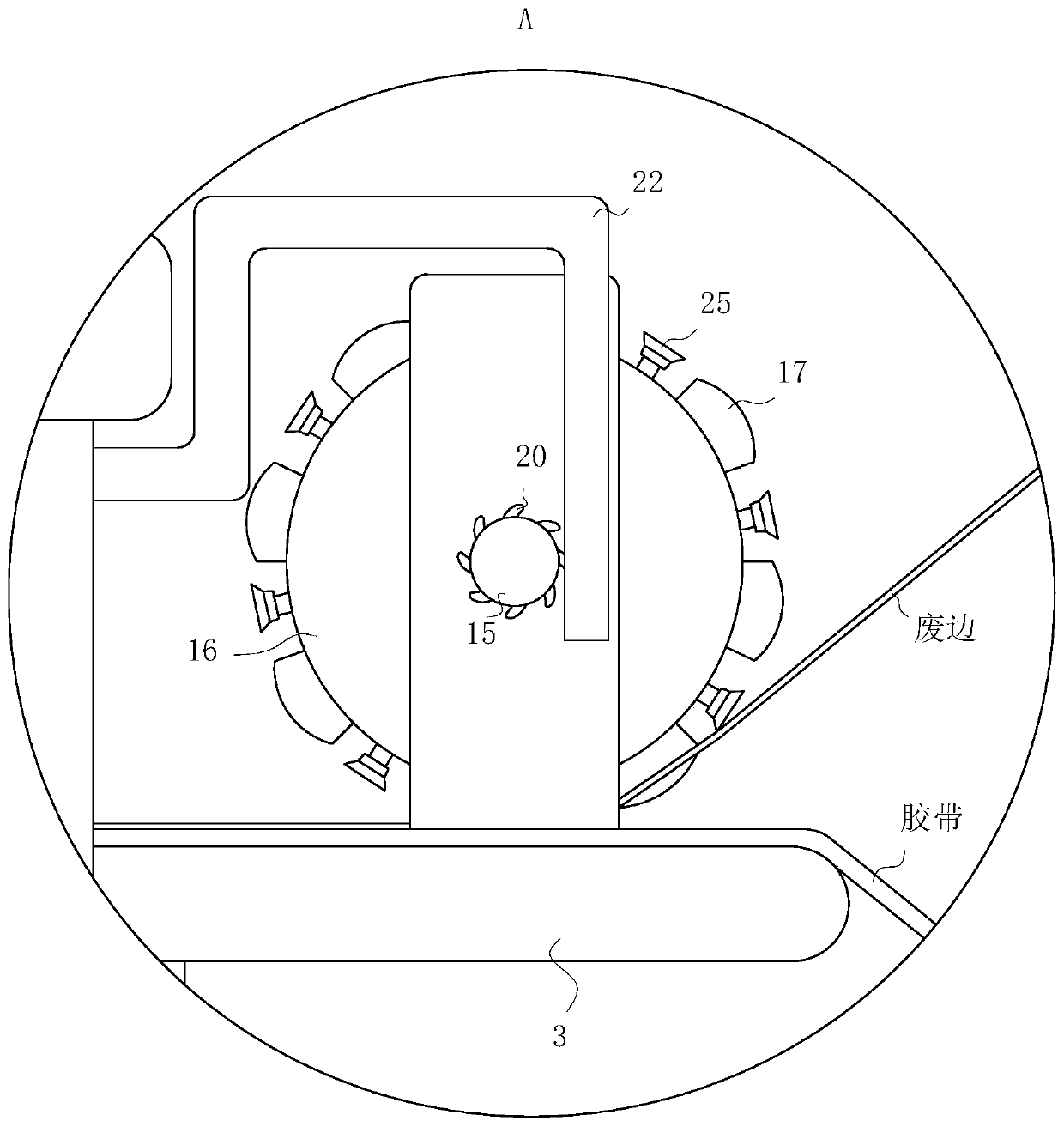

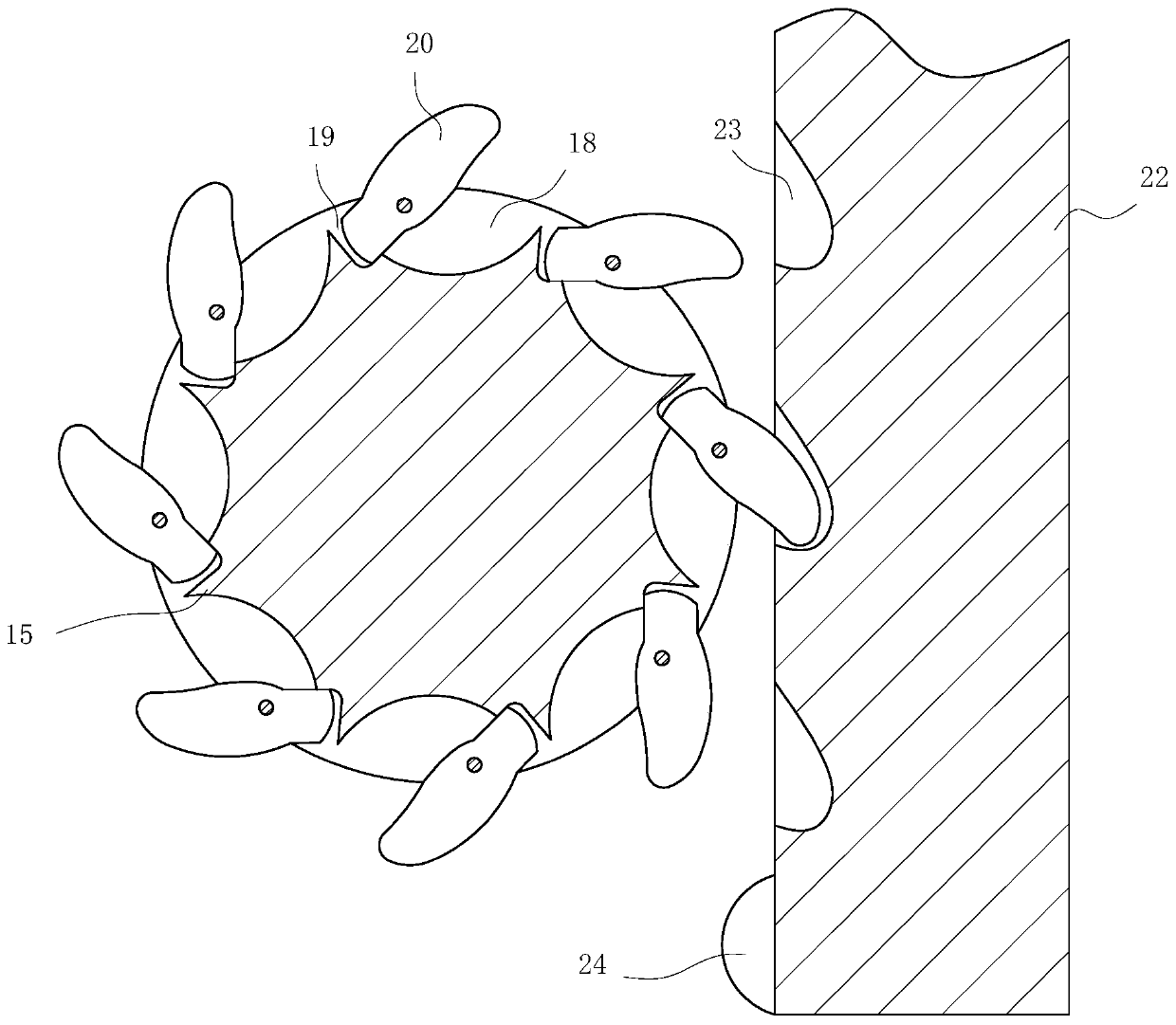

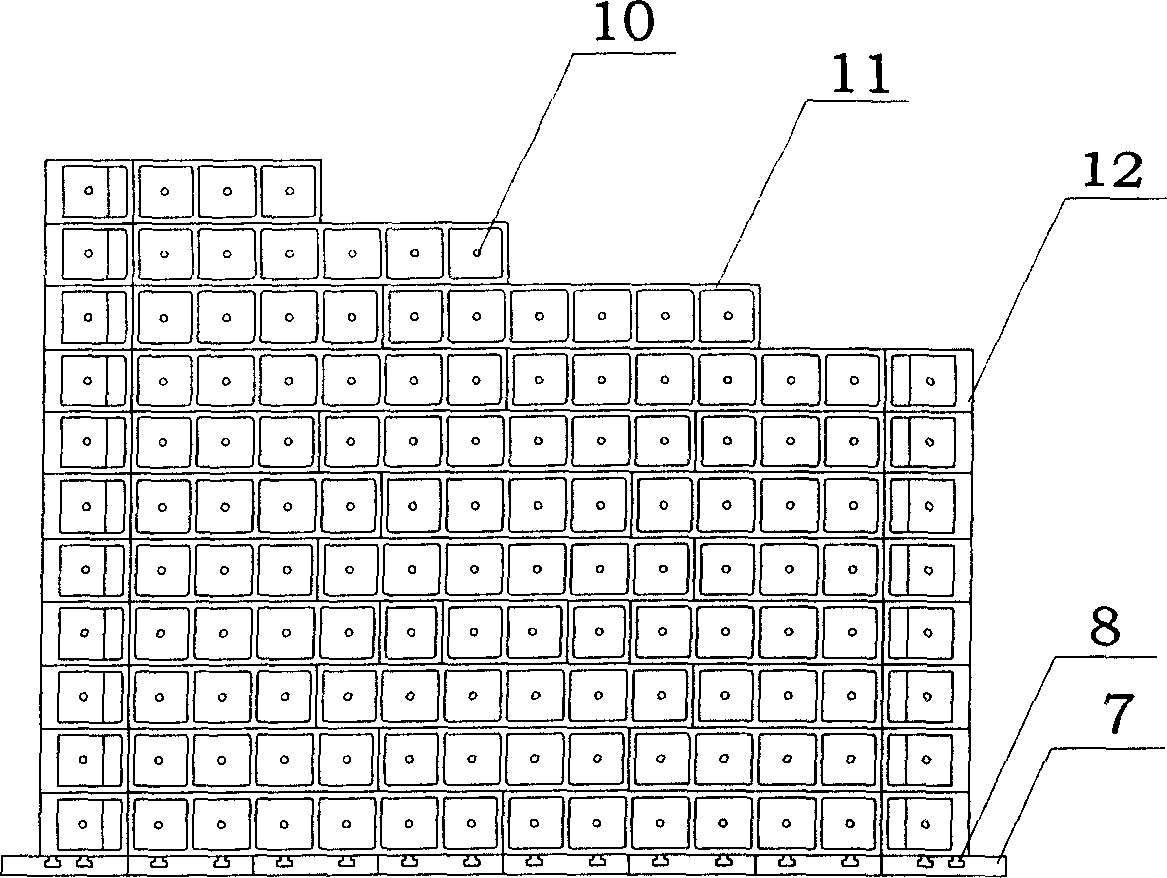

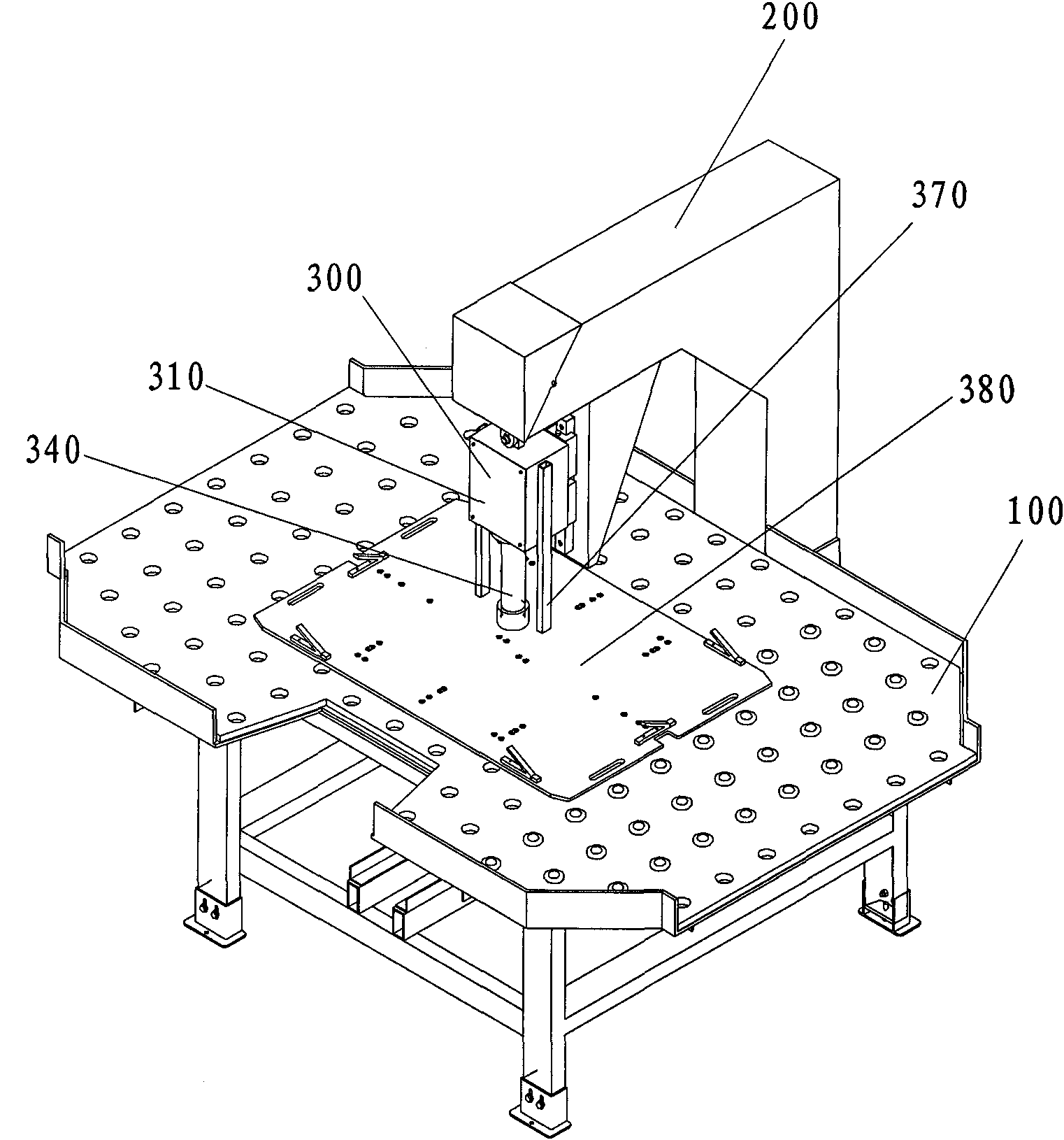

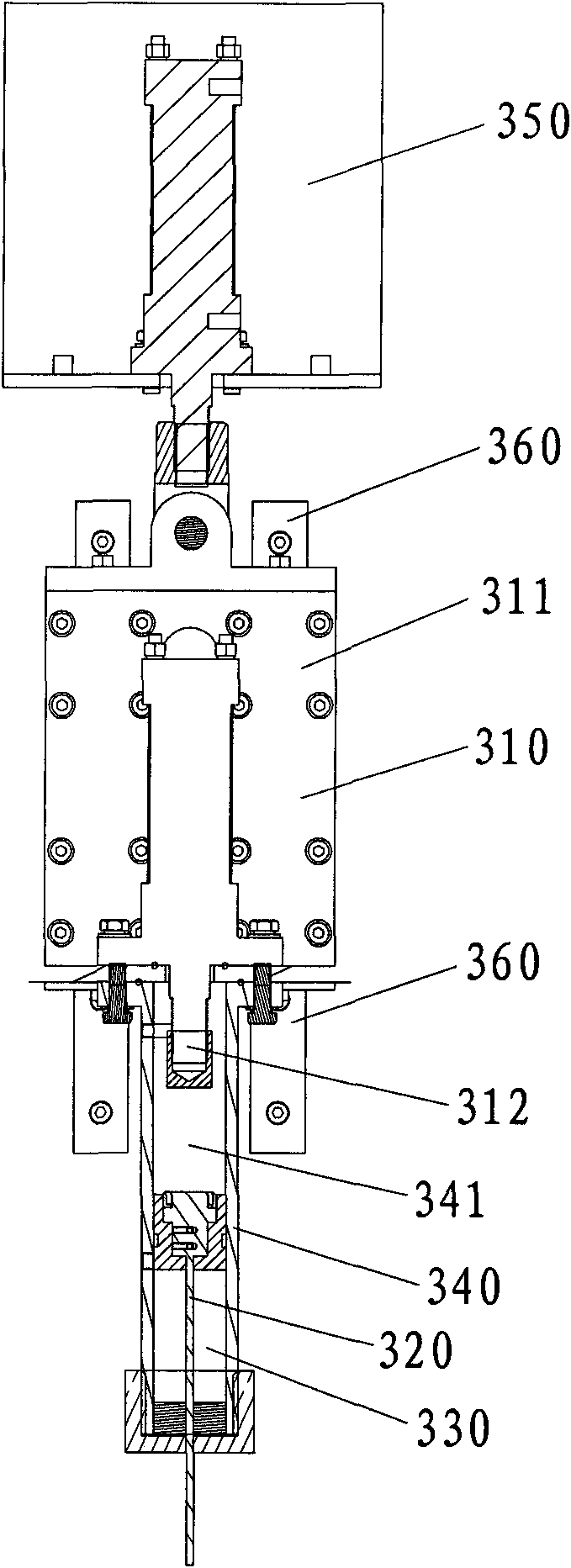

Die cutting device for adhesive tape processing

ActiveCN111037641AImprove waste discharge efficiencyReduce the possibilityMetal working apparatusPhysicsElectric machinery

The invention belongs to the technical field of adhesive tape processing, and particularly relates to a die cutting device for adhesive tape processing. The die cutting device comprises a bottom plate, wherein a hydraulic machine and a mounting plate are fixed at the top end of the bottom plate; the hydraulic machine comprises a workbench, a guide rod, a movable cross beam and a hydraulic cylinder; a first driving motor and a second driving motor are fixed on the side wall of the mounting plate; rotating rollers are fixed at the output shaft ends of the first driving motor and the second driving motor; the rotating rollers are used for winding an adhesive tape and a waste edge correspondingly; and more than two die cutting knives are fixed at the bottom end of the movable cross beam. According to the die cutting device, the adhesive tape is pressed through the arrangement of a pressing plate, so that the adhesive tape cannot be broken during die cutting, and the phenomenon that the cutedge of the adhesive tape is fluffed is avoided; and a limiting block is arranged to protect a product, so that the product cannot be taken up when being separated from the waste edge, and the wastedischarge efficiency of the adhesive tape is improved.

Owner:安徽灿宇光电科技有限公司

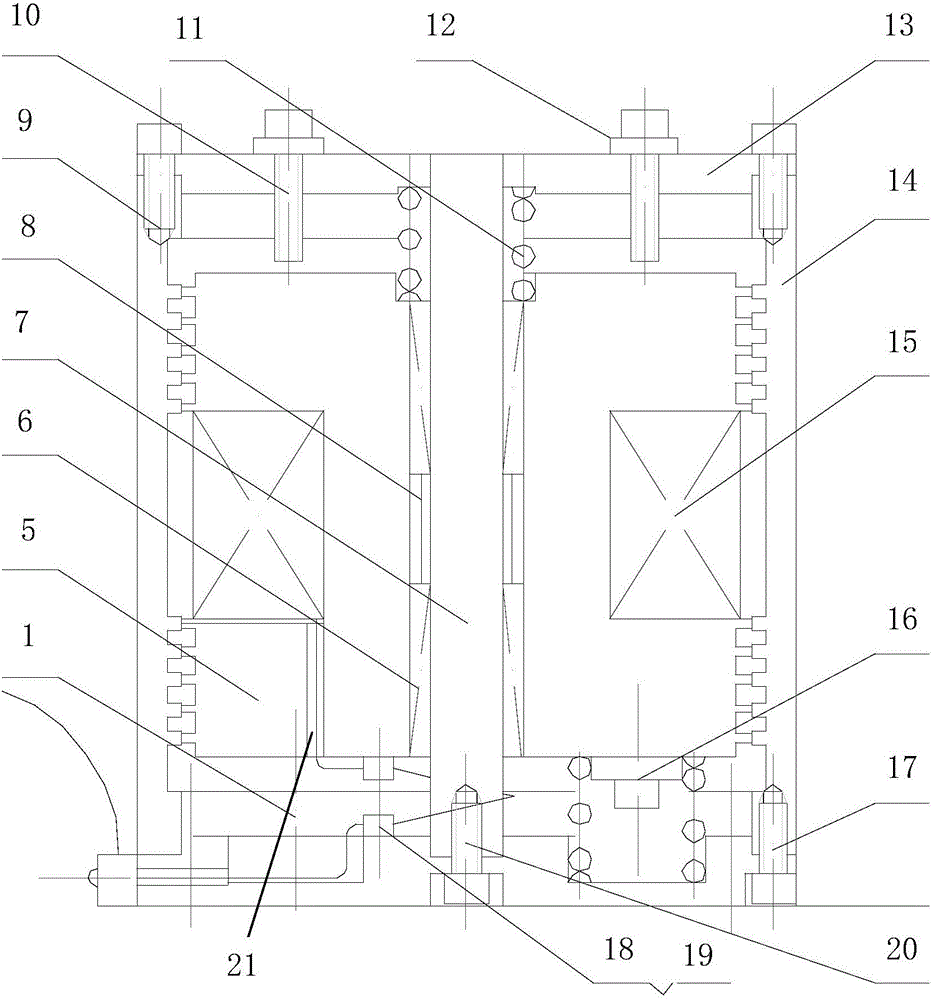

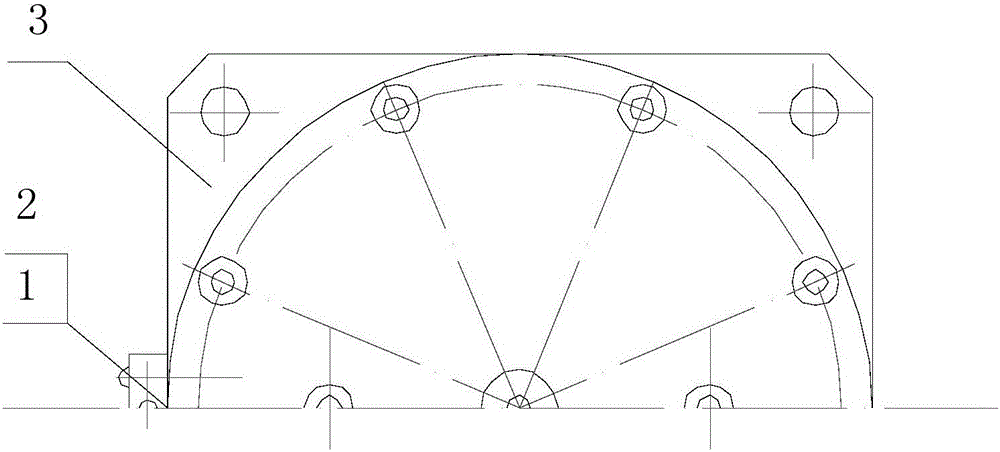

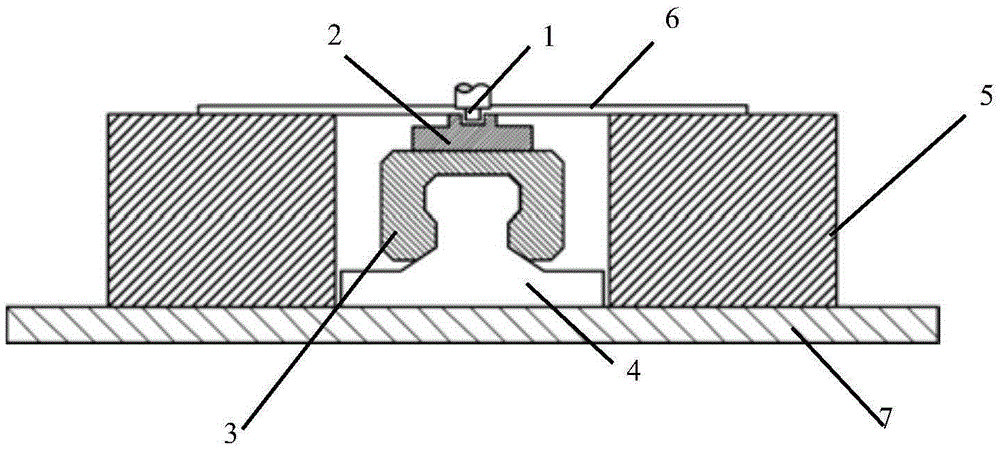

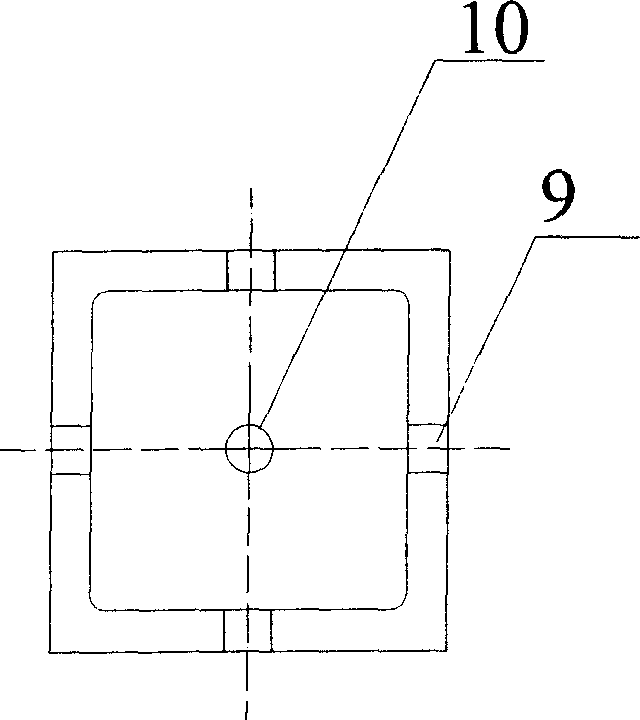

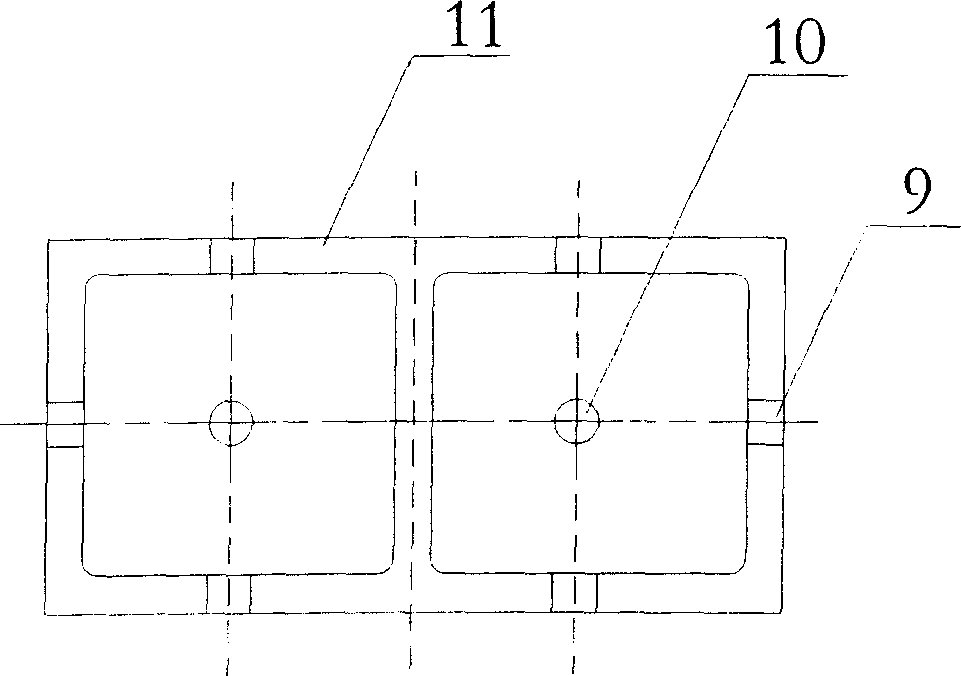

Combined type geomechanics model test stand device

The invention relates to a compound geomechanics model test platform which is formed by steel platform body connected with bottom disk by high strength friction grip bolt. The box type platform is formed by box type steel casting connected with the angle unit at corner by the high strength friction grip bolt. The box type steel casting is formed by a unit box casting and a multi-units box casting, wherein the unit box casting is a square box with hollow structure and front port; the four sides of the unit box casting arranges the high strength friction grip bolt connecting hole and the front side arranges line drilling breather; the multi-units box casting is formed by at least two or a plurality of multi-units box castings; the angle unit is hollow with ports on the adjacent two sides and the friction grip bolt connecting hole on other sides; the bottom disk is formed by parallel connecting the section steel plates with bolt groove.

Owner:SHANDONG UNIV

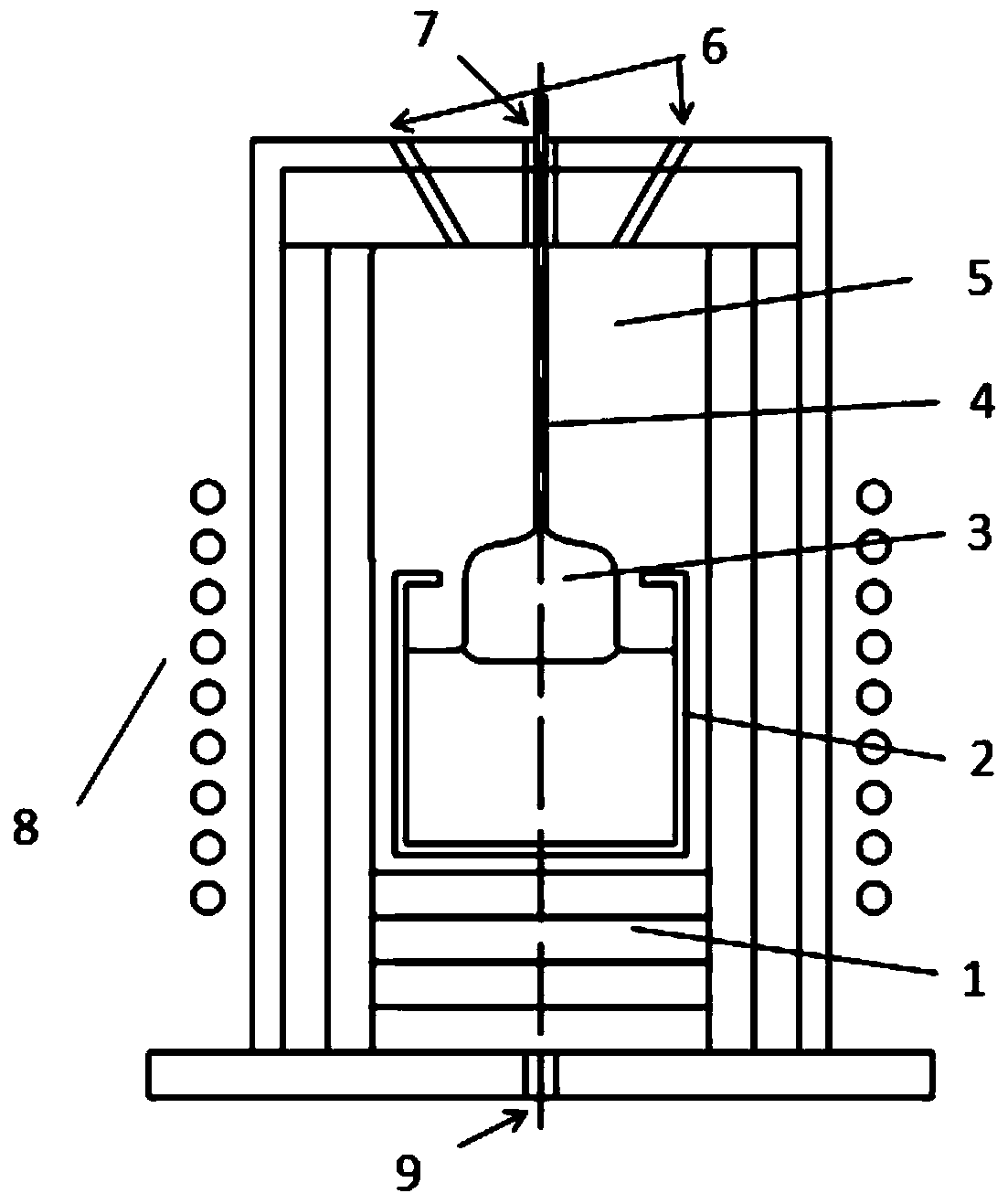

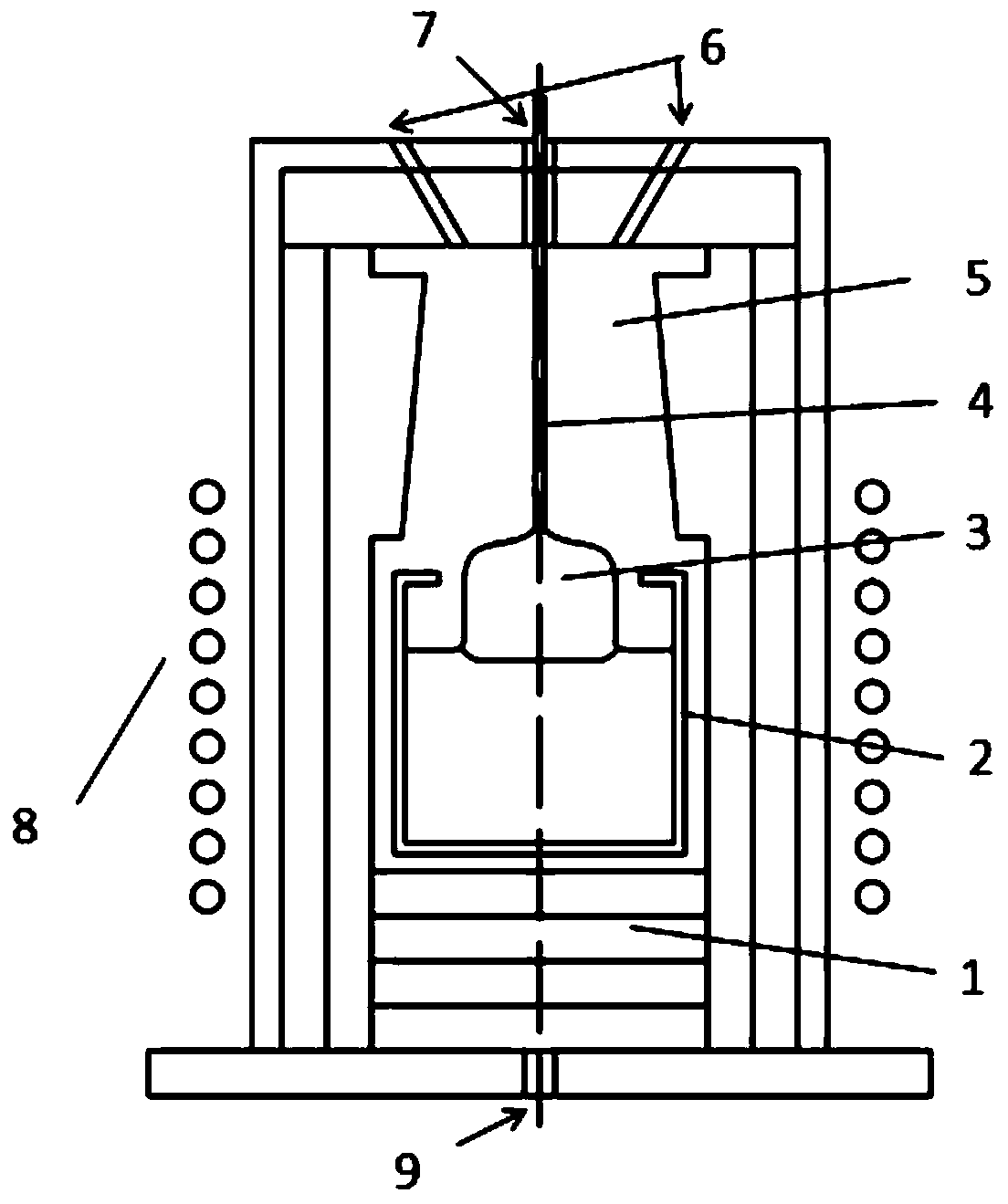

Pulling method crystal growth furnace

InactiveCN103741208AReduce the likelihood of breakageControl flow stateBy pulling from meltRound tableDislocation

The invention discloses a pulling method crystal growth furnace. The pulling method crystal growth furnace is characterized by comprising a furnace body and a crucible (2), wherein the interior of the furnace body is hollow so as to form a furnace cavity (5), the crucible (2) is arranged at the center of the furnace cavity (5), and the crucible (2) is connected with a seed crystal rod (4) which is coaxially arranged in the furnace cavity (5) and used for growing crystals (3) in the crucible (2); and the pulling method crystal growth furnace is characterized in that the inner wall of the furnace cavity (2) at the upper part of the crucible (2) has a certain conicity and a round table cylinder structure is further formed. The growth furnace disclosed by the invention can effectively control the three-dimensional effect of flow and heat transfer in the pulling method furnace cavity, organize a relatively good temperature environment around the crystals and simultaneously form a relatively good temperature gradient at a solid-liquid interface in the growth process of the crystals. The novel furnace cavity structure can reduce the production of dislocation or rupture in the growth process of the crystals and improve the quality of the crystals.

Owner:HUAZHONG UNIV OF SCI & TECH

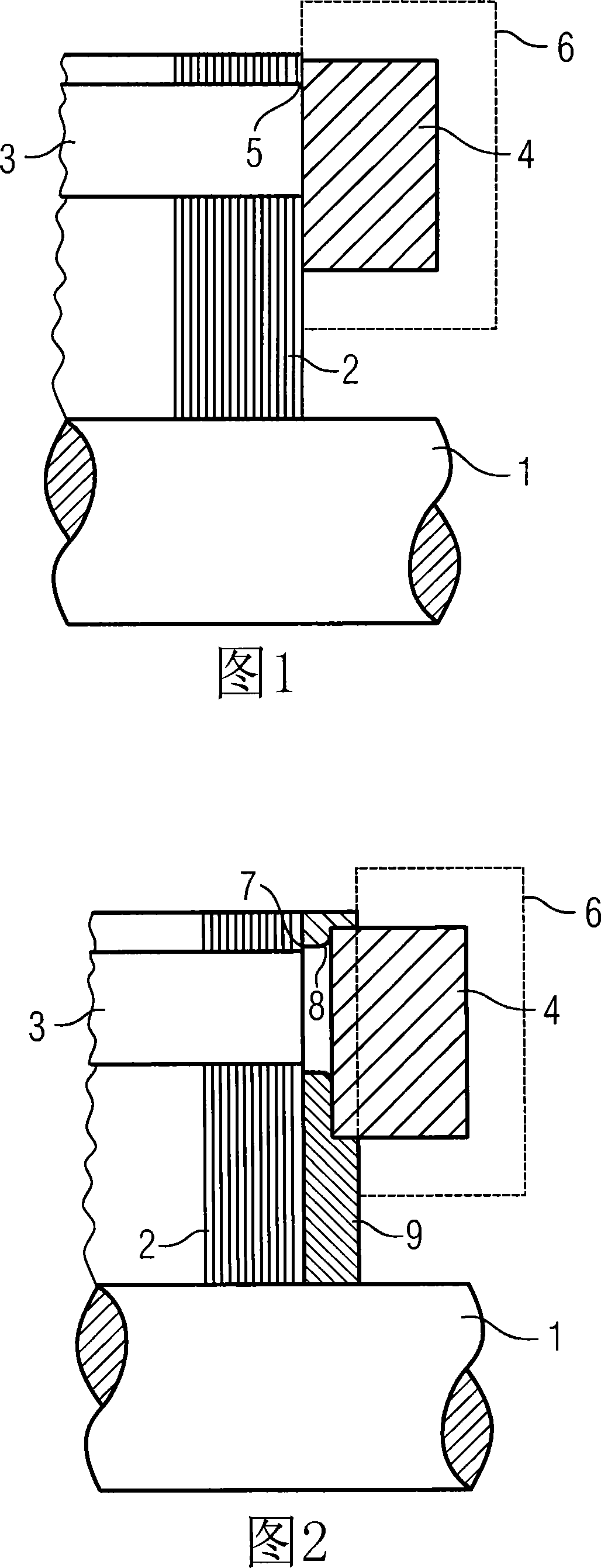

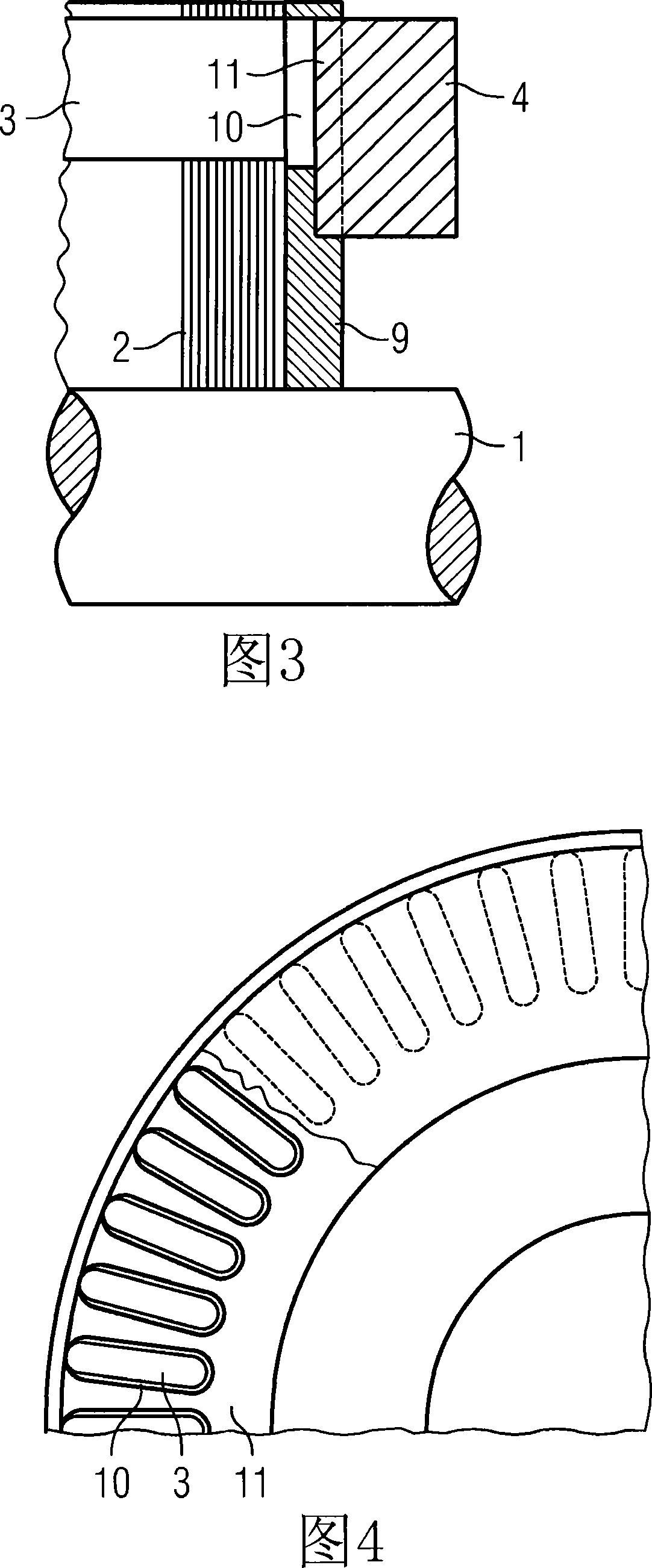

Cage rotor for an asynchronous motor

Owner:SIEMENS AG

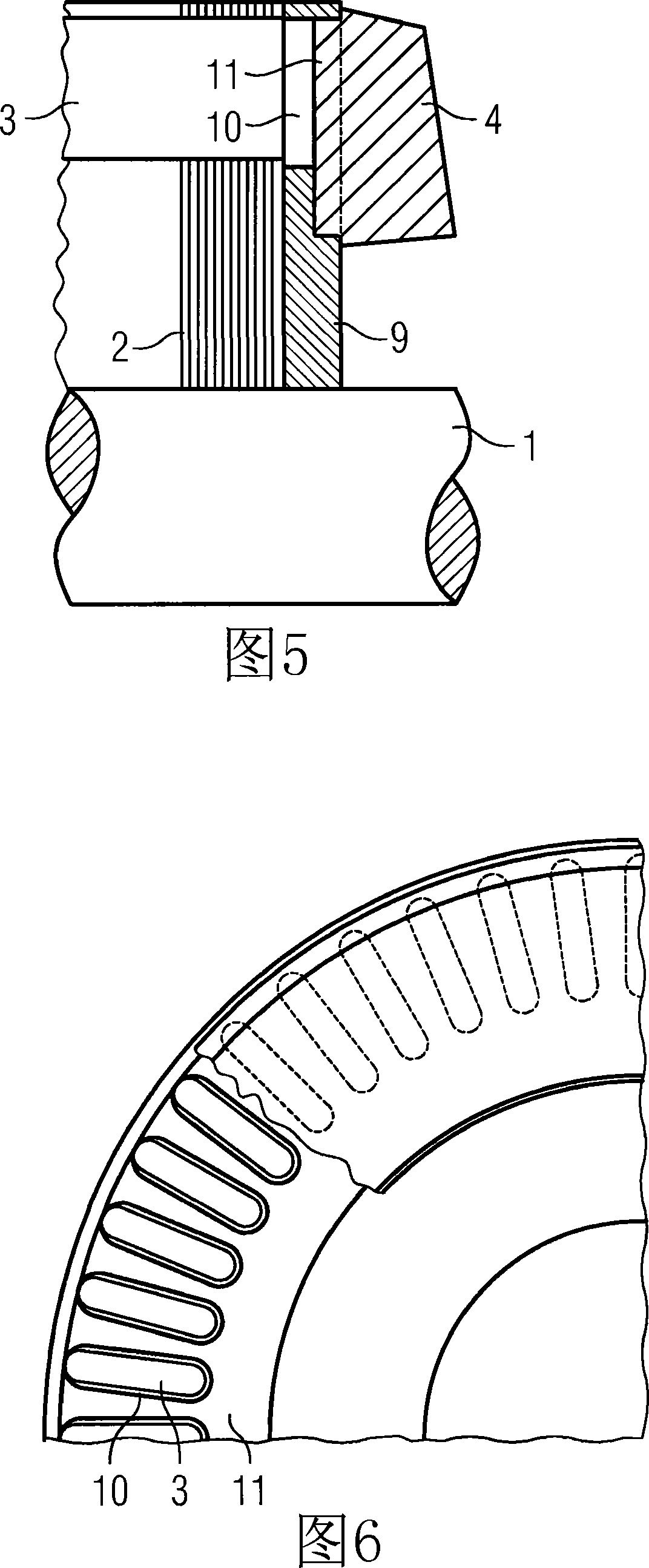

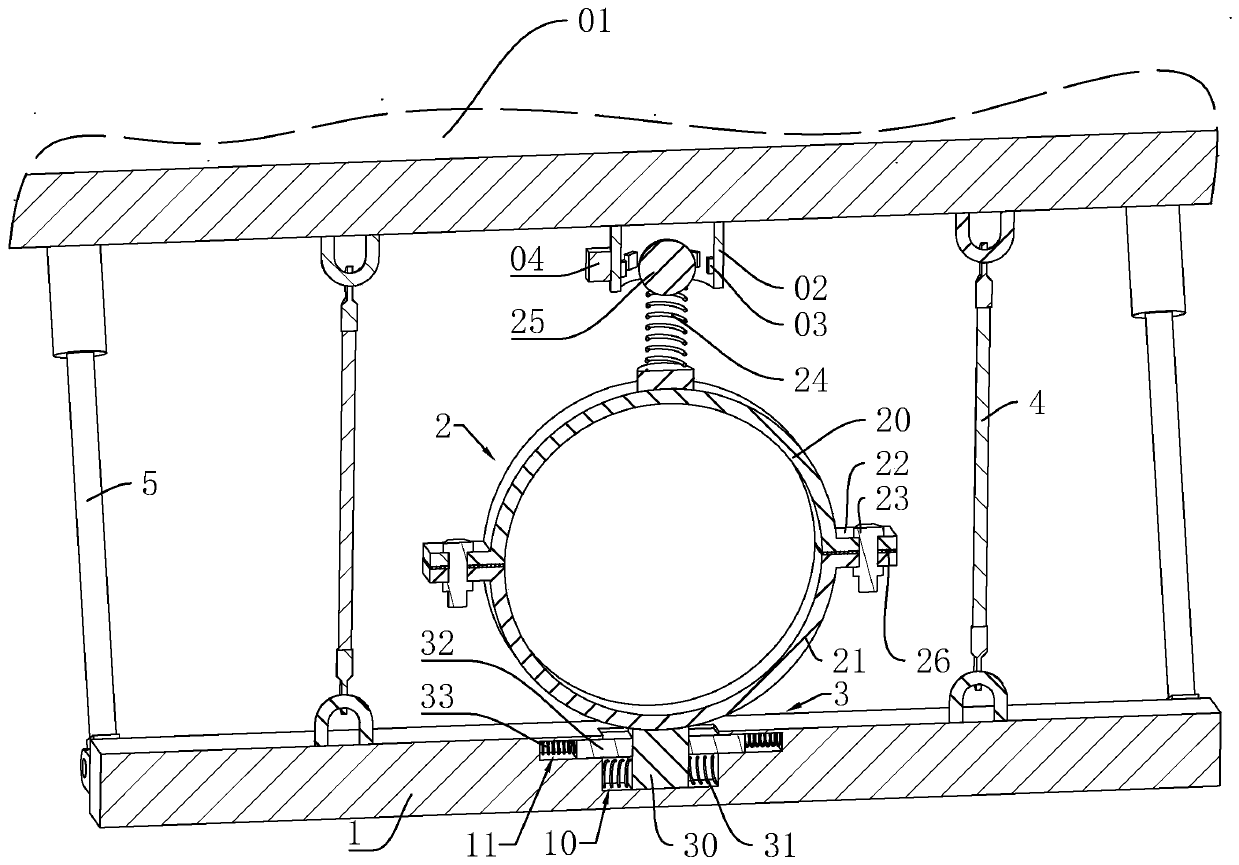

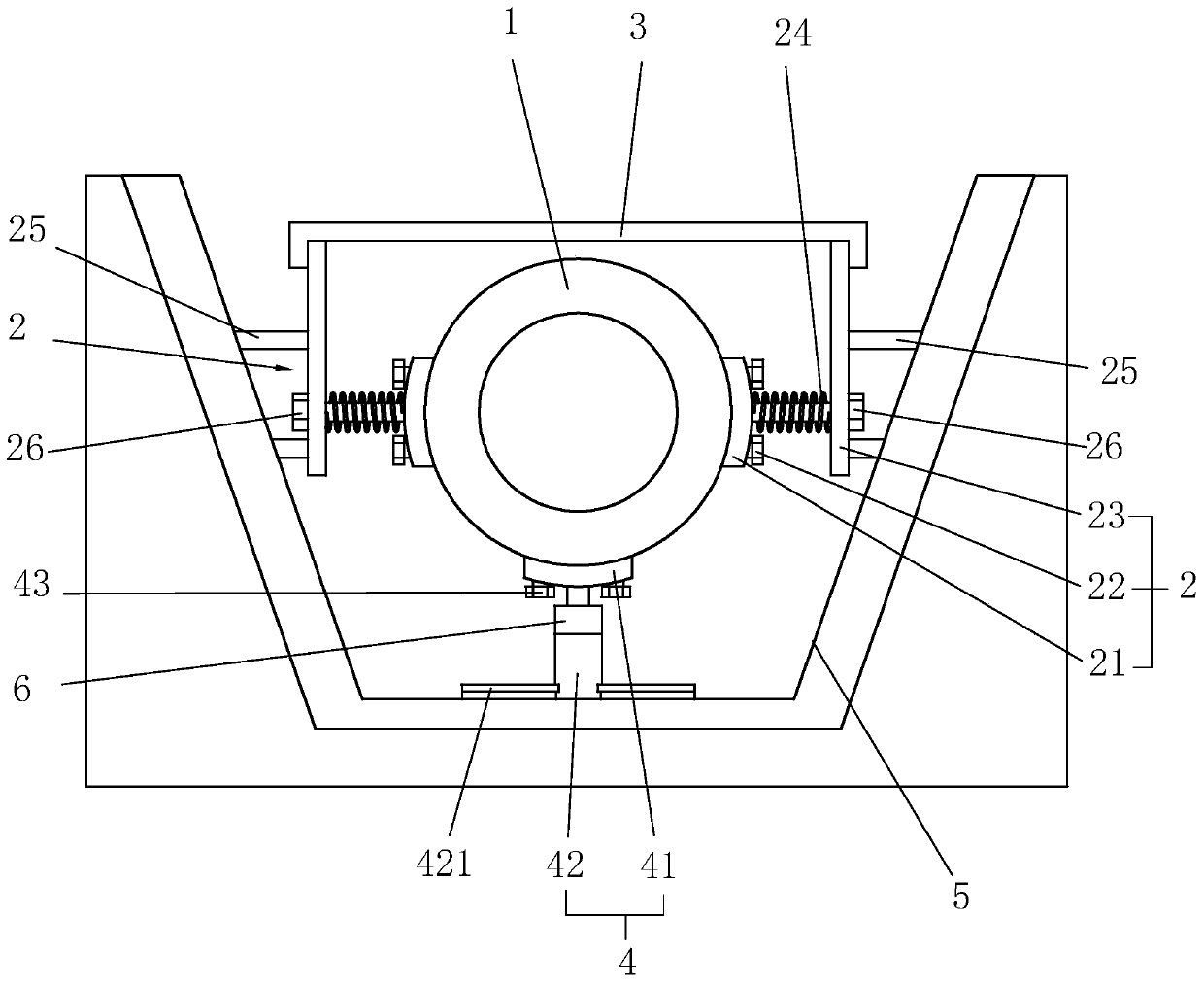

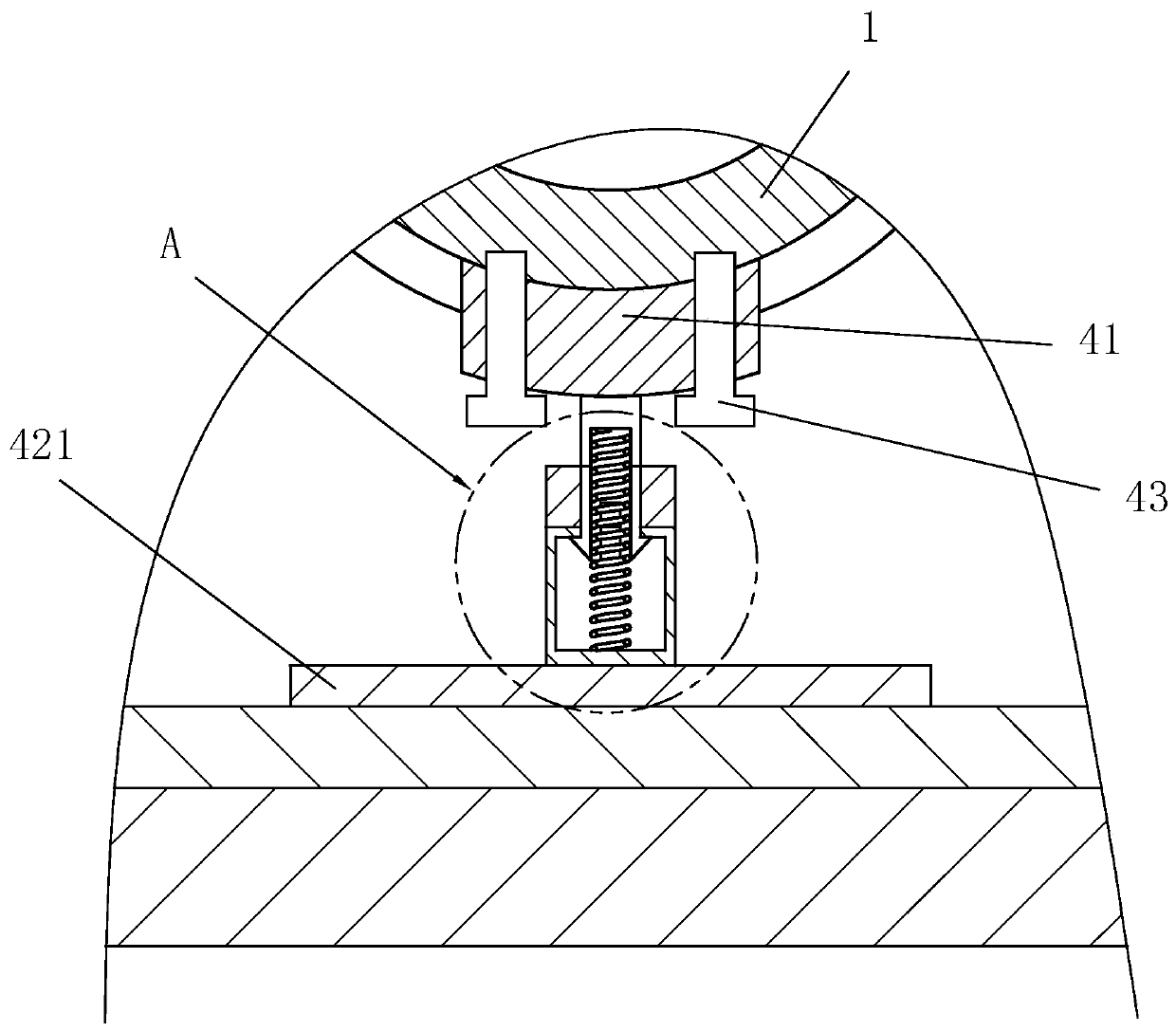

Intelligent damping pipe support hanger

ActiveCN110440059AReduced connection stabilityReduce safety incidentsPipe supportsPipe elementsPipeline transportEngineering

The invention discloses an intelligent damping pipe support hanger. The intelligent damping pipe support hanger comprises a support plate, a mounting assembly for fixing a pipe, a sliding assembly arranged on the support plate, at least two steel wire ropes and two diagonal support assemblies. The mounting assembly is arranged on the side wall of the support plate. One ends of the steel wire ropesare connected with the support plate, and the other ends of the steel wire ropes are connected with the wall body. One ends of the diagonal support assemblies are connected with the wall body, and the other ends of the diagonal support assemblies are connected with the support plate. The two diagonal support assemblies form support sets. The support sets are correspondingly arranged at the two ends of the support plate. When the pipe transports a large amount of liquid, the pipe vibrates, and the sliding assembly is used to drive the pipe to slide and buffer on the support plate; the vibration is transmitted to the wire ropes, and the vibration can be buffered because the wire ropes have good impact toughness; and the vibration is buffered by the diagonal support assemblies, so that the possibility of the decrease in the stability of the connection between the pipe and the hanger can be reduced, the possibility of pipe rupture is reduced, and the possibility of a safety accident is lowered.

Owner:江苏唯斯安建筑科技有限公司

Gas pipeline system laying structure and laying method

ActiveCN110242792AImprove seismic performanceReduce the likelihood of breakagePipe laying and repairEngineeringMechanical engineering

The invention relates to the field of gas pipeline laying, in particular to a gas pipeline system laying structure and a laying method. The system comprises a pipeline, wherein a laying groove is formed in the ground along the laying direction of the pipeline, the pipeline is laid in the laying groove, installation components are arranged on the two sides of the pipeline, the installation components comprise a mounting plate, a fixing bolt, a fixing plate and a first elastic part, the mounting plate is arranged on the peripheral surface of the pipeline and is embedded into the side wall of the pipeline, the fixing bolt is arranged on one side, far away from the pipeline, of the mounting plate and fixes the mounting plate on the pipeline, the fixing plate is vertically arranged on the two sides of the pipeline, the first elastic part is arranged between the fixing plate and the mounting plate, when the mounting plate is arranged on the side wall of the pipeline, the first elastic part is in a stretching state, and a supporting component used for supporting the pipeline is arranged at the bottom of the laying groove, so that the effects of improving the anti-seismic capacity of the pipeline and reducing the possibility of pipeline break are achieved.

Owner:深圳市中港建筑工程有限公司

Structural device capable of quickly removing and installing engine combustor windows

The invention discloses a structural device capable of quickly removing and installing engine combustor windows. Two visual windows include a glass window on the top of an extended piston and a glass cylinder sleeve on the side surface of a combustor. The structural device is of the structure that a cylinder cover is supported by an upright post, the glass cylinder sleeve is arranged between the cylinder cover and a sliding sleeve, the inside diameters of the two sleeves are the same, the glass cylinder sleeve is positioned in a rabbet in the top surface of the sliding sleeve which is fixed on a support flat plate, screw nuts are symmetrically installed on both sides of the flat plate, and screws are screwed into the screw nuts to form a transmission pair. The screws are screwed to descend / lift, so as to drive the circular glass cylinder sleeve arranged in the rabbet of the sliding sleeve to move up and down, so that quick removal and installation are realized. A screw sleeve is arranged on the upper end of the extended piston, and the glass window is arranged in the middle of a piston ring on the top of the extended piston. The screw sleeve is unscrewed, so that the glass window can be taken out from a side hole of the extended piston. By using the structural device, the engine combustor windows can be quickly removed, the structural device has the advantage of good sealing performance, and the experiment efficiency is improved.

Owner:TIANJIN UNIV

PIN needle dissembling device and PIN dissembling head

InactiveCN101808471AReduce the possibilityIncreased thimble lifePrinted circuit assemblingPins needlesBiomedical engineering

The invention discloses a PIN needle dissembling device and a PIN dissembling head thereof. The PIN dissembling head comprises at least one actuating device, a PIN dissembling needle and a protective sleeve thereof and a jacket. The at least one actuating device comprises a pedestal and an actuating rod extending out of the pedestal. The PIN disassembling needle and the protective sleeve are arranged corresponding to the tail end of the actuating rod and are coaxial with the actuating rod. The protective sleeve comprises a first sleeve body and a second sleeve which are embedded with each other, are opposite to each other and slide along opposite directions ; the axle centers of two sleeve bodies are accommodating passages of the PIN needles; the first sleeve body is adjacent to the actuating rod and fixed with one end of the PIN dissembling rod; the PIN dissembling needle is matched with the second sleeve body in a sliding manner and extends out of the tail end of the second sleeve body when two sleeve bodies slide relatively to the nearest distance. The jacket is used for accommodating the actuating rod, the PIN disassembling needle and the openings at two ends of the protective sleeve, one end of the jacket is fixed with the pedestal; the jacket is internally provided with an axial work passage for the sliding of the protective sleeve; and the work passage is longer than the nearest distance when two sleeve bodies slide relative to the nearest distance. The invention effectively protects the PIN dissembling needle, prevents the occurrence of accidents and improves the efficiency.

Owner:NANTONG HUALONG MICROELECTRONICS

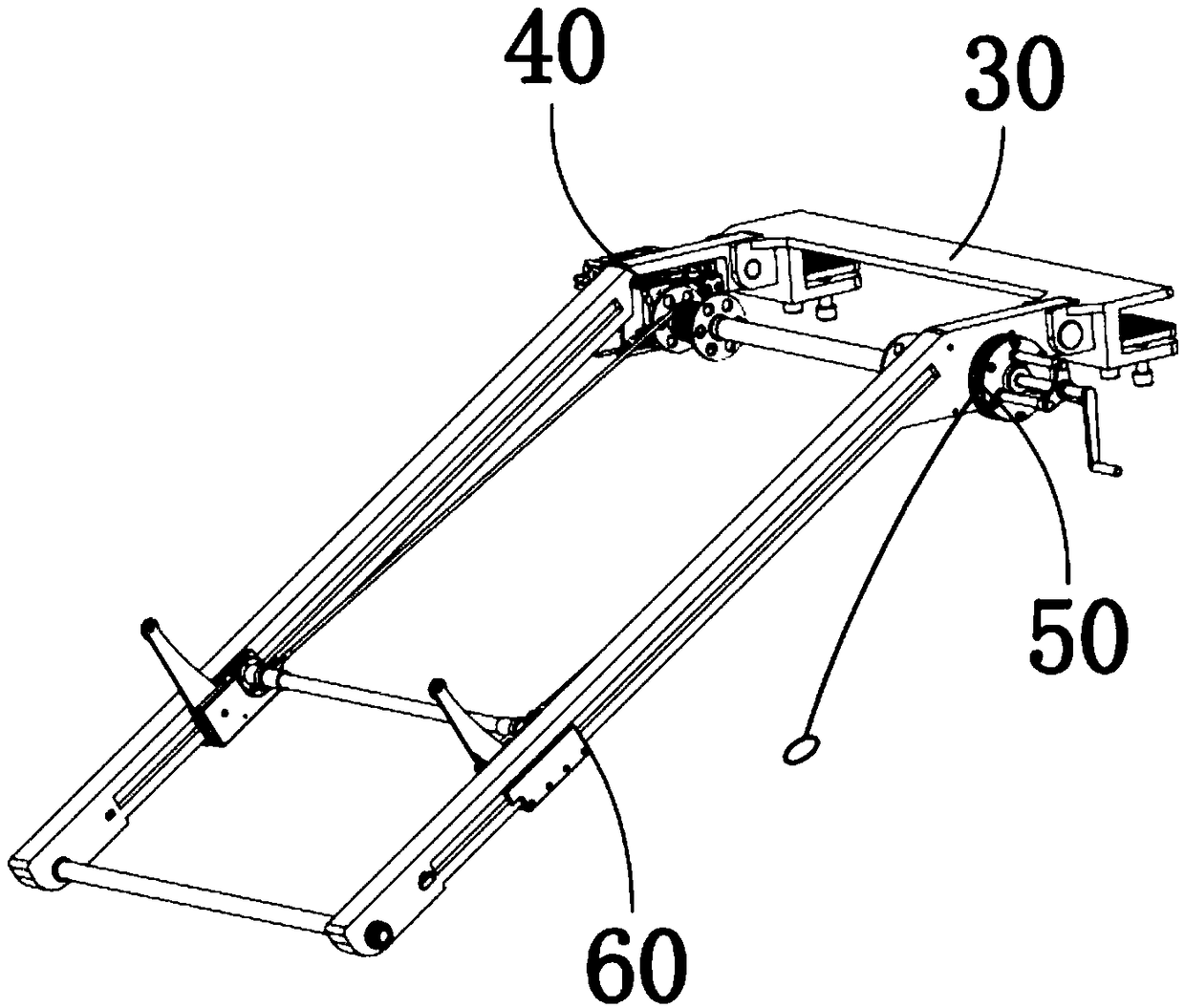

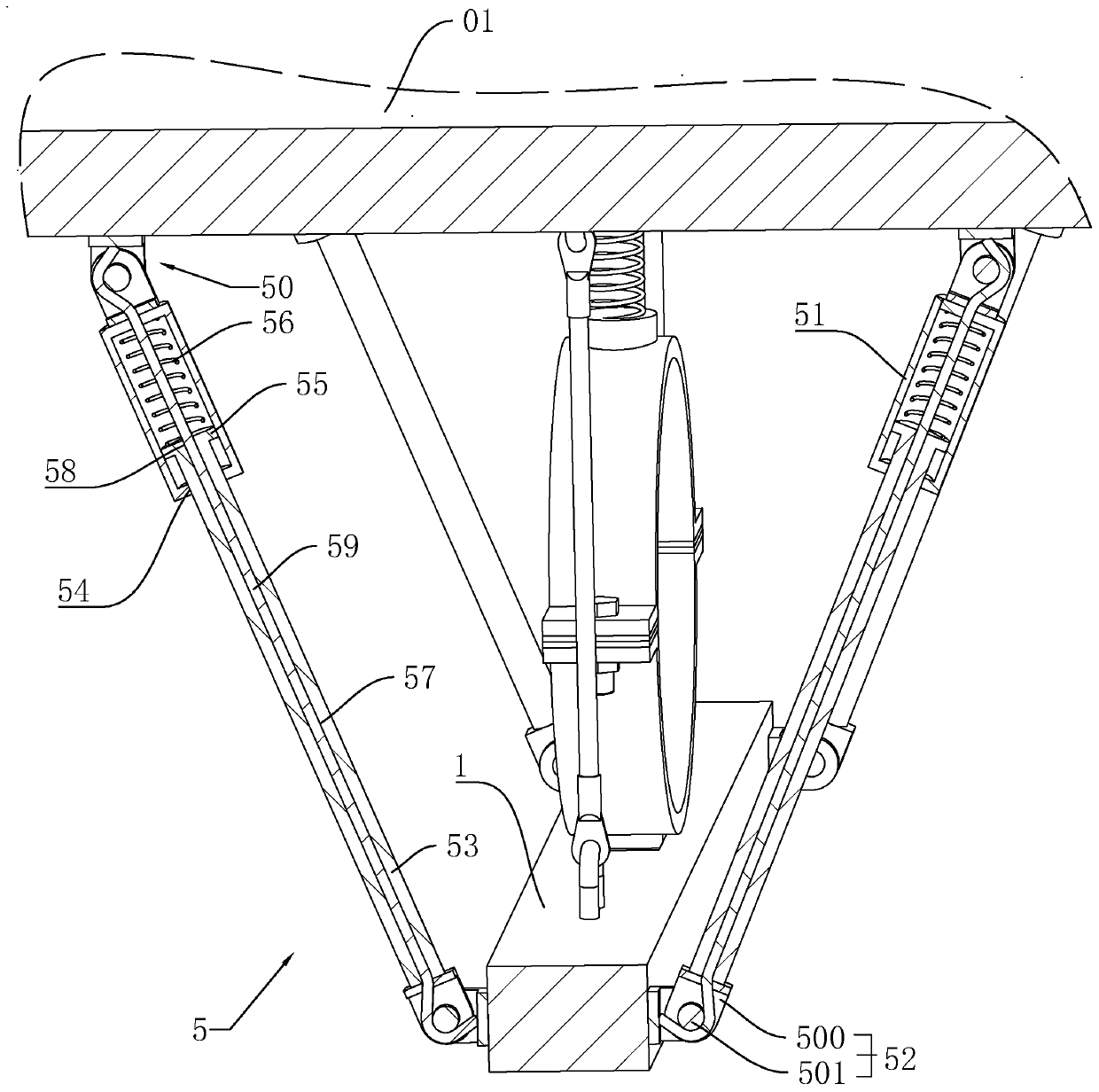

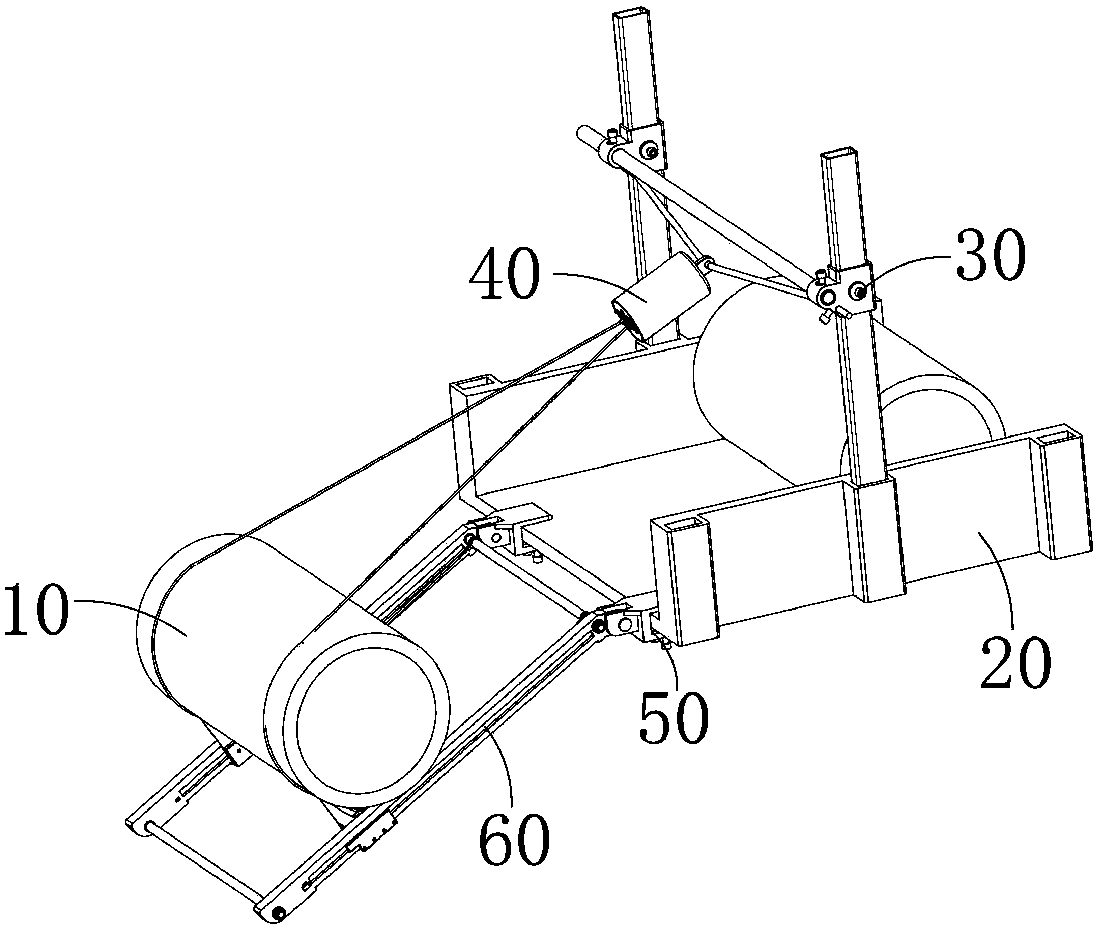

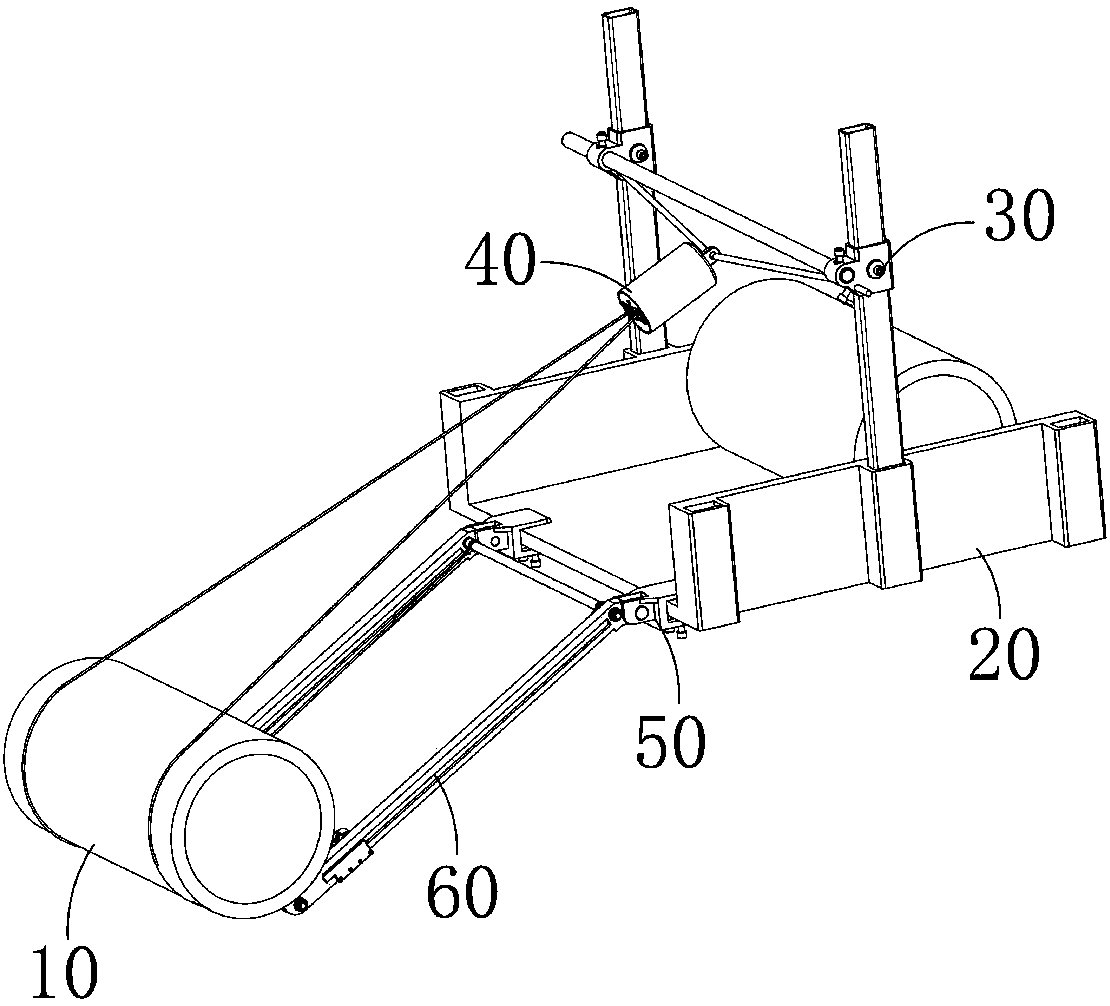

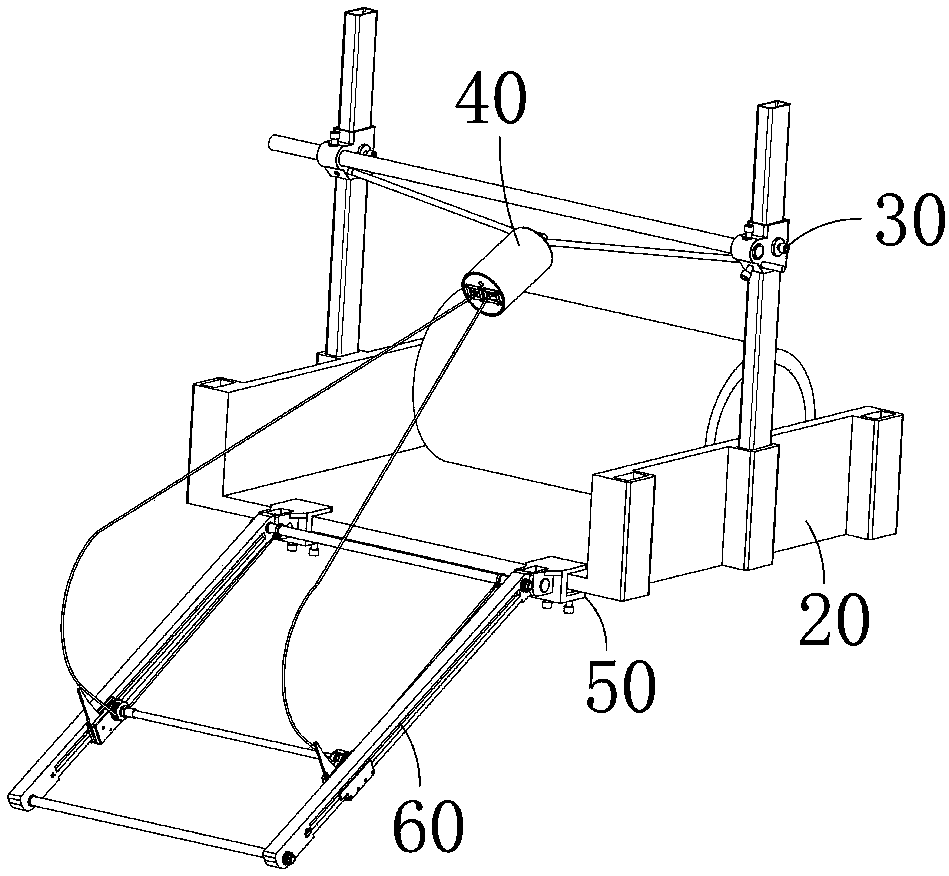

Safe cement duct handling equipment

ActiveCN108382893AReduce the likelihood of breakageInhibit sheddingConveyorsLoading/unloadingPipe fittingEngineering

The invention discloses safe cement duct handling equipment which comprises a high-position conveying device, a low-position slippage mechanism, a transmission and a pulling and holding device, wherein the high-position conveying device is used for conveying pipe fittings; the low-position slippage mechanism is used for slowly slipping and conveying the pipe fittings conveyed by the high-positionconveying device; the transmission is used for providing power for slow conveying of the pipe fittings; the pulling and holding device is used for hanging the transmission; the high-position conveyingdevice is fixed on a conveying carriage through a fastener; one end of the low-position slippage mechanism is connected with the unloading end of the high-position conveying device; the other end ofthe low-position slippage mechanism stretches to the ground; and a slow descent rope for slowly descending the pipe fittings is arranged between the transmission and the low-position slippage mechanism.

Owner:安徽祺瑞建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com