Control method of multifunctional food processor

A food processing machine and multi-functional food technology, which is applied in household machinery for filtering food, kitchen utensils, household utensils, etc., can solve the problems that cannot be separated, cannot be automatically adjusted, and is not easy to clean, so as to achieve easy waste discharge and cleaning. Easy juice separation and good juice extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

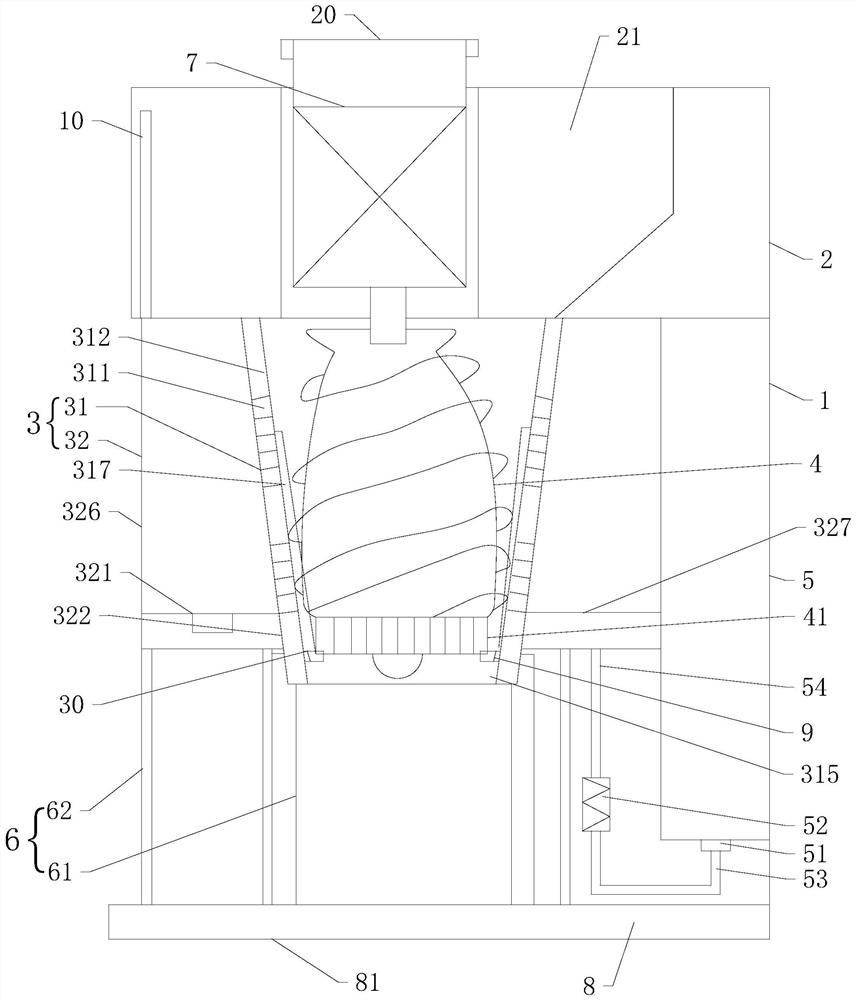

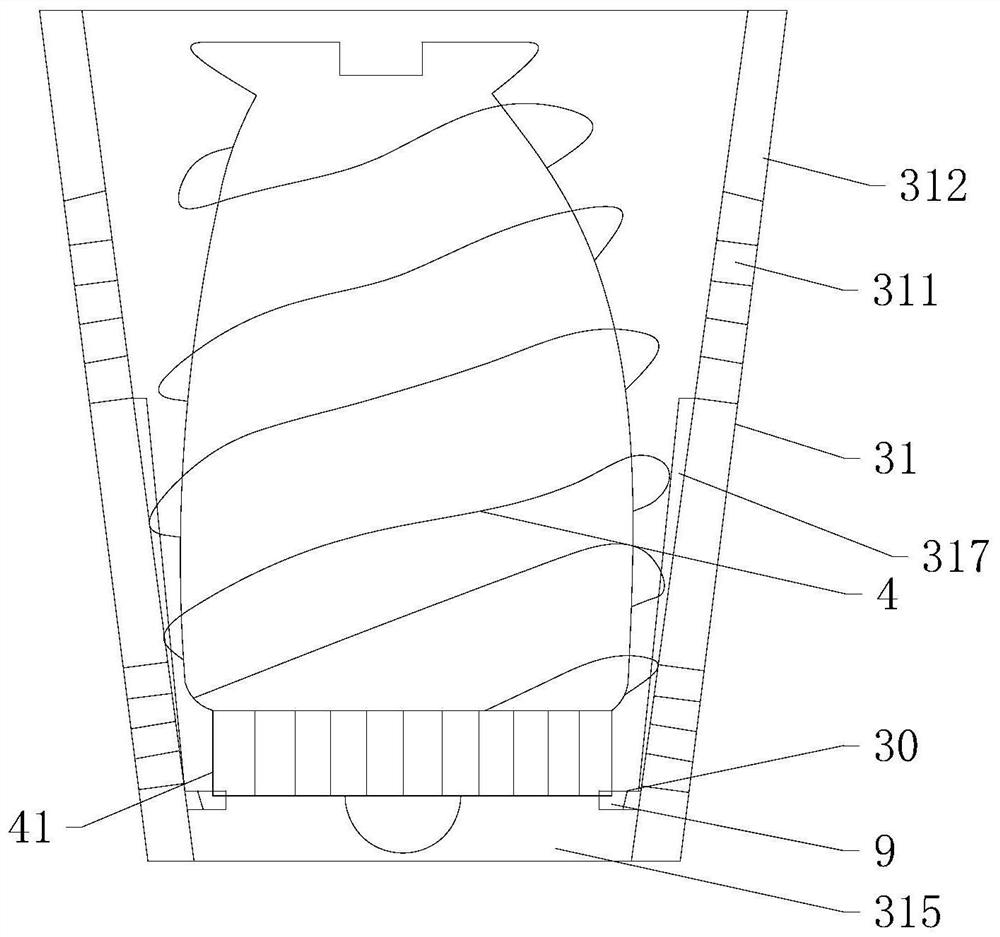

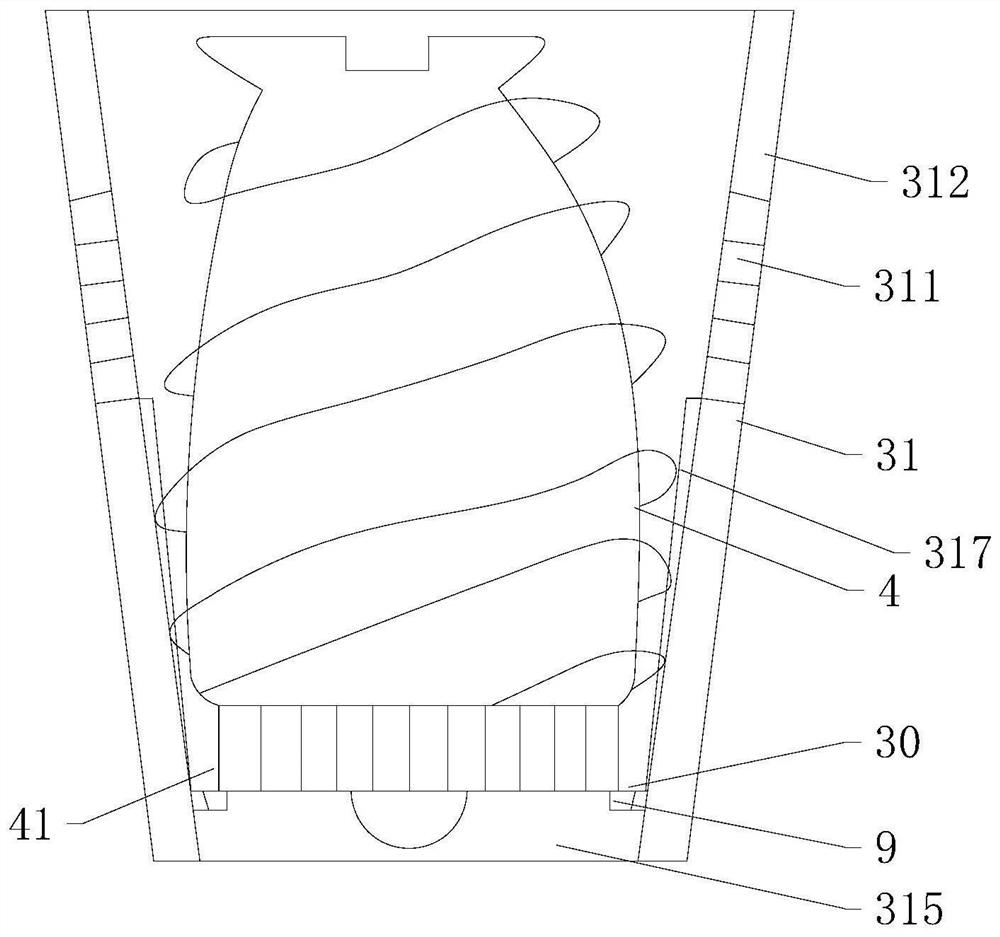

[0043] like Figure 1 to Figure 5 As shown, the multifunctional food processing machine includes a body, and the body includes a body 1 arranged vertically, a head 2 connected to the upper end of the body 1, and a base 8 arranged at the bottom of the body 1, which is arranged on the body 1 The juice squeezing container 3, the screw 4 and the control board 10 are arranged in the juice squeezing container 3, the motor 7 is provided in the machine head 2, and the juice squeezing container 3 includes a juice collecting chamber 32, and a juice collecting chamber 32 is arranged in the juice collecting chamber. The extrusion cylinder 31, the screw 4 is arranged in the extrusion cylinder 31, the grinding rib 317 is arranged in the middle of the extrusion cylinder 31, the juice collecting chamber 32 is installed on the machine head 2, the screw 4 is driven by the motor 7, and the screw 4 is connected with the extrusion cylinder. The grinding ribs 317 in 31 cooperate to squeeze, grind a...

Embodiment 2

[0077] The difference between this embodiment and the first embodiment is: the installation structure of the extrusion cylinder, the slag receiving container and the juice collecting chamber.

[0078] The first fixing ring 323 is provided at the bottom through hole 322 of the juice collecting chamber 32 of the multifunctional food processor in this embodiment, such as Image 6 As shown, the squeezing cylinder 31 is sleeved in the first fixing ring 323, and a sealing structure is arranged between the first fixing ring 323 and the squeezing cylinder 31, and the sealing structure is the sealing ring 9. This structure can also ensure the juice And water does not leak, so that the juice collecting chamber 32 and the squeezing cylinder 31 are easy to assemble and disassemble and easy to clean. At the same time, a second fixing ring 324 is arranged outside the bottom of the juice collecting chamber 32 , and the slag receiving container 61 is sleeved on the second fixing ring 324 , so...

Embodiment 3

[0082] The difference between this embodiment and the second embodiment is: the structure of the juice collecting chamber and the installation method of the slag receiving container.

[0083] In this embodiment, as Figure 7 As shown, the juice collecting cavity 32 of the multifunctional food processor is composed of a cavity body 326 and a cavity bottom 327, the cavity bottom 327 is detachably connected with the cavity body 326, the upper end of the extrusion cylinder 3 and the cavity of the juice collecting cavity 32 The body 326 is detachably connected to the bottom of the handpiece 2, and the inner side of the cavity bottom 327 is provided with a first fixing ring 323. A sealing structure is provided between the pressing cylinder 31, and a sealing structure is also set between the cavity 326 and the cavity bottom 327. The sealing structure is a silicone ring, so that the juice collecting cavity 32 is set to be composed of two parts, and the pressing cylinder 31 is detachab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com