Method for improving position accuracy of mold core of integrated type ceramic mold

An integral, core technology, applied in the directions of ceramic forming cores, ceramic forming mandrels, ceramic forming machines, etc., can solve problems such as increasing the complexity of the process, reduce the possibility of fracture, the method design is reasonable, and the The effect of the possibility of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]For a core that runs through up and down, the method for improving the position accuracy of the integral ceramic casting core includes the following steps:

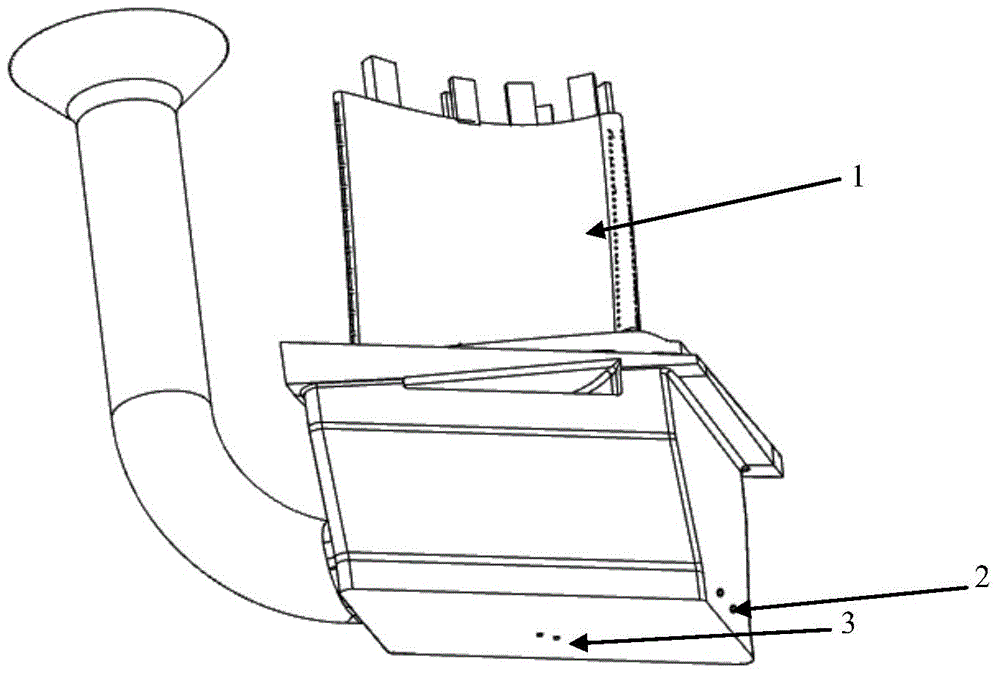

[0045] 1) Manufacture of resin mold

[0046] The present invention utilizes light-curing rapid prototyping technology to manufacture resin molds, first utilizes commercial three-dimensional software to design resin mold CAD models, and manufactures positioning holes, see figure 1 and figure 2 , wherein, 1 is the blade body; 2 is the tenon root positioning hole; 3 is the longitudinal positioning hole; 4 is the core that penetrates up and down; 5 is the shell; STL files are imported into the rapid prototyping system to generate a two-dimensional slice file with a layered thickness of 0.1mm. Under the control of the slice file, the light-cured prototype of the resin mold is quickly and automatically manufactured. After the SL resin mold is manufactured, it is cleaned with alcohol. Excess liquid resin on the surface,...

Embodiment 2

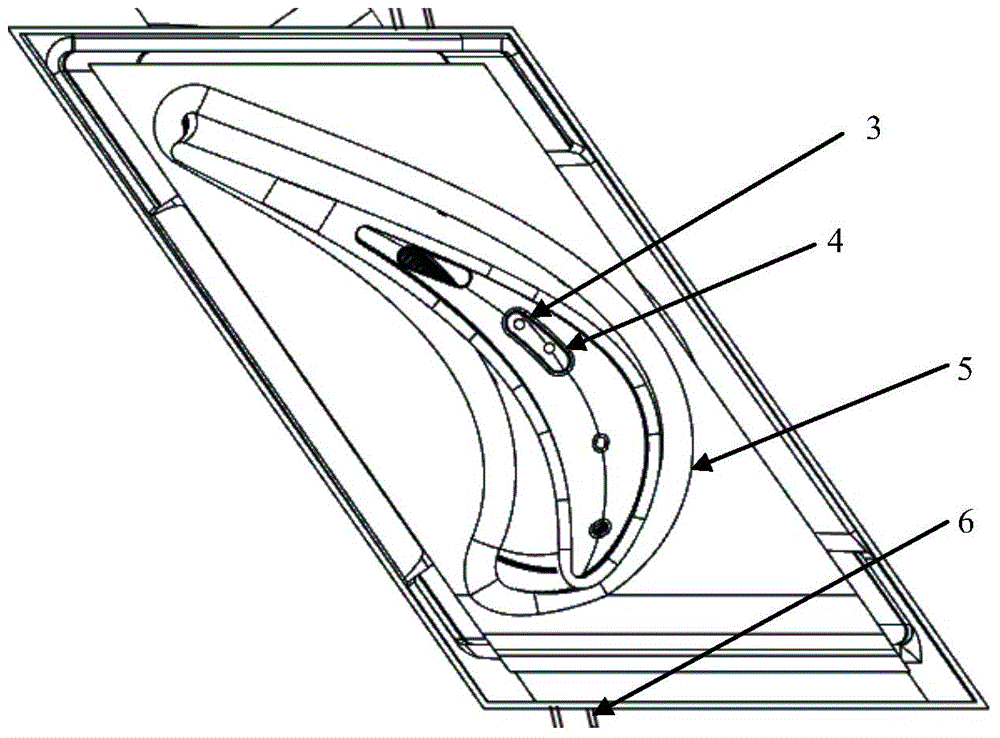

[0060] The difference from Example 1 is that, see figure 2 , for the core that runs through up and down, weave ceramic rods in the cavity and weave ceramic rods at the bottom of the tenon. When the two ends of the ceramic rod are fixed, the bottom ceramic rod is fixed on the bottom of the resin prototype with hot melt adhesive, and the top end uses the blade structure to pre-tighten the ceramic rod on the fixed structure and then fix it. If the core twist is low, the ceramic rod can be inserted directly through it. If the twist of the core is high, insert a ceramic rod from the top and bottom of the core respectively, and the total length of the ceramic rods penetrating into the cavity should be longer than the distance between the upper and lower holes of the resin mold prototype blade. After gel injection molding, the ceramic rod is buried inside the core. The insertion of the ceramic rod can reduce the broken core rate, improve the position accuracy of the core casting pr...

Embodiment 3

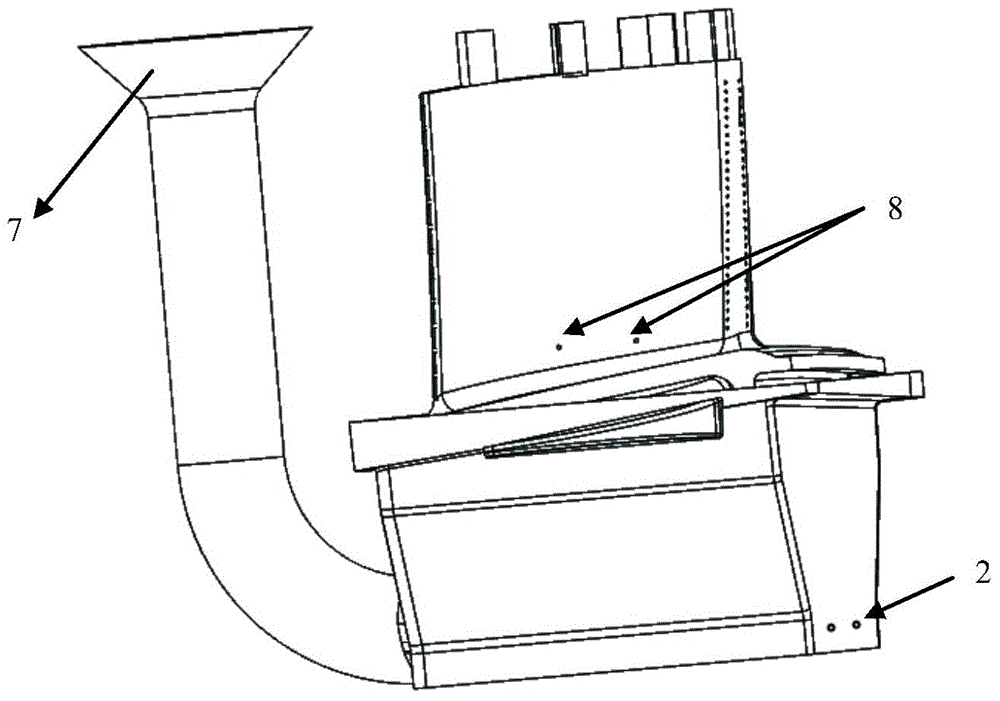

[0062] The difference from Example 1 is that when weaving ceramic fibers, for the core 9 that does not penetrate up and down, such as Figure 5 As shown, the ceramic fiber is penetrated transversely in the positioning hole, such as image 3 , 4 As shown, 7 is the gate; 8 is the horizontal positioning hole; 9 is the horizontal interpenetrating fiber; after the gel injection molding, the ceramic fiber connects the core and the mold shell, the bottom of the core is constrained, the rigidity is enhanced, and the resistance Creep ability is improved. After the mold is prepared, the ceramic fibers are removed to avoid leaving holes on the surface of the blade after pouring the metal. All the other processing steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com