Method for producing multifunctional outer circle chamfering knife with powder as raw material

A multi-functional, rounded chamfering technology, which is applied in the direction of cutting blades, accessories of toolholders, and tools used in lathes, etc., can solve the problems of no back angle, large resistance, and increased rotational friction of the tool, so as to improve cutting efficiency. , Improve waste discharge efficiency and facilitate demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

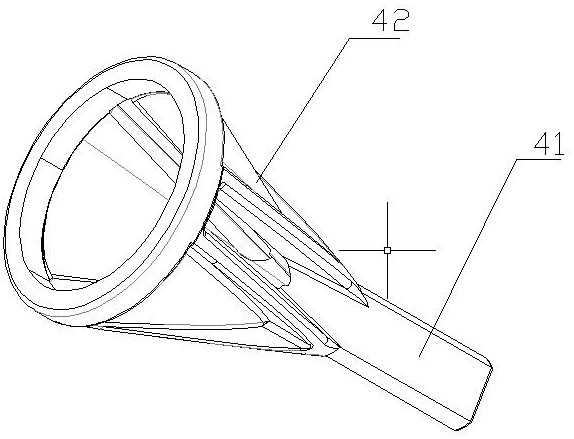

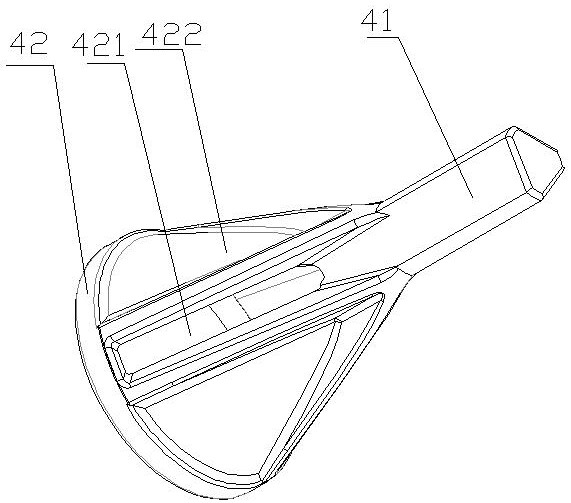

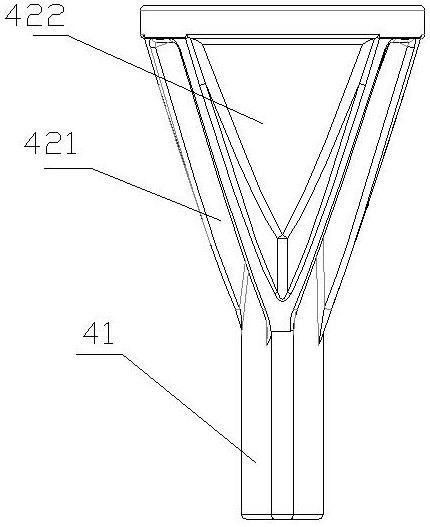

[0058] Such as Figure 1-8 As shown, a multifunctional cylindrical forming tool produced by injection molding technology includes a clamping portion 41 and a cutter body 42.

[0059] A cutter body 42 is arranged at the end of the clamping portion 41, and the cutter body 42 is a hollow bottomless conical structure. A fan-shaped cutter body 422 and a discharge hole 421 are arranged on the cutter body 42. The fan-shaped cutter body 422 and the discharge hole 421 are arranged at intervals, and the fan-shaped cutter body One side of the inner wall of 422 is provided with a knife edge 423 , and the other side of the inner wall of the fan-shaped knife body 422 is offset outward relative to the knife edge 423 to form a knife edge escape portion 424 . The cutter body is designed as a hollow conical structure, which can process the object to be chamfered into rounded corners. A certain space is staggered between the cutting edge and the cutting edge avoiding part, which is convenient f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com