Patents

Literature

33results about How to "Improve waste discharge efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

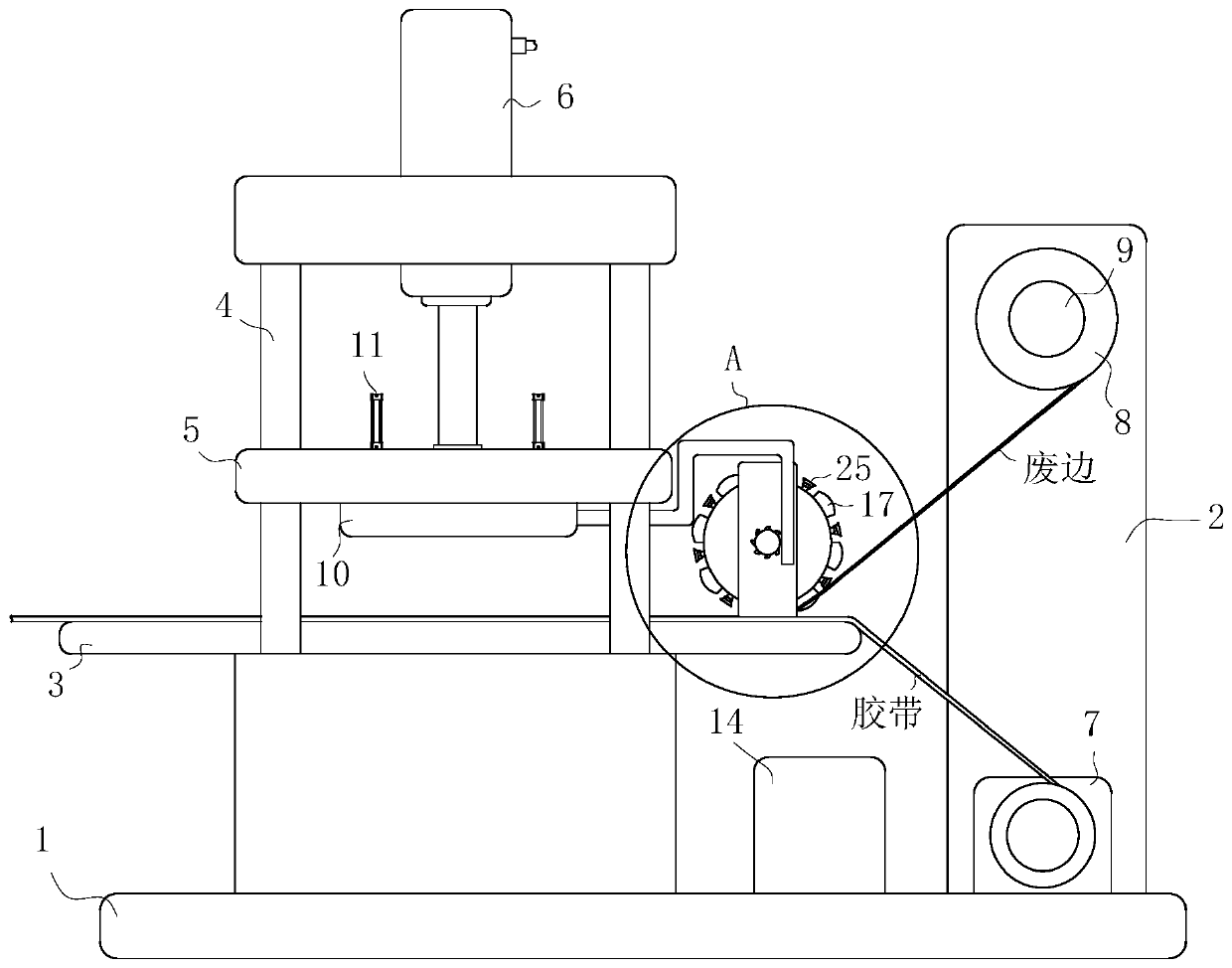

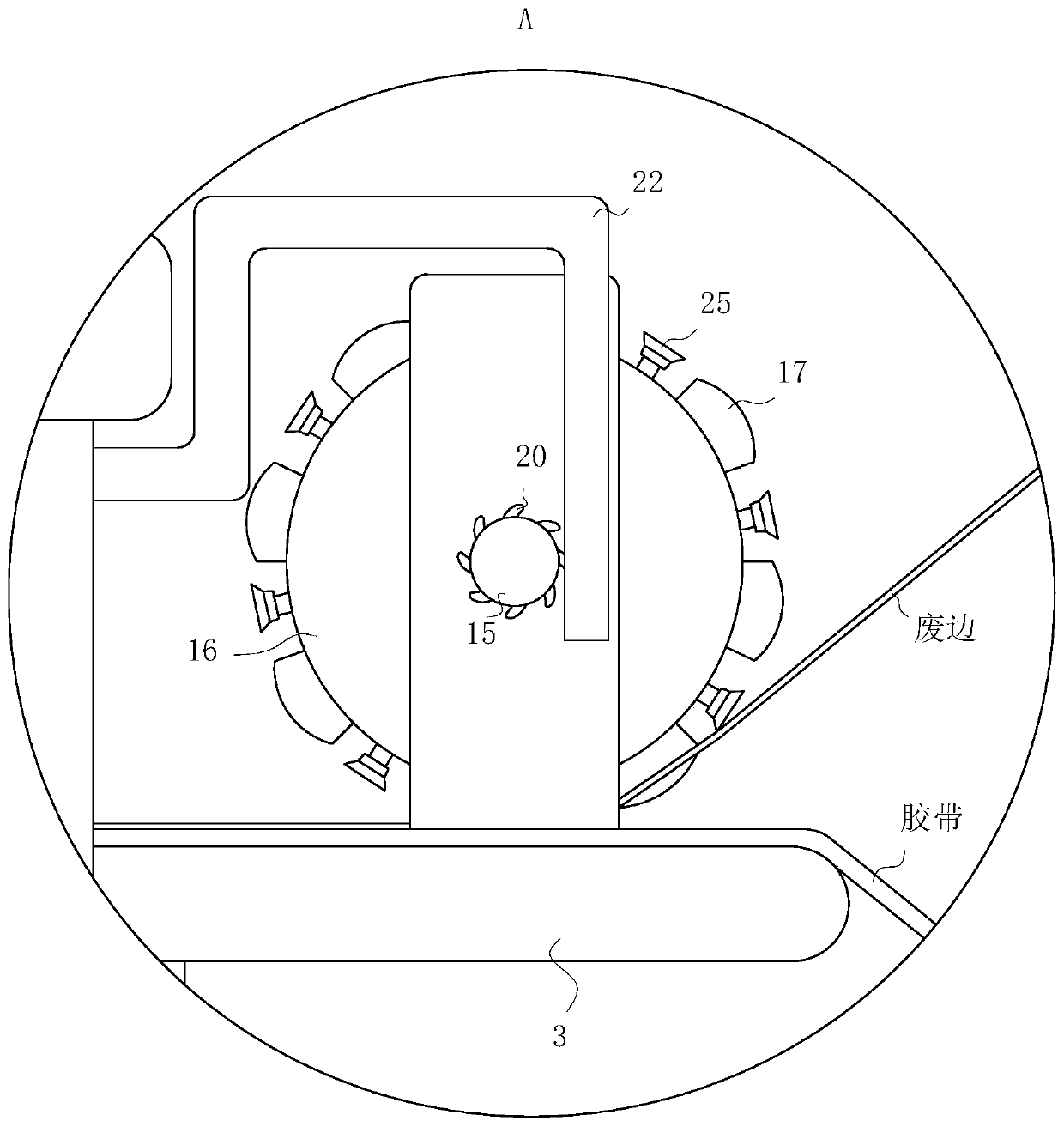

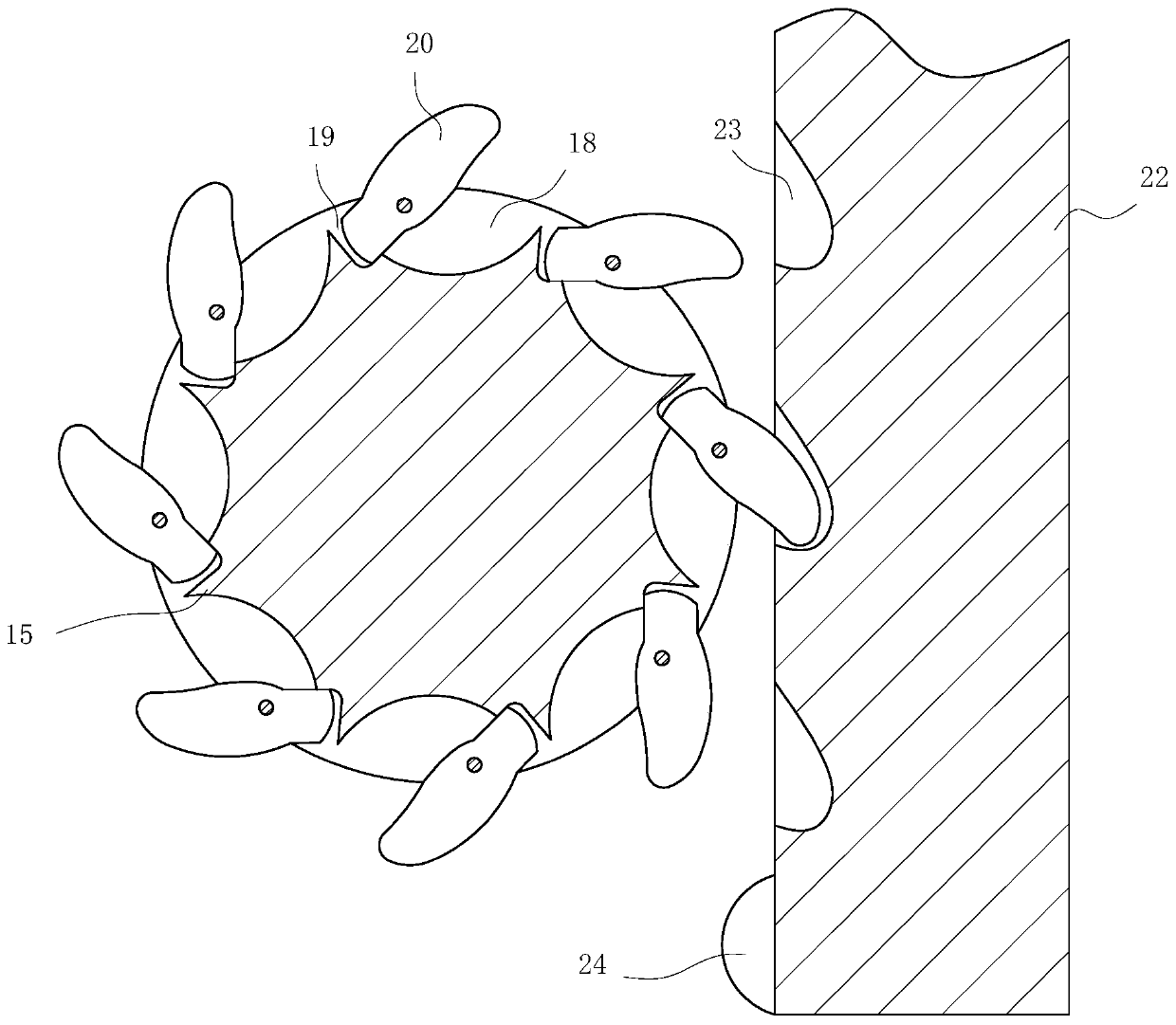

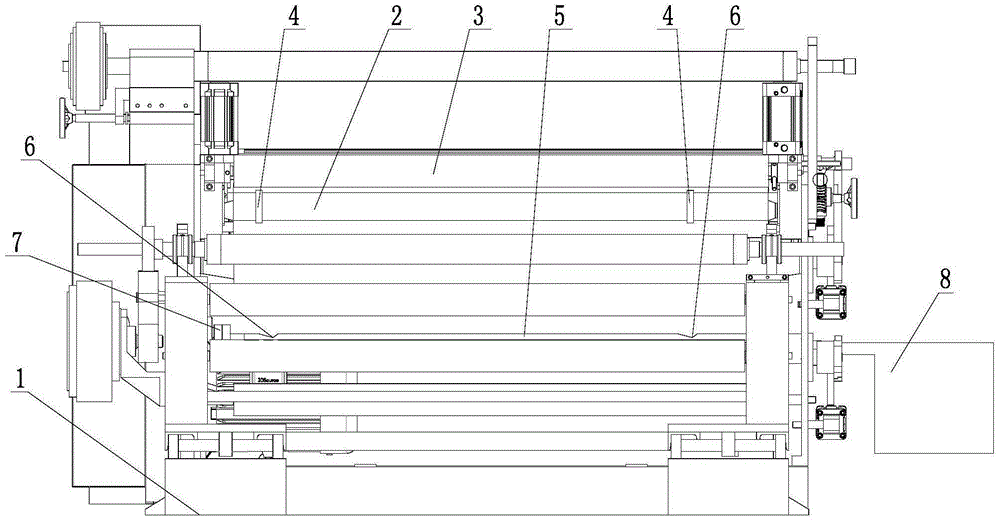

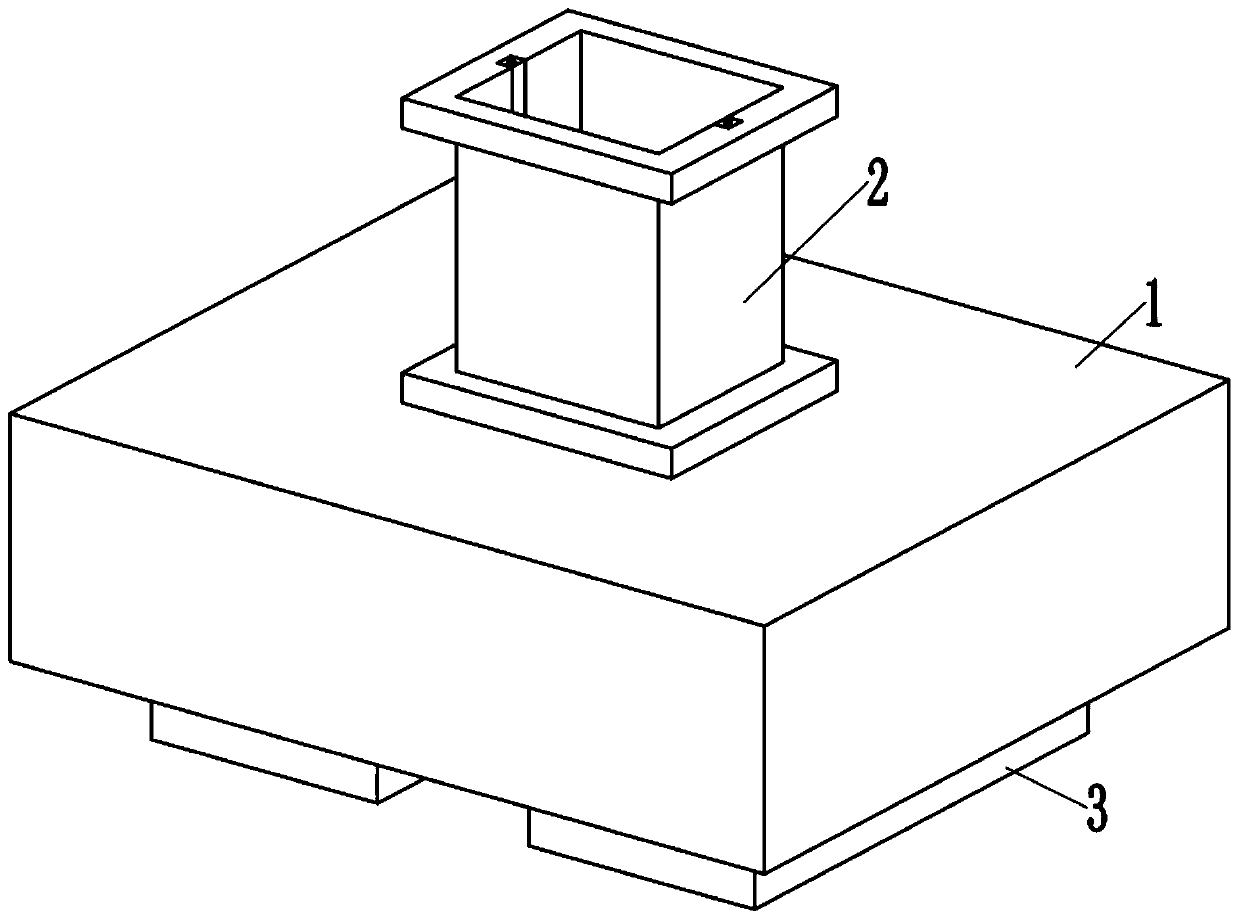

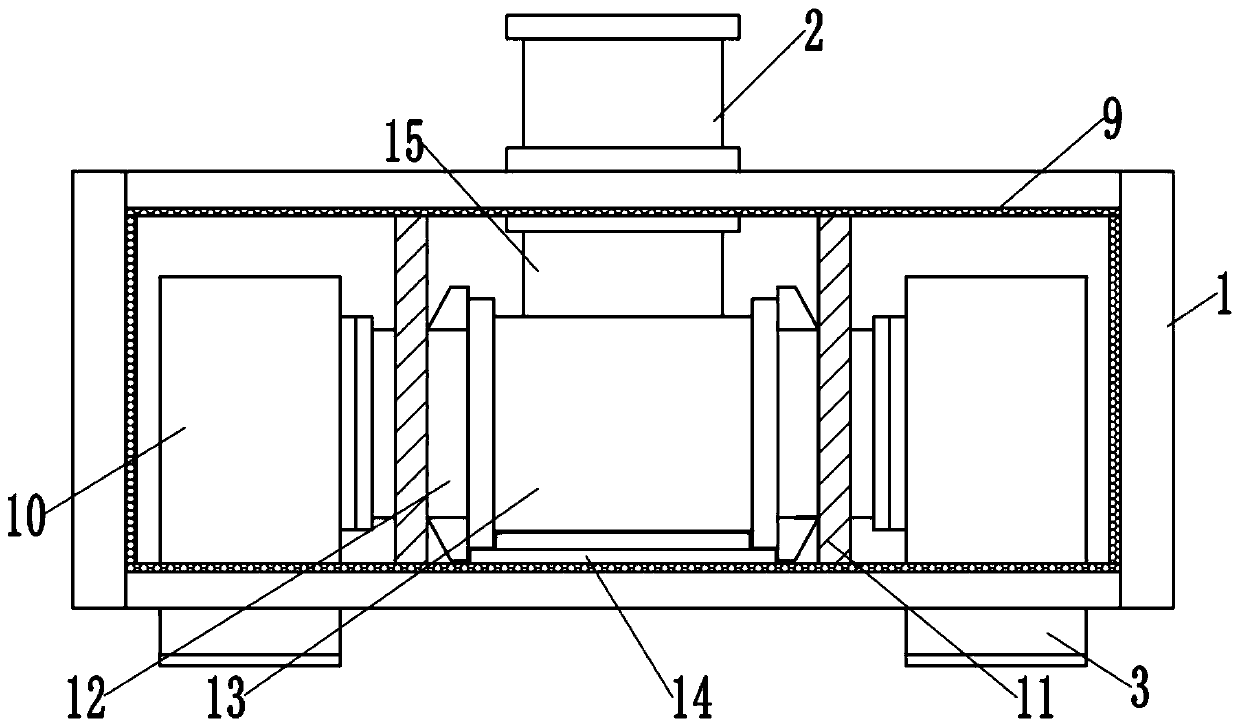

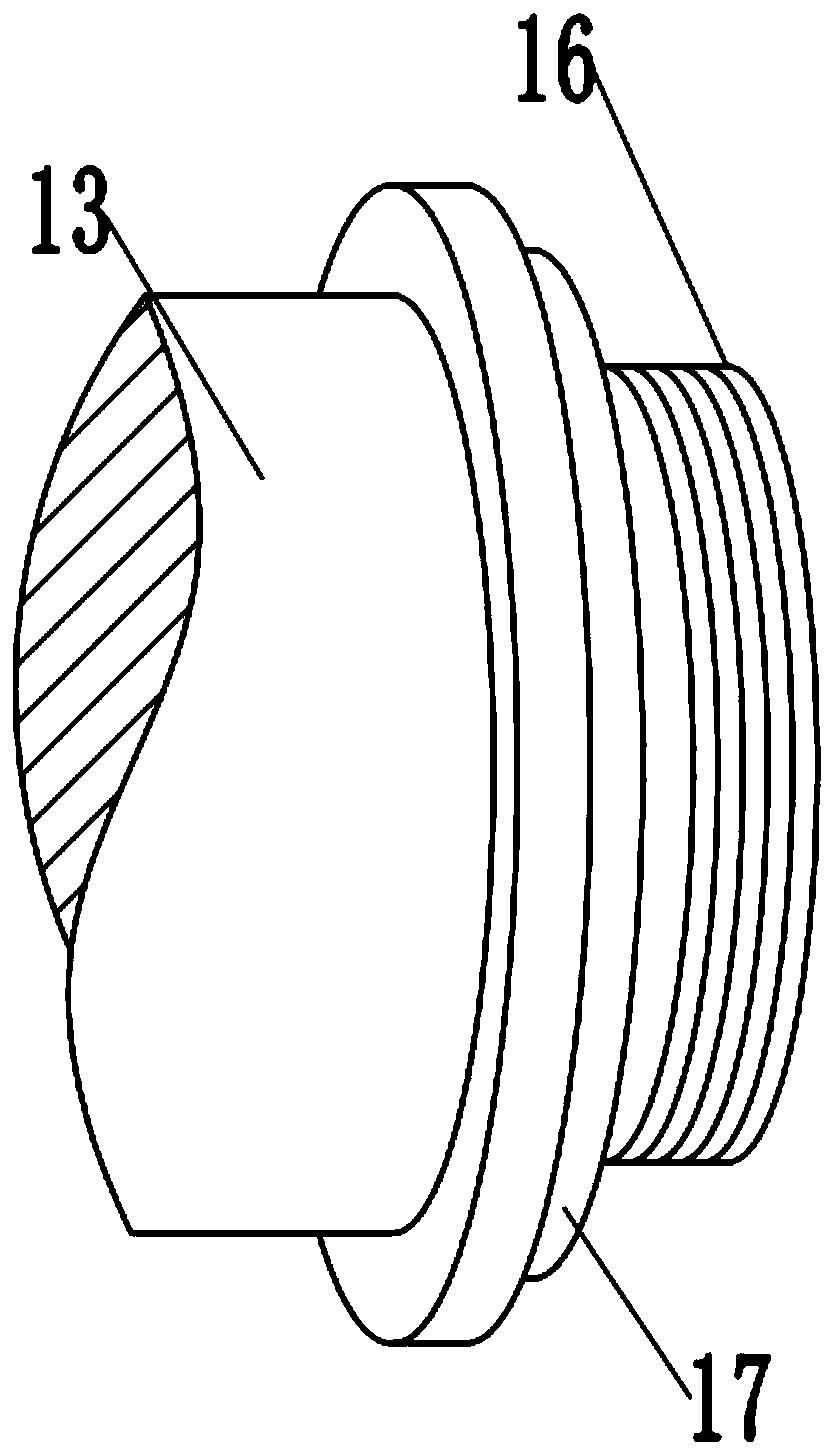

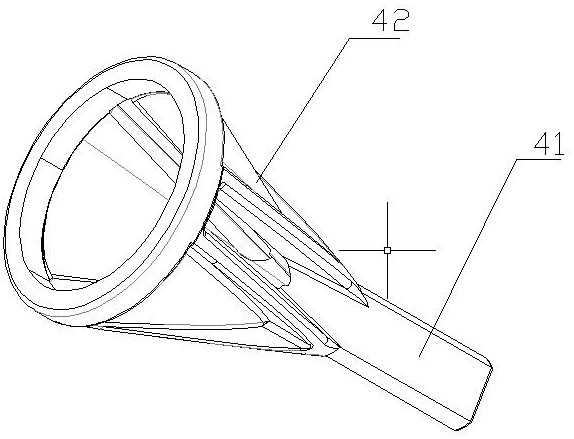

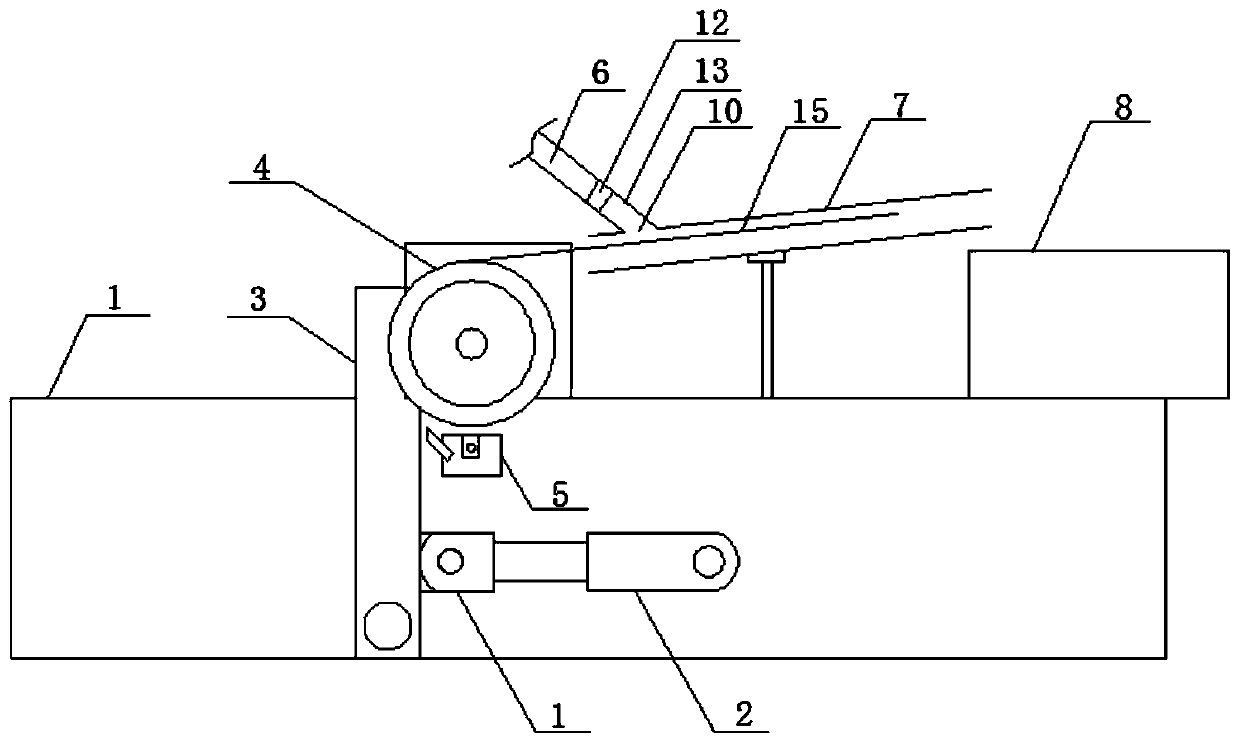

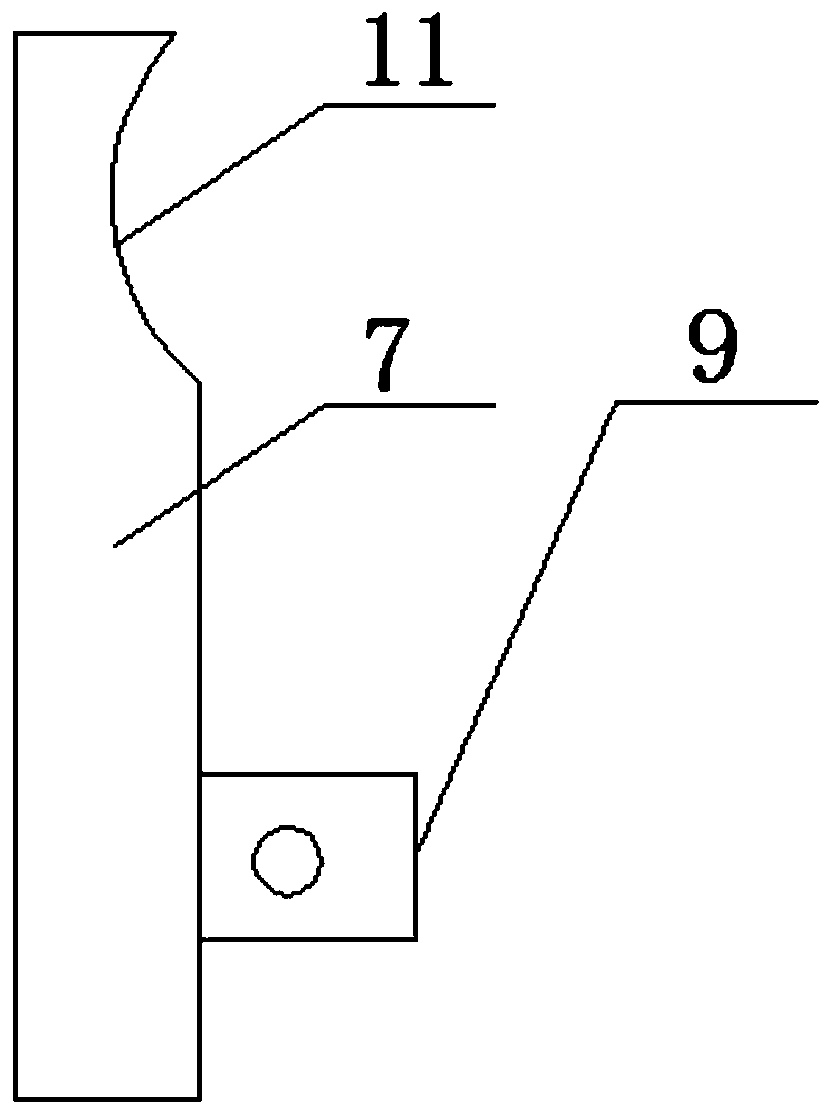

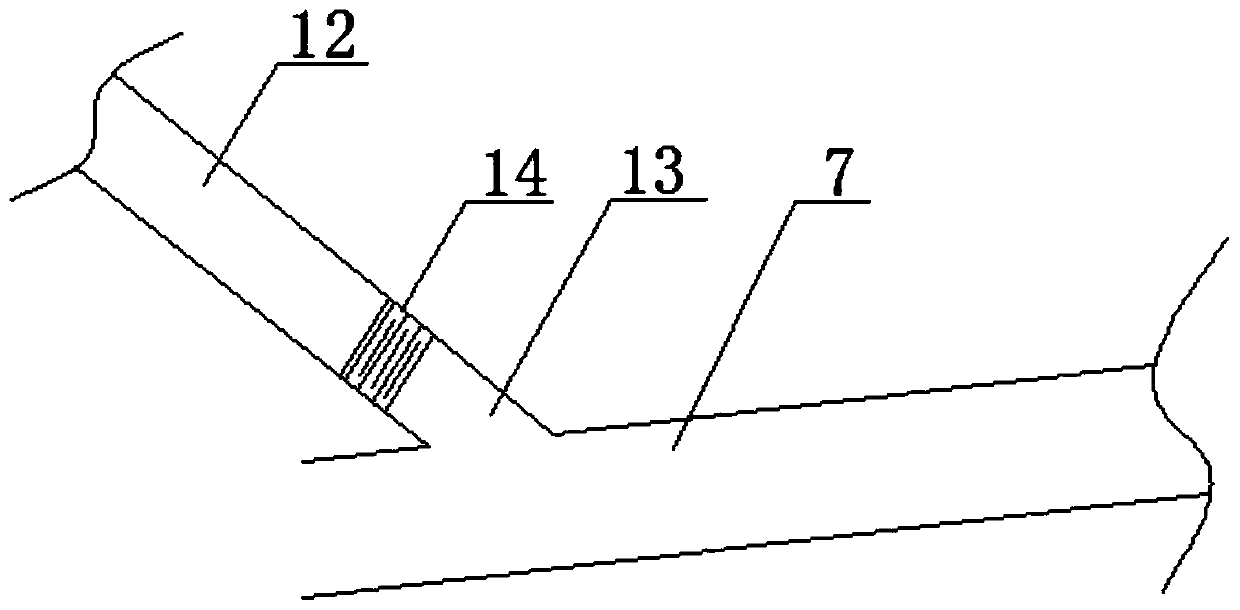

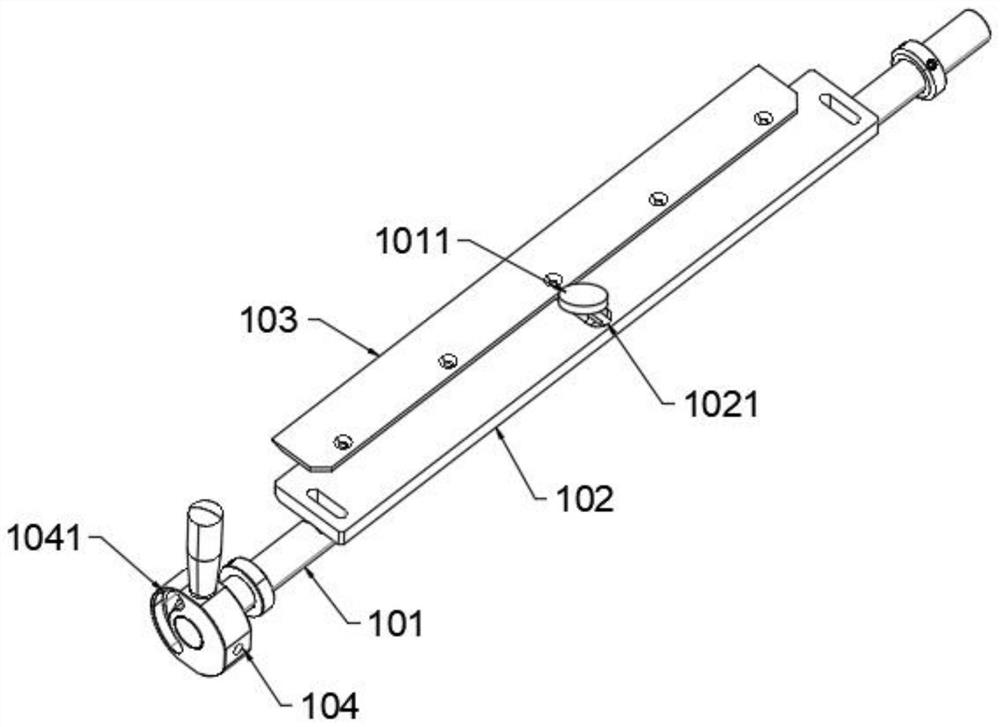

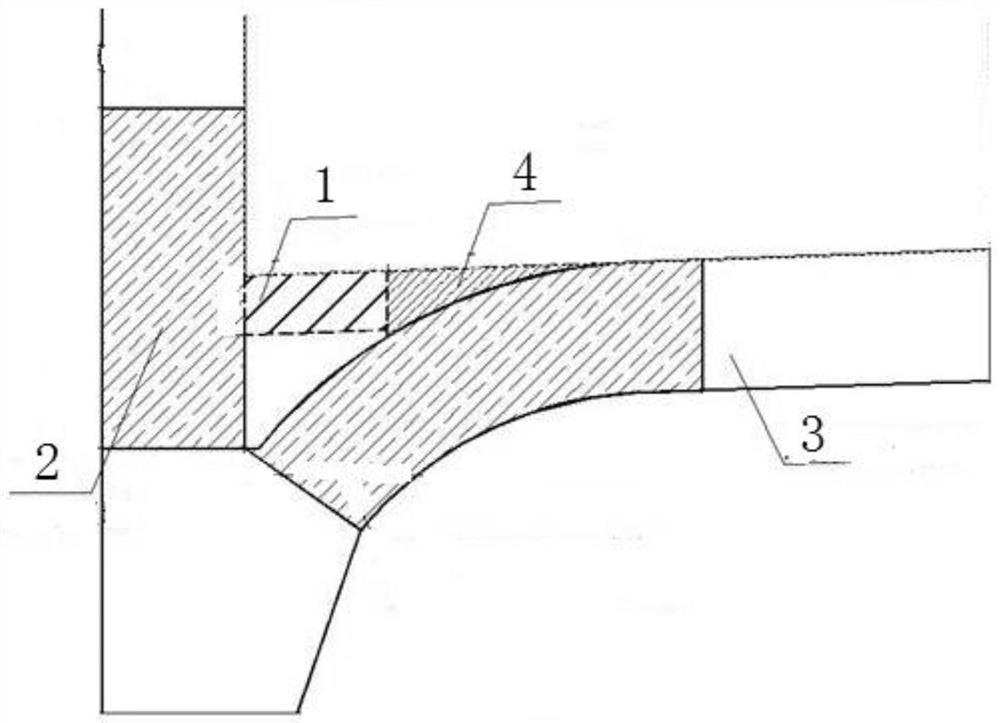

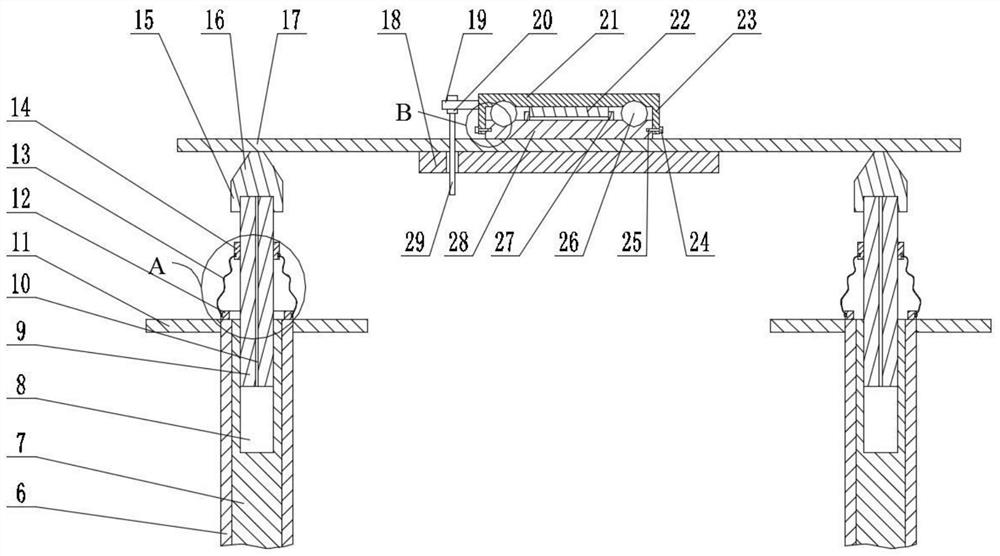

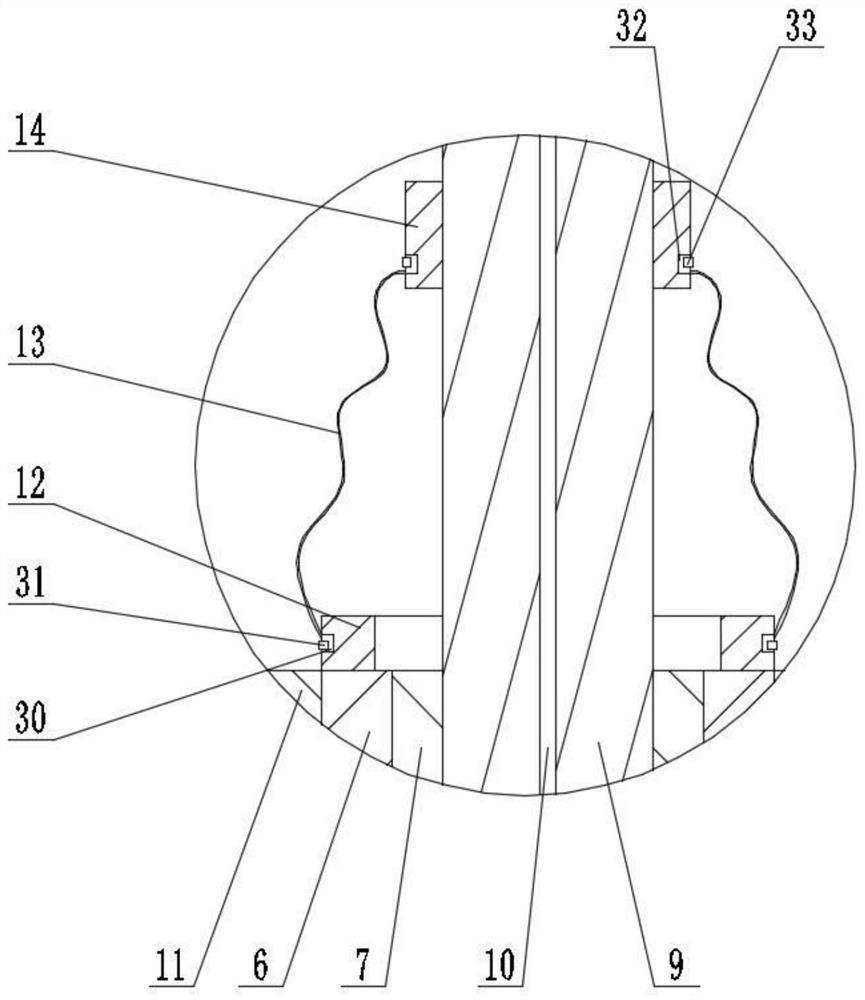

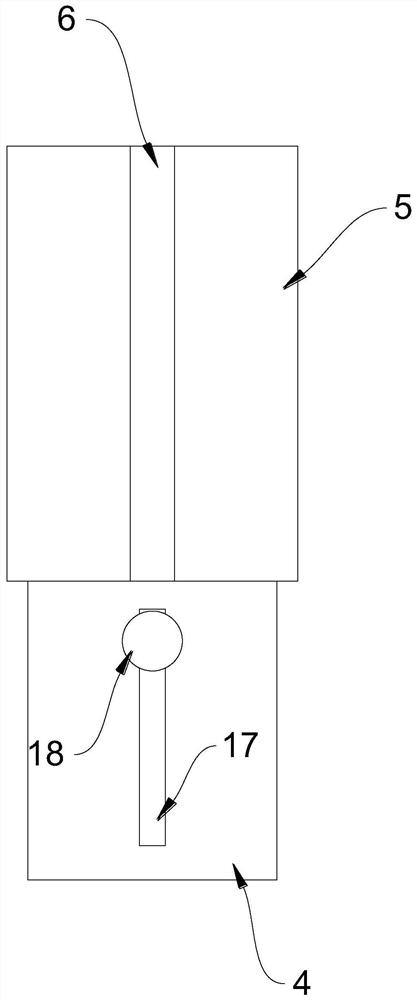

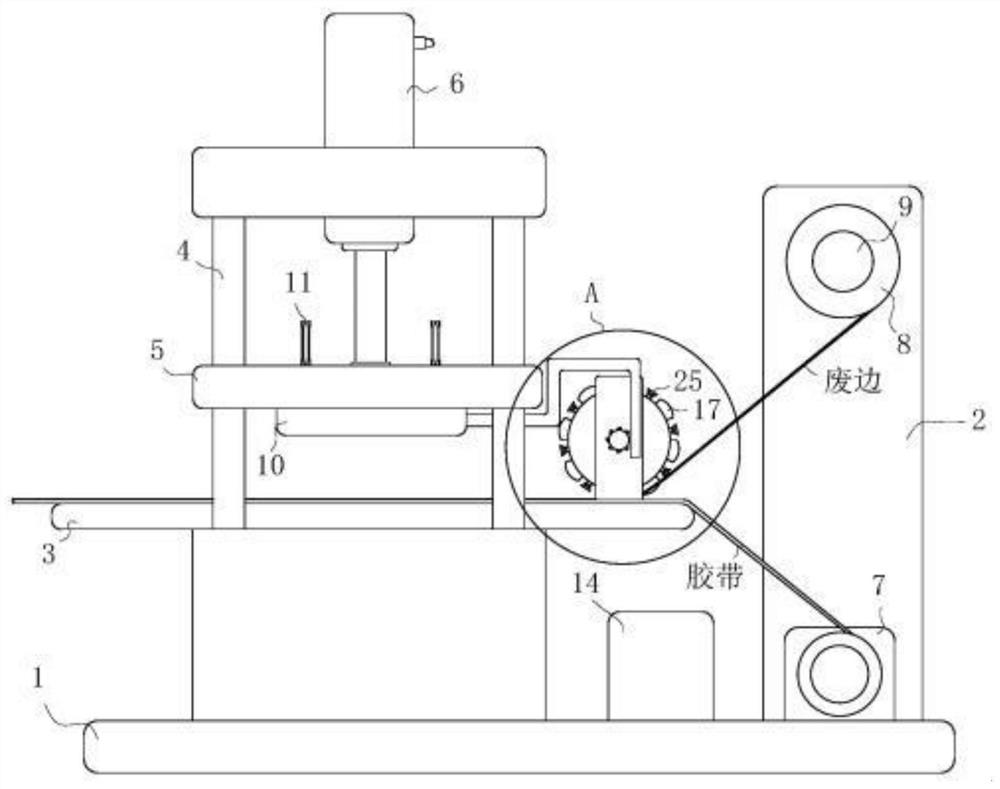

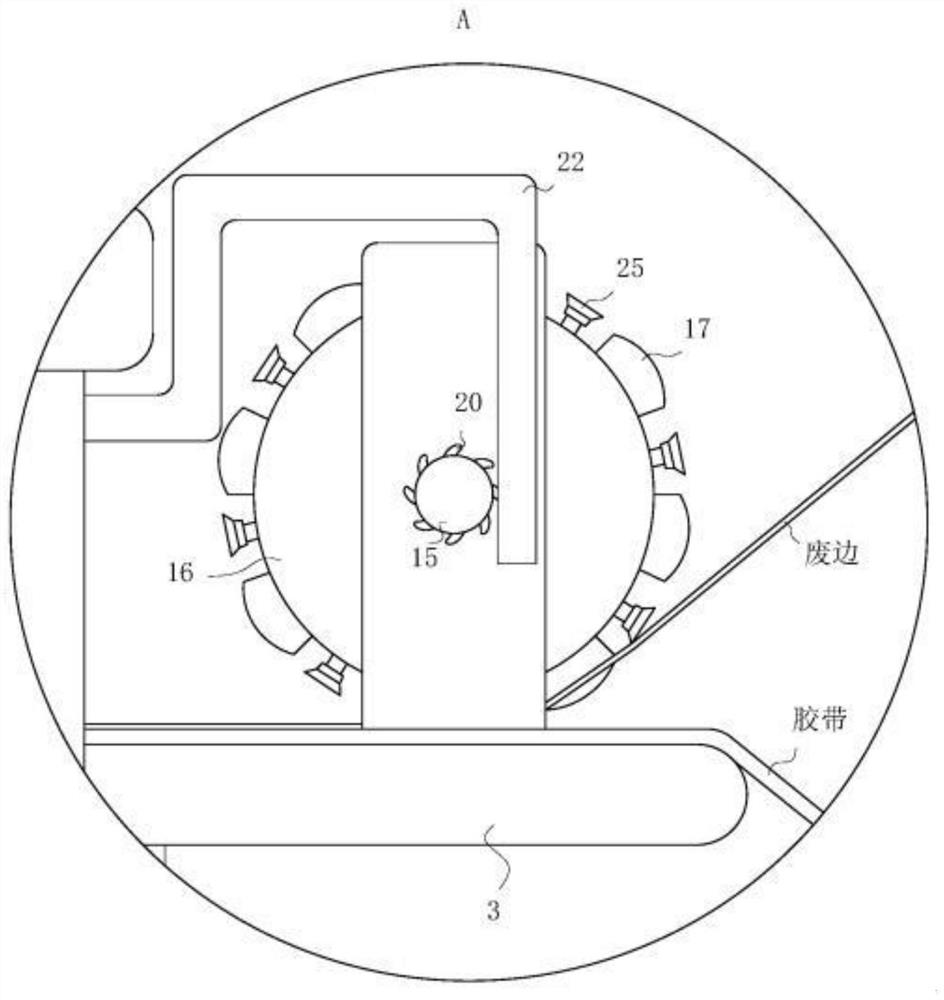

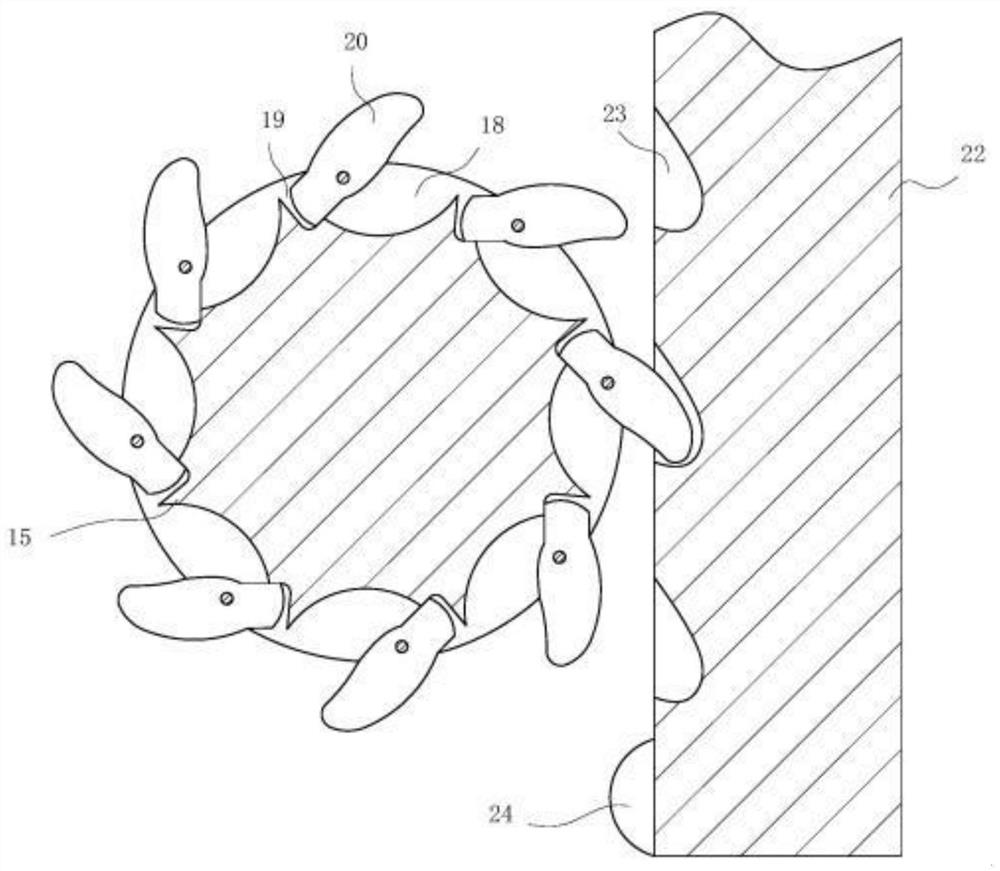

Die cutting device for adhesive tape processing

ActiveCN111037641AImprove waste discharge efficiencyReduce the possibilityMetal working apparatusPhysicsElectric machinery

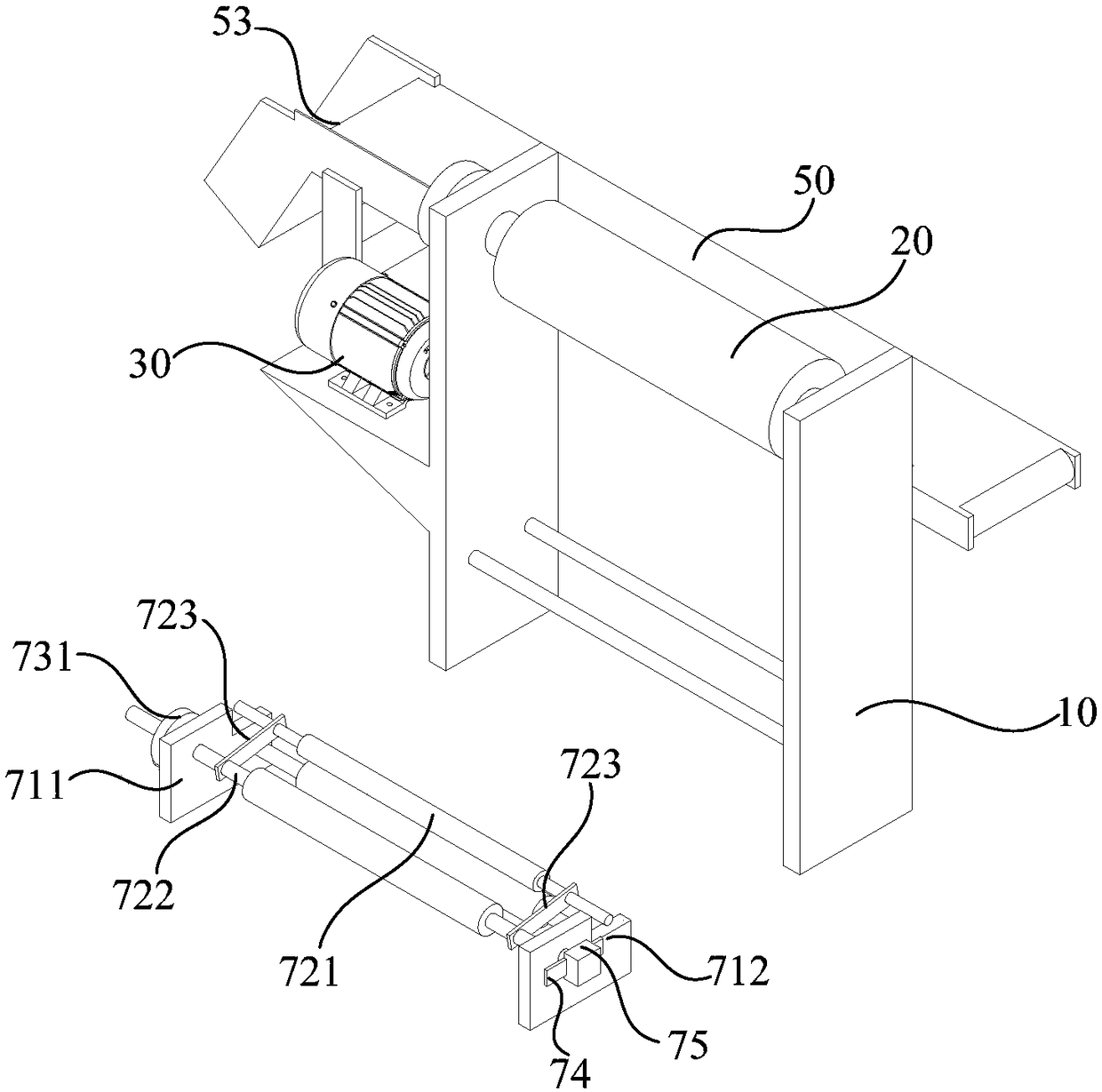

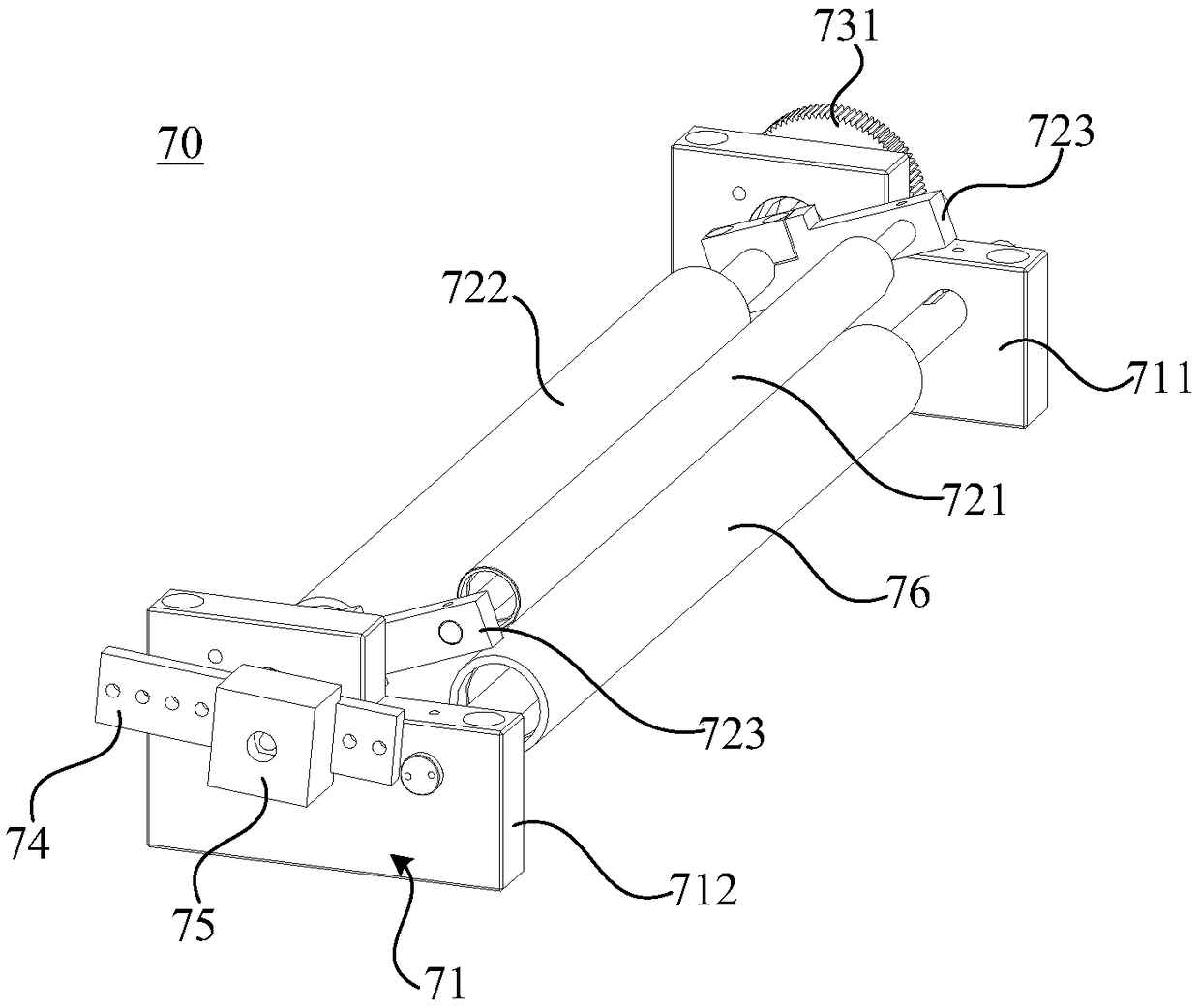

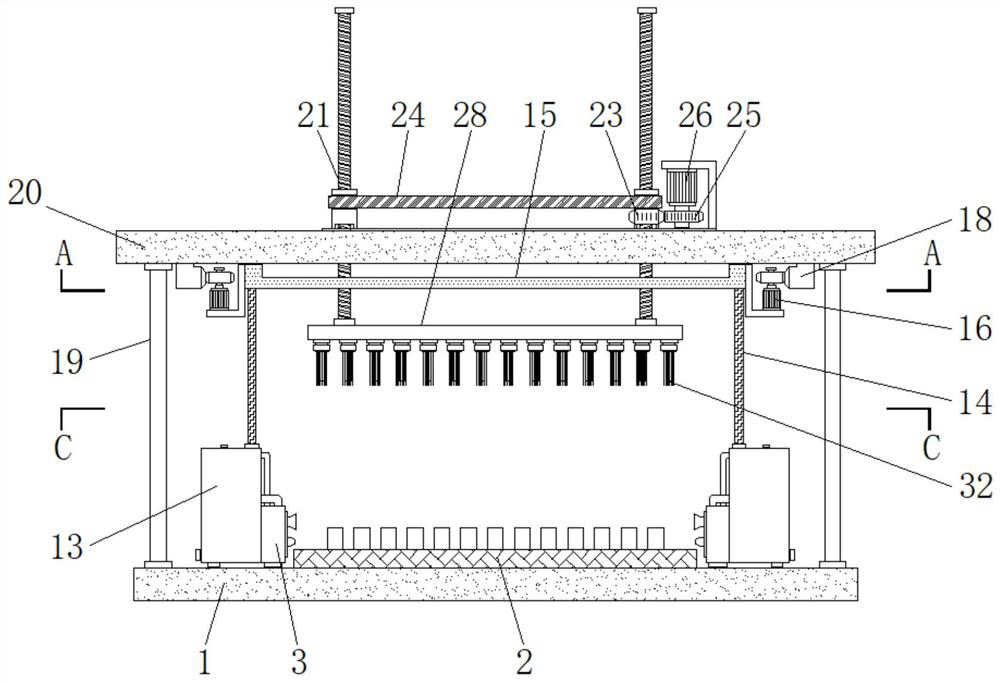

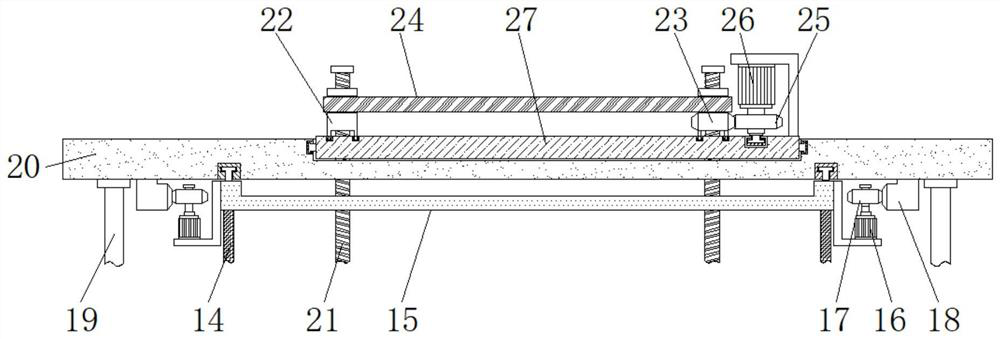

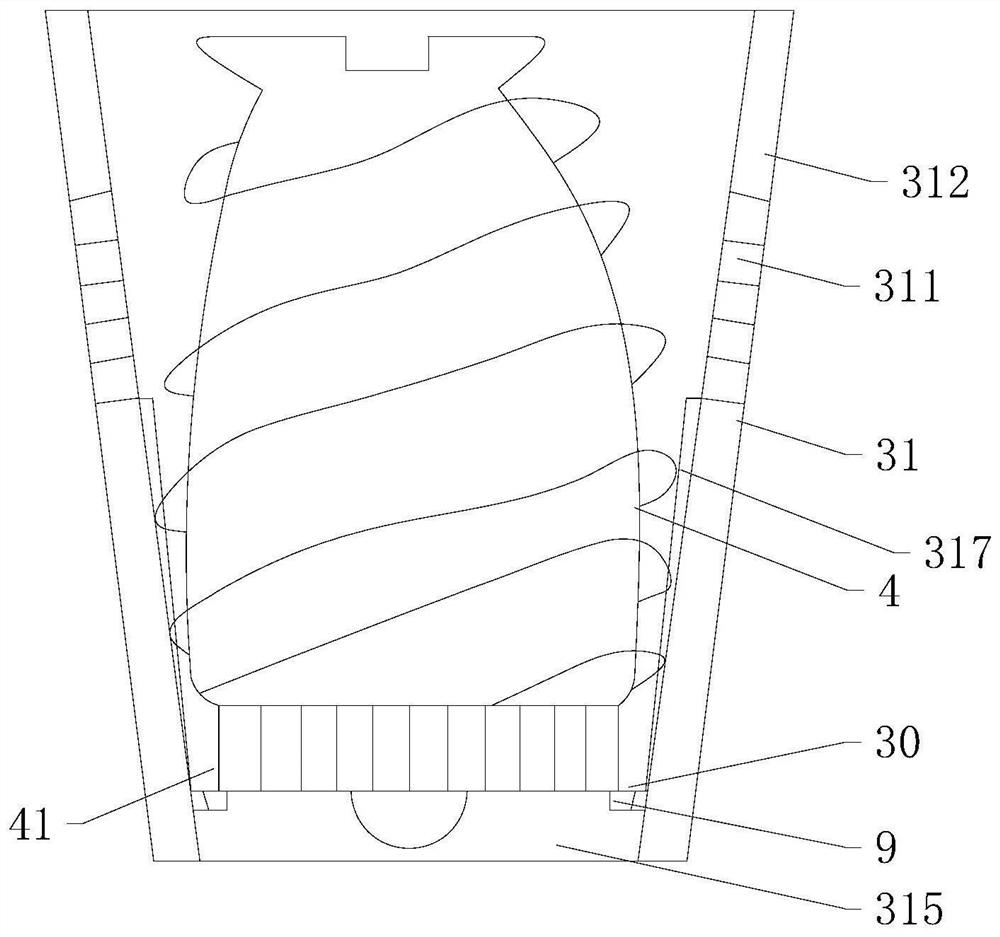

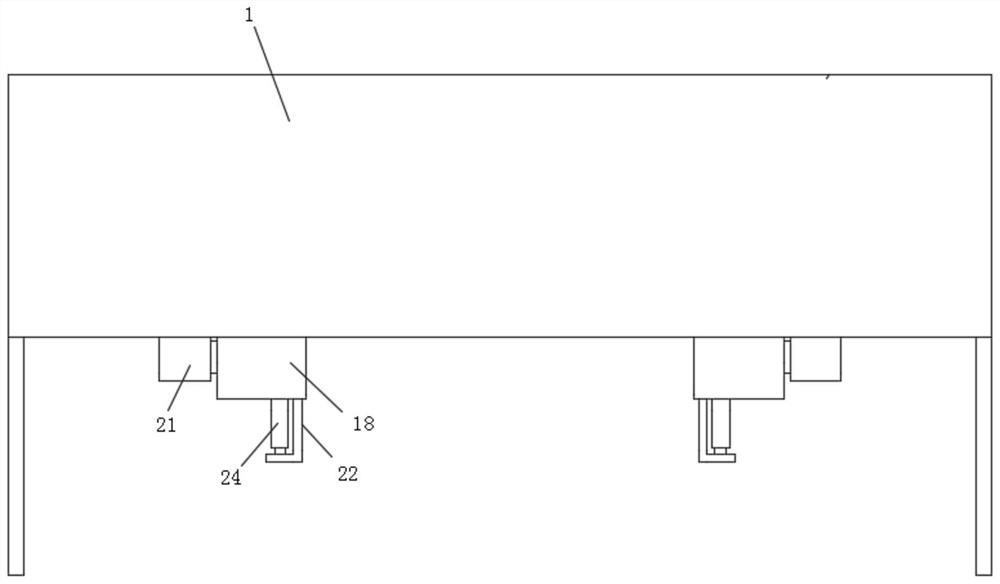

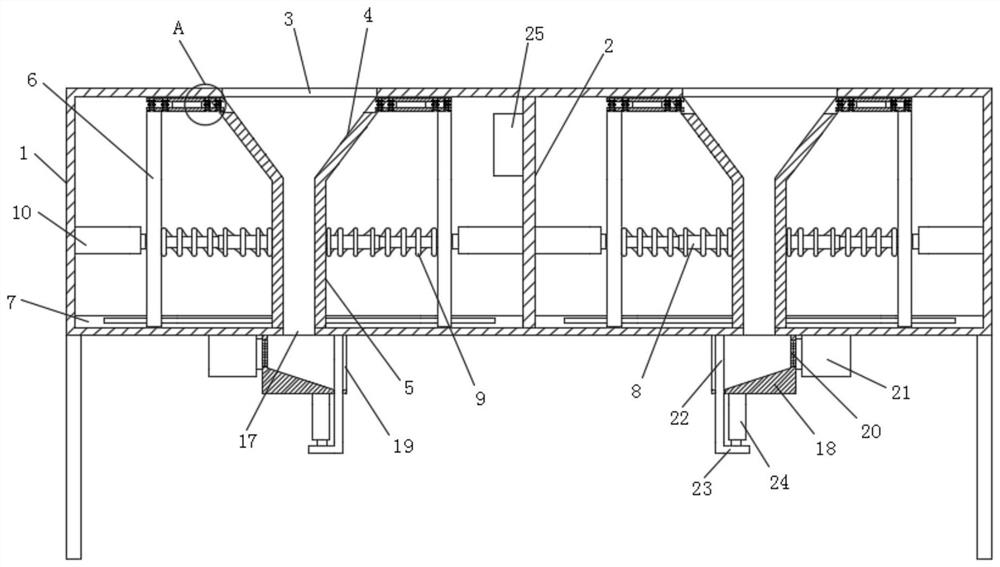

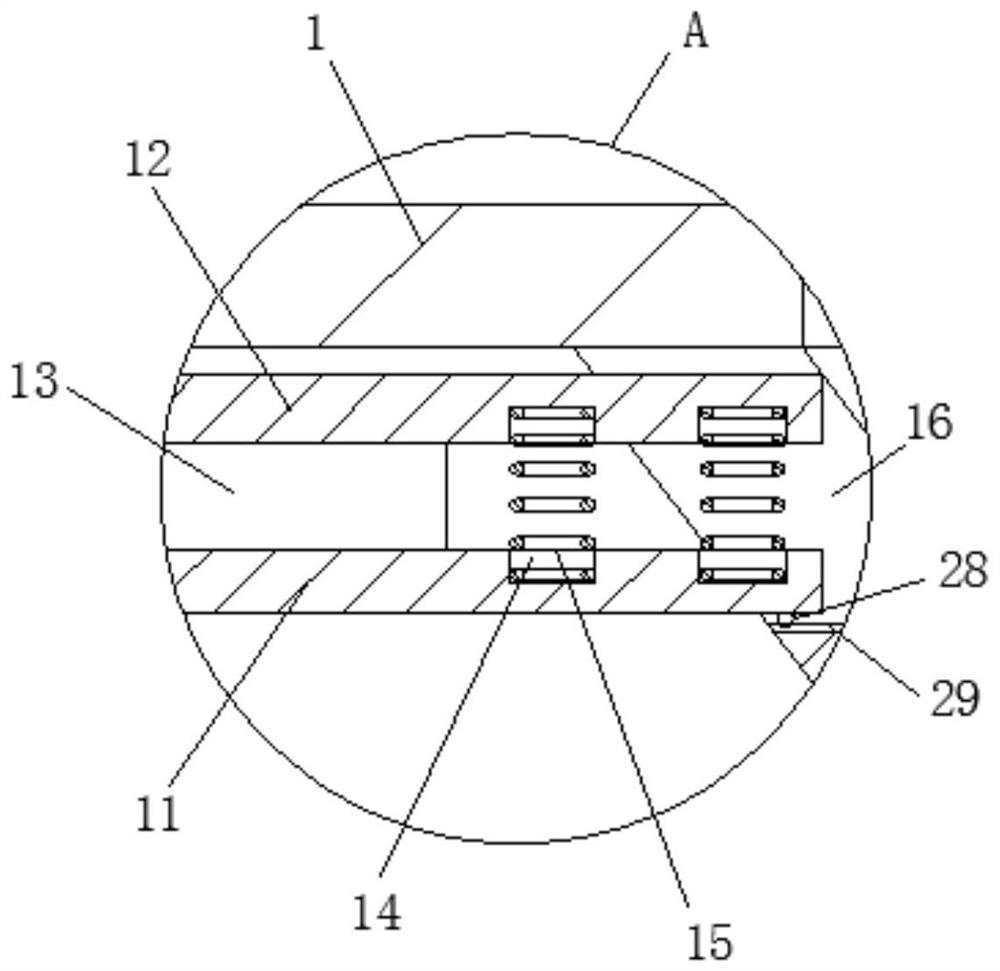

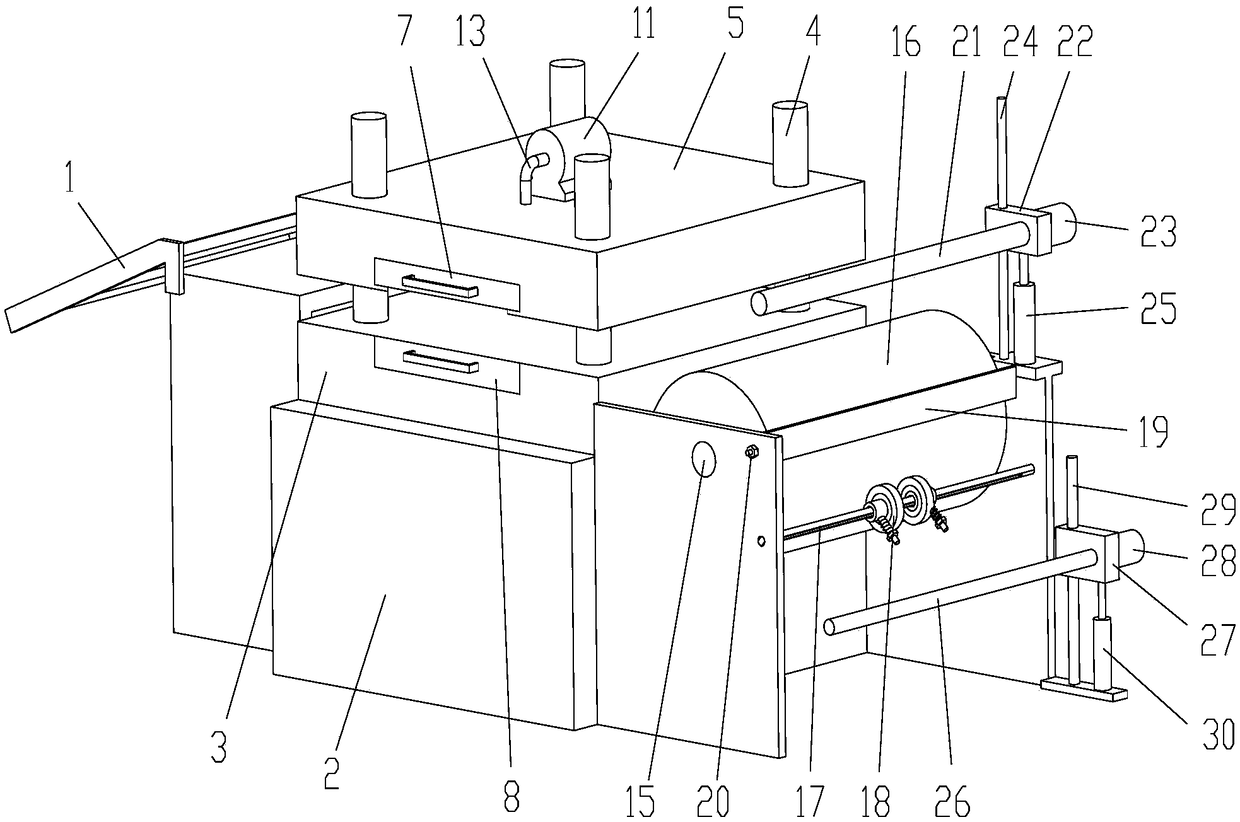

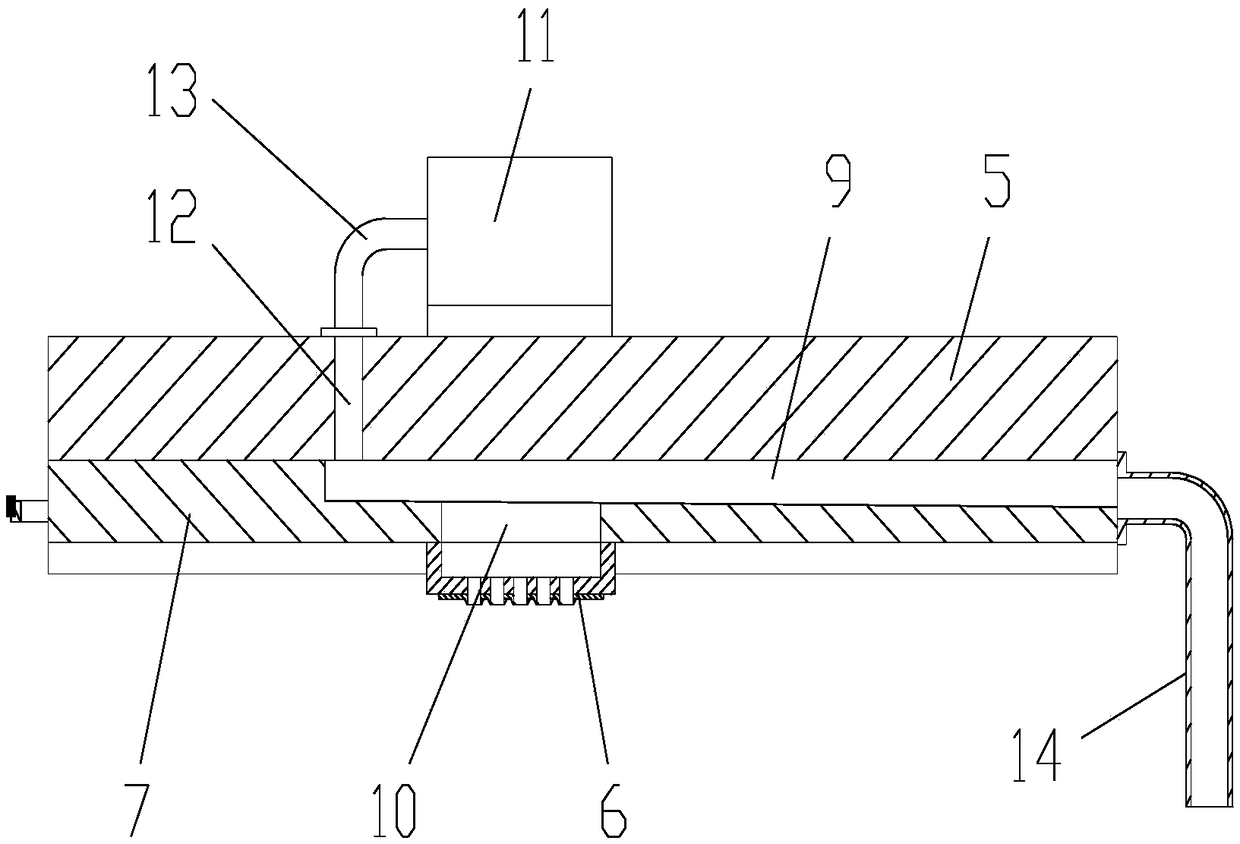

The invention belongs to the technical field of adhesive tape processing, and particularly relates to a die cutting device for adhesive tape processing. The die cutting device comprises a bottom plate, wherein a hydraulic machine and a mounting plate are fixed at the top end of the bottom plate; the hydraulic machine comprises a workbench, a guide rod, a movable cross beam and a hydraulic cylinder; a first driving motor and a second driving motor are fixed on the side wall of the mounting plate; rotating rollers are fixed at the output shaft ends of the first driving motor and the second driving motor; the rotating rollers are used for winding an adhesive tape and a waste edge correspondingly; and more than two die cutting knives are fixed at the bottom end of the movable cross beam. According to the die cutting device, the adhesive tape is pressed through the arrangement of a pressing plate, so that the adhesive tape cannot be broken during die cutting, and the phenomenon that the cutedge of the adhesive tape is fluffed is avoided; and a limiting block is arranged to protect a product, so that the product cannot be taken up when being separated from the waste edge, and the wastedischarge efficiency of the adhesive tape is improved.

Owner:安徽灿宇光电科技有限公司

Waste discharging device used on slitting machine

The invention discloses a waste discharging device used on a slitting machine. The silting machine comprises a machine frame, a first guide roller and a second guide roller, wherein the first guide roller and the second guide roller are rotatably arranged on the machine frame in the axis direction of the machine frame. A gap used for conveying materials is formed between the first guide roller and the second guide roller. Cutters used for cutting the edges of the materials are arranged on the side portions of the two ends of the first guide roller. The waste discharging device comprises a waste discharging pipe arranged on the machine frame, a guide-in opening formed in the waste discharging pipe and used for guiding in waste cut off by the cutters, and a driving device arranged on the machine frame, communicated with one end of the waste discharging pipe and used for making the waste enter the waste discharging pipe through the guide-in opening. According to the waste discharging device used on the slitting machine, the waste discharging pipe and the guide-in opening are arranged, the waste is sucked into the waste discharging pipe from the guide-in opening and is discharged, and thus the problem of halts of the slitting machine caused when the waste is accumulated and gets stuck in a rotary shaft is solved. The waste discharging device used on the slitting machine is simple in structure and high in waste discharging efficiency.

Owner:隆扬电子(昆山)股份有限公司

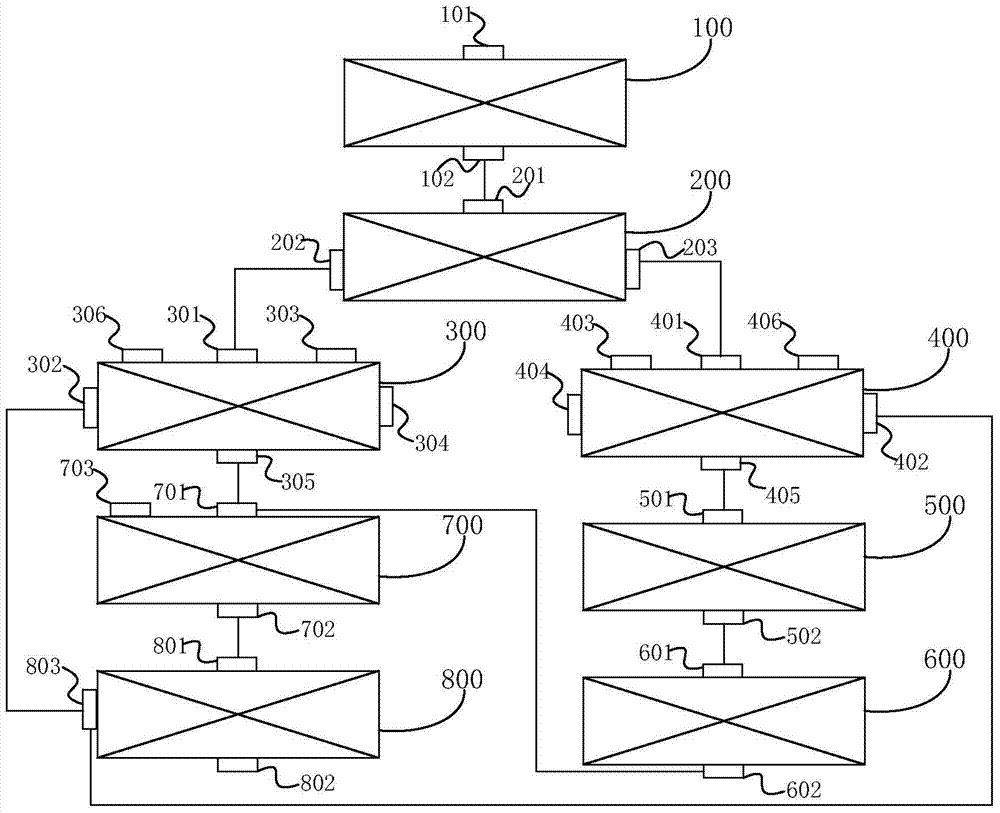

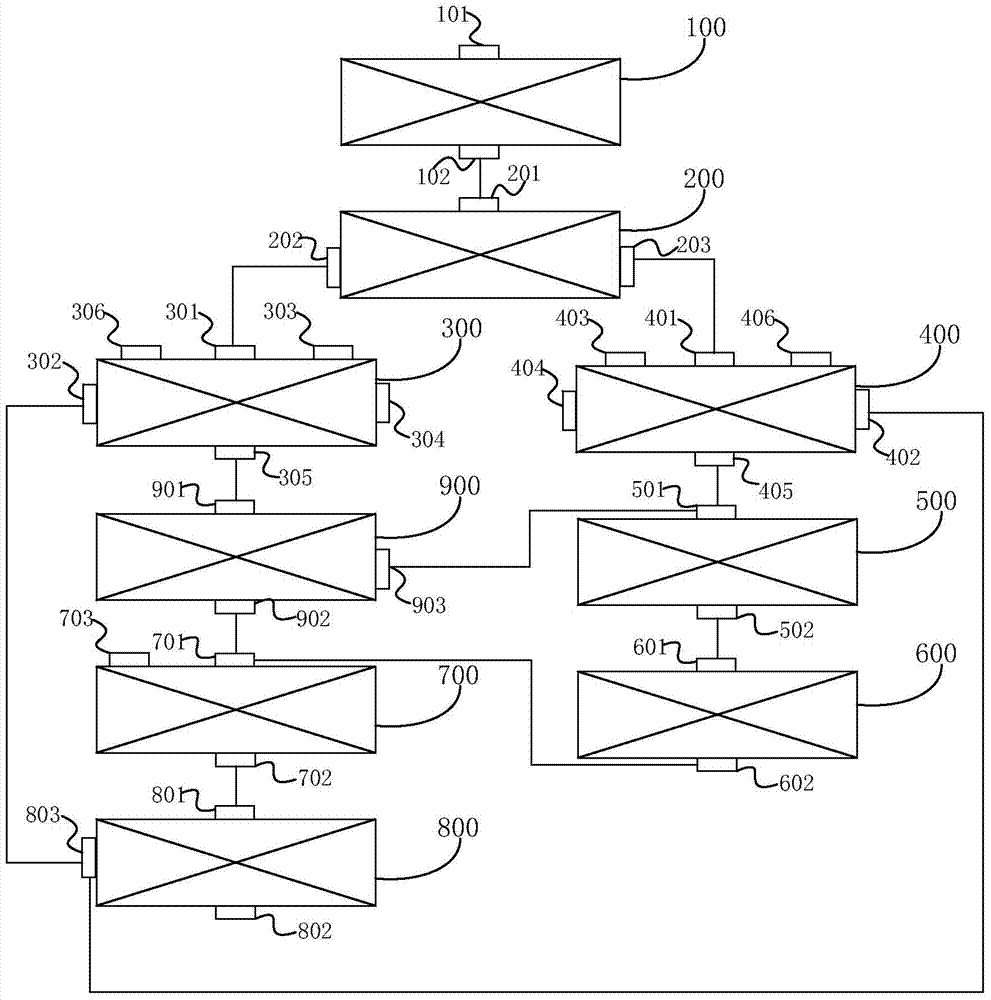

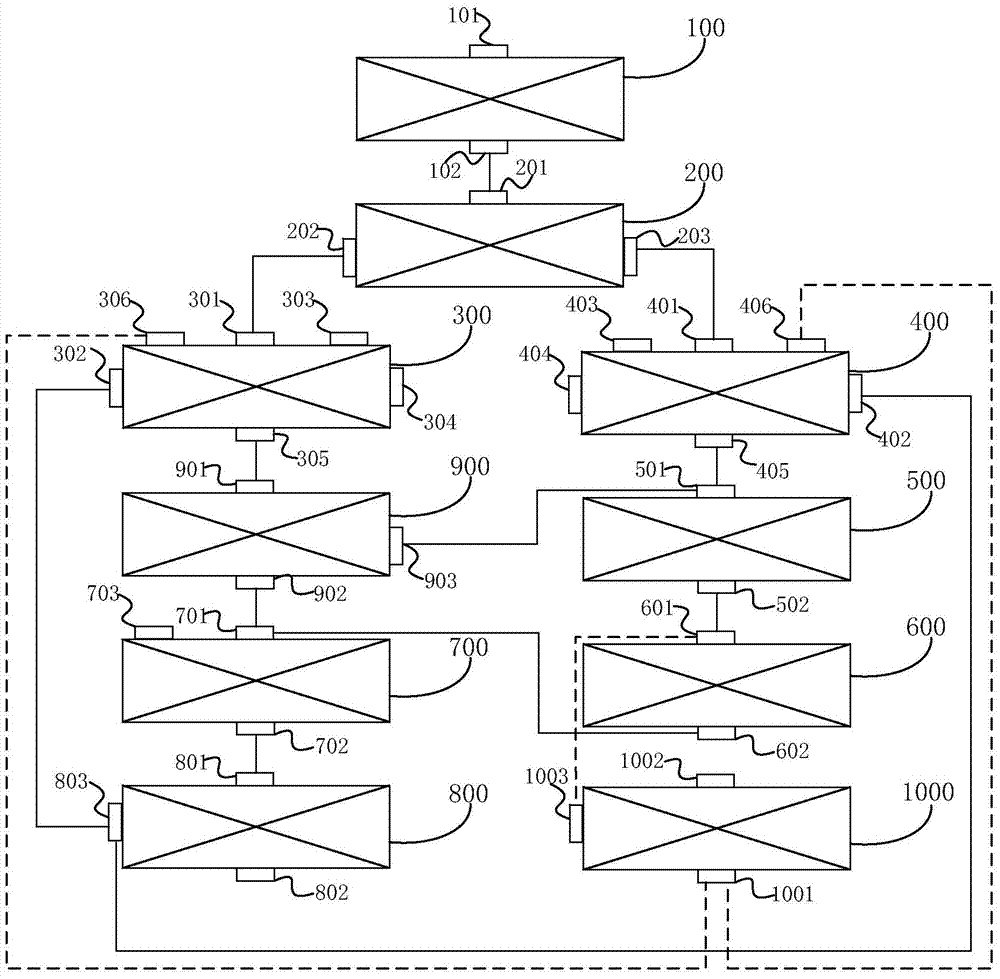

System and method for treating low-rank coal

ActiveCN105537121AImprove sorting efficiencyHigh sorting accuracyGas current separationDrying gas arrangementsEngineeringDischarge rate

The invention discloses a system and method for treating low-rank coal. The system comprises a low-rank coal pulverizing device, a low-rank coal screening device, a lump coal hot-wind dense-medium sorting device, a pulverized coal hot-wind flow sorting device, a clean coal pulverizing device, a forming device, a pyrolysis device and a waste heat recovery device, wherein the lump coal hot-wind dense-medium sorting device is provided with a lump coal inlet, a first hot wind inlet, a solid dense medium inlet, a first clean coal outlet and a first tail gas outlet; the pulverized coal hot-wind flow sorting device is provided with a pulverized coal inlet, a second hot wind inlet, a second clean coal outlet and a second tail gas outlet; the pyrolysis device is provided with a feed inlet, a semi-coke outlet and a pyrolysis oil gas outlet; the waste heat recovery device is provided with a semi-coke inlet and a hot air outlet, the semi-coke inlet is connected with the pyrolysis device, and the hot air outlet is connected with the first hot wind inlet and the second hot wind inlet. By means of the system, the gangue discharging rate of the low-rank coal can be remarkably increased, and therefore the quality and yield of pyrolyzed products in the subsequent pyrolysis process can be improved; moreover, the energy cost can be obviously lowered by recovering waste heat generated in the pyrolysis process and applying the waste heat to the gangue discharging process.

Owner:SHENWU TECH GRP CO LTD

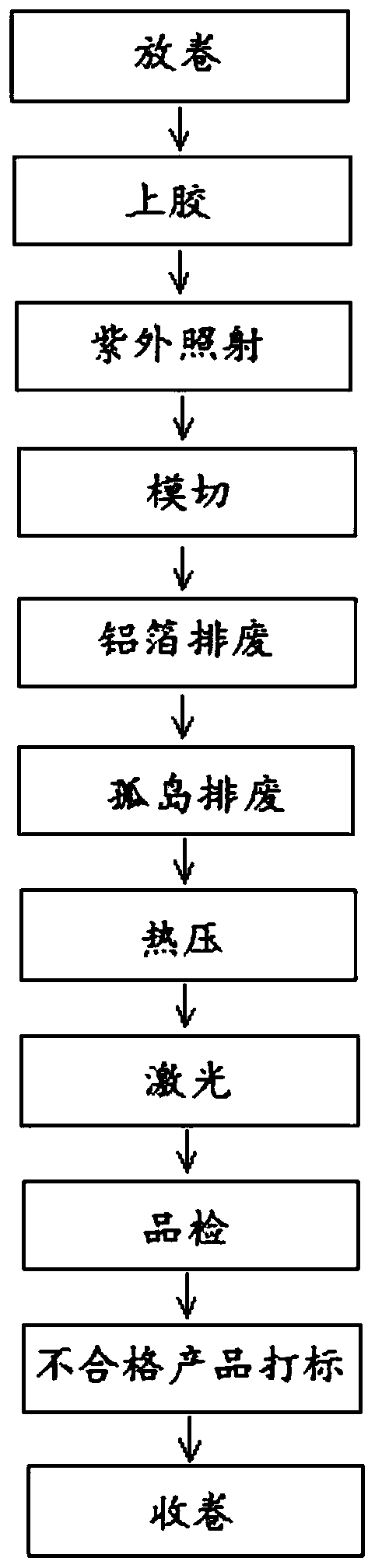

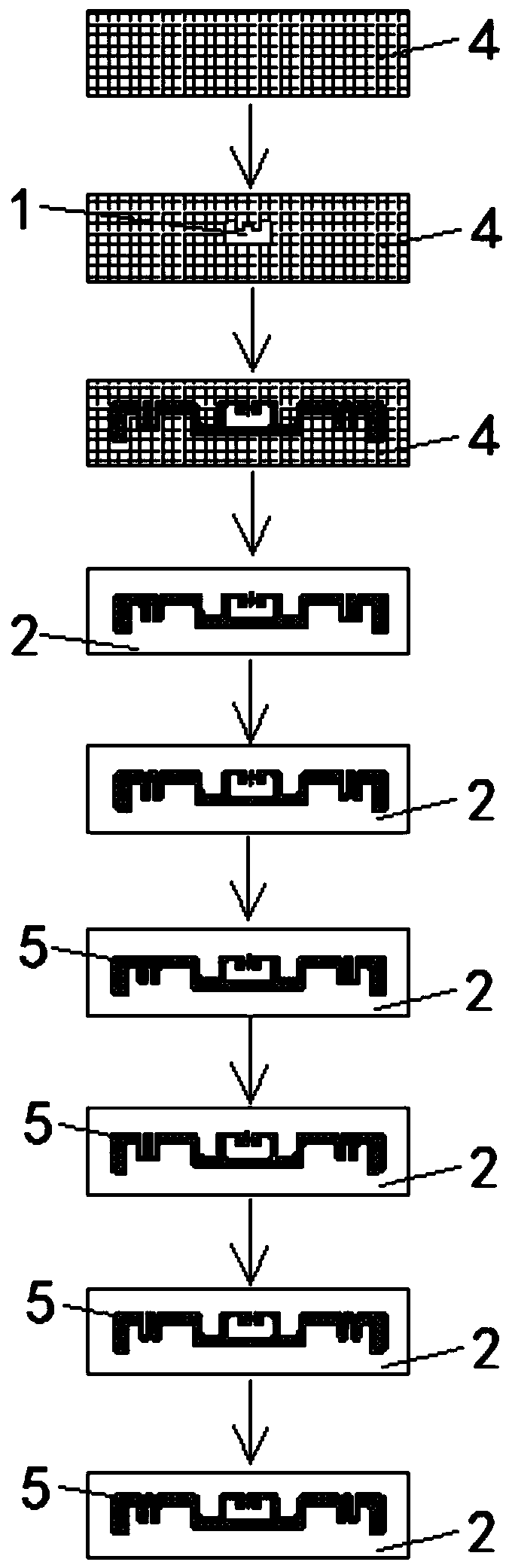

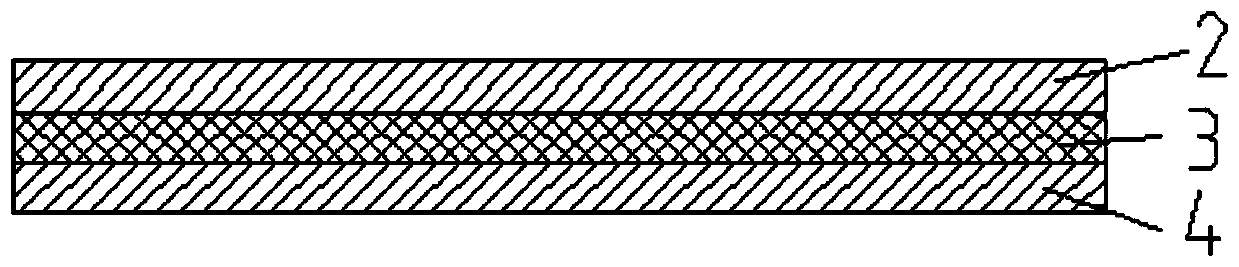

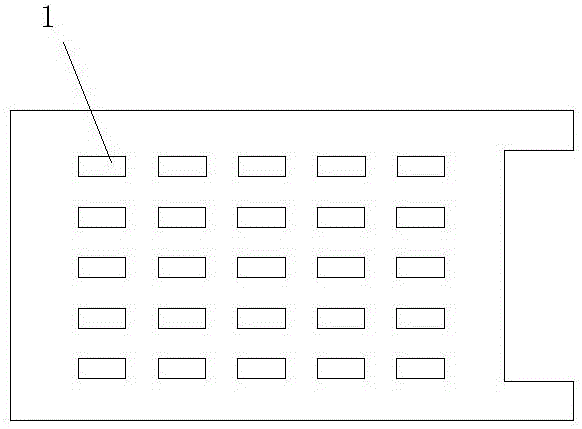

Manufacturing method of environment-friendly RFID tag antenna

InactiveCN110350292AReduce pollutionReduce processing difficultyAntenna supports/mountingsRadiating elements structural formsTag antennaEngineering

The invention relates to a manufacturing method of an environment-friendly RFID tag antenna; the manufacturing method comprises the following steps of S1, coating an island at a raw material set position with glue of 10-20 [mu]m to form a glue layer; S2, enabling the raw materials which are glued to be subjected to die cutting treatment, and meanwhile, carrying out waste discharge treatment to obtain a primary product; S3, carrying out hot-pressing treatment on the primary product; S4, carrying out laser cutting treatment on the hot-pressed primary product to obtain a finished product; and S5,carrying out inspection on the finished product to obtain a qualified product. The method has the beneficial effects that a traditional chemical corrosion processing technology is replaced by adopting a physical processing technology, so that the processing difficulty is reduced, the processing efficiency is improved, the environmental pollution is greatly reduced, and meanwhile, the production cost is lowered.

Owner:武汉中鼎智科物联网科技有限公司

Trademark production process capable of conveniently discharging wastes

InactiveCN106142815ARealize automatic waste dischargeImprove waste discharge efficiencyLamination ancillary operationsLaminationDischarge efficiencyBiochemical engineering

The invention discloses a trademark production process capable of conveniently discharging wastes. The trademark production process is characterized by comprising the following steps: (1) dispensing an adhesive: dispensing the adhesive on the back surface of a waste region of a product; (2) laminating: laminating release paper on the back surface of the product so as to stick the waste region part with a non-release surface of the release paper; (3) chopping: chopping the product to separate the waste region from the product, wherein a half-chopping chopping process is adopted in a chopping process so as to guarantee that the release paper on the back surface of the product is not chopped off; (4) discharging the wastes: taking away the chopped product and leaving the chopped-off wastes stuck on the release paper; recycling the release paper to discharge the wastes. The adhesive is dispensed on the back surface of the waste region and the release paper is laminated and the half-chopping chopping process is adopted; the wastes are stuck on the un-chopped release paper and the wastes are discharged by only if recycling the release paper, so that a bottom plate and a cutter are protected; automatic waste discharge is realized and the waste discharge efficiency is improved.

Owner:KUNSHAN HUAGUAN TRADEMARK PRINTING

System and method for treating low-rank coal

ActiveCN105537120AImprove sorting efficiencySolve the problem of low gangue discharge rateGas current separationDrying gas arrangementsDischarge rateProcess engineering

The invention discloses a system and method for treating low-rank coal. The system comprises a low-rank coal pulverizing device, a low-rank coal screening device, a lump coal hot-wind dense-medium sorting device, a pulverized coal hot-wind dense-medium sorting device, a clean coal pulverizing device, a forming device, a pyrolysis device and a waste heat recovery device, wherein the lump coal hot-wind dense-medium sorting device is provided with a lump coal inlet, a first hot wind inlet, a first solid dense medium inlet and a first clean coal outlet; the pulverized coal hot-wind dense-medium sorting device is provided with a pulverized coal inlet, a second hot wind inlet, a second solid dense medium inlet and a second clean coal outlet; the pyrolysis device is provided with a feed inlet, a semi-coke outlet and a pyrolysis oil gas outlet; the waste heat recovery device is provided with a semi-coke inlet and a hot air outlet, the semi-coke inlet is connected with the pyrolysis device, and the hot air outlet is connected with the first hot wind inlet and the second hot wind inlet. By means of the system, the gangue discharging rate of the low-rank coal can be remarkably increased, and therefore the quality and yield of pyrolyzed products in the subsequent pyrolysis process can be improved; moreover, the energy cost can be obviously lowered by recovering waste heat generated in the pyrolysis process and applying the waste heat to the gangue discharging process.

Owner:SHENWU TECH GRP CO LTD

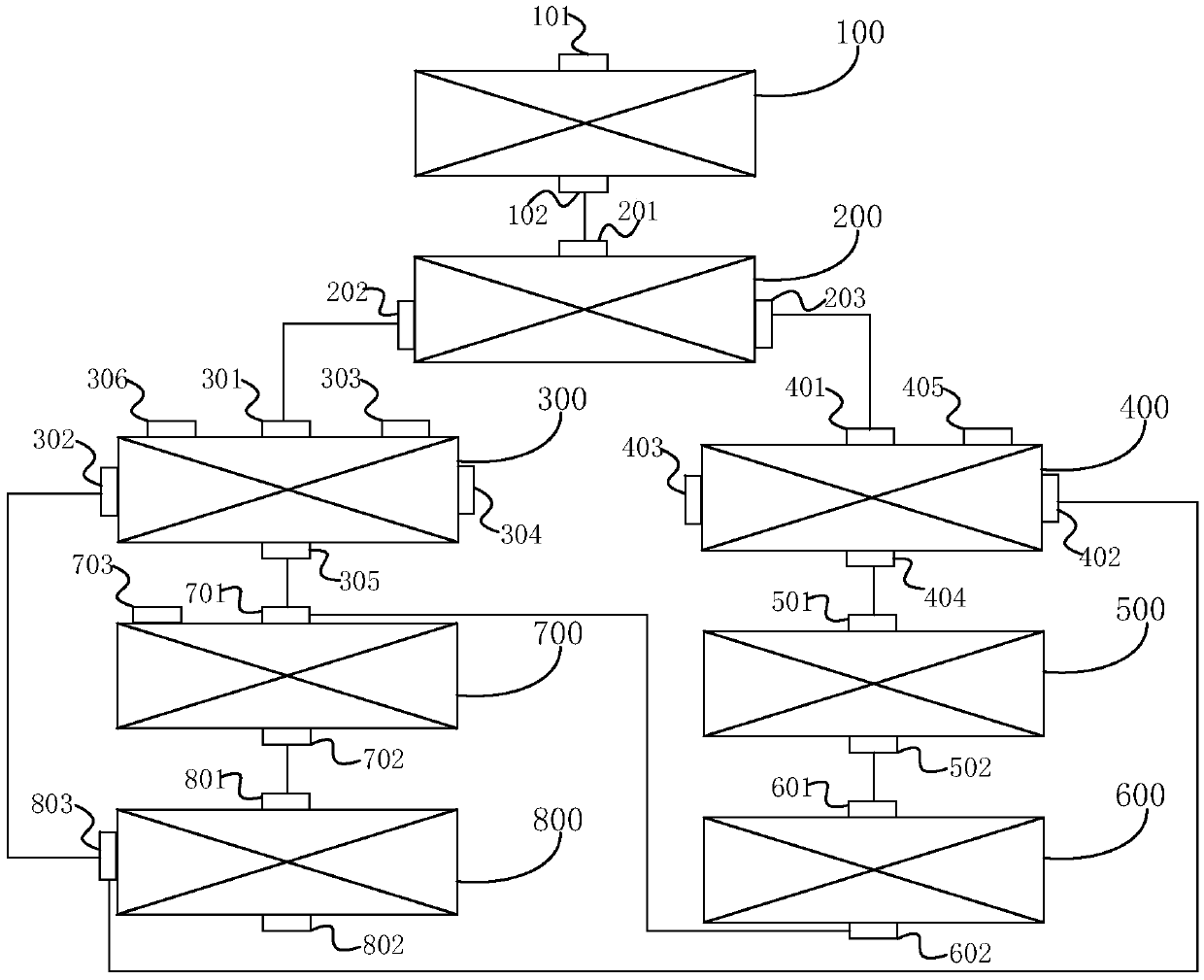

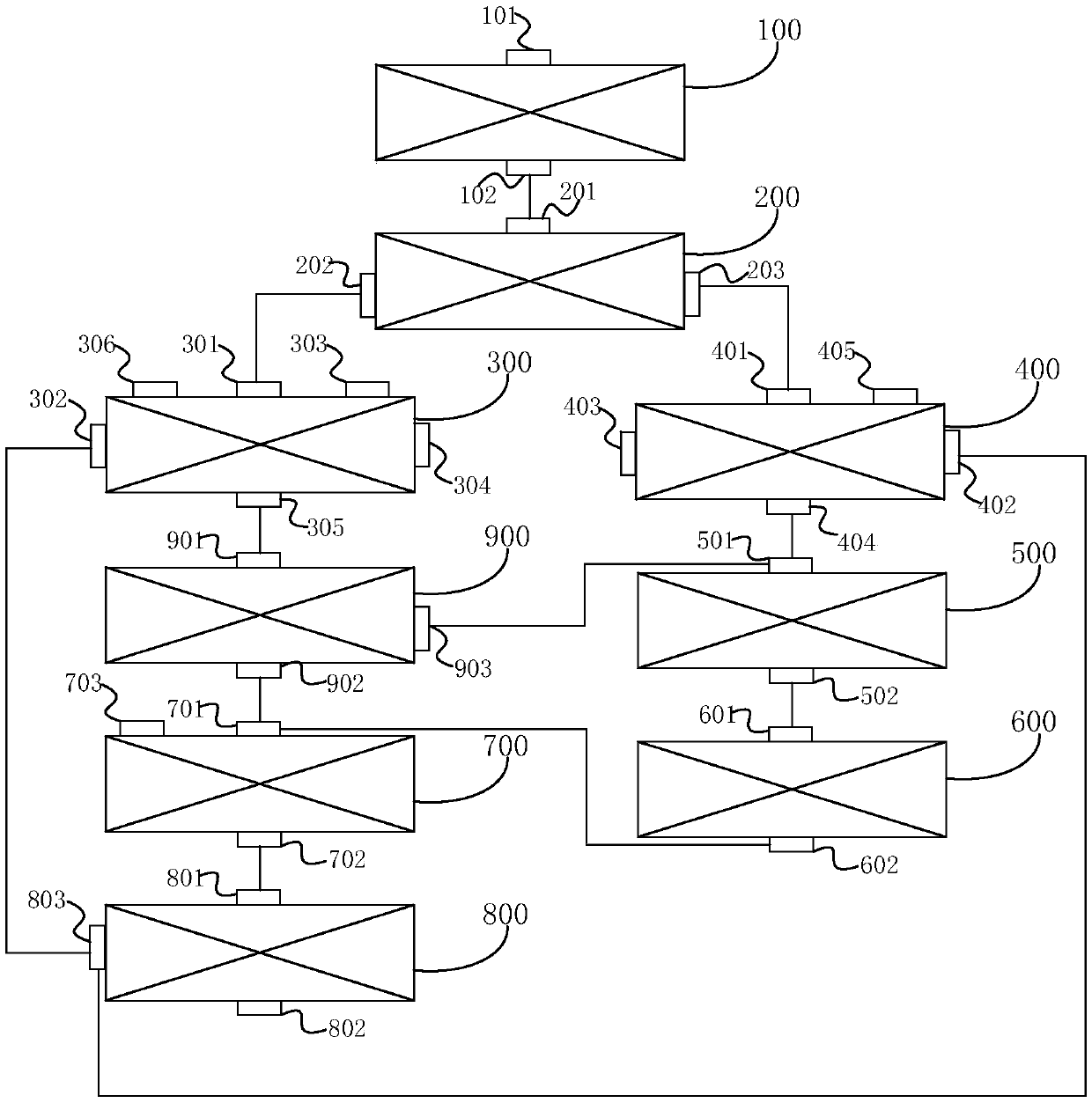

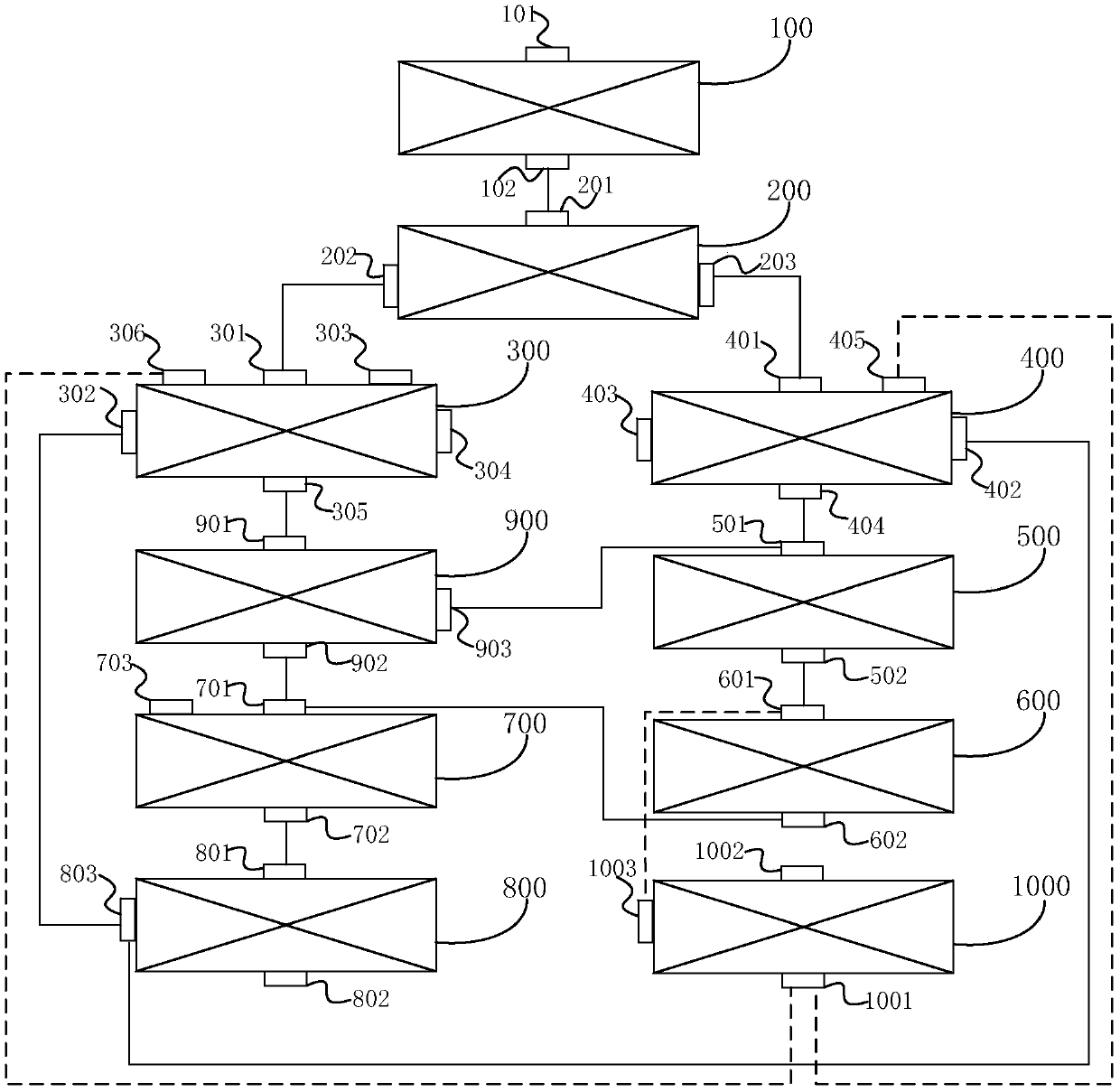

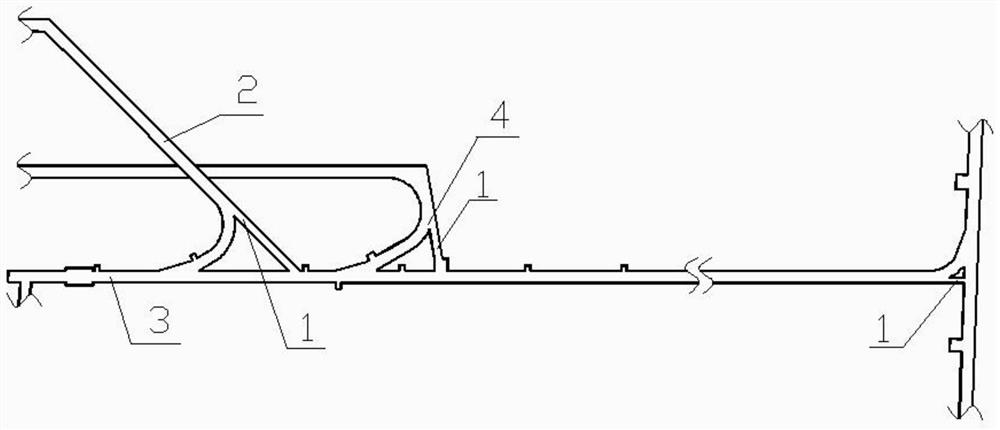

Buffering foam adhesive film production line

PendingCN112659240AEasy to observeHigh degree of automationMetal working apparatusProduction lineEngineering

The invention discloses a buffering foam adhesive film production line which sequentially comprises a first laminating device, a first die cutting mechanism, a second laminating device, a second die cutting mechanism, a first waste discharging mechanism, a third die cutting mechanism, a third laminating device, a fourth die cutting mechanism and a second waste discharging mechanism according to the production process. The first laminating device sequentially comprises a foam paying-off roller and a first tape pressing mechanism according to the production process, a first adhesive tape paying-off roller is arranged above the first tape pressing mechanism, the foam paying-off roller is sleeved with a foam layer, the foam layer is pressed on the first tape pressing mechanism, the first adhesive tape paying-off roller is sleeved with first adhesive tape, the first adhesive tape penetrates through the first tape pressing mechanism to be attached to the foam layer, and a first release film of the first adhesive tape is connected with a first release film taking-up roller. The buffering foam adhesive film production line performs die cutting and waste discharging after laminating all layers, the automation degree is high, and whether waste is removed or not can be conveniently observed.

Owner:昆山域之光电子有限公司

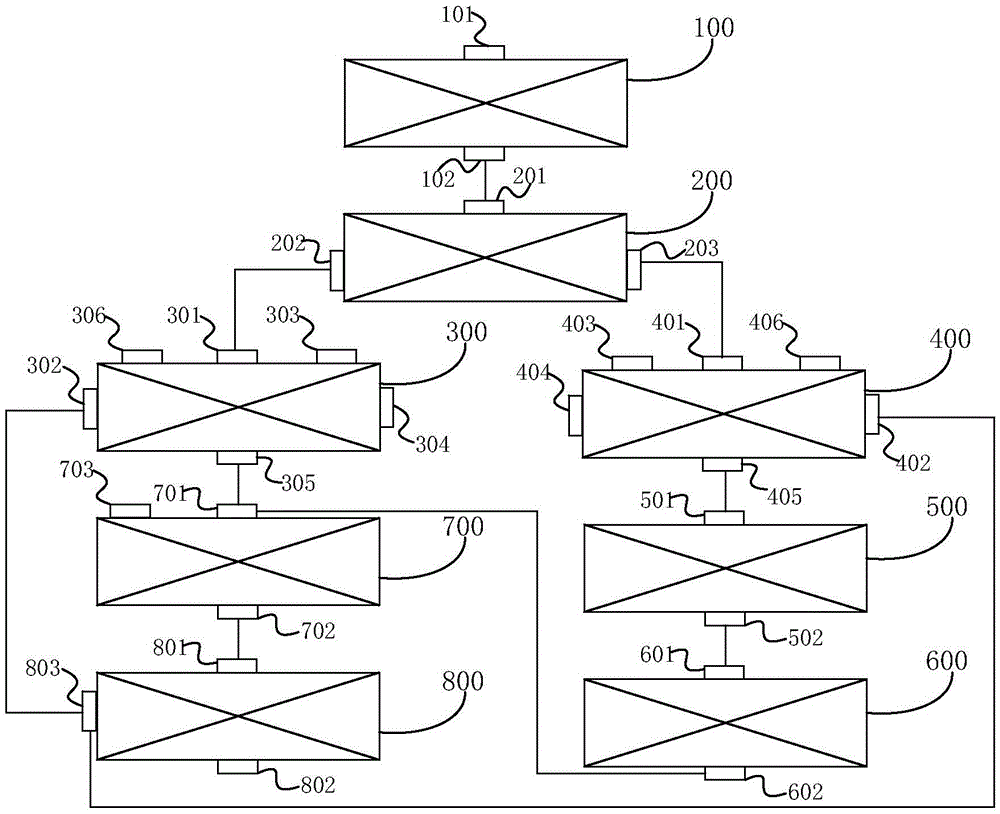

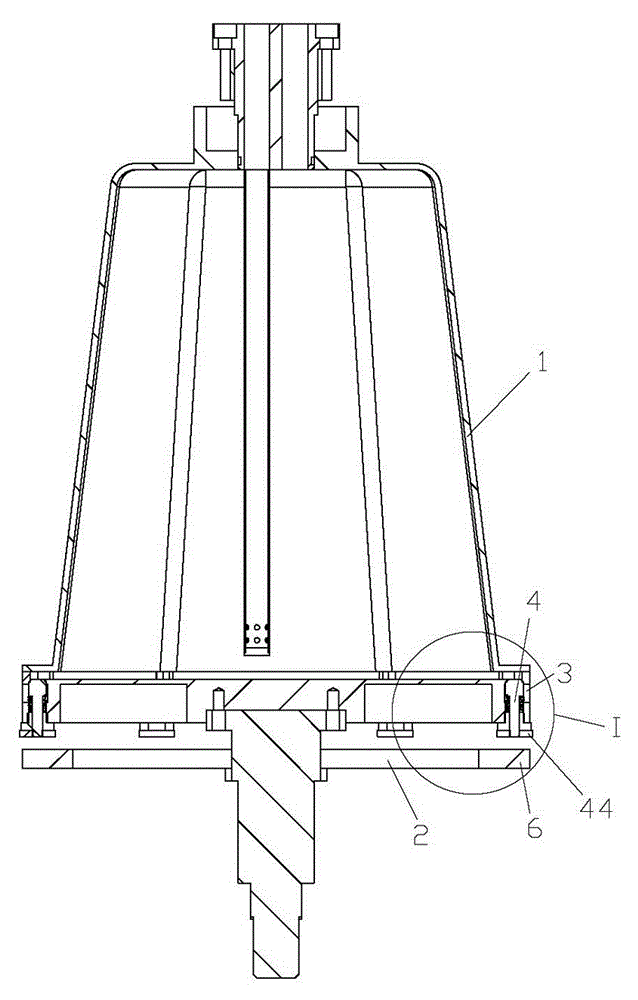

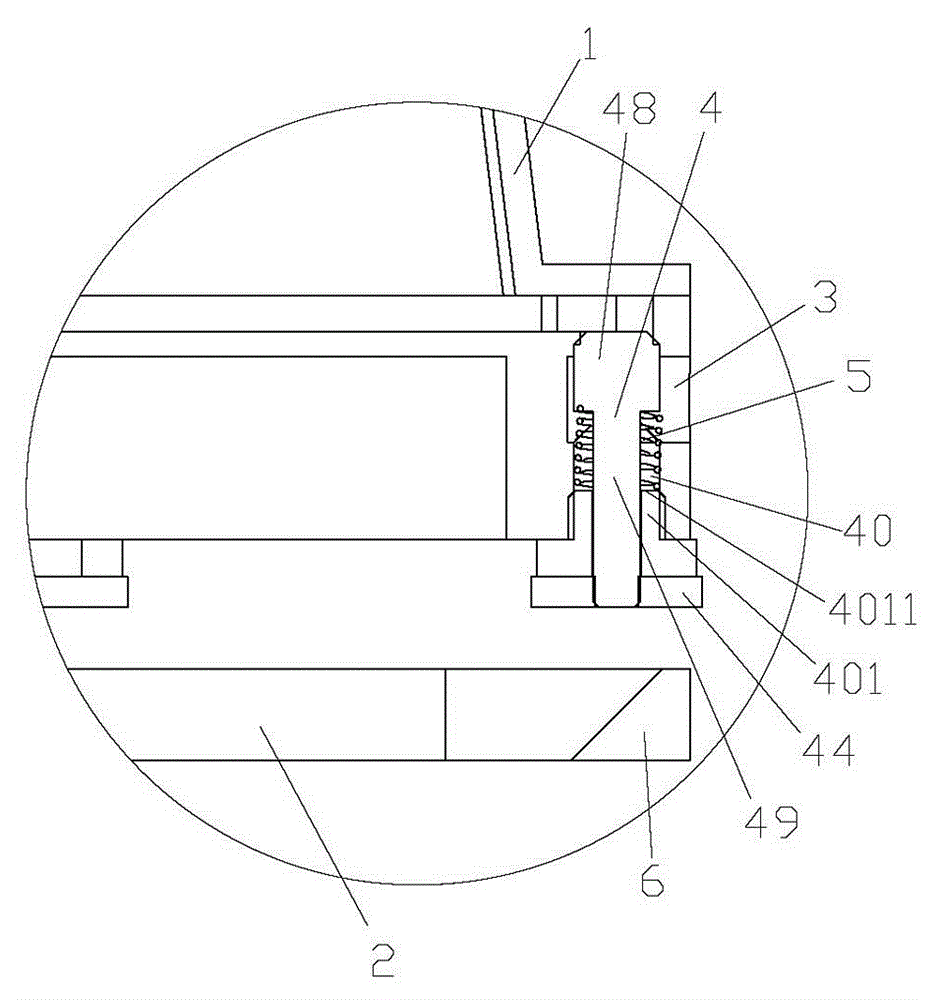

Camera obscura detection system of chemiluminescence immunity analyzer

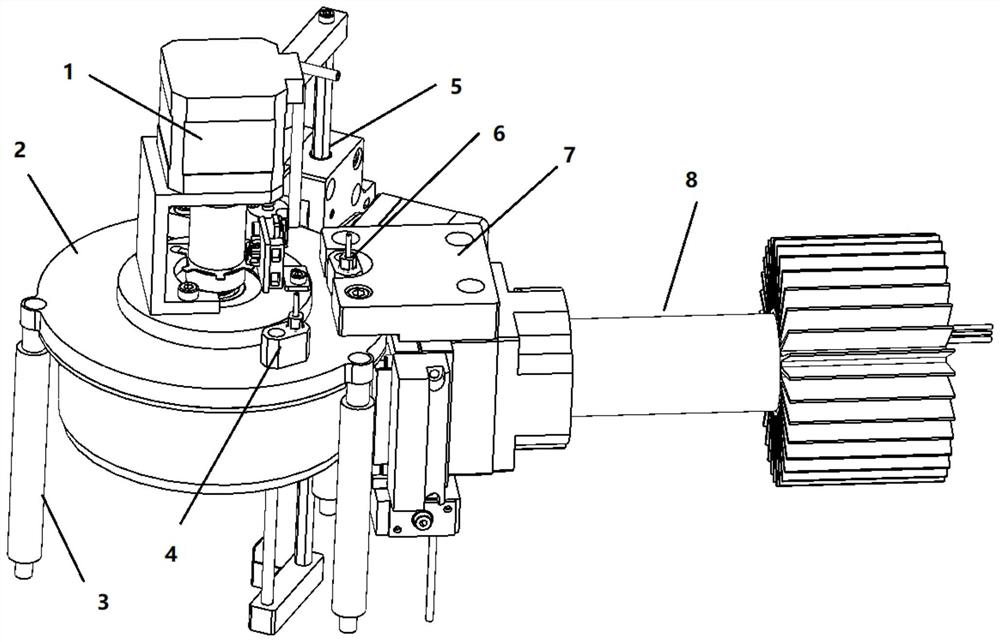

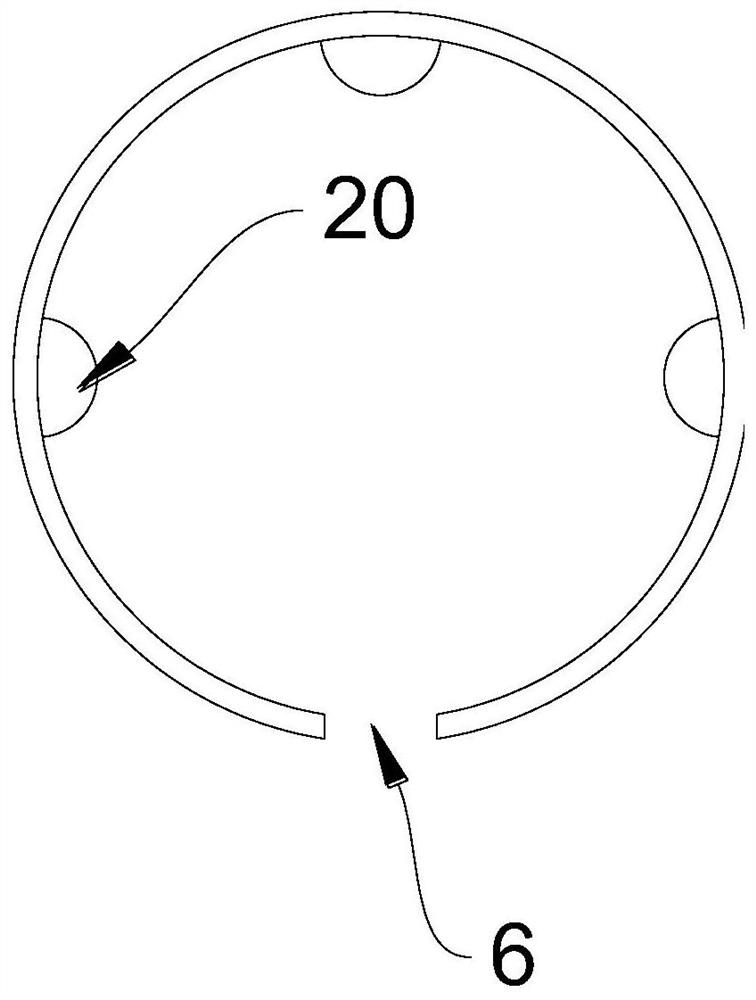

PendingCN112798775AImprove reading efficiencyImprove waste discharge efficiencyBiological testingMedicineImmunity

The invention provides a camera obscura detection system of a chemiluminescence immunity analyzer. The camera obscura detection system is composed of a driving device (1), a darkroom (2), a PMT module (8), a PMT connecting block (7), an excitation fixed assembly (4), an excitation fixed assembly (6) and a waste discharge part (5). The reaction cup is automatically rotated to the excitation liquid adding position, the detection position and the cup discharging hole after entering the camera obscura detection system from the cup inlet hole, and waste liquid and empty cups are discharged from the cup discharging hole through the waste liquid needle. The integrated design is adopted, the camera obscura adopts the annular design, the dark background is excellent, an original waste liquid discharging mechanism and an original empty cup discharging mechanism are combined together and completed at a time through a waste liquid needle, the product structure is more compact, the occupied space is reduced, and the waste discharging efficiency is improved.

Owner:烟台晟锋医疗科技有限责任公司

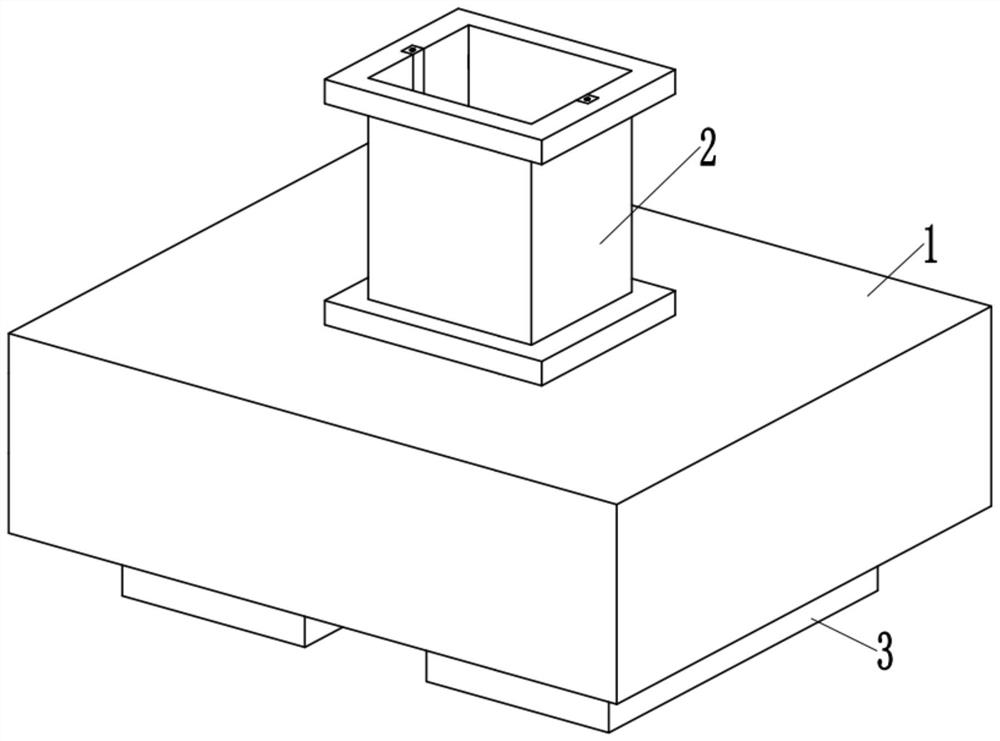

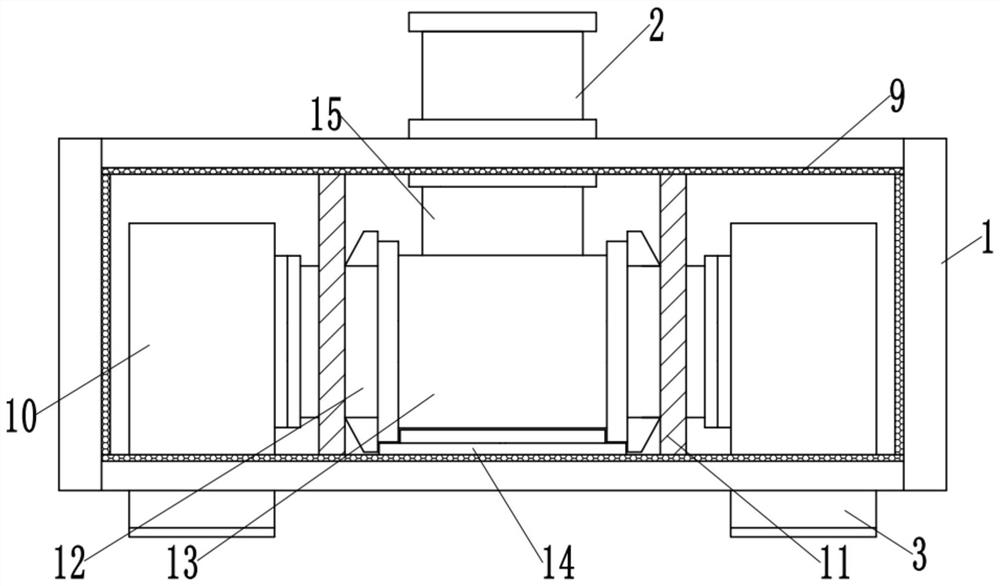

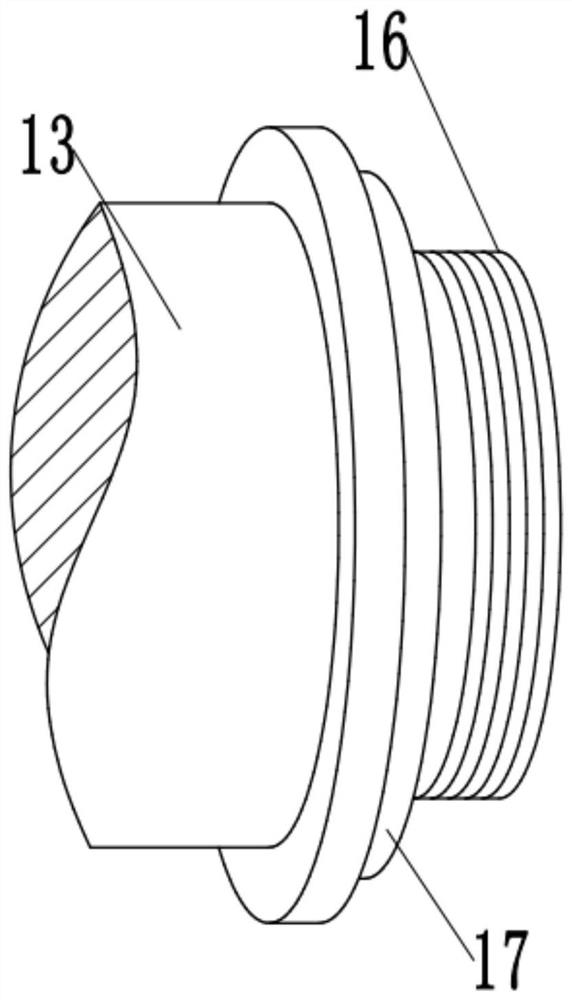

Pneumatic automatic waste discharge device of maintenance-free liquid filter of centrifugal machine

InactiveCN104984838ARealize automatic controlQuality improvementCentrifugesProcess engineeringMechanical engineering

The invention relates to the technical field of centrifuge equipment, in particular to a pneumatic automatic waste discharge device of a maintenance-free liquid filter of a centrifugal machine. The device comprises a rotor main cylinder capable of rotating, wherein the lower part of the rotor main cylinder is connected with a chassis; the chassis is provided with a transverse waste discharge channel communicated from the internal to the external of the rotor main cylinder; the waste discharge channel is additionally matched with a valve core for closing and opening the waste discharge channel; the valve core is arranged in a chute formed in the chassis for transversely moving the valve core and communicated with the waste discharge channel; and the valve core is matched with a transverse driving mechanism capable of enabling the valve core to transversely move in a direction intersected with the conducting direction of the waste discharge channel. The device is safe and stable in operation, high in efficiency, excellent in smoothness and excellent in waste discharge effect.

Owner:沈路平

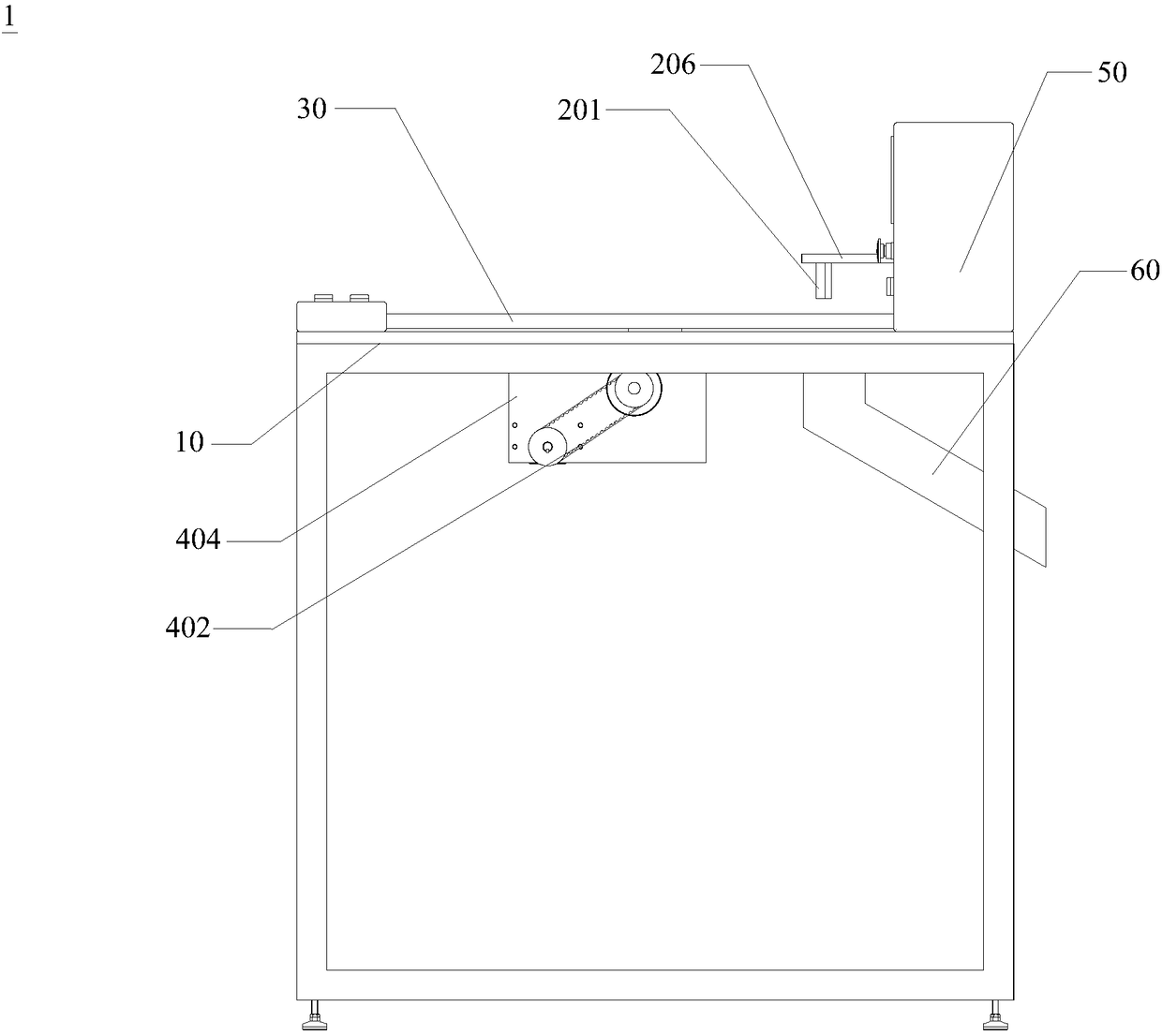

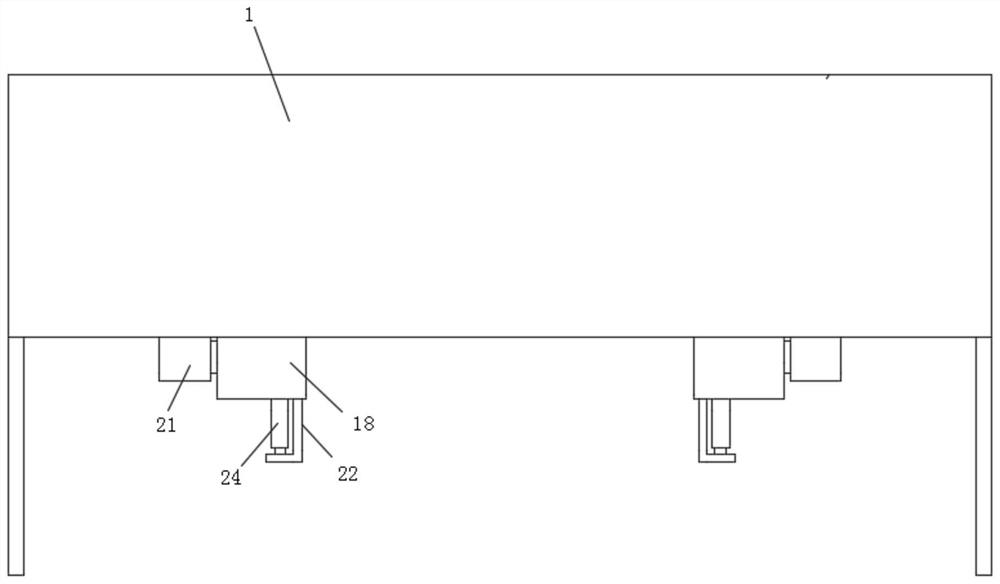

Workpiece waste exclusion device

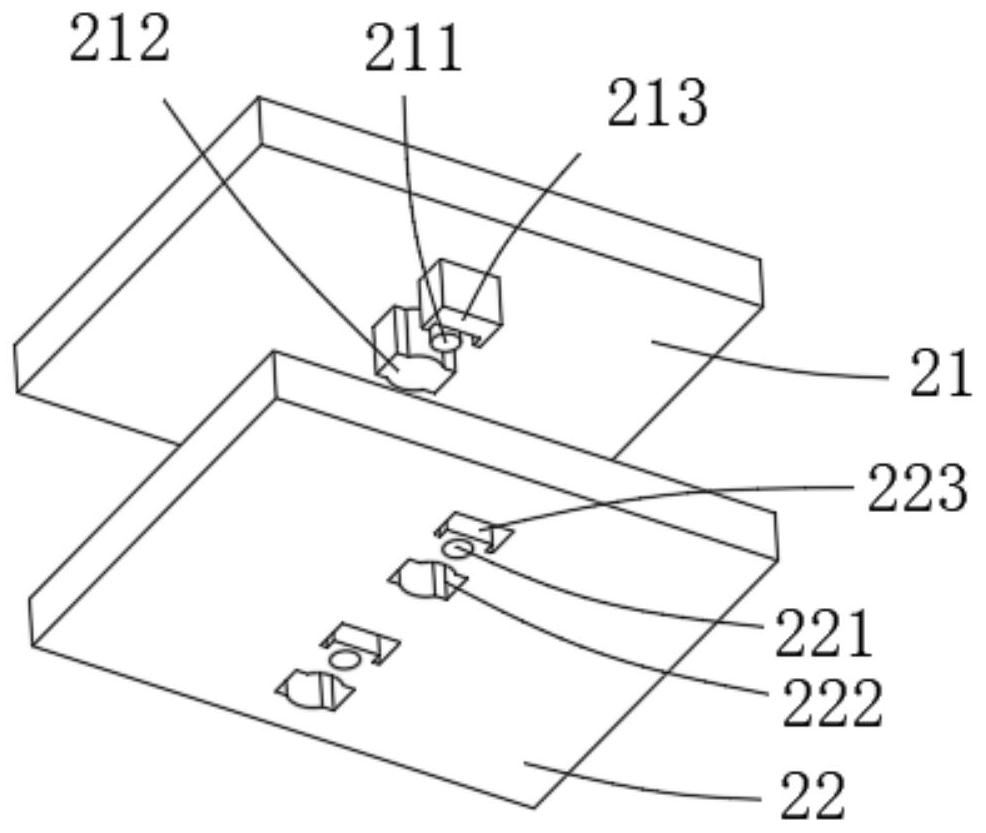

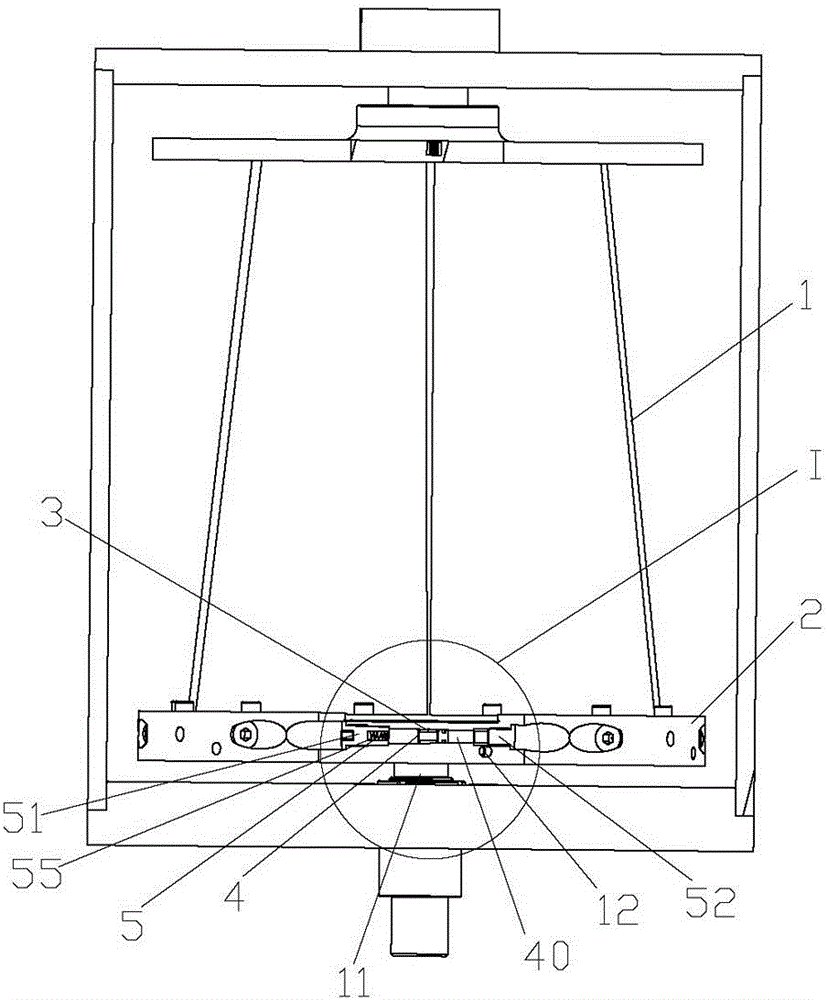

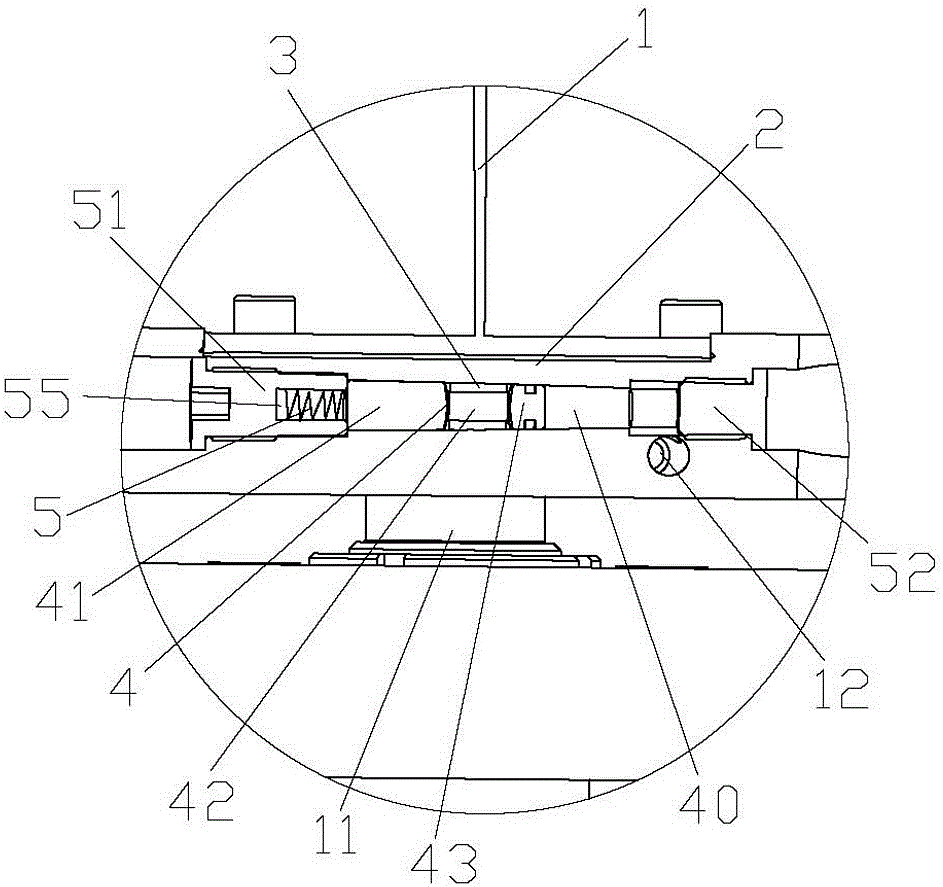

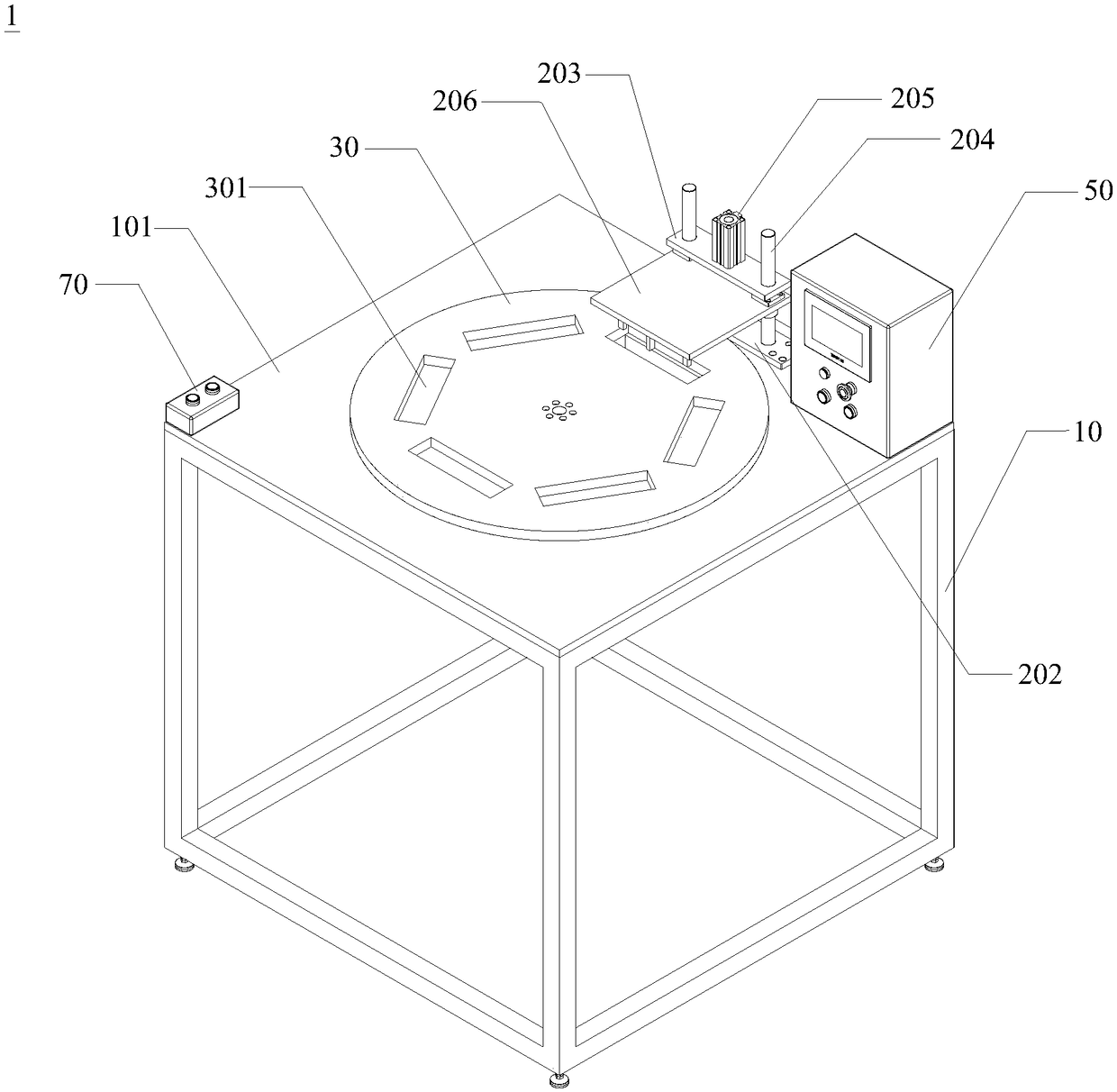

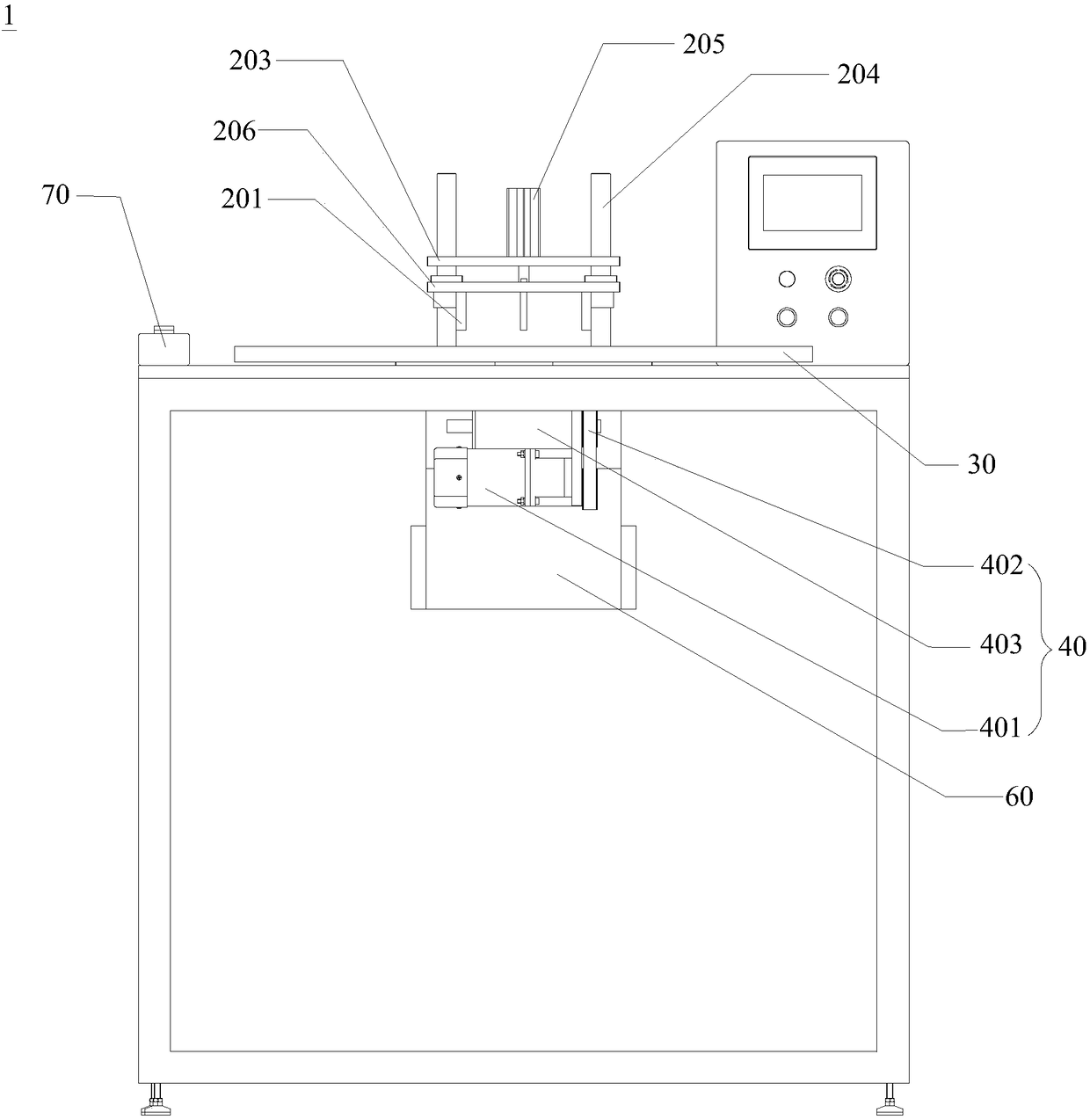

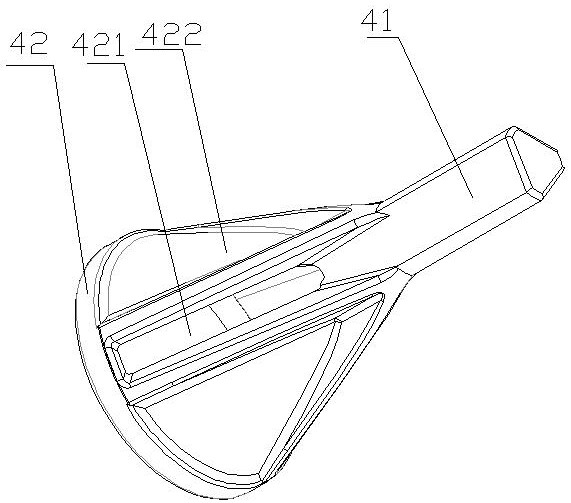

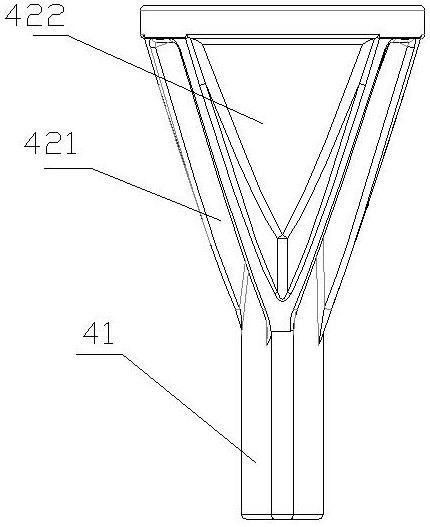

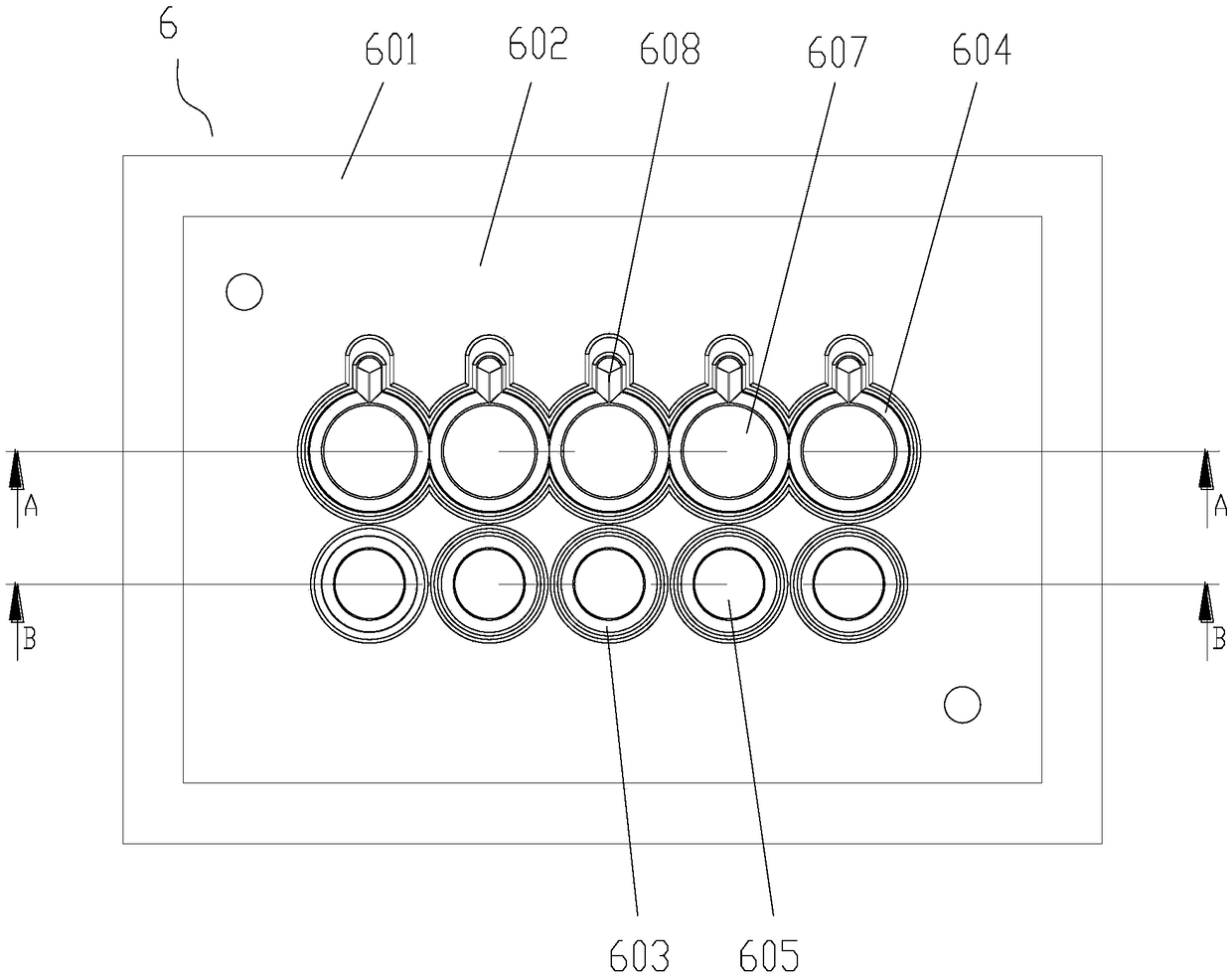

PendingCN108372549ARealize waste recyclingImprove waste discharge efficiencyMetal working apparatusRotary valveEngineering

The invention discloses a workpiece waste exclusion device. The device comprises a rack, a thimble assembly, a thimble assembly driving mechanism, a rotary table, a rotary table driving mechanism anda control circuit, wherein the thimble assembly is arranged on the rack, the thimble assembly driving mechanism is arranged on the rack, connected with the thimble assembly and can drive the thimble assembly to move up and down; the rotary table is arranged on the rack, the rotary table is provided with multiple dies, the dies are provided with through holes, and the number of the through holes corresponds to that of thimbles in the thimble assembly; the rotary table driving mechanism is arranged on the rack to drive the rotary table to rotate; the control circuit is respectively connected with the rotary table driving mechanism and the thimble assembly driving mechanism to control the running of the rotary table driving mechanism and the thimble assembly driving mechanism. The workpiece waste exclusion device has the advantages that the thimbles can be inserted into the inner bores of the workpieces placed on the dies to quickly remove the waste of workpiece through holes, the rotatable rotating table is provided with the multiple dies, circular waste discharging of the worpieces can be achieved, thereby greatly improving the efficiency of waste discharging, the operation is moreconvenient, and the labor can be reduced.

Owner:深圳市睿晖新材料有限公司

Electromagnetic type automatic waste discharge device of maintenance-free liquid filter of centrifugal machine

InactiveCN104998768AEfficient and stable waste discharge operationReduce the chance of damageCentrifugesEngineeringMechanical engineering

The invention relates to the technical field of centrifugal machine equipment, in particular to an electromagnetic type automatic waste discharge device of a maintenance-free liquid filter of a centrifugal machine. The electromagnetic type automatic waste discharge device comprises a rotatable rotor main barrel body, the lower portion of the rotor main barrel body is connected with a bottom disc, and a transverse waste discharge channel communicated with the rotor main barrel body from the inside to the outside is formed in the bottom disc. The waste discharge channel is further provided with a valve element for closing and opening the waste discharge channel, and the valve element is arranged in a sliding groove formed in the bottom disc, wherein the sliding groove is used for allowing the valve element to vertically slide. The valve element is provided with a vertical driving mechanism capable of enabling the valve element to move vertically. The electromagnetic type automatic waste discharge device is safe and stable in running, high in efficiency, good in smoothness and good in waste discharge effect.

Owner:沈路平

Viscose paper waste discharging system

The invention relates to a viscose paper waste discharging system. The viscose paper waste discharging system comprises a support, a roller, a first motor, a waste removing scraping piece and a wasteconveying mechanism. The roller is rotationally installed on the support. A rotating shaft of the first motor is in transmission connection with the roller, and the roller is used for rotating and winding waste viscose paper. The waste removing scraping piece is arranged on the support, the waste removing scraping piece and the side wall of the roller are arranged in an interval manner, and the waste removing scraping piece is used for scraping waste viscose paper wound on the side wall of the roller. The waste conveying mechanism is located below the roller and used for conveying the waste viscose paper to a waste collection area. Compared with a traditional viscose paper waste discharging system, the viscose paper waste discharging system has the beneficial effects that it does not needto conduct shutdown when unloading and waste discharging operation is carried out on waste viscose paper rolls formed by winding on the roller, the waste removing scraping piece scraps the waste viscose paper wound on the side wall of the roller in time, the waste viscose paper is conveyed to the waste collection area through the waste conveying mechanism, shutdown operation is not needed, and theworking efficiency is greatly improved.

Owner:GUANGZHOU JIUHENG BAR CODE

Waste discharge device capable of avoiding damage to circuit unit for printed circuit board processing

InactiveCN111906086AAvoid damageImprove cleaning efficiencyDirt cleaningCleaning using toolsPrinted circuit boardBackplane

The invention discloses a waste discharge device capable of avoiding damage to a circuit unit for printed circuit board processing. The waste discharge device comprises a bottom plate, suction and blowing fans, a top plate and a bearing plate, wherein a printed circuit board is arranged on the bottom plate, and connecting boxes are arranged on the left side and the right side of the printed circuit board; material absorption openings are formed in the inner side surfaces of the connecting boxes, the outer sides of the material absorption openings are connected with first buffer boxes, and theupper ends of the first buffer boxes are connected with first connecting pipes; and the upper ends of second buffer boxes are provided with the tail ends of second connecting pipes, and second filterplates are arranged inside the upper ends of the second connecting pipes. According to the waste discharge device capable of avoiding damage to the circuit unit for printed circuit board processing, damage to circuit unit components can be avoided during waste discharge, and waste chips adhering to the surface of the printed circuit board can be removed, so that cleaning is thorough enough, the cleaning efficiency is high, and rapid and efficient cleaning can be achieved.

Owner:王钟

Automatic rejected cup discharging device

InactiveCN110090815ASimple structureImprove waste discharge efficiencyPaper-makingBox making operationsWaste productPulp and paper industry

The invention discloses an automatic rejected cup discharging device which is characterized by comprising a leading-in pipe, a screening device, a detection probe and a controller; the pipe wall of the leading-in pipe is hollow; paper cups manufactured on paper cup manufacturing equipment can freely fall into the leading-in pipe, and an air pipe is arranged on the left side of the leading-in pipe;the screening device comprises a finished product channel pipe, a waste discharge pipe communicating with the finished product channel pipe is arranged on the lower side of the finished product channel pipe, a blade capable of swinging up and down is arranged at the junction of the finished product channel pipe and the waste discharge pipe, a power device capable of enabling the blade to swing upand down is connected to the blade, and the power device is connected with the controller; the detection probe is used for detecting whether a paper cup produced on the paper cup manufacturing equipment is qualified or not, and is connected with the controller; the right end of the leading-in pipe is connected with the left end of the finished product channel pipe, and the right end of the finished product channel pipe is connected with a conveying pipe. The automatic rejected cup discharging device has the characteristics of simple structure, automatic completion of waste screening and highefficiency.

Owner:浙江超凡科技股份有限公司

Mechanical waste discharge device of railway vehicle

ActiveCN111572576AImprove stabilityWith shock absorbing effectRailway heating/coolingControl theoryMechanical engineering

The invention relates to the technical field of railway vehicles, in particular to a mechanical waste discharge device of a railway vehicle. The device comprises a shell; silencing cotton adheres to the periphery of the inner side wall of the shell;a supporting base is installed in the center of the inner wall of the bottom of the shell through bolts;and baffles are welded to the inner walls of the two sides, close to the supporting base, of the shell. The device has the beneficial effects that the jackinggroove enables the supporting baseto be better attached to the outer side wall of afan; the working stability of the fan is improved; the jacking seat has a certain damping effect on the fan under the action of the spring; a good protection effect is achieved on the fan; the service lifeof the fan is further prolonged;the sound insulation lining barrel enables the noise generated by the fact that air flow impacts the air channel to be reduced when the fan sucks air through the air inlet, the silencing cotton further reduces the noise generated when the fan works, a quiet environment is provided for passengers, and the comfort of the passengers when the passengers take the rail vehicle is improved.

Owner:南京天普机电产品制造有限公司

Method for producing multifunctional outer circle chamfering knife with powder as raw material

Owner:YANGZHOUSSHINE POWDER METALLURGY

Systems and methods for processing low rank coal

ActiveCN105537121BImprove sorting efficiencyHigh sorting accuracyGas current separationDrying gas arrangementsProcess engineeringDischarge rate

The invention discloses a system and method for treating low-rank coal. The system comprises a low-rank coal pulverizing device, a low-rank coal screening device, a lump coal hot-wind dense-medium sorting device, a pulverized coal hot-wind flow sorting device, a clean coal pulverizing device, a forming device, a pyrolysis device and a waste heat recovery device, wherein the lump coal hot-wind dense-medium sorting device is provided with a lump coal inlet, a first hot wind inlet, a solid dense medium inlet, a first clean coal outlet and a first tail gas outlet; the pulverized coal hot-wind flow sorting device is provided with a pulverized coal inlet, a second hot wind inlet, a second clean coal outlet and a second tail gas outlet; the pyrolysis device is provided with a feed inlet, a semi-coke outlet and a pyrolysis oil gas outlet; the waste heat recovery device is provided with a semi-coke inlet and a hot air outlet, the semi-coke inlet is connected with the pyrolysis device, and the hot air outlet is connected with the first hot wind inlet and the second hot wind inlet. By means of the system, the gangue discharging rate of the low-rank coal can be remarkably increased, and therefore the quality and yield of pyrolyzed products in the subsequent pyrolysis process can be improved; moreover, the energy cost can be obviously lowered by recovering waste heat generated in the pyrolysis process and applying the waste heat to the gangue discharging process.

Owner:SHENWU TECH GRP CO LTD

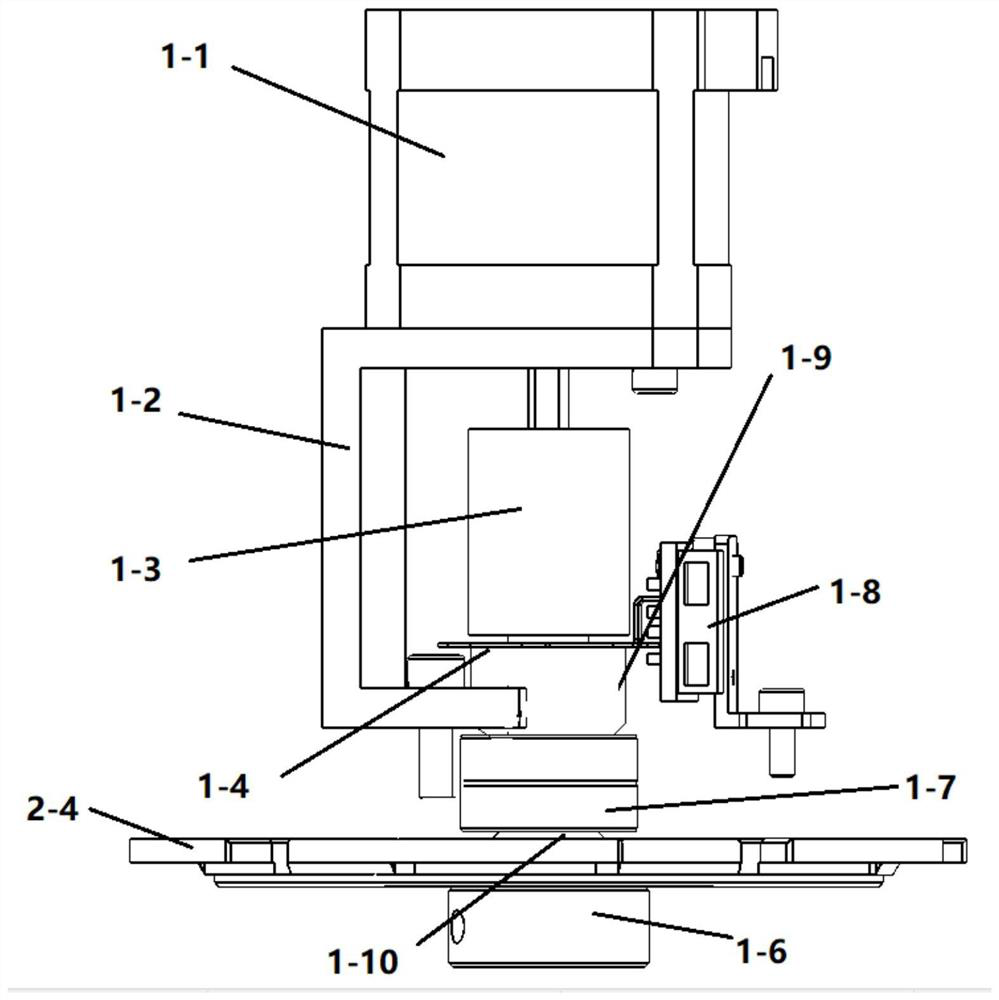

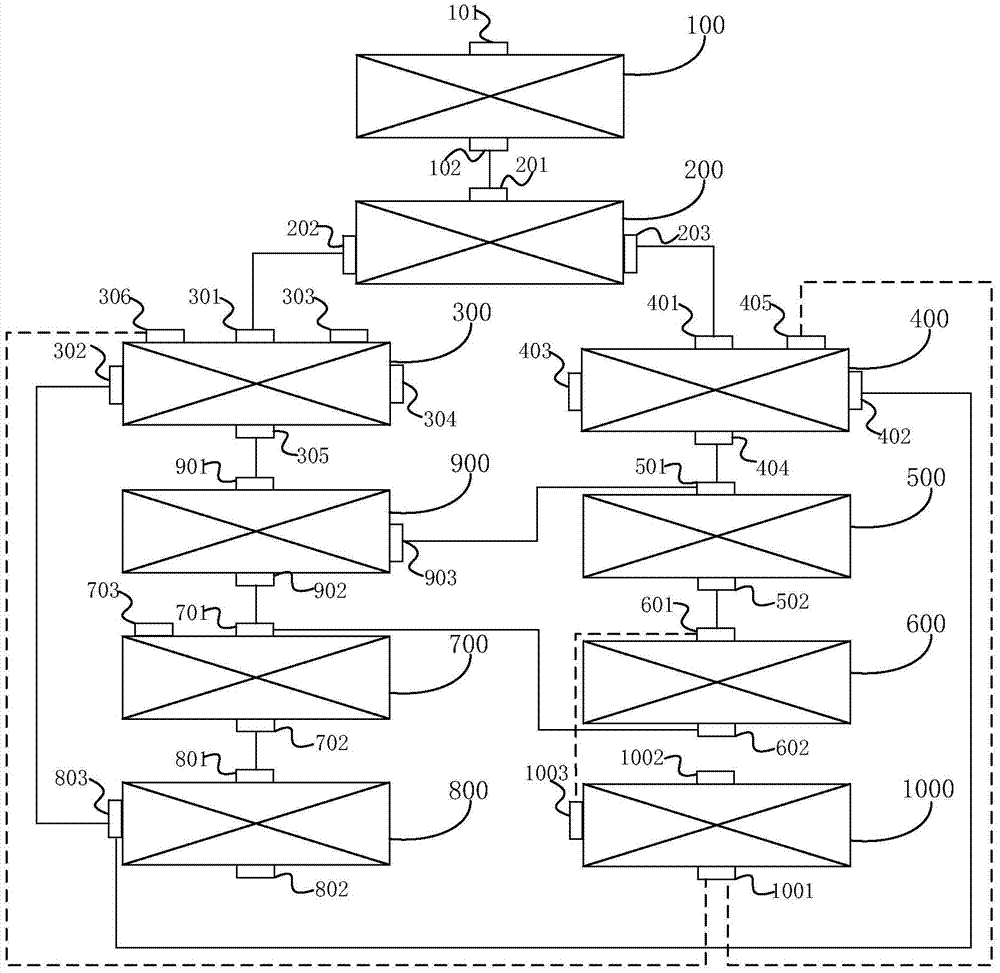

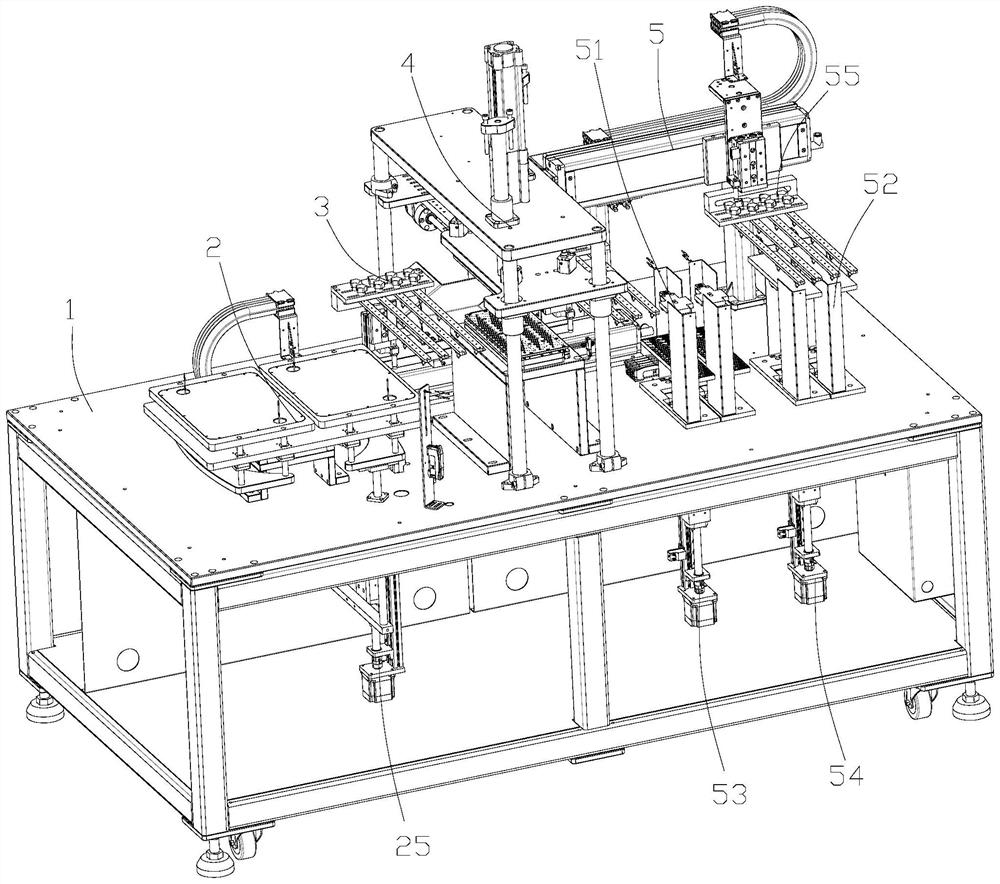

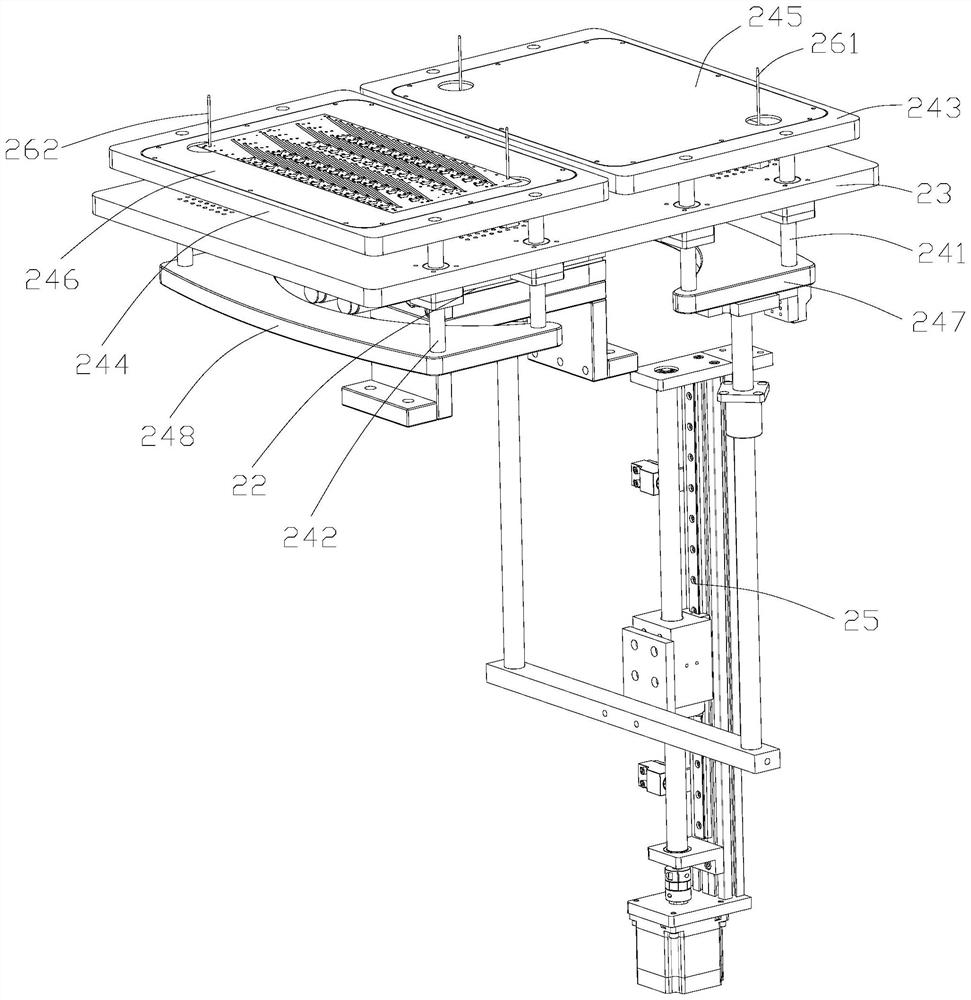

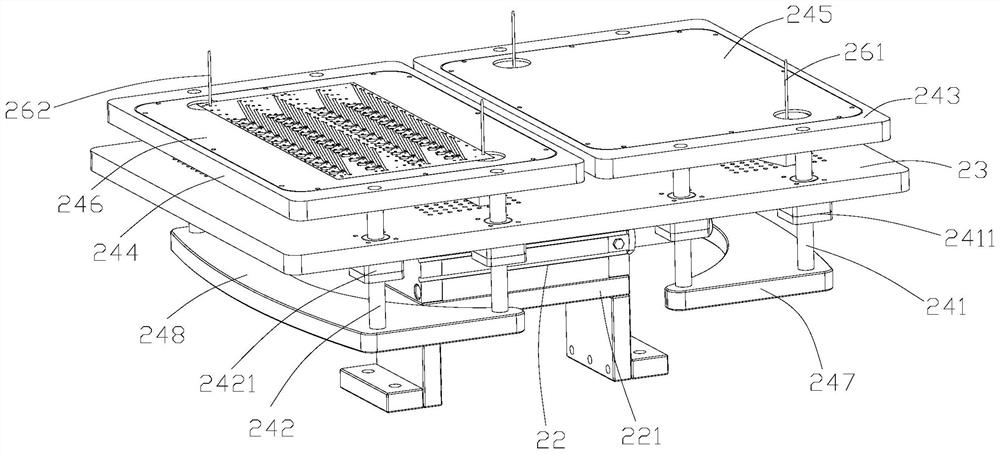

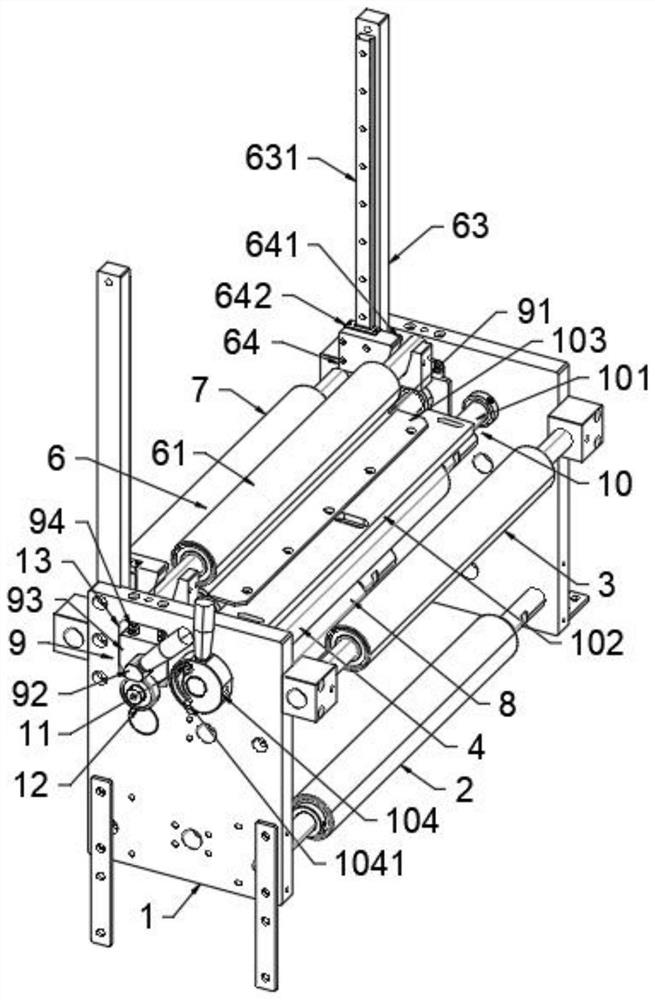

Full-automatic FPC waste discharge equipment

PendingCN113787149AImprove production efficiencyRealize automatic controlShaping toolsStripping-off devicesProcess engineeringFully automated

The invention discloses full-automatic FPC waste discharge equipment. The full-automatic FPC waste discharge equipment comprises a mounting platform and a rotary feeding mechanism, a feeding and discharging transferring mechanism, a stamping waste discharge mechanism and a discharging stacking mechanism which are mounted on the mounting platform; the rotary feeding mechanism is used for automatically feeding FPC workpieces to be subjected to waste discharge; the feeding and discharging transferring mechanism is used for transferring the FPC workpieces in the rotary feeding mechanism into the stamping waste discharge mechanism and transferring and discharging products obtained after waste discharge in the stamping waste discharge mechanism; the stamping waste discharge mechanism is used for conducting automatic waste discharge work on the FPC workpieces; and the discharging stacking mechanism is used for stacking the products obtained after waste discharge and diaphragms at intervals. The full-automatic FPC waste discharge equipment has the advantage of being high in automation degree, the waste discharge efficiency can be greatly improved during actual implementation, labor cost and time cost are saved, the machining quality and the yield of products can be improved, and production benefits of enterprises can be further improved.

Owner:SHENZHEN BAOMING TECH

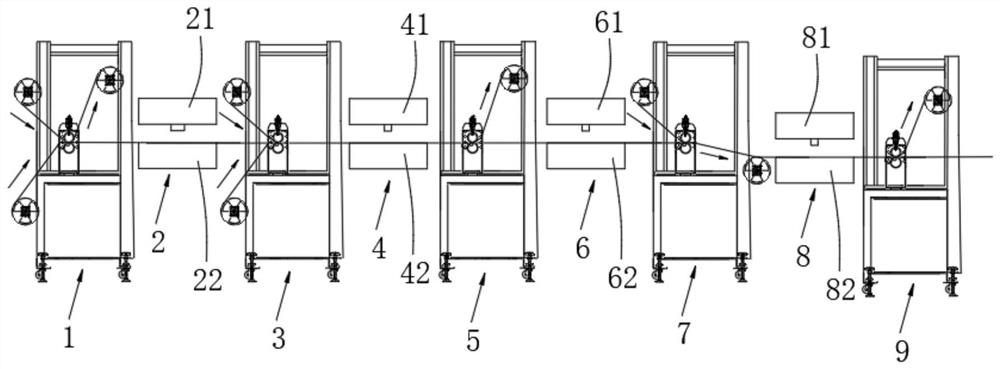

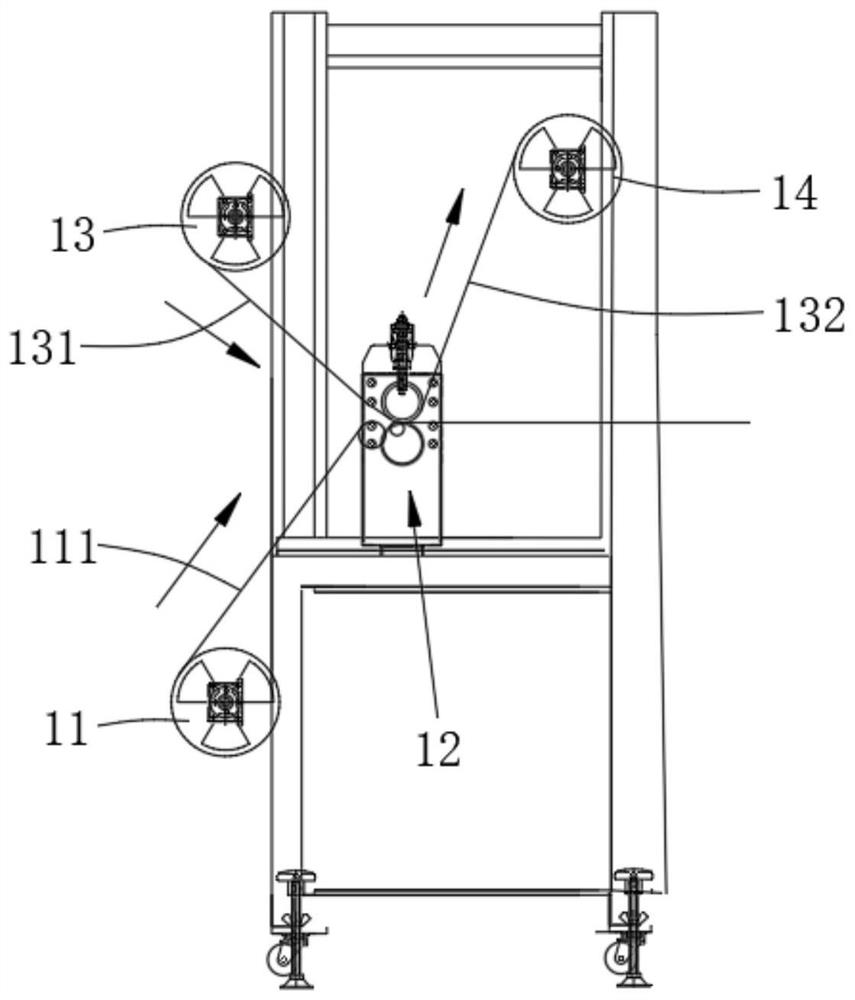

Non-stop waste discharge device for label production

PendingCN110843018AEasy to cleanAvoid the problem of scheduled shutdown to clean the waste edge collection rollerMetal working apparatusDischarge efficiencyMechanical engineering

The invention discloses a non-stop waste discharge device for label production. The non-stop waste discharge device comprises a rack, and further comprises a cylinder, a pressure lever, a pull roll, ascraper, an air blowing device, a guiding channel and a recycle bin, wherein the cylinder is mounted and fixed on the surface of the rack; a fixing end is fixed to the head end of a rod body of the cylinder; the head end of the rod body of the cylinder is connected and fixed to the pressure lever; the pull roll is mounted on the right side of the upper end of the pressure lever and above the cylinder; the scraper is mounted below the pull roll; a ventilation opening is formed in the upper surface of the head end of the guiding channel; the air blowing device is mounted on the left side abovethe guiding channel; and the recycle bin is arranged at the tail end of the guiding channel. Waste edges are guided out through the pull roll, and are quickly blown in the recycle bin through the guiding channel and the air blowing device, the waste edges in the recycle bin are very conveniently cleaned, the problem that in the prior art, a machine needs to be stopped in time to clean a waste edgecollecting roll is avoided, time is saved, and the waste discharge efficiency is improved.

Owner:竹林伟业科技发展(天津)股份有限公司

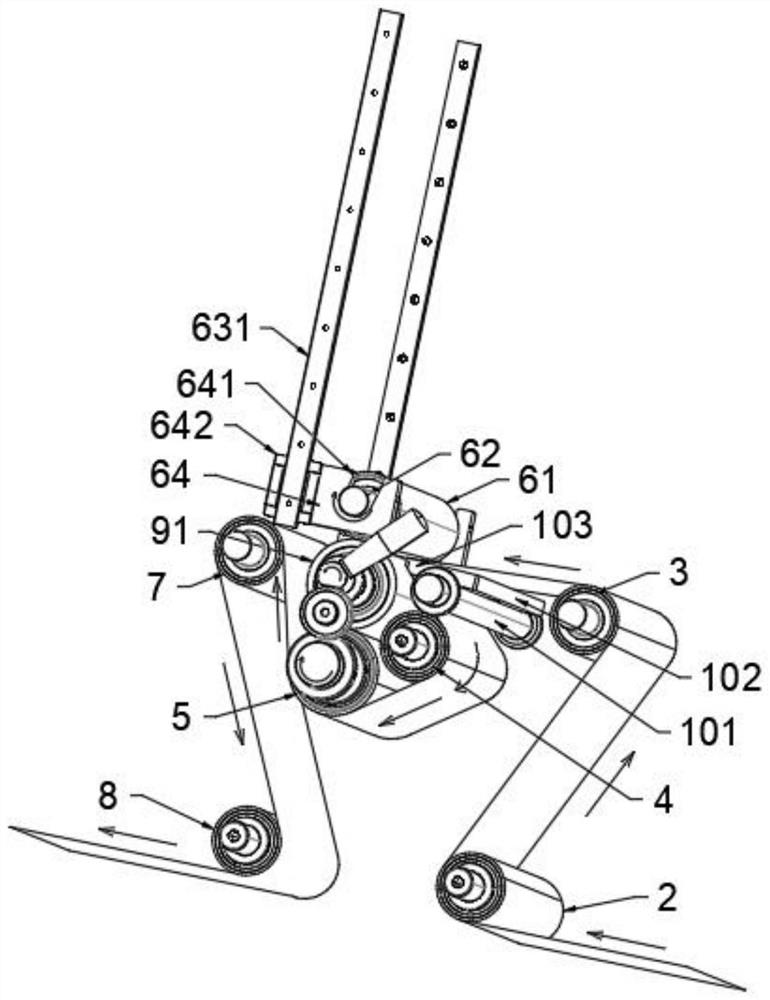

Waste discharging device and equipment for windowing machining

PendingCN112320449AEfficient separationEfficiently separate and collectArticle deliveryWebs handlingWindow openingProcess engineering

The invention provides a waste discharging device and equipment for windowing machining, and belongs to the field of windowing label waste discharging equipment. The waste discharging device for windowing machining comprises two parallel supporting bodies, and a first guide roller, a second guide roller, a third guide roller, a fourth guide roller, a waste collecting mechanism, a fifth guide roller, a sixth guide roller, a transmission mechanism and a separating mechanism which are rotationally mounted inside two supporting bodies; the first guide roller and the sixth guide roller are symmetrically mounted at the lower ends of the supporting bodies; and the second guide roller and the fifth guide roller are symmetrically mounted at the positions, corresponding to the outsides of the thirdguide roller, the fourth guide roller, the waste collecting mechanism and the separating mechanism, at the upper ends of the supporting bodies. The waste discharging device for windowing machining issimple in structure and convenient to use, the waste discharging efficiency of products can be effectively improved, and the human input for product machining is reduced.

Owner:上海弘华数码设备有限公司

Systems and methods for processing low rank coal

ActiveCN105537120BImprove sorting efficiencySolve the problem of low gangue discharge rateGas current separationDrying gas arrangementsProcess engineeringEngineering

Owner:SHENWU TECH GRP CO LTD

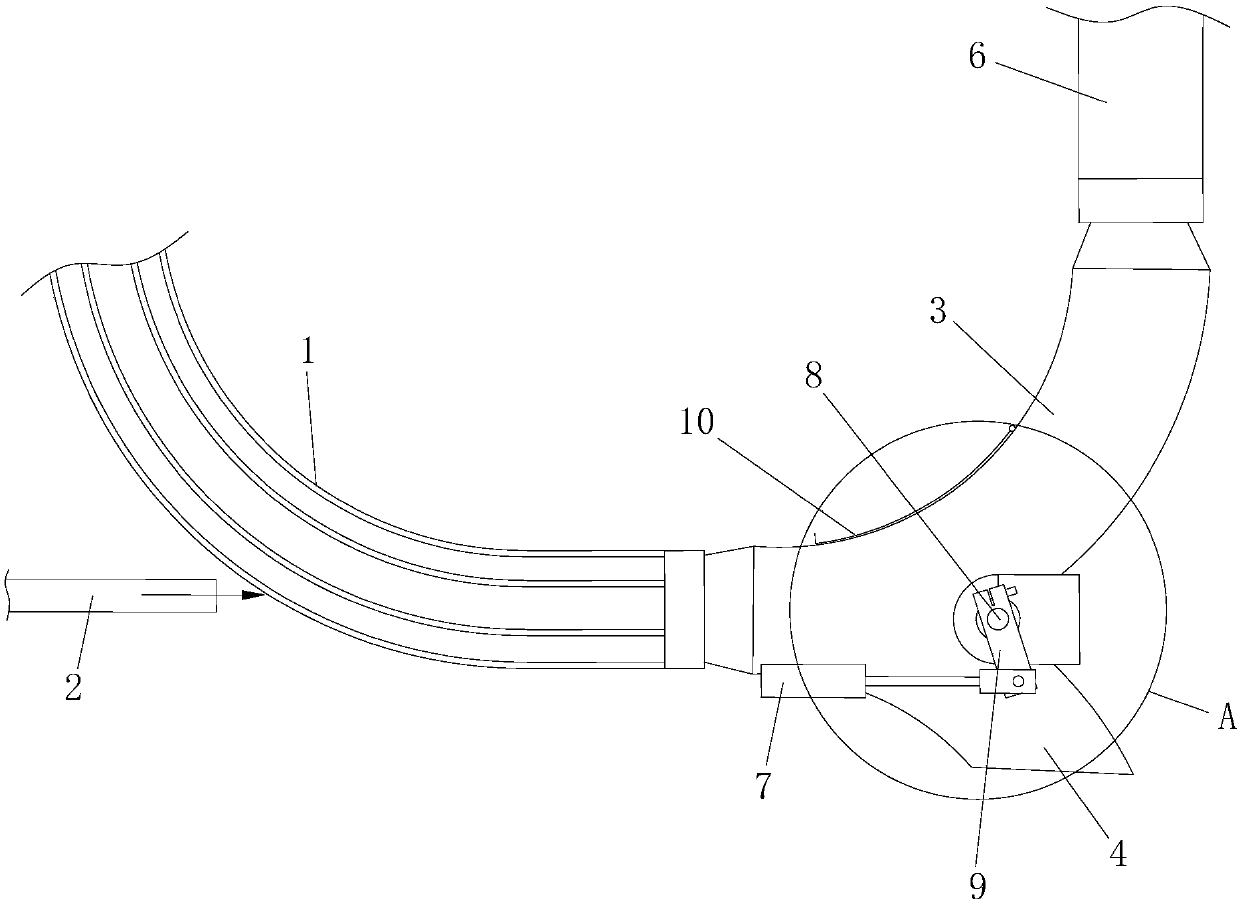

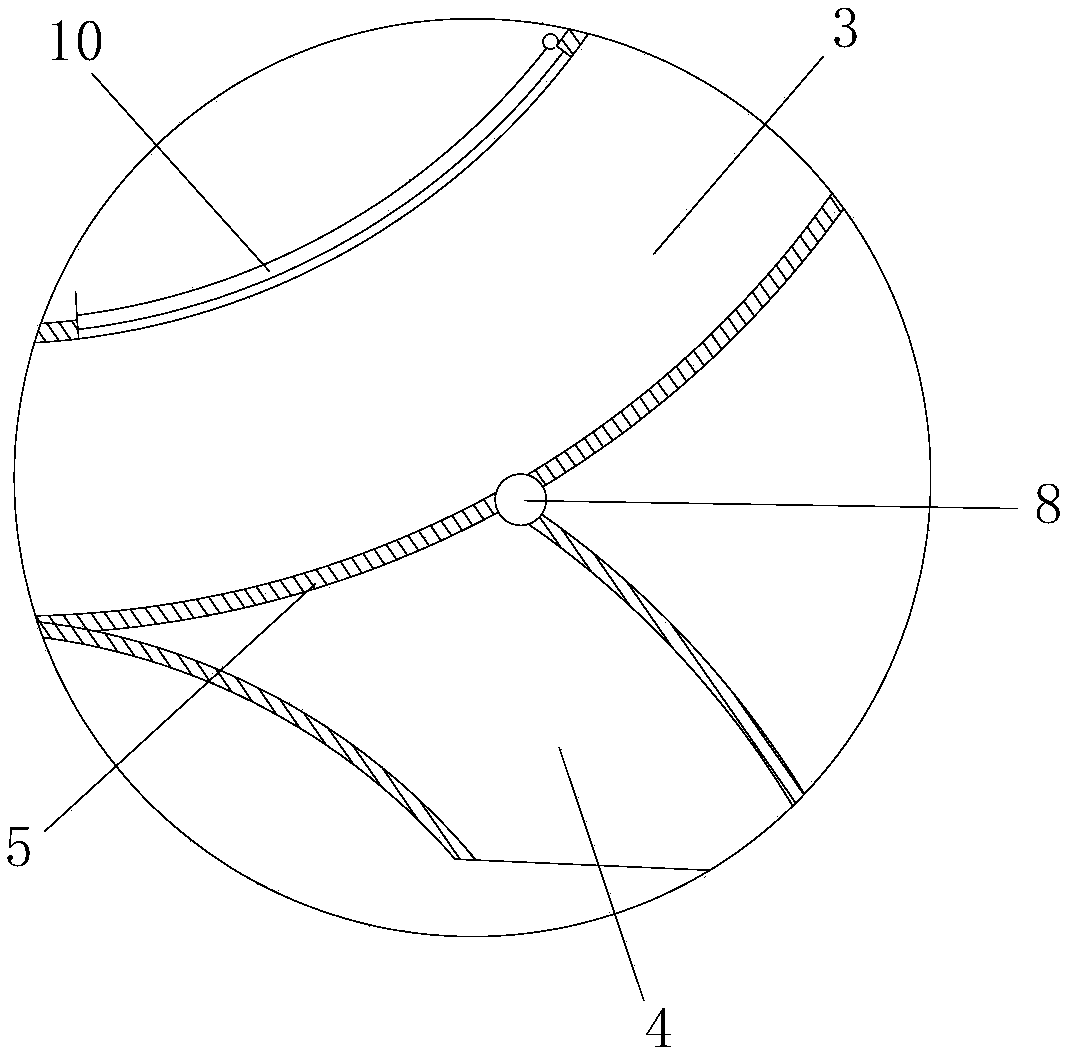

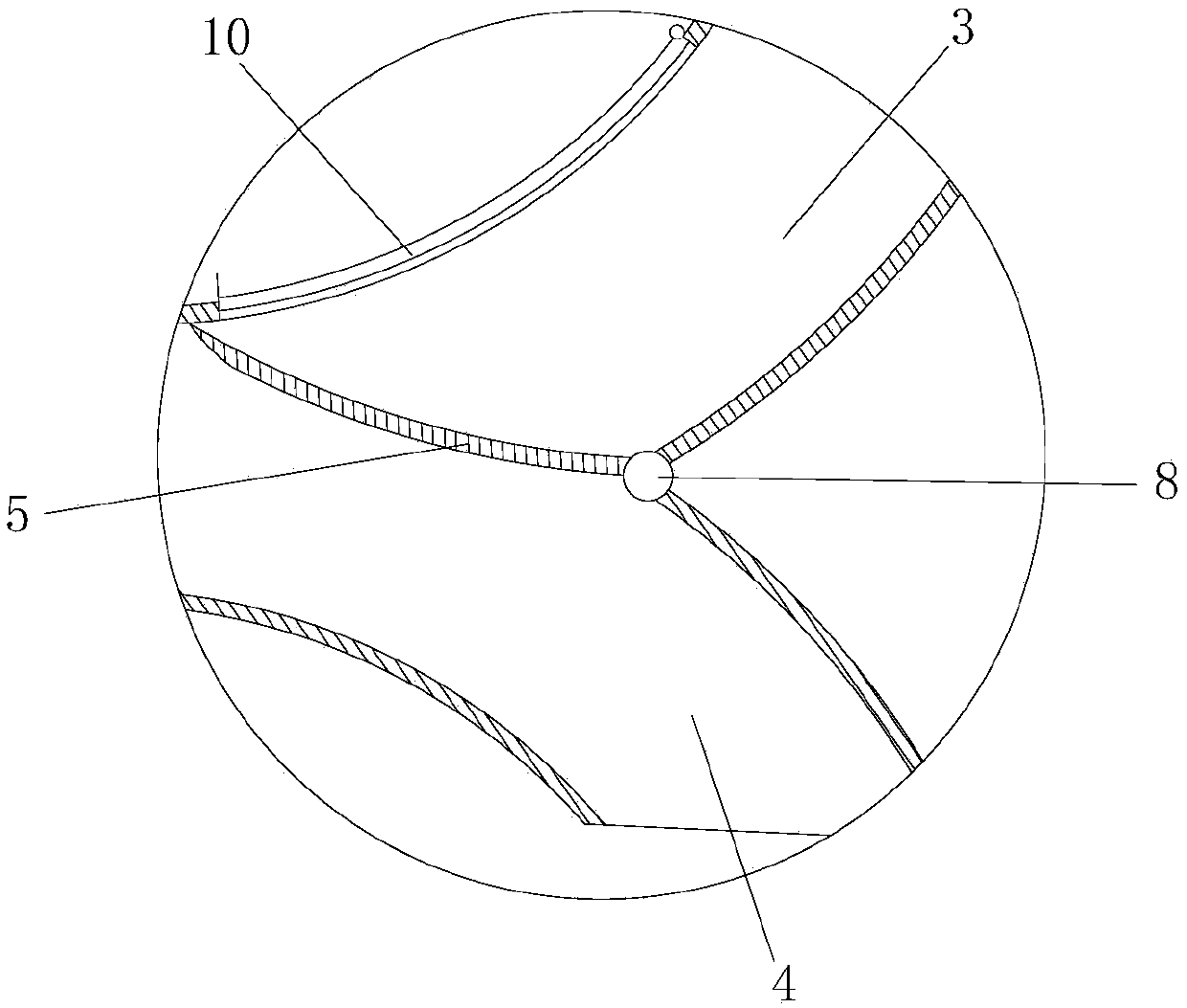

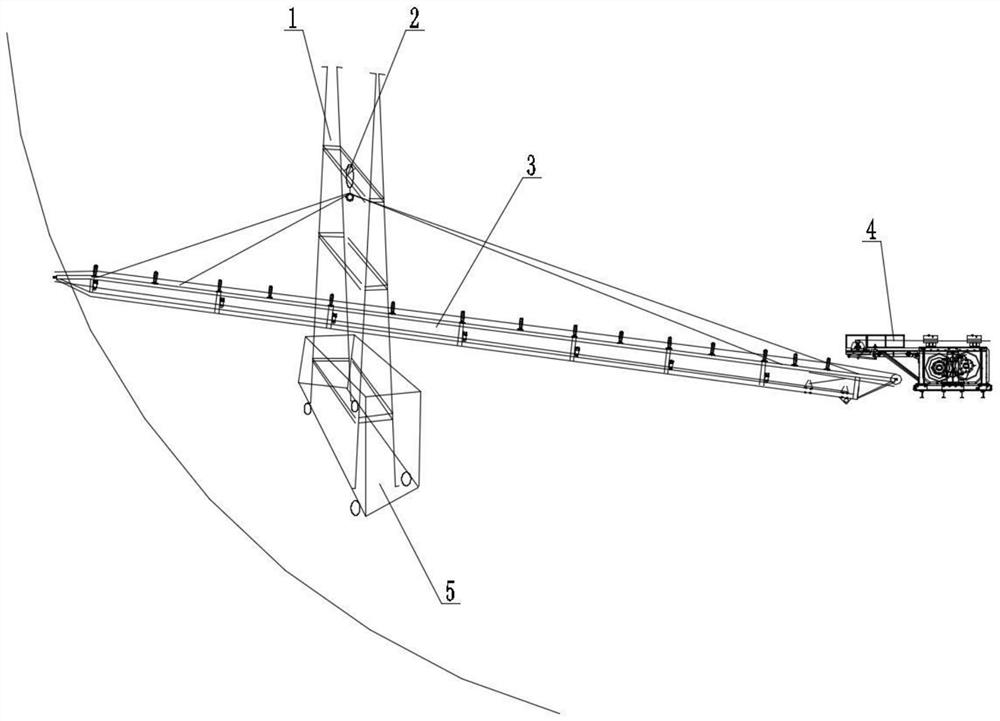

Pilot-tunneling roadway belt conveyor continuous gangue removing device for large-curvature-radius winding roadway construction

PendingCN111846761AOptimize roadway designImprove the efficiency of gangue discharge in the back roadConveyorsEarth drilling and miningCoal miningContinuous use

The invention discloses a pilot-tunneling roadway belt conveyor continuous gangue removing device for large-curvature-radius winding roadway construction, and belongs to the field of coal mining equipment. The pilot-tunneling roadway belt conveyor continuous gangue removing device for large-curvature-radius winding roadway construction comprises a pilot-tunneling roadway, wherein a belt conveyor is arranged on an upper track and a lower track so as to be used for conveying raw coal and gangue; one end of a large-curvature roadway is connected onto the lower track; the other end of the large-curvature roadway is connected onto the upper track; the pilot-tunneling roadway is arranged on the outer side face of a curved face of the large-curvature roadway; one end of the pilot-tunneling roadway is connected onto the lower track; and the other end of the pilot-tunneling roadway is connected onto the upper track. According to the pilot-tunneling roadway belt conveyor continuous gangue removing device for large-curvature-radius winding roadway construction, the roadway design is optimized, the posterior gangue removing efficiency is improved, the equipment maintenance labor is reduced, and the pilot-tunneling roadway belt conveyor continuous gangue removing device for large-curvature-radius winding roadway construction can be widely applied to large-curvature-radius winding roadways such as a mine lot track car field and can solve the problem that the belt conveyor is off-tracking caused by the excessive belt turning radius of the belt conveyor, so that the belt conveyor can be continuously used.

Owner:HUAIBEI MINING IND

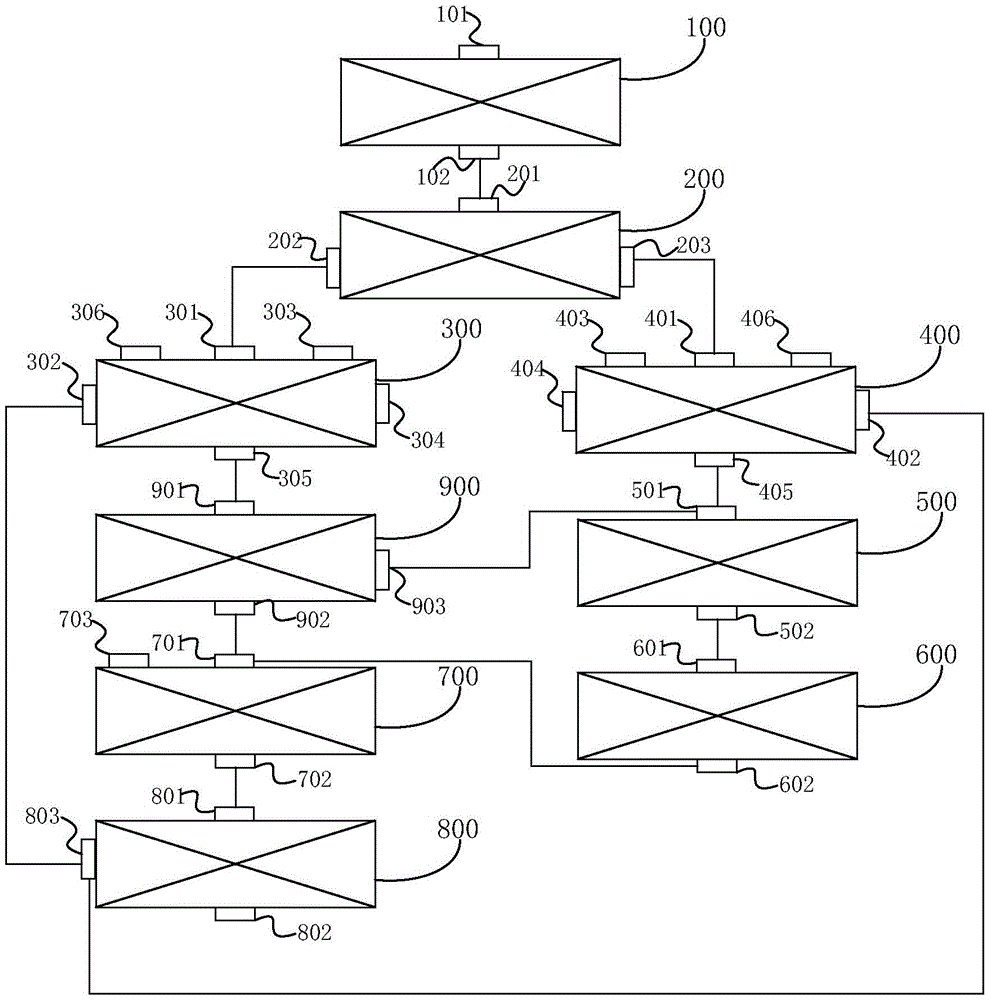

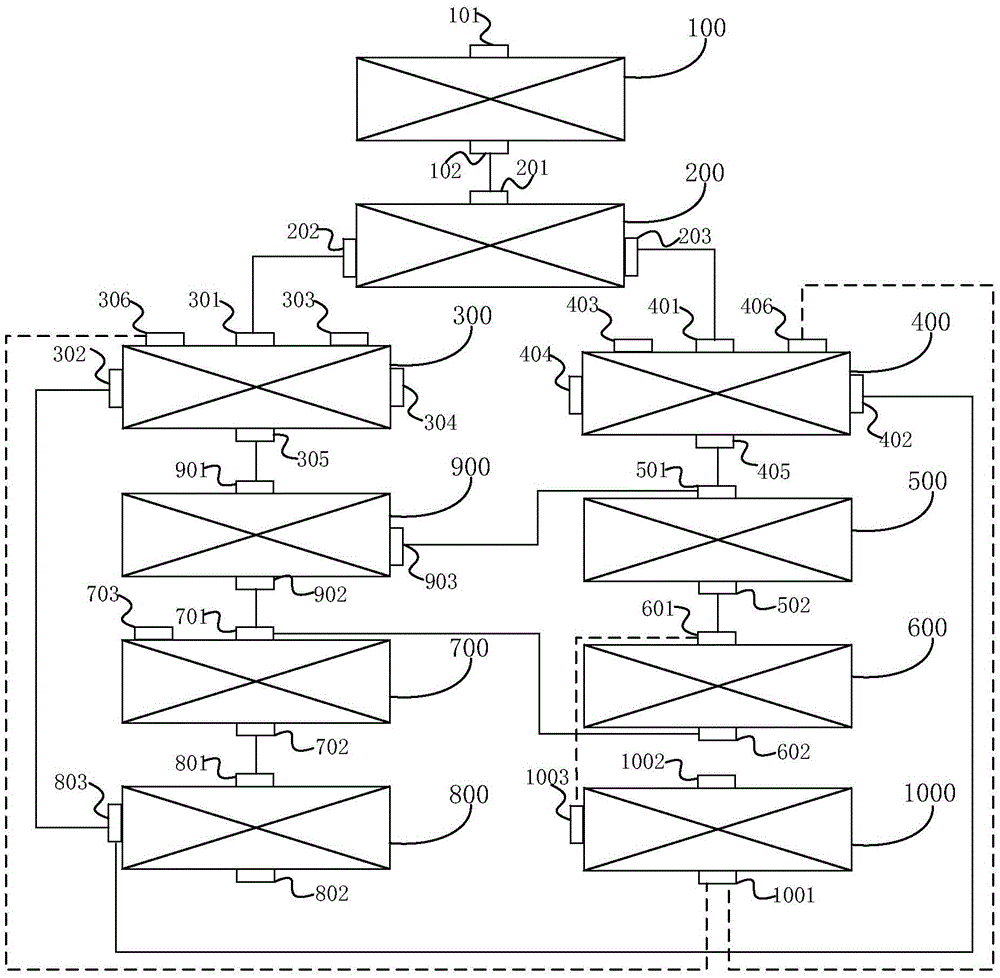

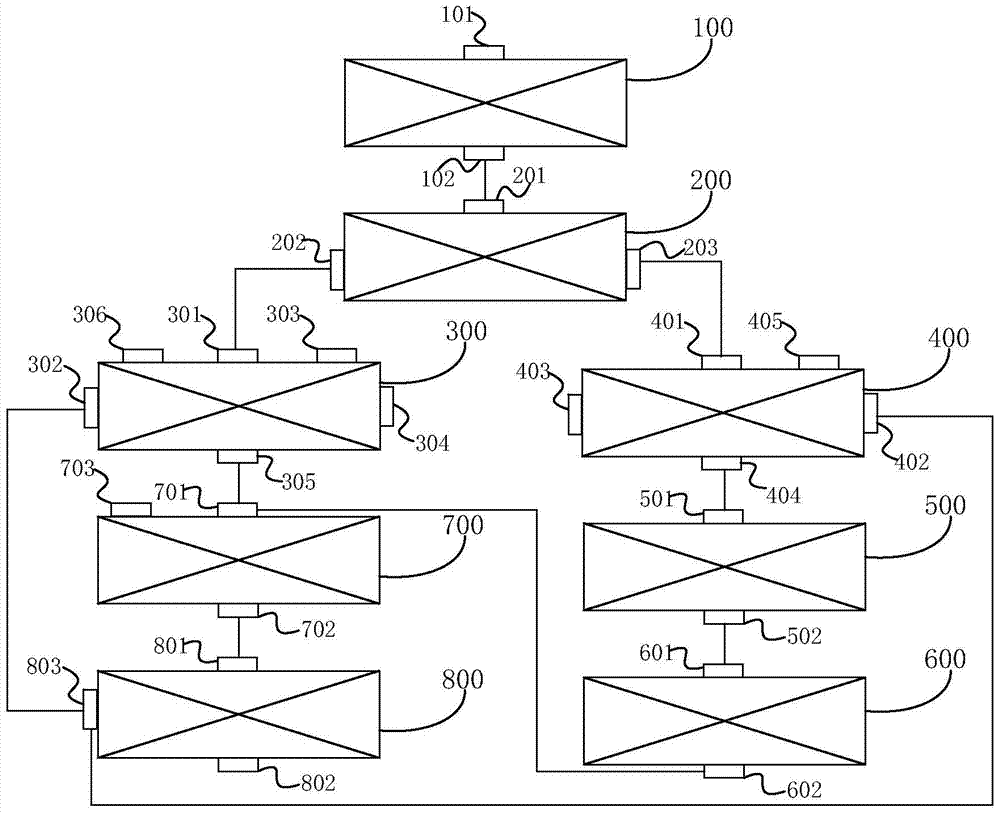

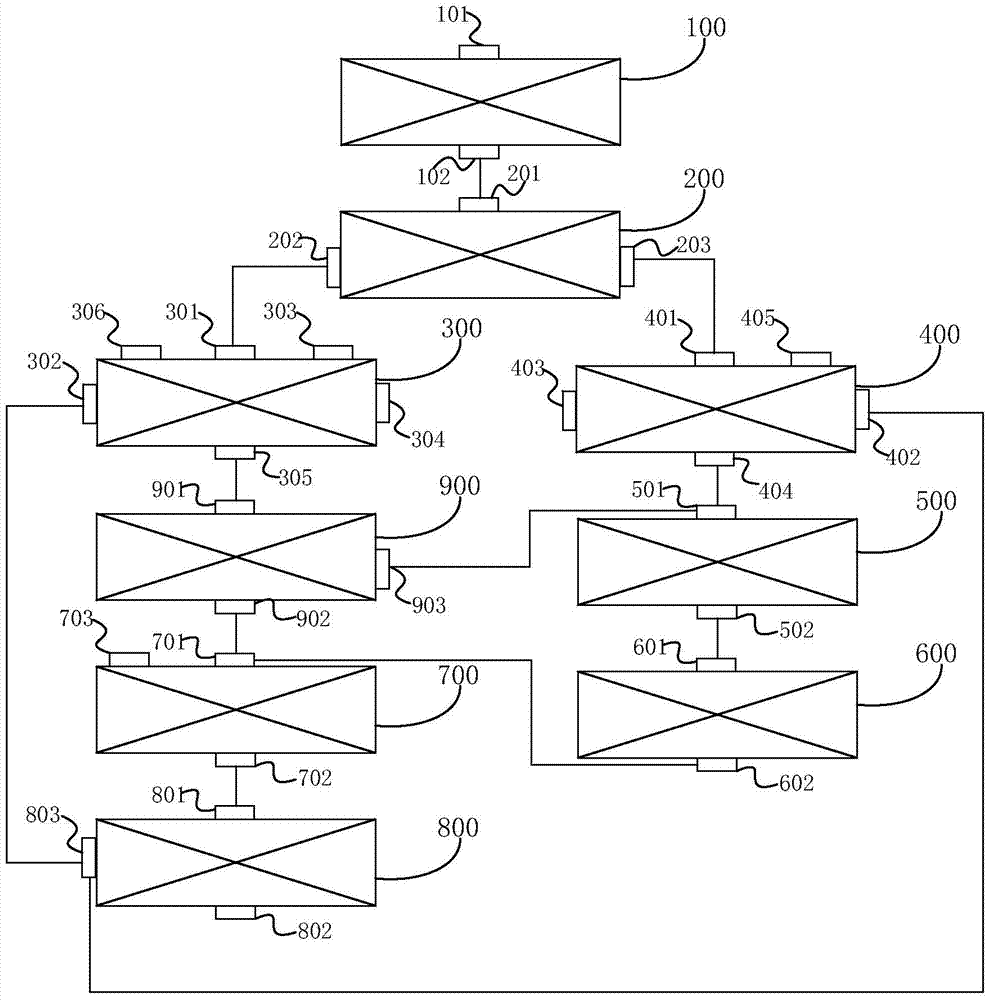

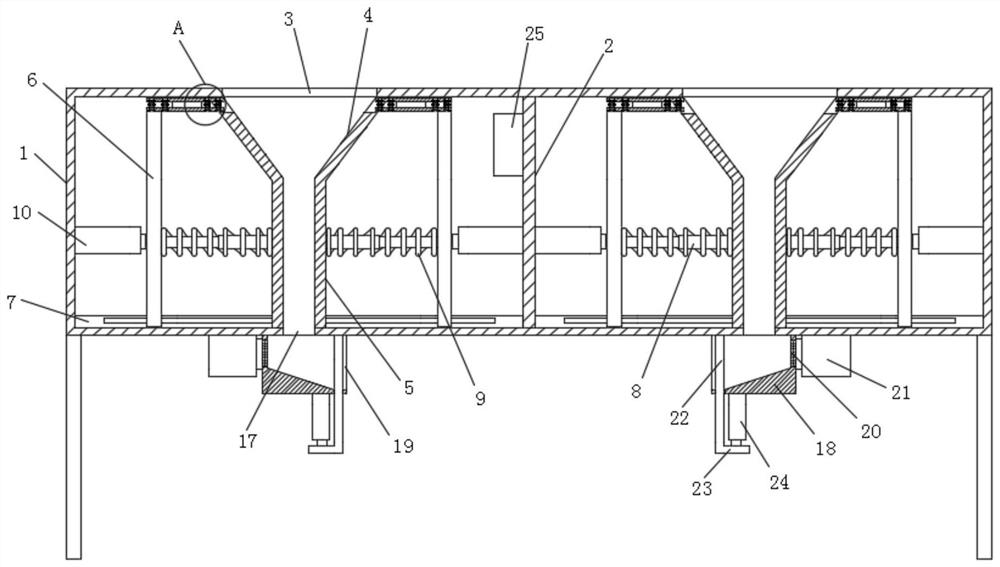

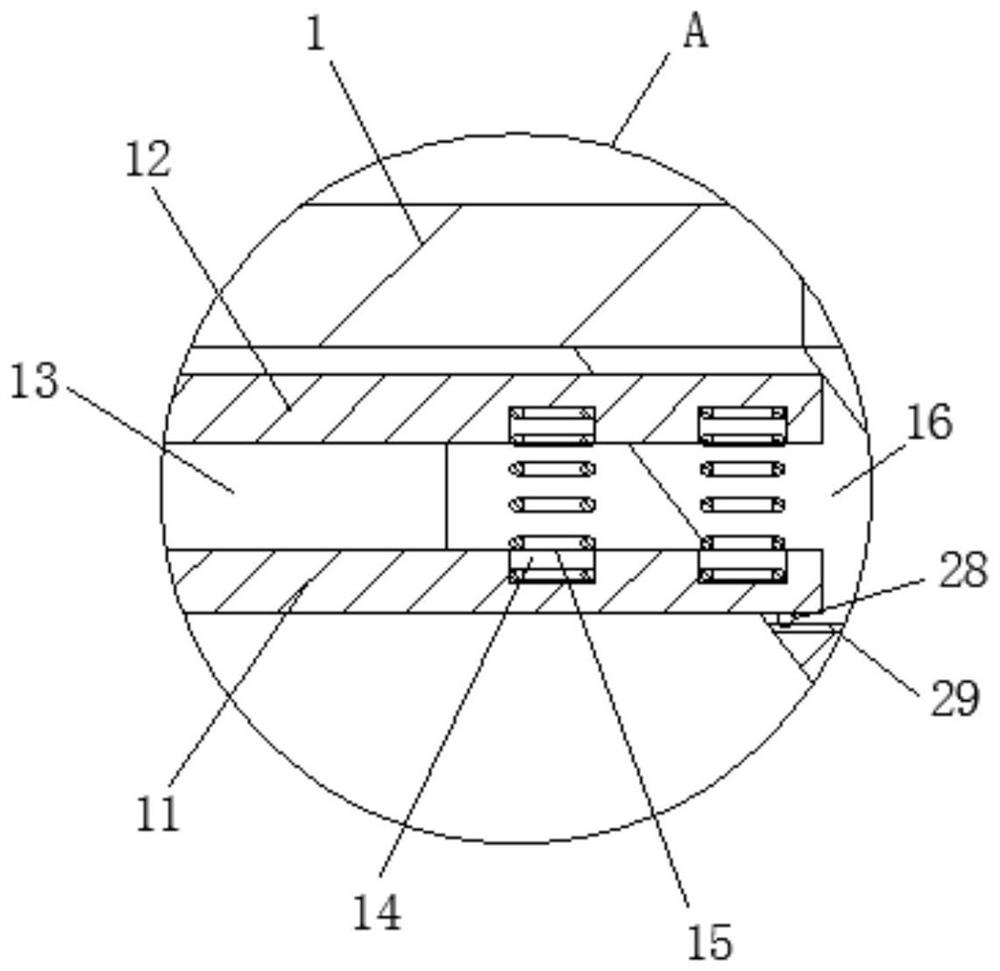

Automatic waste discharging system and method in automatic mold production line

ActiveCN111889578AAvoid cloggingSpeed up entryMetal-working feeding devicesStripping-off devicesProcess engineeringWaste material

The invention discloses an automatic waste discharging system and method in an automatic mold production line. The system comprises a mold table, a partition plate is fixedly installed in the middle of the inner side of the mold table, automatic waste discharging units are arranged at two ends of the partition plate, a stock bin and a waste channel are sequentially arranged in the mold table fromtop to bottom, a waste guiding-out device is installed at the lower end of the mold table and communicates with a falling outlet of the waste channel, a stock bin opening and closing mechanism is arranged in the mold table and used for controlling opening and closing of the stock bin, a backwashing device is arranged on one side of the waste guiding-out device and communicates with the waste channel, and a controller is installed on one side of the partition plate. According to the automatic waste discharging system and method, a gravity sensing plate assembly is arranged at the position of afalling inlet in a closed mode, opening and closing of the stock bin opening and closing mechanism are realized by monitoring the pressure, meanwhile, when the waste channel is blocked by waste, the backwashing device is adopted to enable the waste channel to be in a negative pressure state, the waste is promoted to enter a waste box, so that waste blockage is avoided, and the waste discharging efficiency is improved.

Owner:HUNAN TONGXIN MOLD MFG

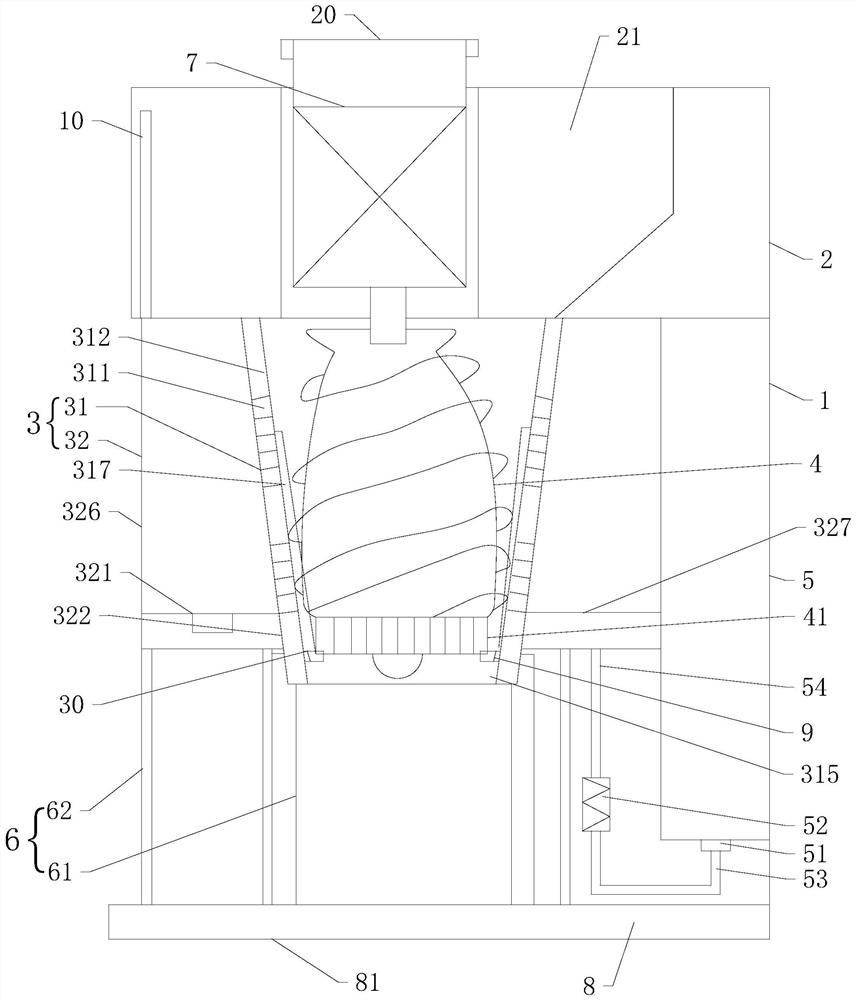

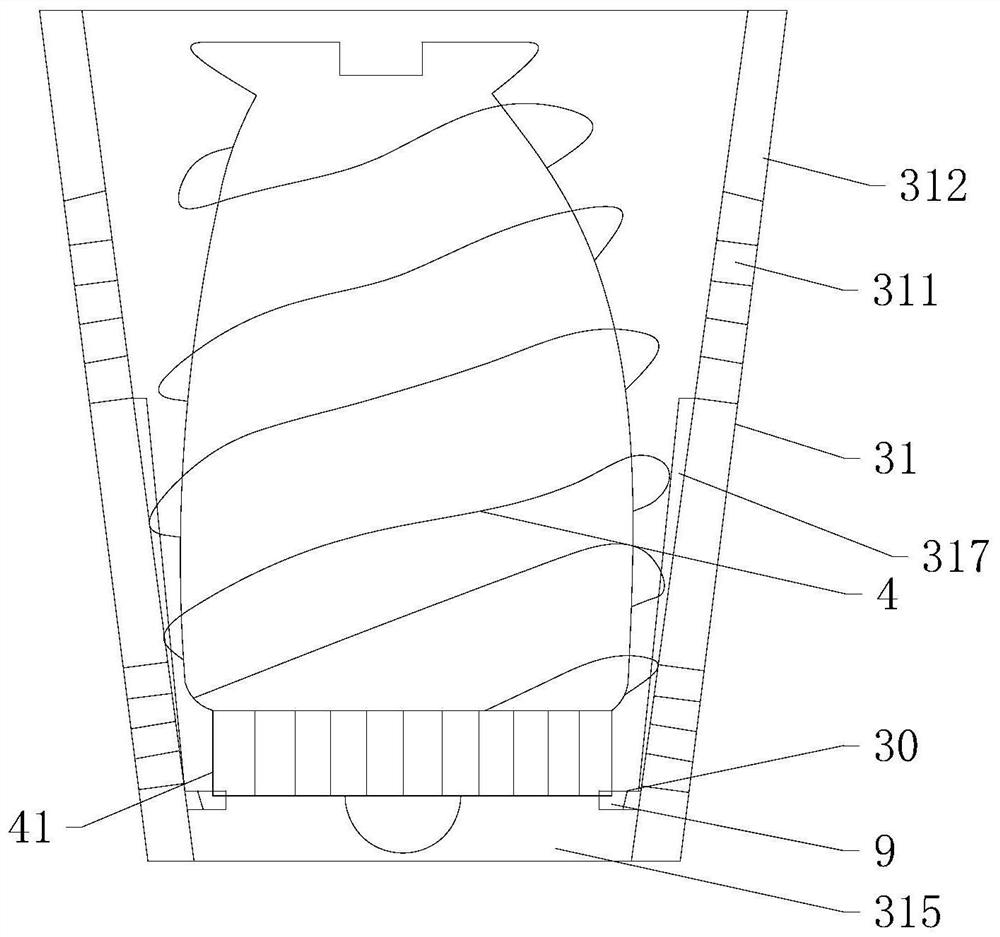

Control method of multifunctional food processor

PendingCN114847744AGuaranteed rotation effectConvenient waste disposalStrainersProcess engineeringMechanical engineering

The invention provides a control method of a multifunctional food processor, the food processor comprises a juice squeezing container and a screw rod arranged in the juice squeezing container, the food processor is characterized in that the bottom of the juice squeezing container is provided with a waste discharge channel, the screw rod is driven to be at a first working position for closing the waste discharge channel, and the screw rod rotates in the juice squeezing container; and the driving screw rod is located at a second working position for opening the waste discharging channel, and waste discharging work is conducted through the waste discharging channel. The screw can be switched between two working positions in the juicing or cleaning working process, operation is convenient, the juice yield of fruit and vegetable juice or soybean milk made through the control method is higher, and the residue and juice separation effect is good; when the control method is used for executing cleaning work, the cleaning effect is good, automatic cleaning can be achieved, and during automatic cleaning, the cleaning work is simpler, and cleaning is more thorough.

Owner:JOYOUNG CO LTD

System and method for automatic waste discharge in automatic mold production line

ActiveCN111889578BAvoid cloggingSpeed up entryMetal-working feeding devicesStripping-off devicesProcess engineeringSilo

The invention discloses an automatic waste discharge system and method in an automatic mold production line. The system includes a mold table, the middle part of the inner side of the mold table is fixed with a partition, and the two ends of the partition are equipped with an automatic waste discharge unit. The lower end of the mold table is in communication with the blanking outlet of the waste channel. The opening and closing mechanism of the silo is arranged in the mold table and is used to control the switch of the silo. Connected, the controller is installed on one side of the partition. In the present invention, the gravity sensing plate assembly is arranged at the position of the blanking inlet, and the opening and closing of the opening and closing mechanism of the silo is realized by monitoring the pressure. At the same time, when the waste material blocks the waste material channel, the backwashing device is used to keep the waste material channel in a negative pressure state. , to promote waste into the waste box, to avoid waste clogging, and to improve the efficiency of waste discharge.

Owner:HUNAN TONGXIN MOLD MFG

A mechanical waste discharge device for rail vehicles

ActiveCN111572576BImprove stabilityWith shock absorbing effectRailway heating/coolingControl theoryMechanical engineering

The invention relates to the technical field of rail vehicles, in particular to a mechanical waste discharge device for rail vehicles, which includes a casing, sound-absorbing cotton is bonded around the inner wall of the casing, and a support is installed at the center of the inner wall of the bottom of the casing through bolts. The housing is welded with baffles on both sides of the inner wall close to the support seat. Beneficial effects of the present invention The top holding groove enables the top holding seat to be better bonded to the outer wall of the fan, improving the stability of the fan during operation. The top holding seat has a certain shock absorption effect on the fan through the action of the spring. The fan plays a very good protective role, thereby prolonging the service life of the fan. The sound insulation lining makes the fan reduce the noise generated by the air flow impacting the air duct when the fan draws air through the air inlet, and the sound-absorbing cotton further reduces the noise generated by the fan when it is working. Noise, provide passengers with a quiet environment, and improve the comfort of passengers when riding rail vehicles.

Owner:南京天普机电产品制造有限公司

Rotary gangue discharging system

PendingCN113844830AImprove securityAvoid uneven distributionConveyorsSupporting framesThermodynamicsEngineering

A rotary gangue discharging system comprises a gangue discharging conveyor belt and a gangue conveying conveyor belt which are sequentially arranged, the starting end of the gangue discharging conveyor belt is located below the tail end of the gangue conveying conveyor belt, the tail end of the gangue discharging conveyor belt is higher than the starting end, the gangue discharging conveyor belt is further connected with a support used for supporting the gangue discharging conveyor belt, and the support is connected with a winch used for pulling the support to rotate around the starting end of the gangue discharging conveyor belt. According to the rotary gangue discharging system, the gangue discharging direction can be controlled, the situation of uneven distribution is avoided, the safety degree of a gangue dump is improved, and the gangue discharging efficiency can be greatly improved.

Owner:义煤集团宜阳义络煤业有限责任公司

Waste discharging device for protective film waste and waste discharging method

InactiveCN113753632AReduce harmEasy to operateArticle deliveryWebs handlingAdhesive beltWaste material

The invention discloses a waste discharging device for protective film waste, and relates to the field of waste discharging devices. The waste discharging device comprises a rack, a driving roller, a winding roller and a clamping assembly; the rack is provided with a conveying roller set used for conveying a rubber belt body; the driving roller is rotationally arranged on the rack; the winding roller is detachably connected with the driving roller and can synchronously rotate along with the driving roller, so that a protective film is wound on the winding roller; the clamping assembly is used for clamping the end of the protective film. The waste discharging device can automatically collect the protective film waste, and the labor cost and the rejection rate of products are greatly reduced while the waste discharging efficiency is guaranteed. The waste discharging method is achieved on the basis of the waste discharging device, rapid waste discharging can be achieved through the waste discharging device, the waste discharging method is easy and convenient to operate, and the waste discharging efficiency of the protective film waste can be greatly improved.

Owner:成都冠佳科技有限公司

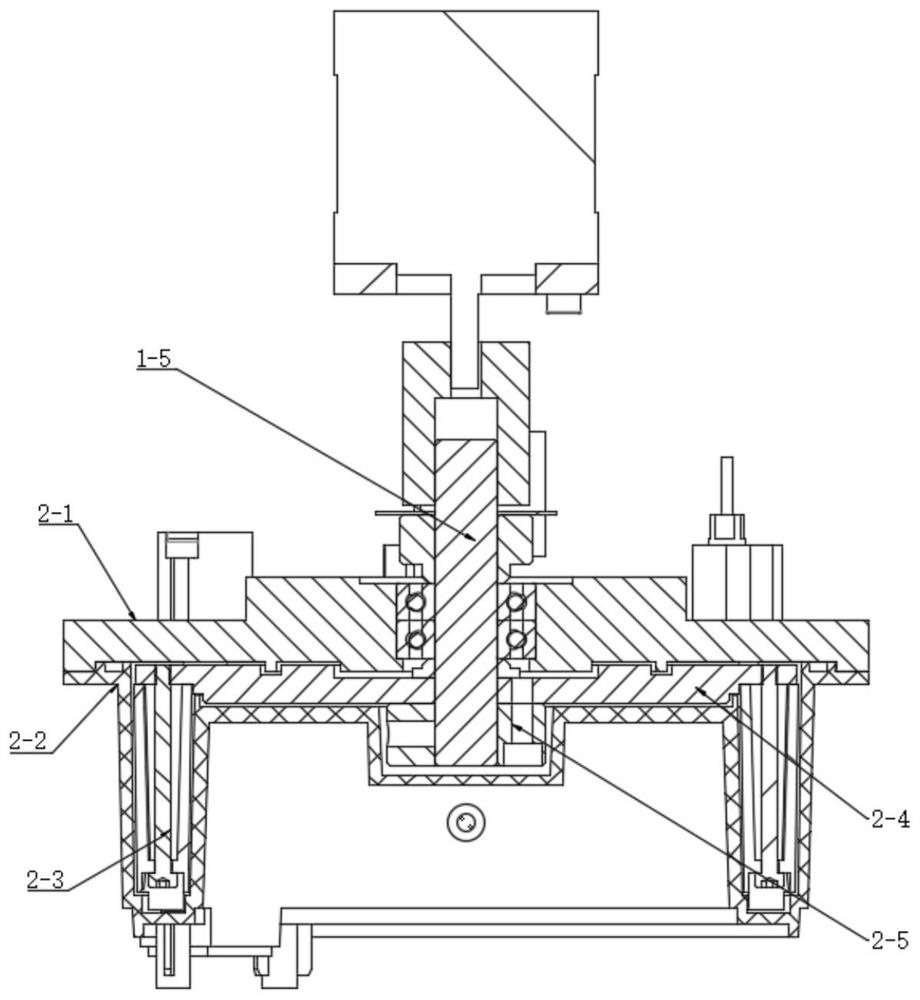

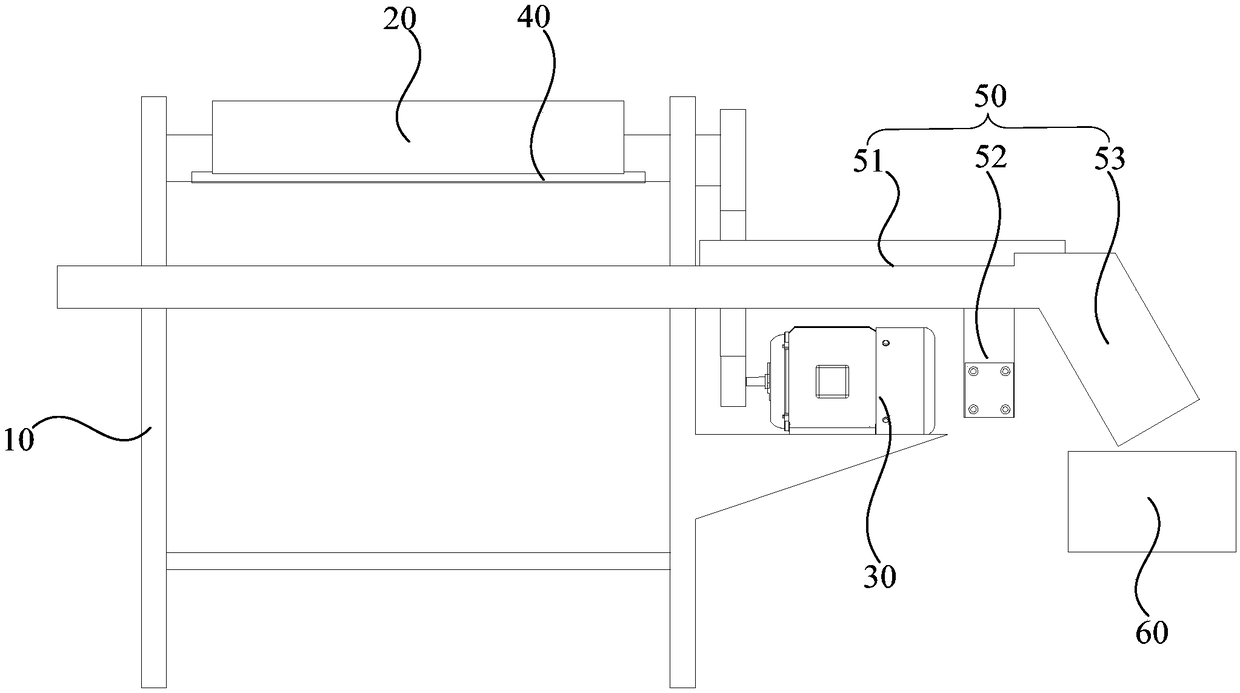

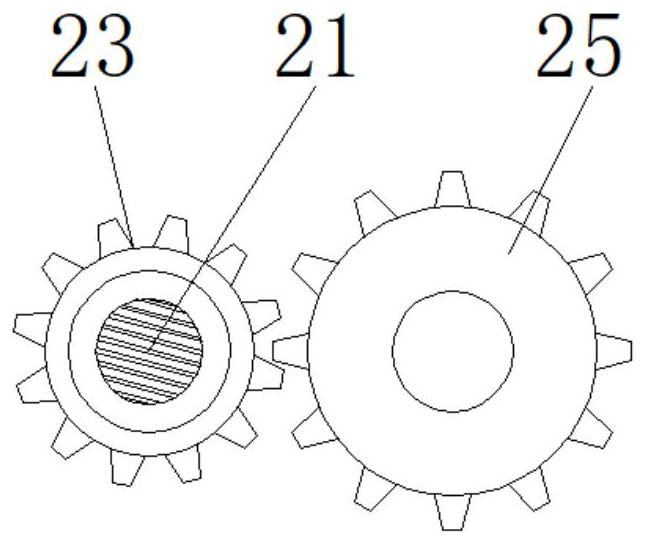

A conductive ring die-cutting machine with automatic waste discharge function

ActiveCN107336283BFor automatic dischargeImprove waste discharge efficiencyMetal working apparatusPunchingConductor Coil

The invention discloses a conducting ring die-cutting machine with an automatic waste discharge function. The conducting ring die-cutting machine comprises a feeding conveying device, a die-cutting device and a discharging conveying device which are arranged in sequence. The die-cutting device comprises a machine frame, a guide column, a punching die and the like. The discharging conveying device comprises a driving roller, a driven roller assembly, a waste winding device, a finished product winding device and the like. The conducting ring die-cutting machine can automatically complete waste discharge operation and is high in waste discharge operation efficiency, and the labor cost can be reduced.

Owner:重庆信强科技有限公司

Die-cutting equipment for tape processing

ActiveCN111037641BAvoid fluffingImprove waste discharge efficiencyMetal working apparatusHydraulic cylinderAdhesive belt

The invention belongs to the technical field of adhesive tape processing, and particularly relates to a die cutting device for adhesive tape processing. The die cutting device comprises a bottom plate, wherein a hydraulic machine and a mounting plate are fixed at the top end of the bottom plate; the hydraulic machine comprises a workbench, a guide rod, a movable cross beam and a hydraulic cylinder; a first driving motor and a second driving motor are fixed on the side wall of the mounting plate; rotating rollers are fixed at the output shaft ends of the first driving motor and the second driving motor; the rotating rollers are used for winding an adhesive tape and a waste edge correspondingly; and more than two die cutting knives are fixed at the bottom end of the movable cross beam. According to the die cutting device, the adhesive tape is pressed through the arrangement of a pressing plate, so that the adhesive tape cannot be broken during die cutting, and the phenomenon that the cutedge of the adhesive tape is fluffed is avoided; and a limiting block is arranged to protect a product, so that the product cannot be taken up when being separated from the waste edge, and the wastedischarge efficiency of the adhesive tape is improved.

Owner:安徽灿宇光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com