Patents

Literature

34results about How to "Convenient waste disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

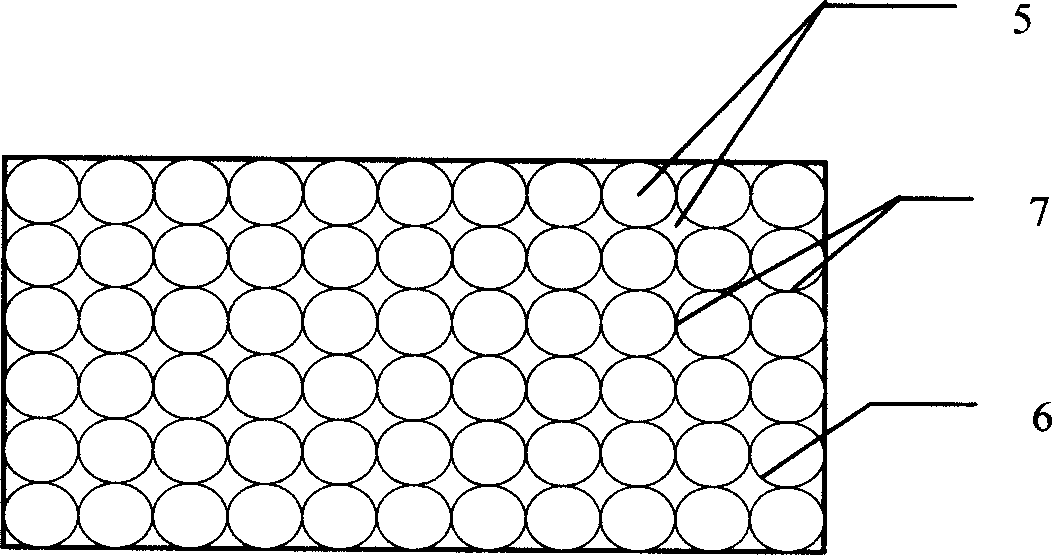

Chopped false proof paper products and method for manufacturing and using the same

InactiveCN1635219AConvenient waste disposalEasy to useSpecial paperCellulosic plastic layered productsAdhesive gluePulp and paper industry

Owner:张勇

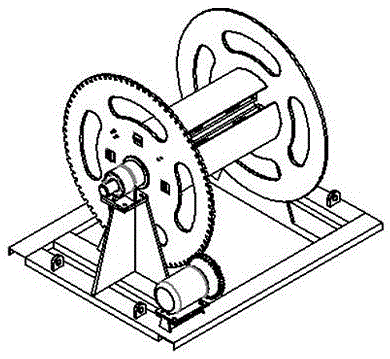

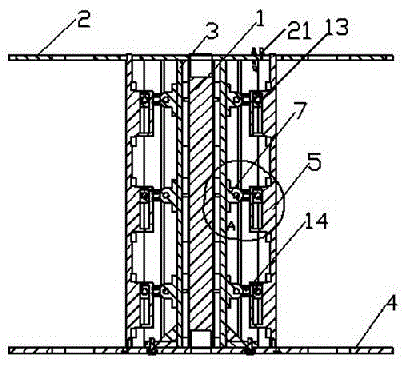

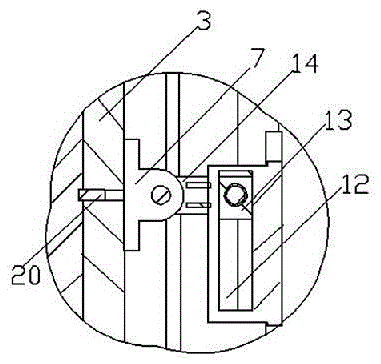

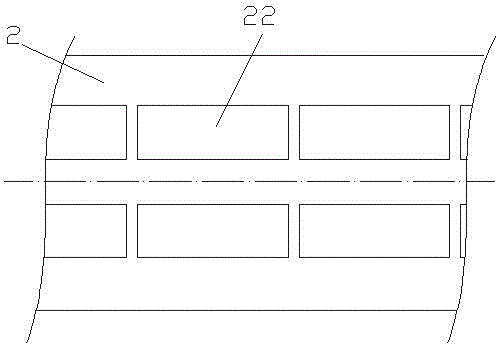

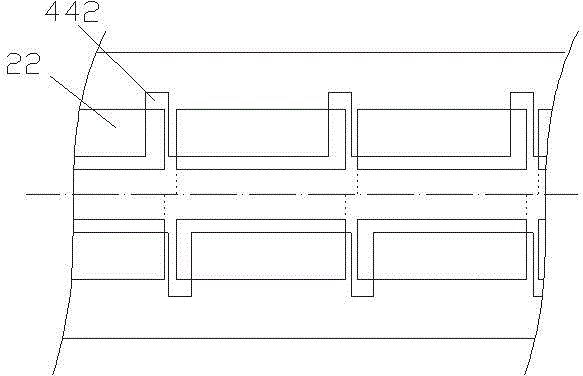

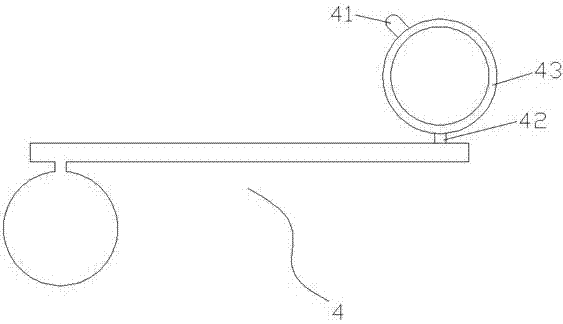

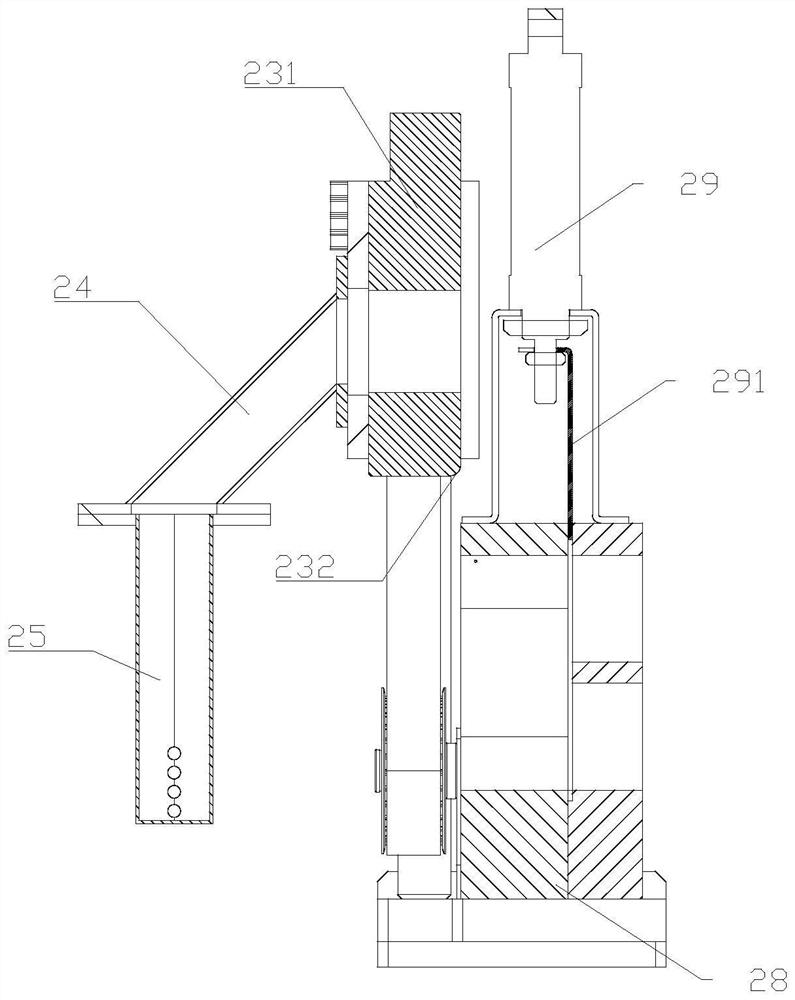

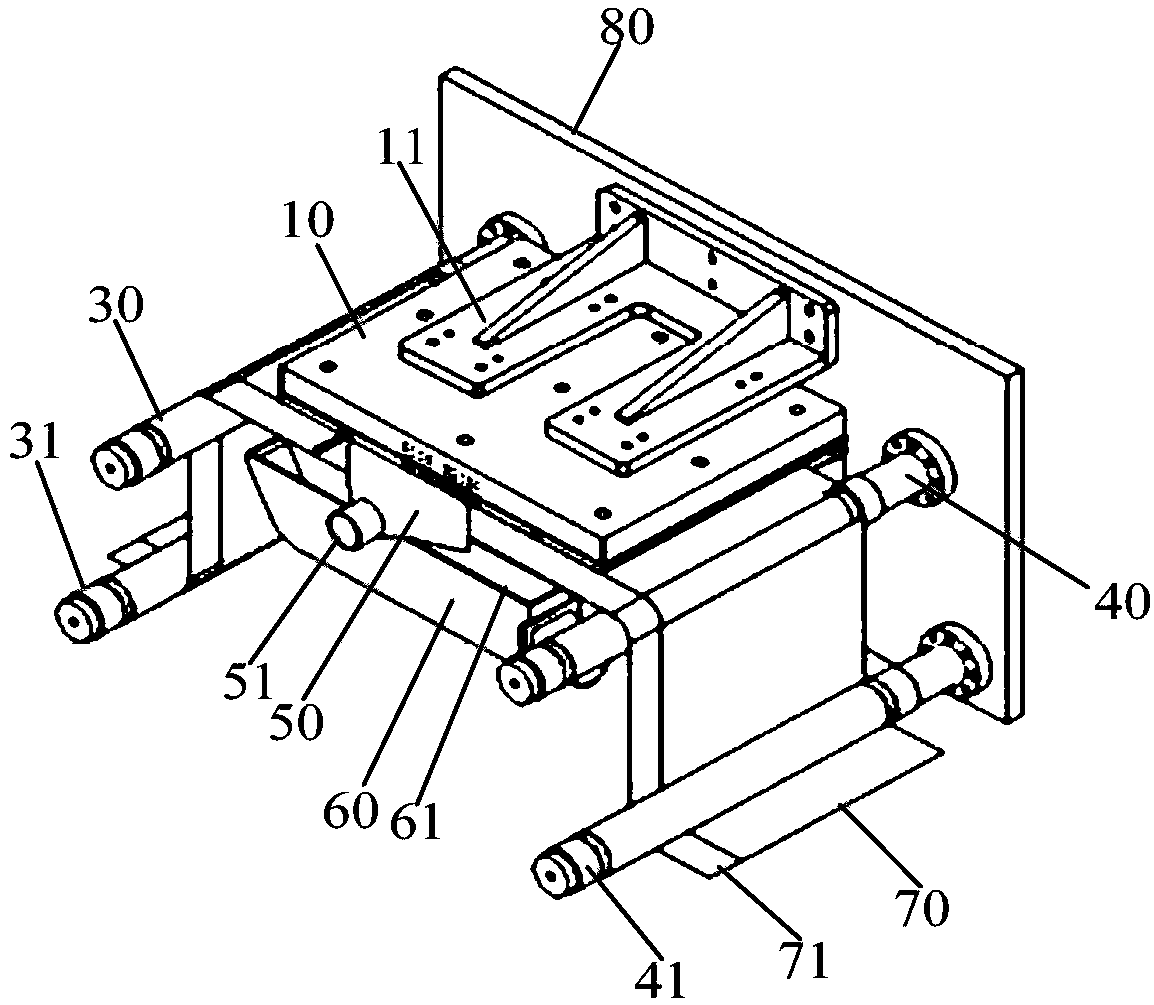

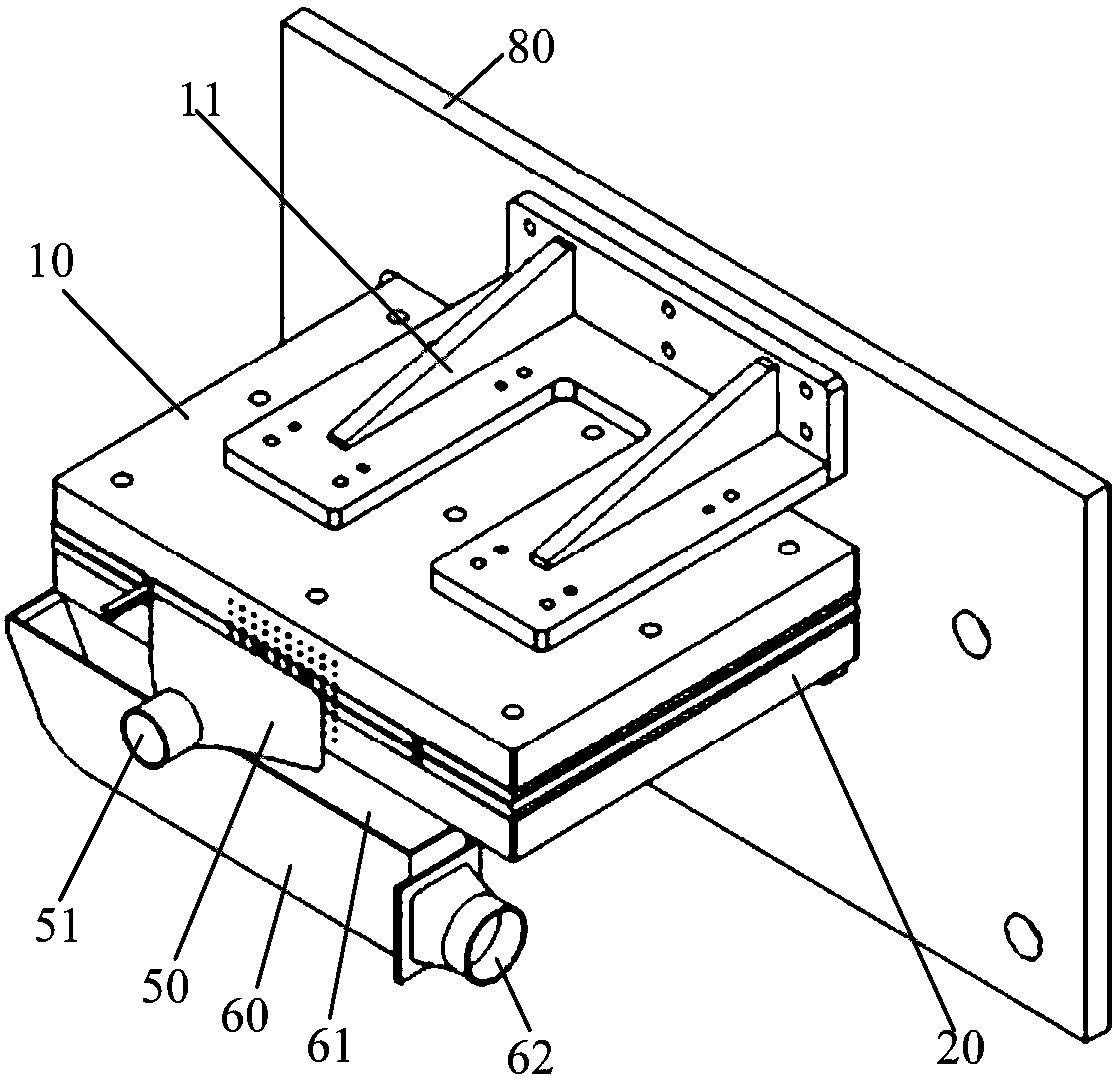

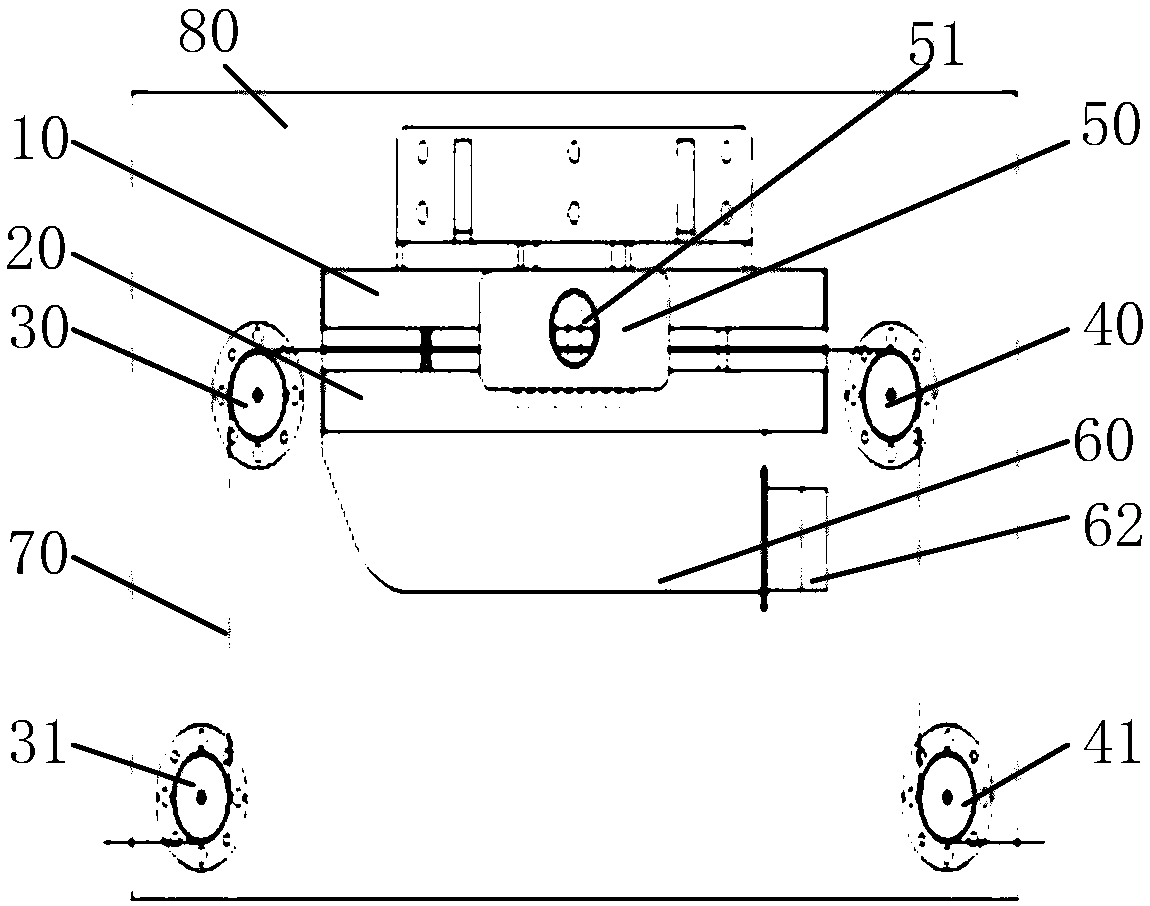

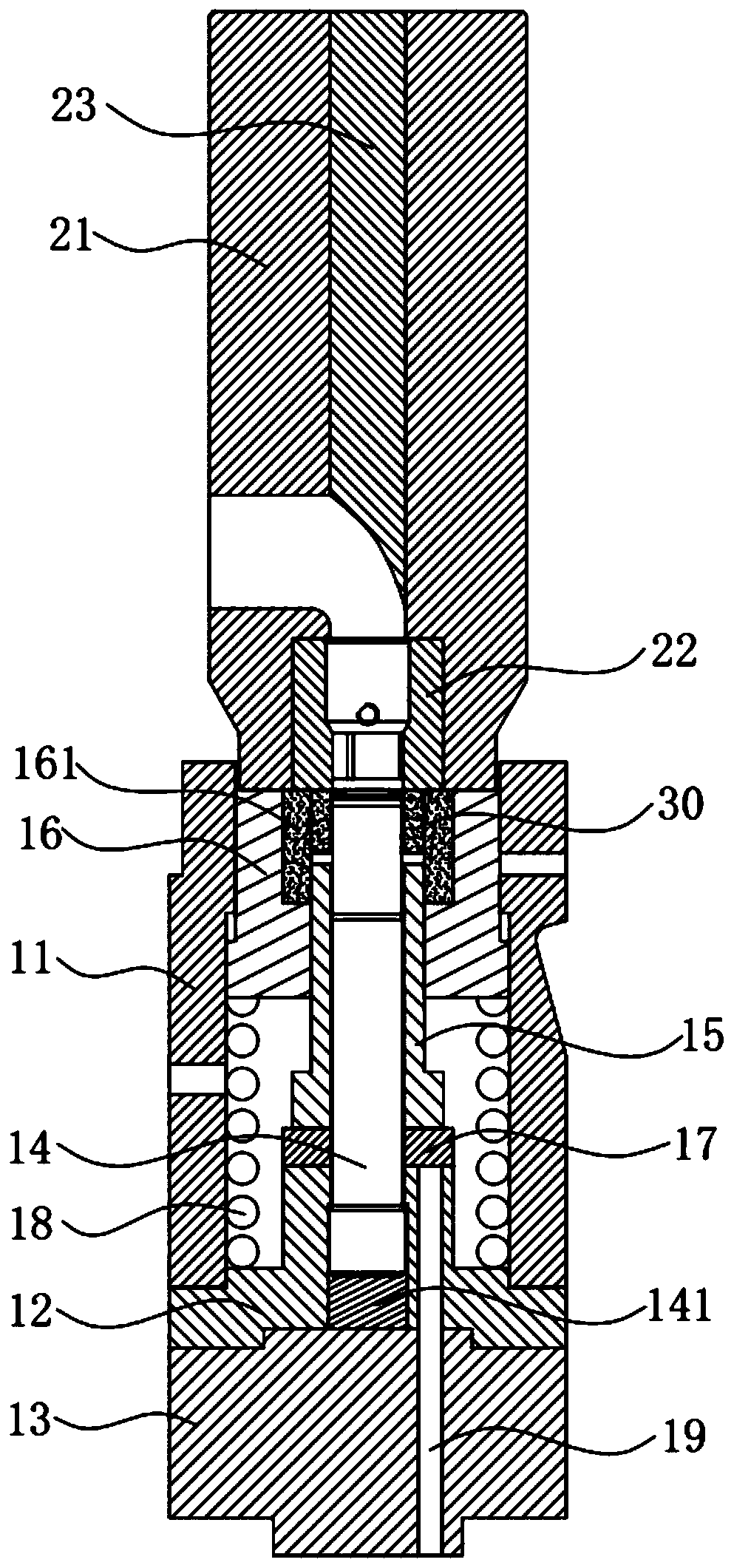

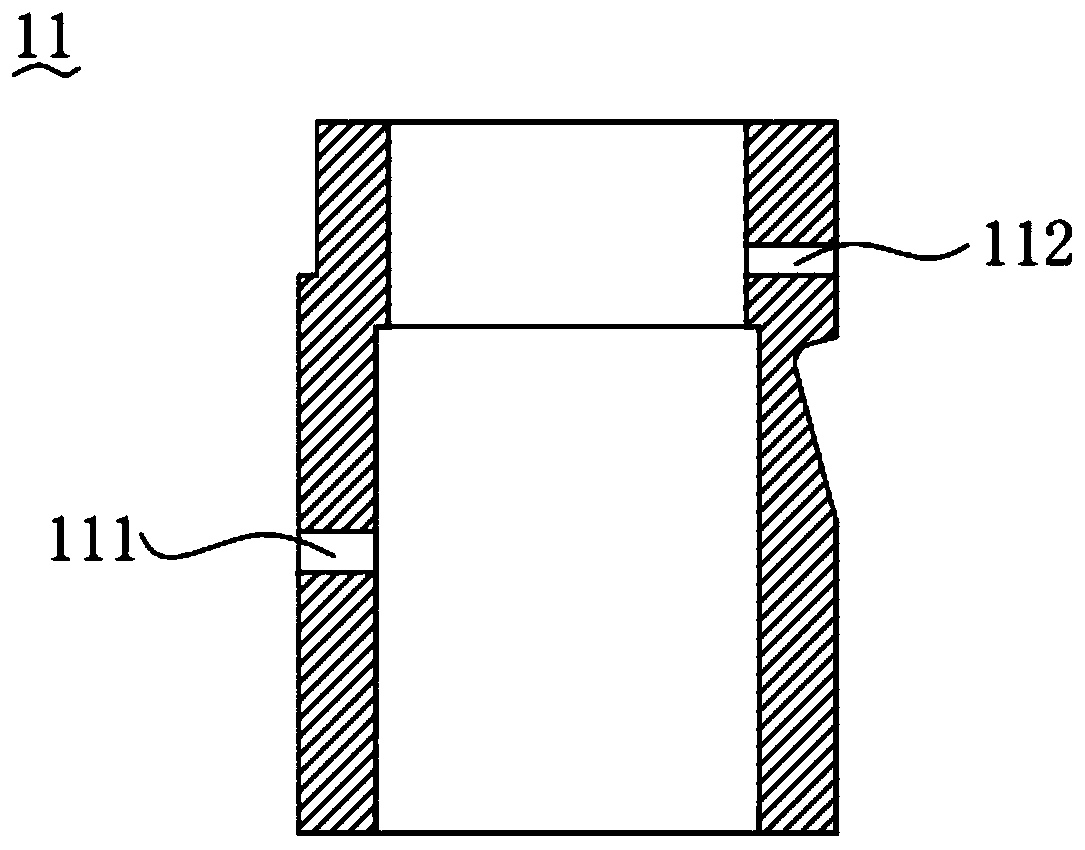

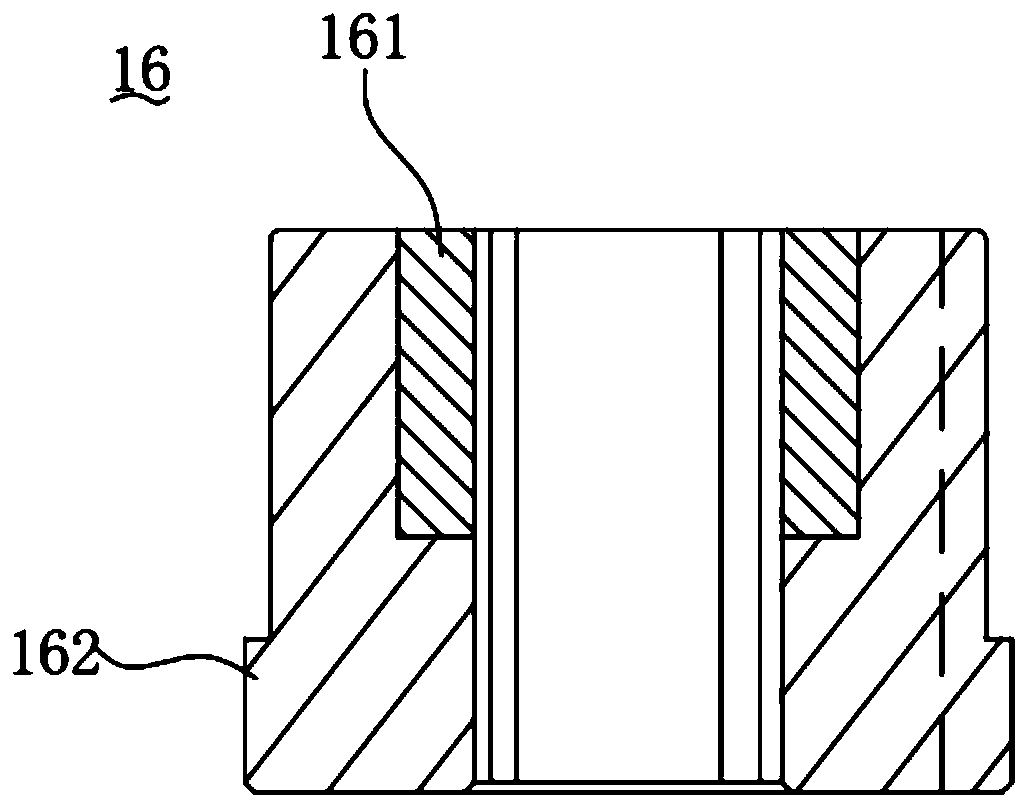

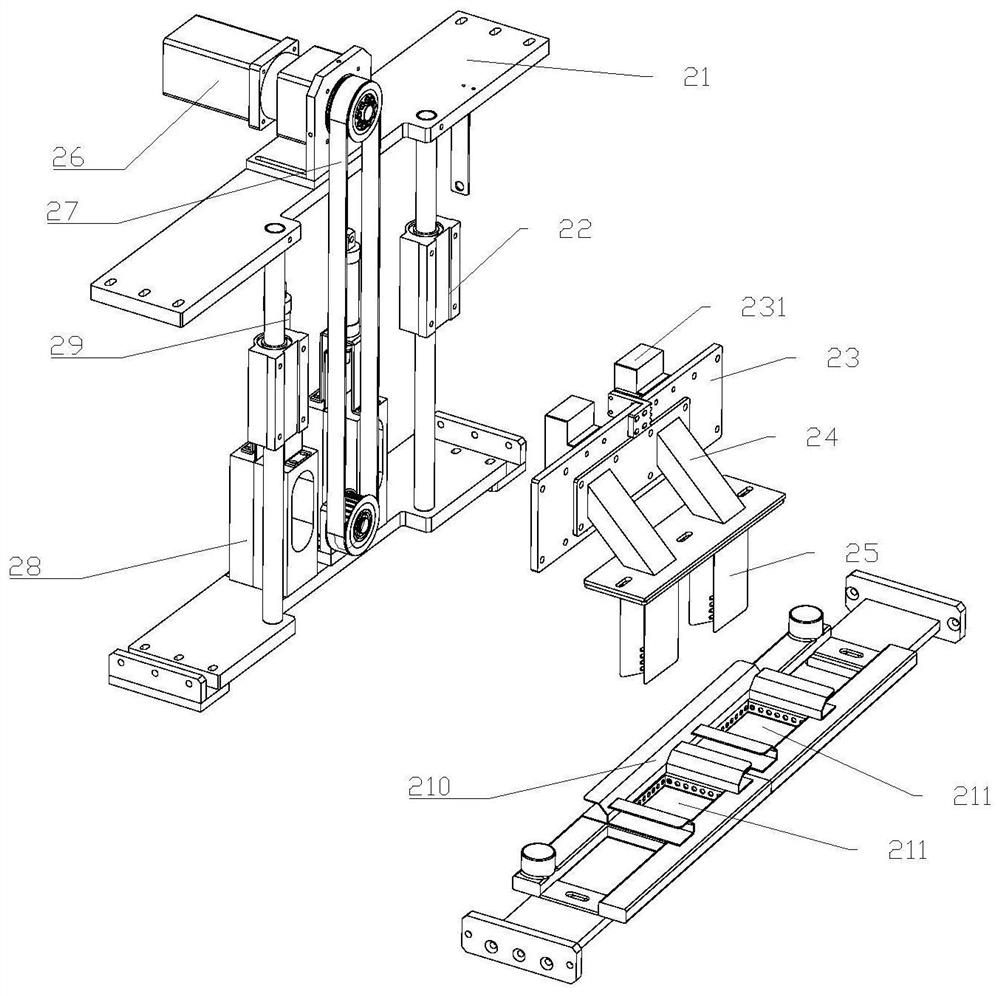

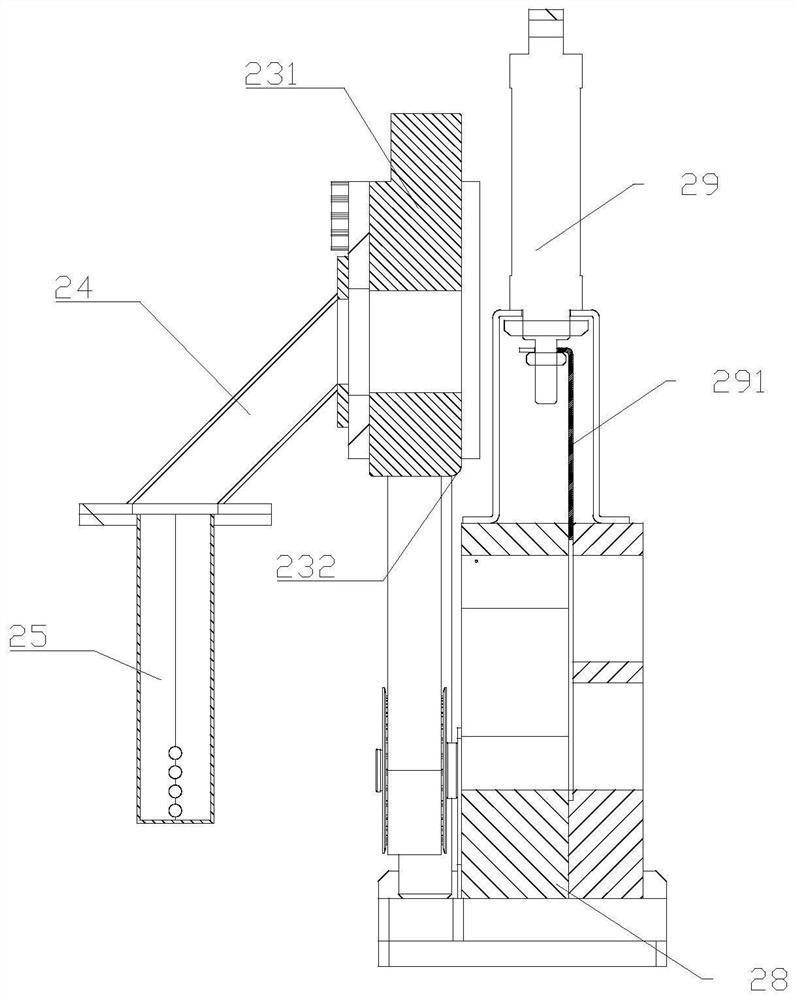

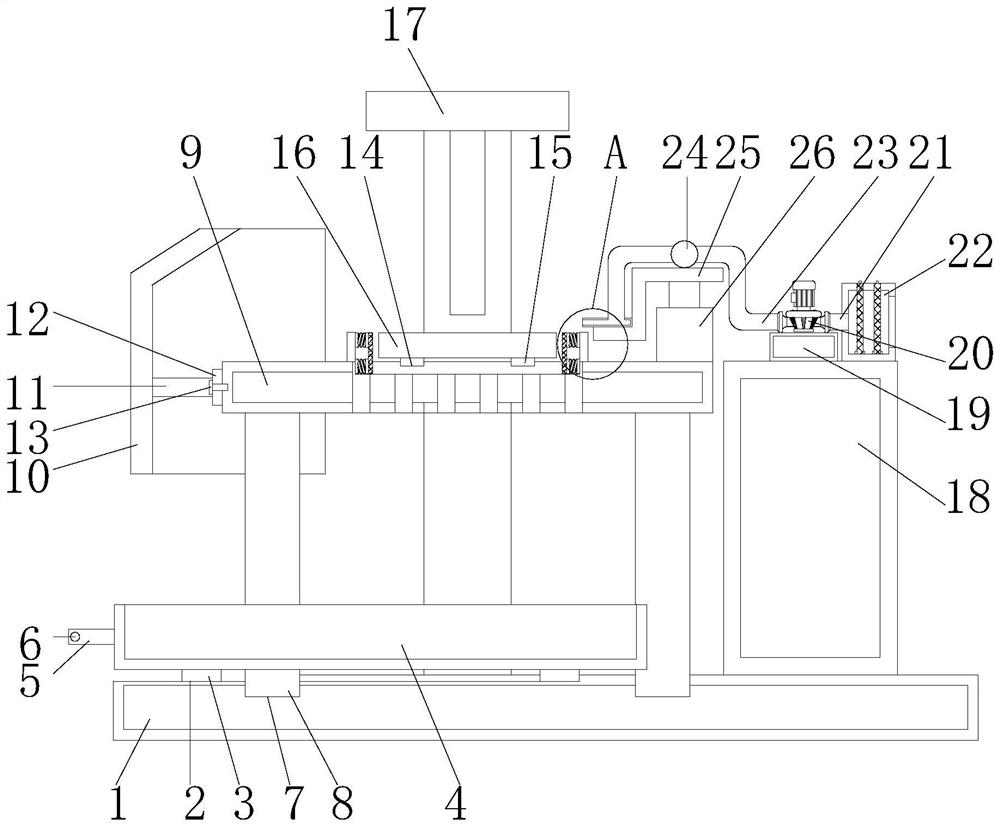

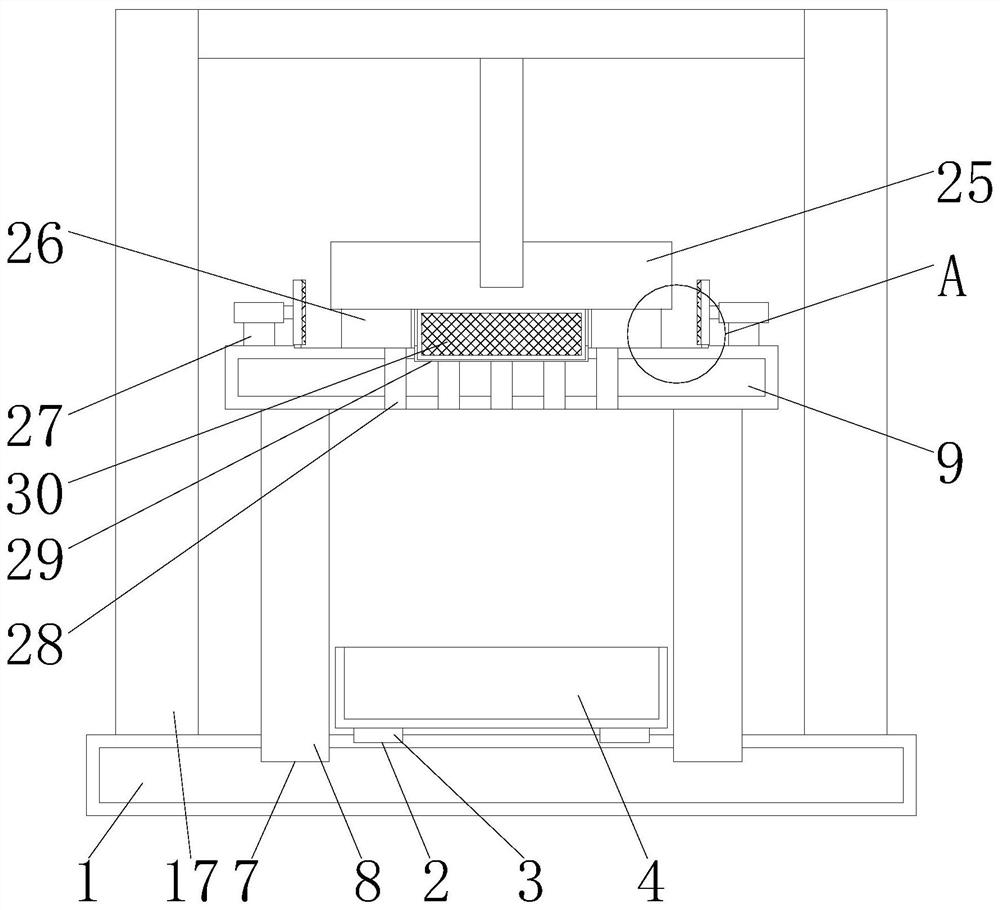

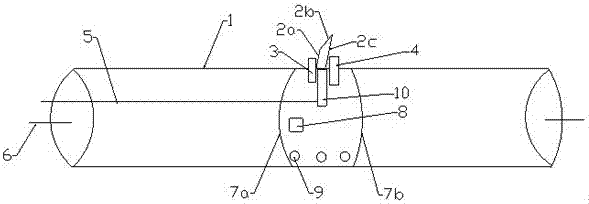

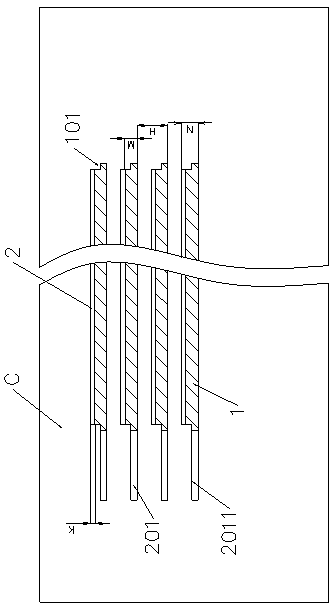

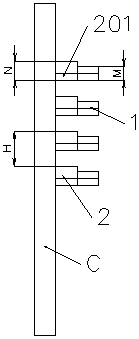

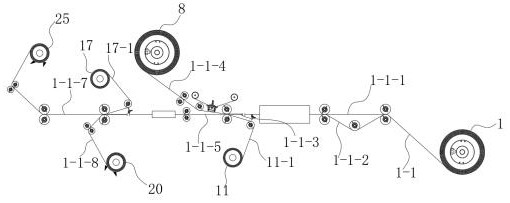

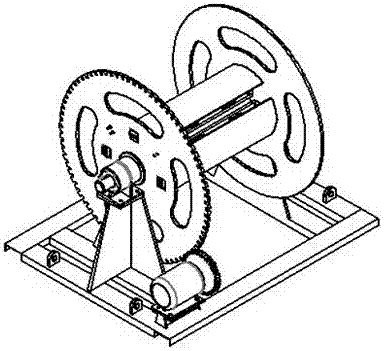

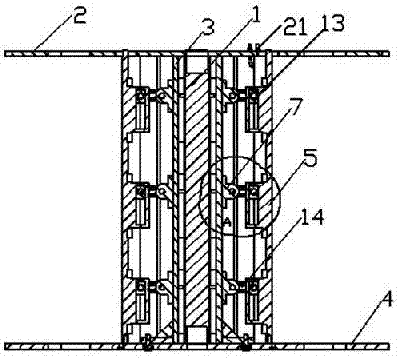

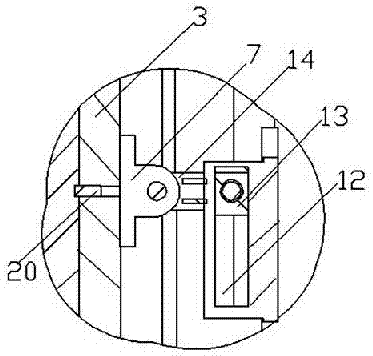

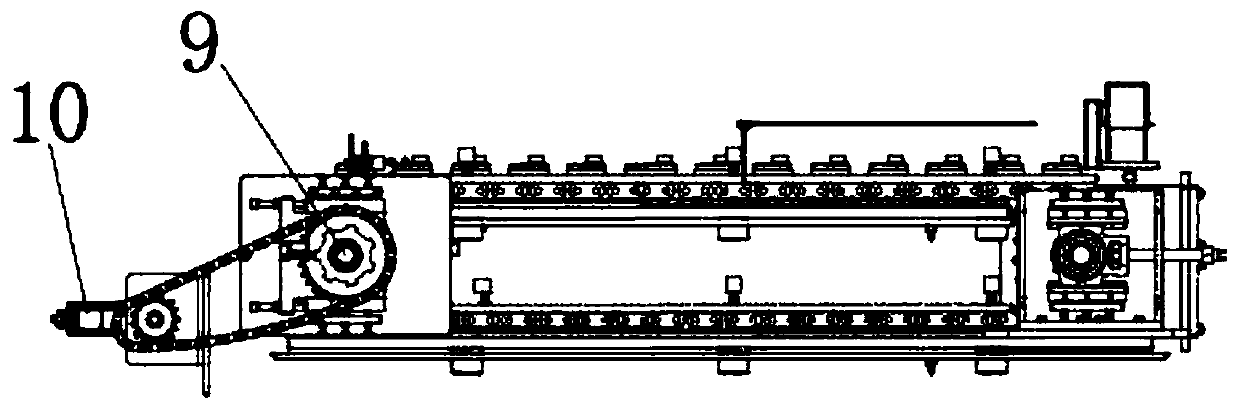

Steel wire rope winding device

ActiveCN105460817AEasy to rewindConvenient waste disposalWinding mechanismsGear wheelElectric machinery

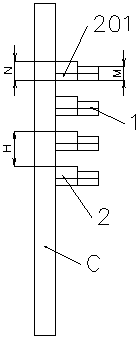

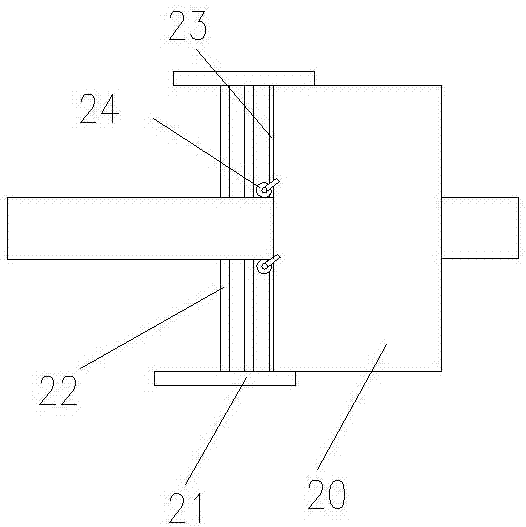

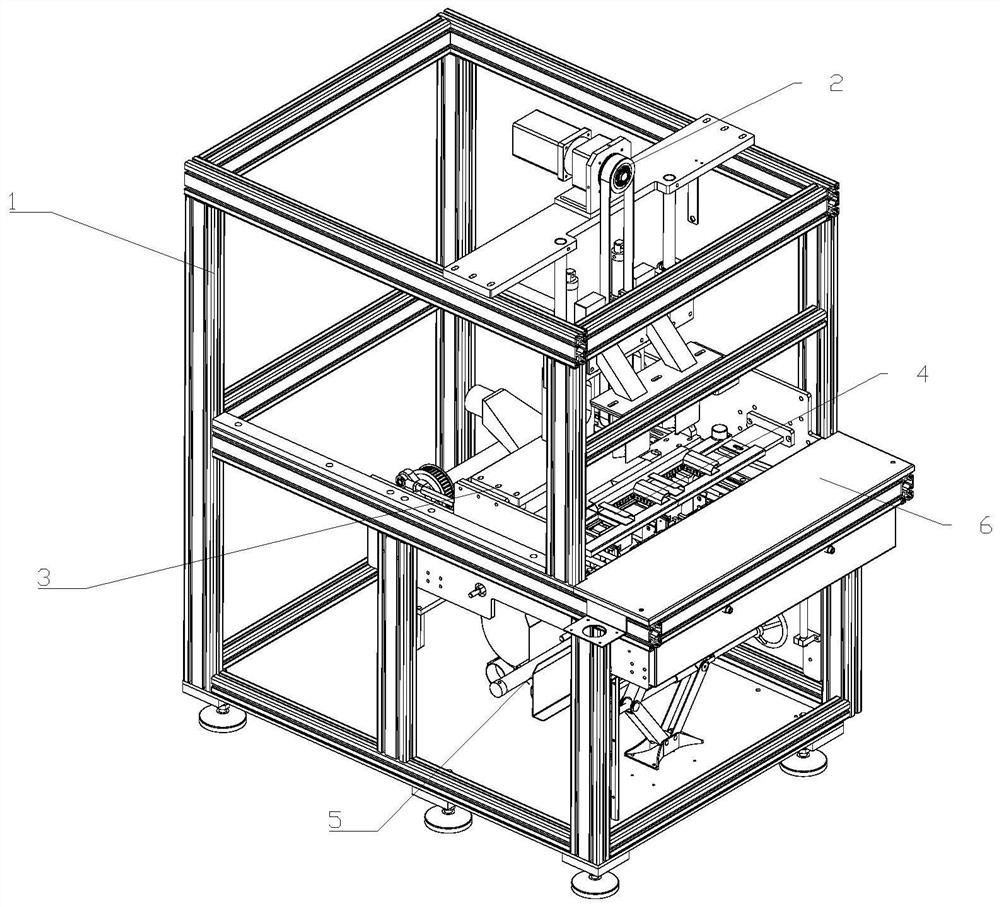

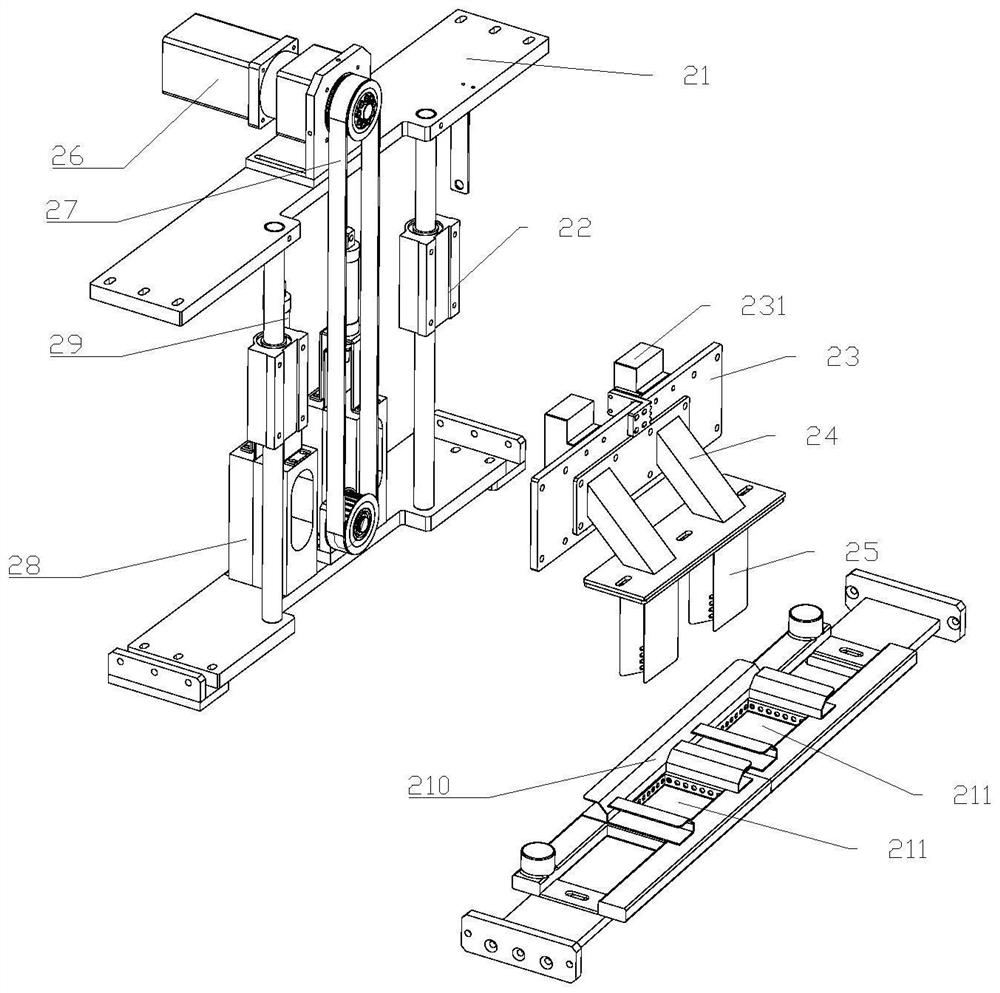

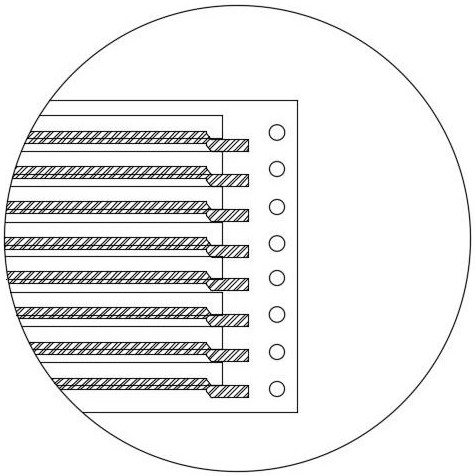

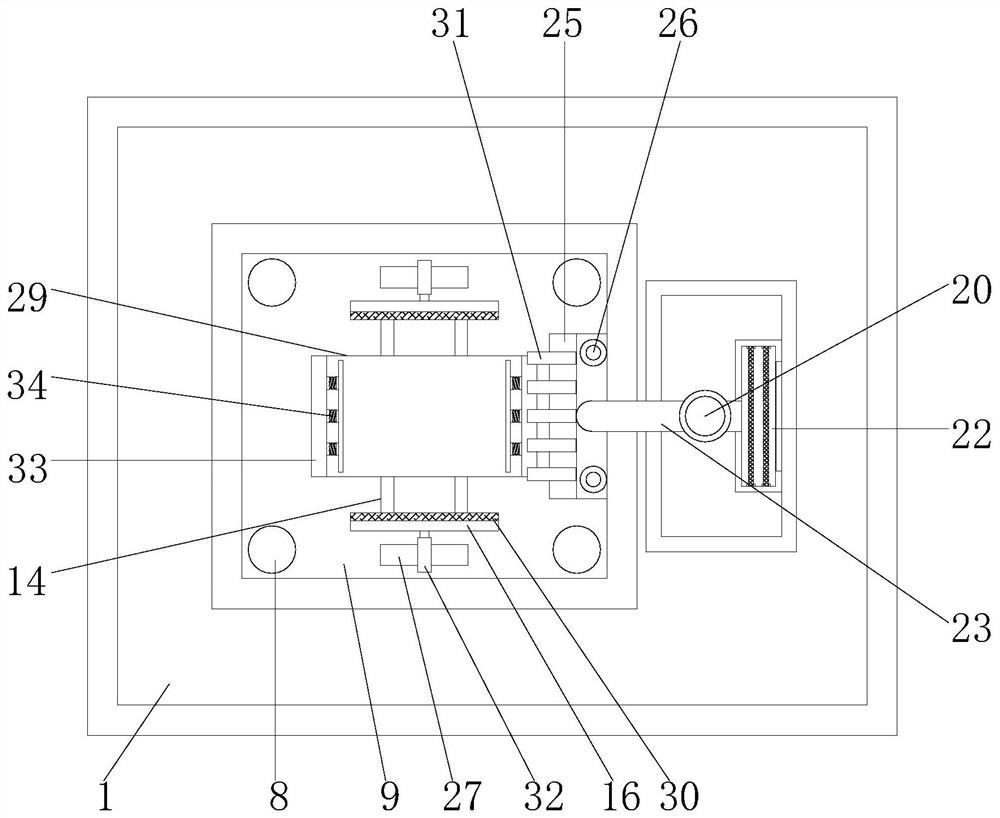

The invention relates to a steel wire rope winding device. The steel wire rope winding device comprises a spool device, spool fixing devices, a bracket and a driving device, wherein the spool device comprises a spindle, a gear of which the side center of a circle is fixedly perpendicular to one end of the spindle, four rectangular connecting plates which are circumferentially distributed along the spindle at equal intervals, a side plate which is connected to the other end of the spindle and four fan-shaped plates; the spool fixing devices are fixed to both opposite sides of the bracket, the spool fixing devices are formed by sliding shafts, shaft sleeves and locking pins which are used for the sliding shafts to be axially positioned in the shaft sleeves, and the sliding shafts are assembled in blind holes in both ends of the spindle, so that the spool device is positioned; the driving device is fixed to the bracket and is driven to be engaged with the gear by a motor, so as to drive the gear to rotate, so that a steel wire rope is wound. According to the steel wire rope winding device, the expansion and contraction of the fan-shaped plates in the radial direction of the gear are realized by utilizing the displacement of the fan-shaped plates in the radial direction of the gear, the winding and waste discharge of the steel wire rope are realized by utilizing the removable side plate, and the winding and waste discharge of steel wire ropes of various sizes can be conveniently and quickly completed, so that the labor intensity is reduced, and additionally, the working efficiency is improved.

Owner:HANGANG GRP HANBAO IRON & STEEL +1

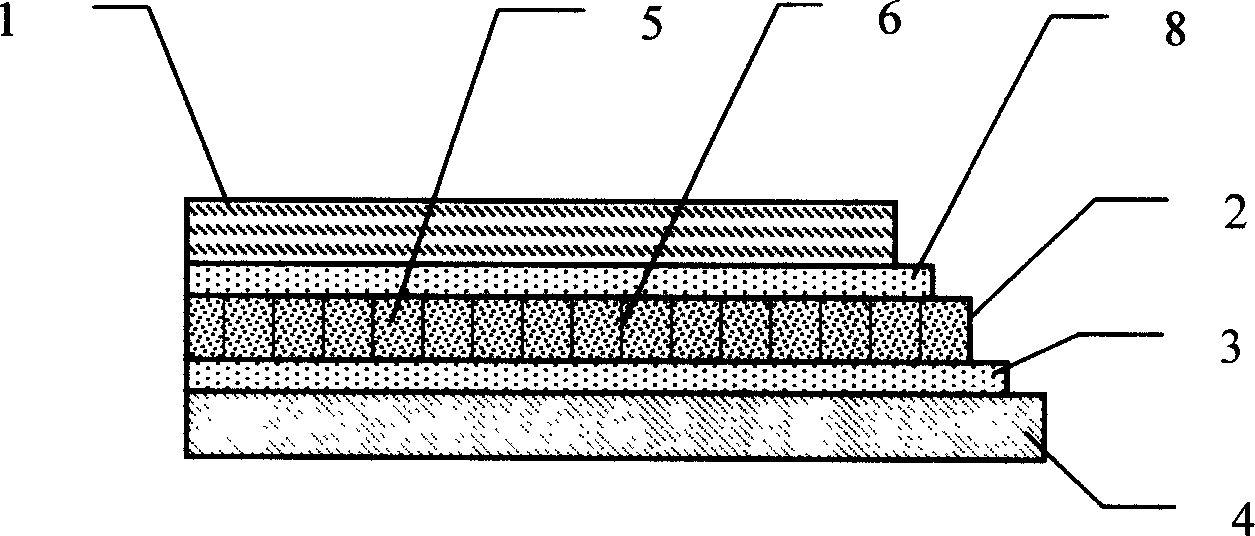

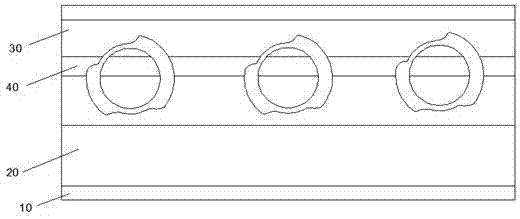

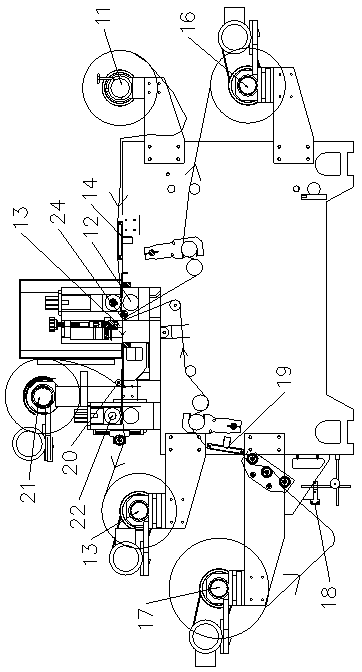

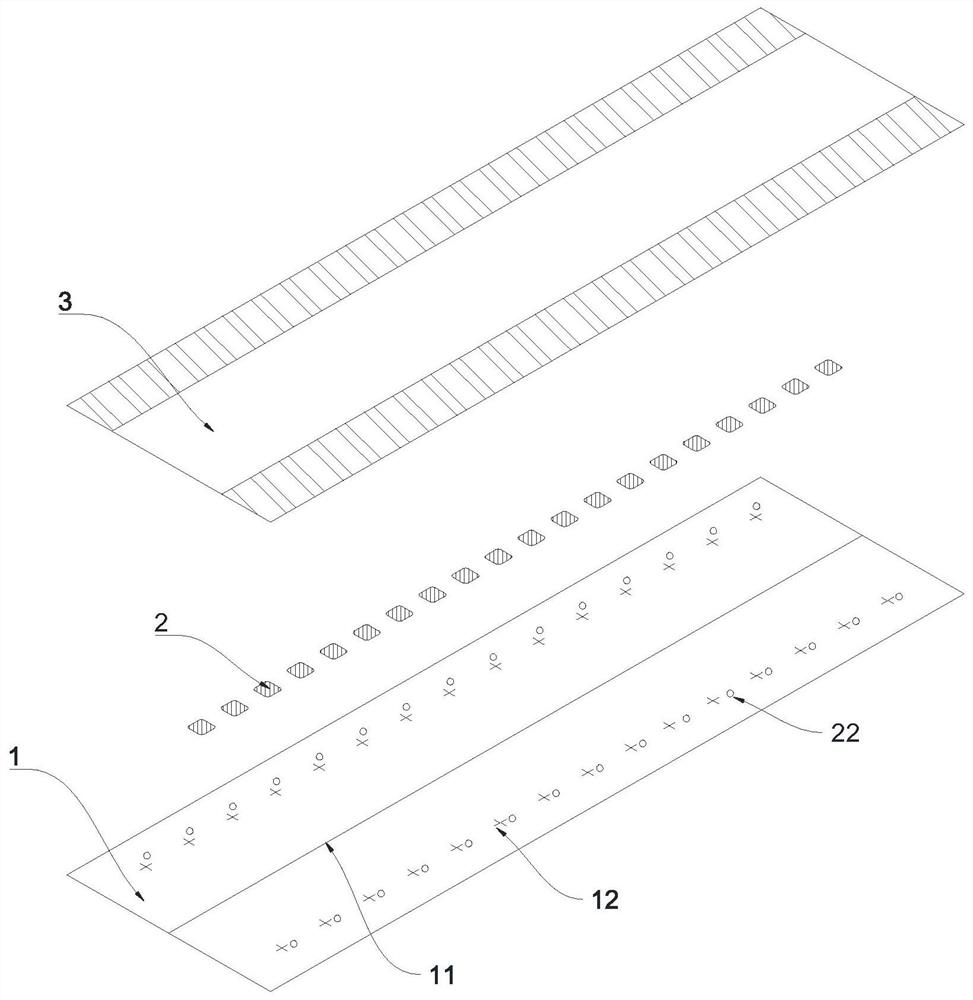

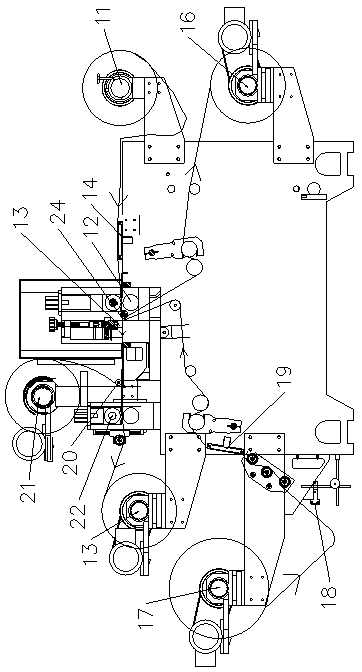

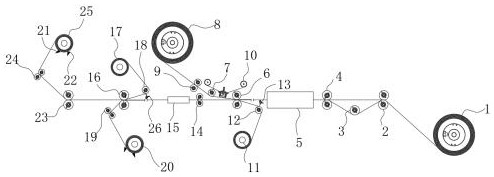

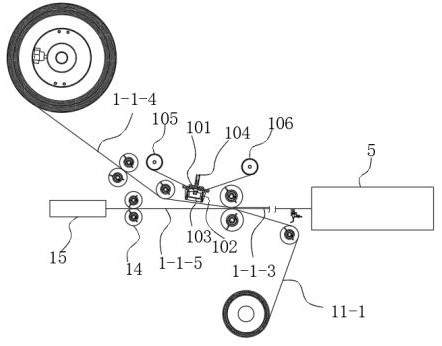

Production method for making hot stamping RFID electronic label

InactiveCN107247987ASimple structureShort processing cycleDuplicating/marking methodsCo-operative working arrangementsProduction lineHot stamping

The invention belongs to the information technology field and particularly relates to a production method for making a hot stamping RFID electronic label. An antenna is compounded on a PET layer, binding with a chip is carried out, a hot melt adhesive film is then compounded or coated, and the hot stamping label is acquired; die cutting of the hot stamping label is carried out, a knife edge of a die cutting cutter is provided with die cutting connection points, after die cutting, the connection points are distributed at periphery of the hot stamping label with intervals, and the label is connected with the PET layer through the connection points; on a label hot stamping machine, hot stamping of the hot stamping label onto a target object surface is carried out through a hot stamping head, under the action of a cooling device, cooling of a hot stamping adhesive film is realized, the PET film layer is pulled through a coiling shaft, the label is disconnected at the connection points, the label is marked on the target object surface, residual materials are removed, and making the hot stamping RFID electronic label is accomplished. The method is advantaged in that the RFID intelligent electronic label can be pasted to the target object surface in a hot stamping mode based on the PET film, the label PET has antennas at one surface or two surfaces, performance and quality are stable, and packaging production line large-scale application is facilitated.

Owner:孙涵

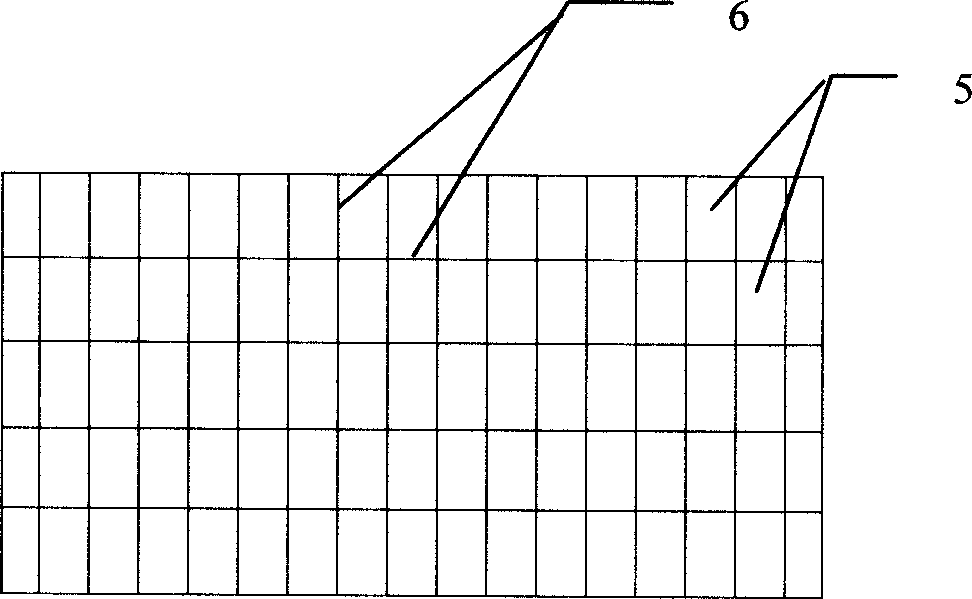

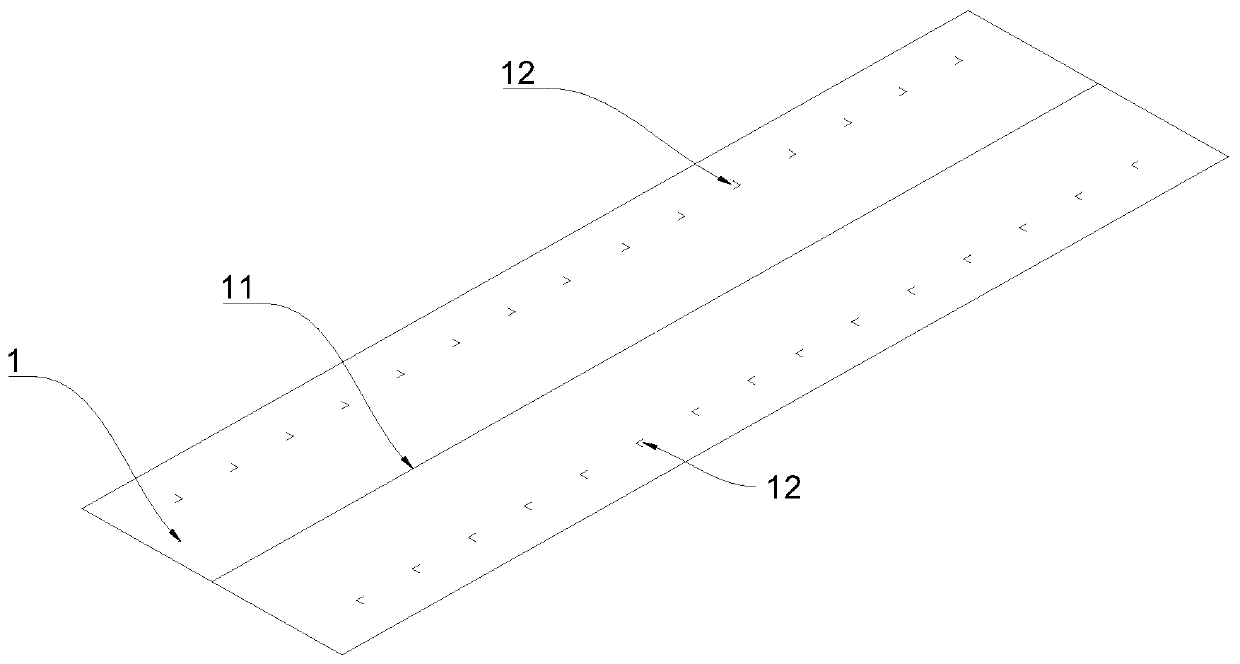

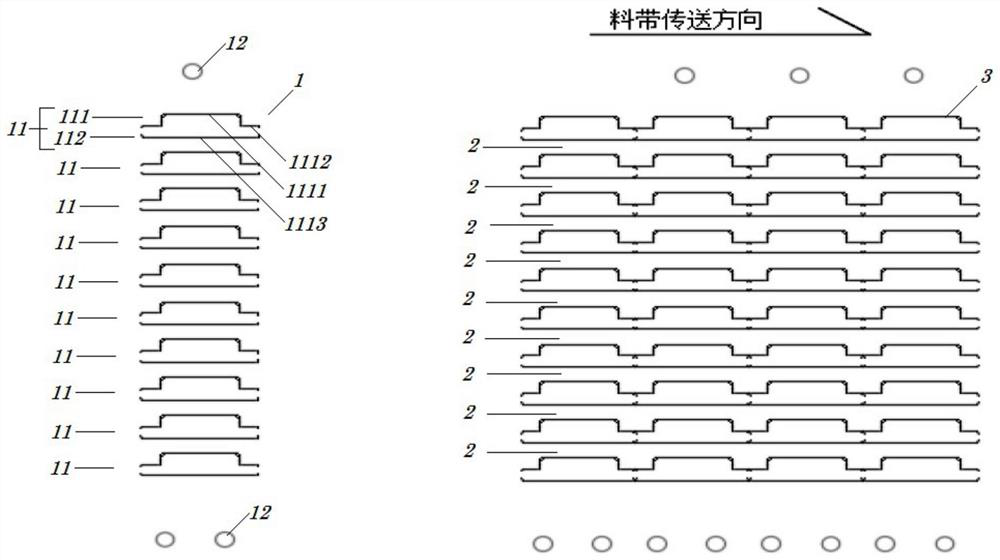

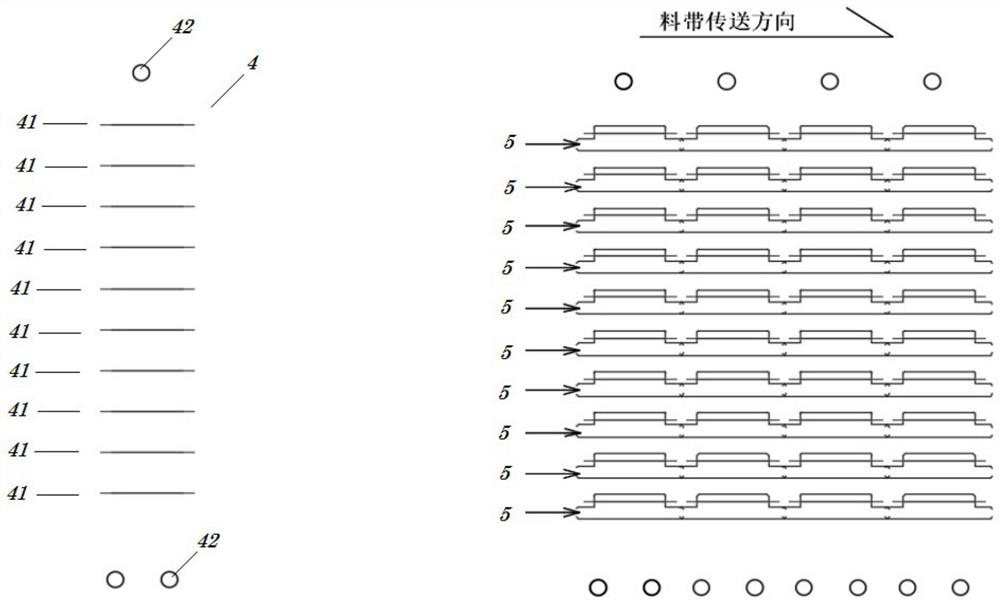

Label production process

ActiveCN104802217AImprove continuityGuaranteed continuityMetal working apparatusAssembly lineWaste material

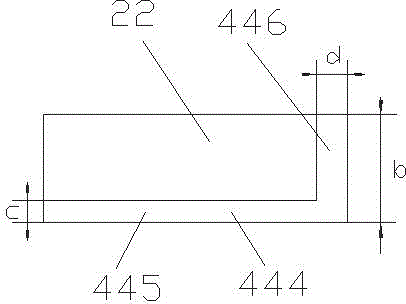

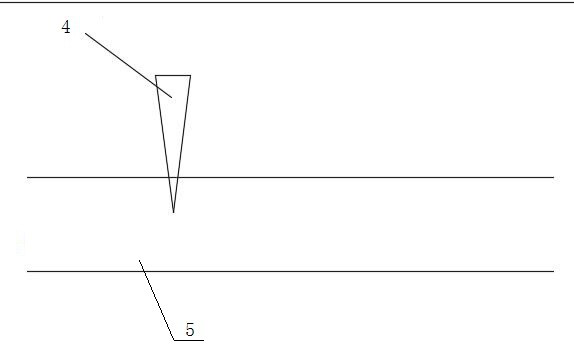

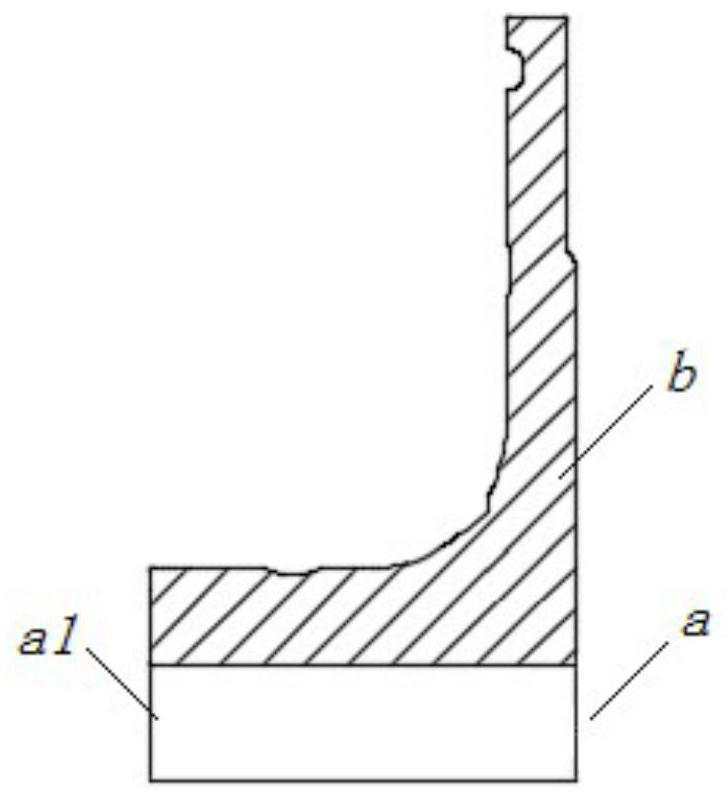

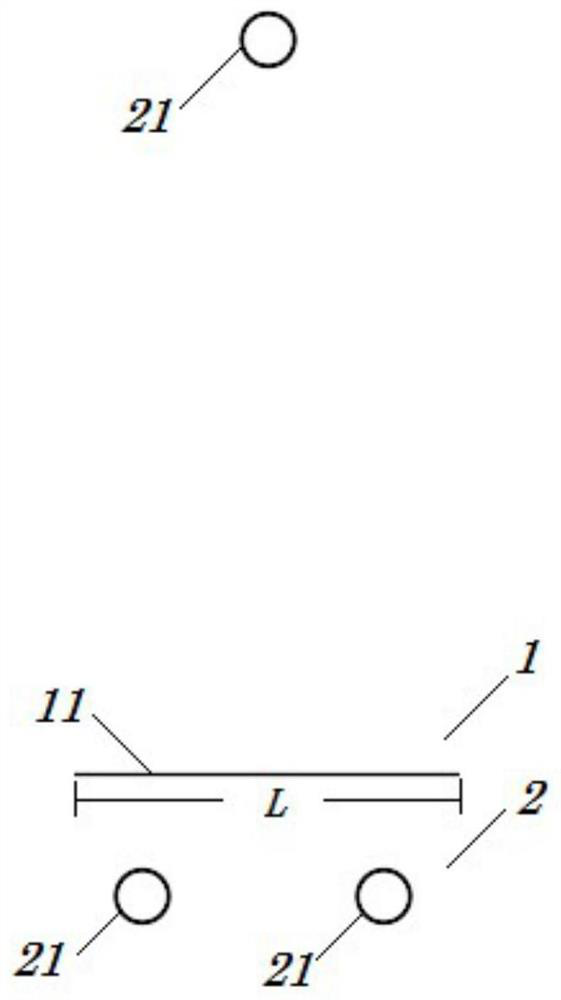

The invention discloses a label production process. The label production process comprises: (1) printing all label printing materials on a label base stock to obtain a label semi-finished product material strap; (2) chopping a double sticky tape raw material transmitted to an assembly line through at least one first cutting die line so as to connect waste materials at one side of the first cutting die line to be of a strap shape, and connecting chopping finished-products at another side of the first cutting die line to be of a strap shape, wherein the shape of the first cutting die line is of an inverted U shape or a continuously-inverted U shape, and an extending direction extends an assembly line direction; (3) carrying out waste discharge; (4) enabling the chopping finished products and the label semi-finished product material straps to be adhered by the assembly line; and (5) chopping the adhered products to obtain the label finished products. According to the label production process provided by the invention, the first cutting die line which is of either the inverted U shape or the continuously-inverted U shape is adopted when the double sticky tape is chopped, so as to be convenient for further chopping to obtain an L shape successively and ensure the continuity of the waste materials, therefore the assembly line processing can be realized and the waste materials can be conveniently discharged; meanwhile, the streamlining of the whole label production process can be realized, the efficiency can be improved, and the quality can be ensured.

Owner:KUNSHAN HUAGUAN TRADEMARK PRINTING

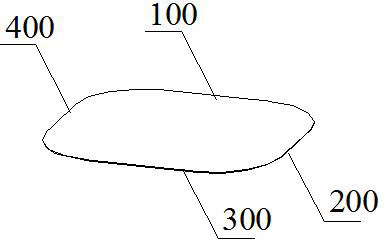

Method for die-cutting foam

ActiveCN112140235AGuaranteed smoothQuality improvementMetal working apparatusPolymer sciencePunching

The invention relates to a method for die-cutting foam. The method comprises the following steps that a first protective film is attached to a second protective film; the second protective film is primarily punched; the second protective film is attached to protective film waste after primary punching to be separated from the second protective film; then the foam, double faced adhesive tape and afirst release film are sequentially attached to the second protective film; an inner frame is obtained through secondary punching on the first release film and the foam, and the first release film onthe surface of the inner frame and the inner frame waste obtained after secondary punching are removed; the first release film on an intermediate product is completely removed, a complete second release film is attached to the surface of the foam, an outer frame is obtained through tertiary punching on the second release film, the foam and the second protective film, all waste on the appearance ofthe product is removed, and the second release film on the product is removed; and the outer frame is larger than the inner frame in size. Compared with the prior art, the method has the advantages of high processing precision, no product deformation, no arching of the protective films and the like.

Owner:上海昊佰智造精密电子股份有限公司

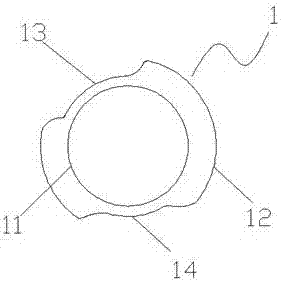

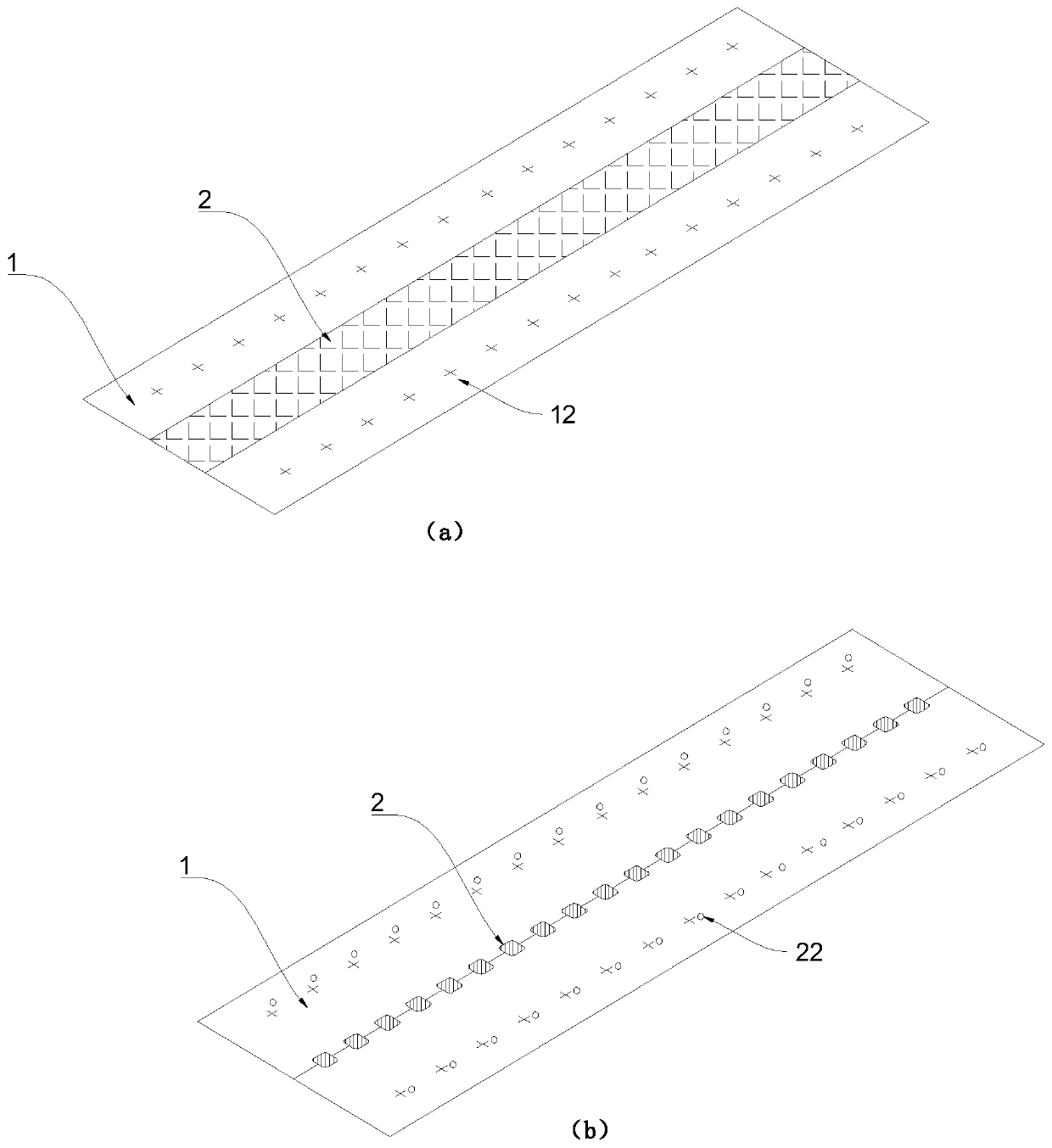

Label production technology with automatic waste discharge function

ActiveCN107187108AReduce the bonding areaConvenient waste disposalPaper/cardboard articlesEngineeringAdhesive

The invention discloses a label production technology with the automatic waste discharge function. The technology comprises following steps: firstly, a mopp film is bonded on release type base paper, a low-viscosity film is bonded on the upper surface of the mopp film, and first Mara adhesive tape is arranged on the area to be subject to die cutting between the mopp film and the low-viscosity film; secondly, a first cutter die is used for carrying out die cutting on the low-viscosity film and the first Mara adhesive tape, a round hole is formed in the low-viscosity film in a die-cutting manner, low-viscosity film waste materials on the periphery of the round hole and the first Mara adhesive tape which is subject to die cutting are discharged together; thirdly, high and low viscosity dual-face adhesive tape is bonded on the upper surface of the low-viscosity film obtained after waste discharge, a second cutter die is used for carrying out die cutting on the high and low viscosity dual-face adhesive tape, the die cutting position and the round hole position are consistent, a round hole in the high and low viscosity dual-face adhesive tape obtained after die cutting and the round hole obtained after die cutting from the low-viscosity film are discharged together; fourthly, a third cutter die is used for carrying out die cutting on the periphery of the round hole of the high and low viscosity dual-face adhesive tape; fifthly, the high and low viscosity dual-face adhesive tape and the low-viscosity film are discharged from the mopp film; sixthly, a die cutting device is used for carrying out whole-shaped die cutting on the mopp film, and waste is discharged.

Owner:KUNSHAN HUAGUAN TRADEMARK PRINTING

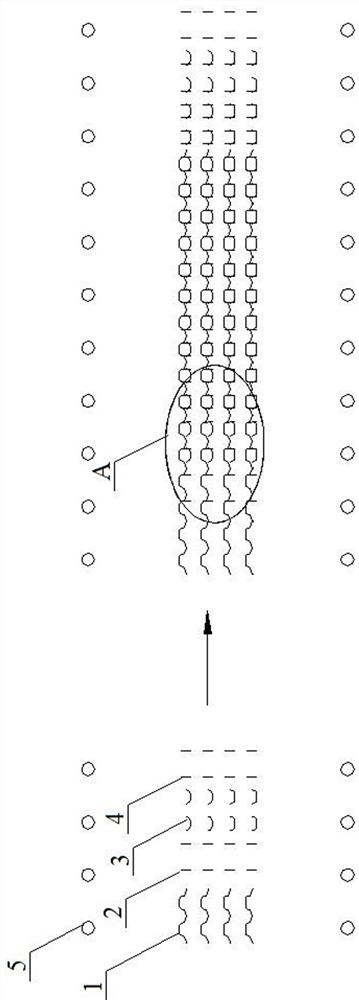

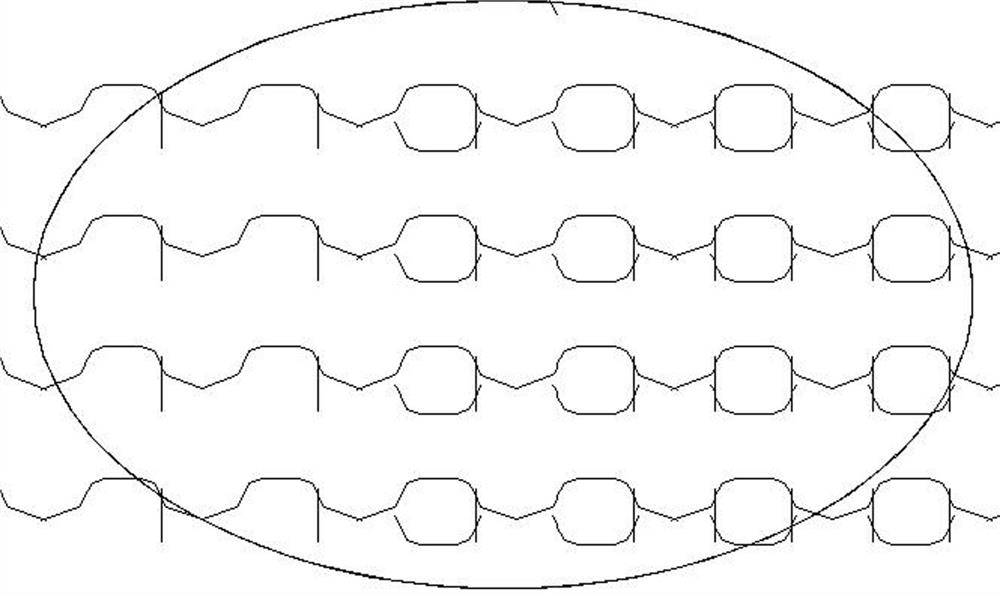

Die cutting production method for cut mark-free cotton adhesive tape

The invention relates to a die cutting production method for a cut mark-free cotton adhesive tape . According to the method, a bottom film needs not to be replaced and waste is discharged conveniently, and the obtained cotton adhesive tape is free of burrs, cut marks and excessive glue. The production method comprises the following steps: feeding a laminated die obtained by laminating an isolatingfilm and the bottom film and the cotton adhesive tape without body paper step by step into a clearance machine for die cutting, wherein the cotton adhesive tape and the laminating die are stepped once after die cutting every time; cutting the middle main body part of the cotton adhesive tape by a lower cross cutter line, and forming a cotton adhesive tape unit, the width of which is equal to thestepping distance of the cotton adhesive tape, in the vertical direction of the middle main body part of the cotton adhesive tape during stepping every time and adhering the cotton adhesive tape unitto the surface of the isolating film; starting to calculate the die cutting number of times and the stepping number of times from 0 after stepping some time, encircling the cutting line of the middlemain body part of the isolating film by an upper cross cutter line and a side cutter line during (N+1)th die cutting and the cutting line of the middle main body part of the isolating film during Nthdie cutting after stepping for N times to form an isolating film unit; and discharging waste in the periphery of the isolating film unit.

Owner:成都冠佳科技有限公司

Cutting method for non-substrate double faced adhesive tape

ActiveCN111113497AAvoid squeezingPrevent extrusion, can effectively prevent product deformationLamination ancillary operationsLaminationPolymer sciencePolymer chemistry

The invention discloses a cutting method for non-substrate double faced adhesive tape. The cutting method comprises the following steps that S1, a backing film is compounded on a carrier tape, the carrier tape and the backing film are cut off centrally along a product zone by using a circular cutter, and a straight gap is formed; S2, the non-substrate double faced adhesive tape is compounded on the product zone of the carrier tap, sleeve cutting is conducted through the circular cutter along the gap obtained in the step S1, and a non-substrate double faced adhesive tape material in the determined shape is obtained; and S3, a transferring film is compounded on the non-substrate double faced adhesive tape material, the non-substrate double faced adhesive tape material is subjected to sleevecutting through the circular cutter, layout of the non-substrate double faced adhesive tape material is dressed, then, the backing film is removed along the gap in two steps, and the non-substrate double faced adhesive tape material is pasted on a product zone of the transferring film. According to the cutting method for the non-substrate double faced adhesive tape, the obtained non-substrate double faced adhesive tape material is not prone to deformation and disengagement and can achieve quantitative production.

Owner:DONGGUAN LINGYI PRECISION MFG TECH CO LTD

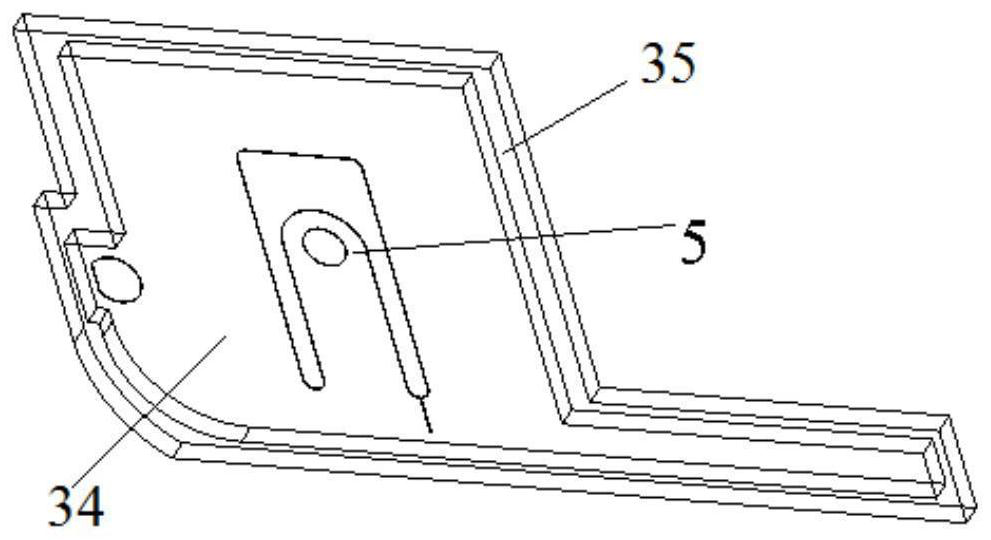

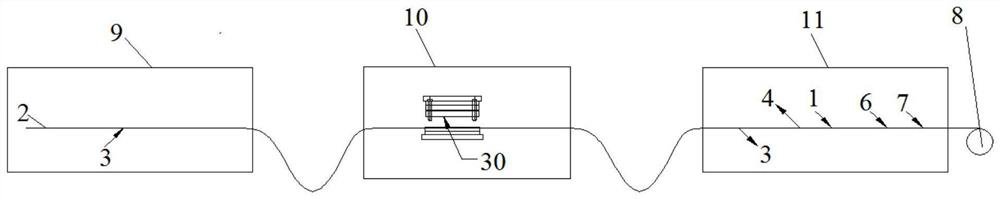

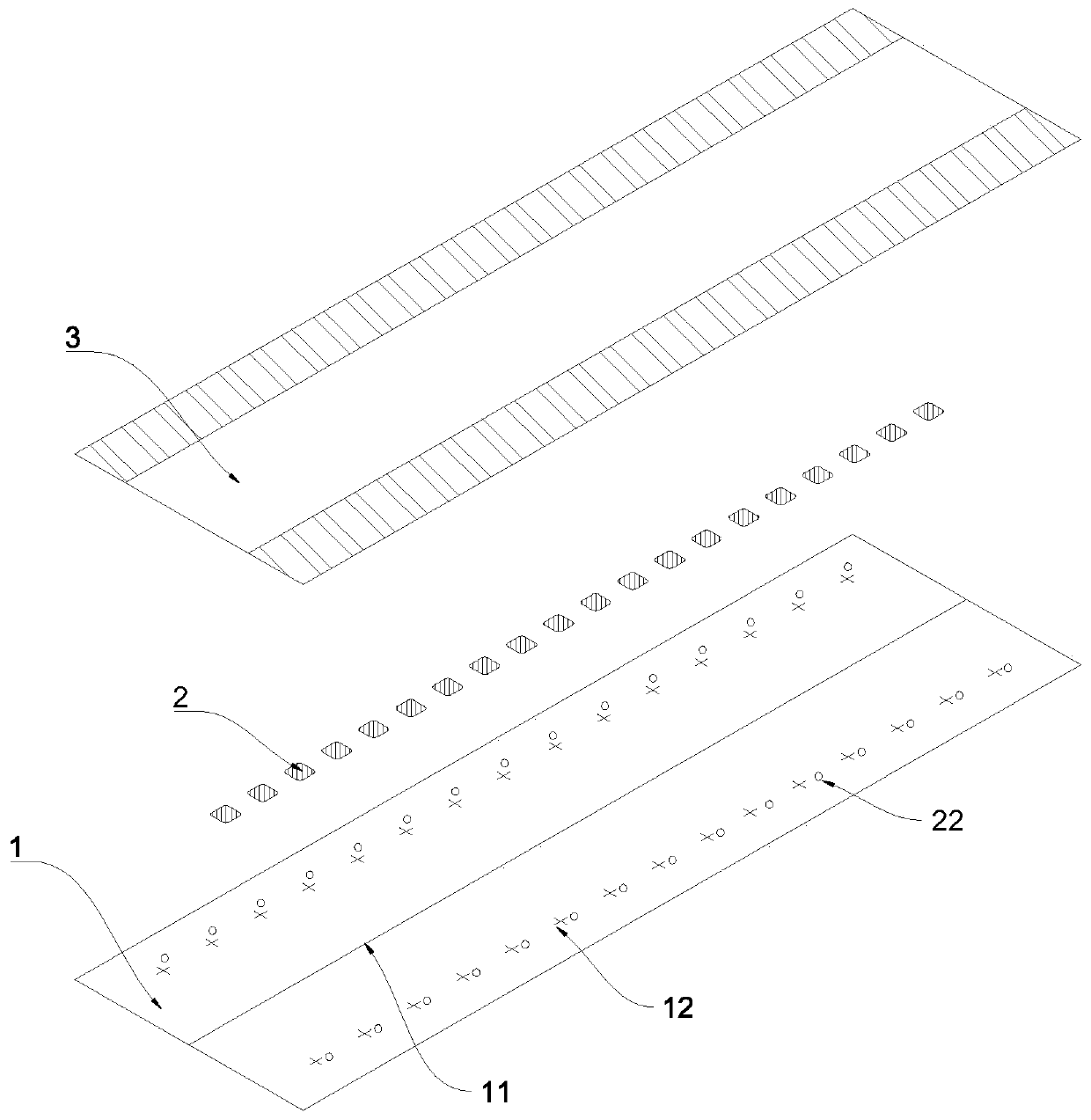

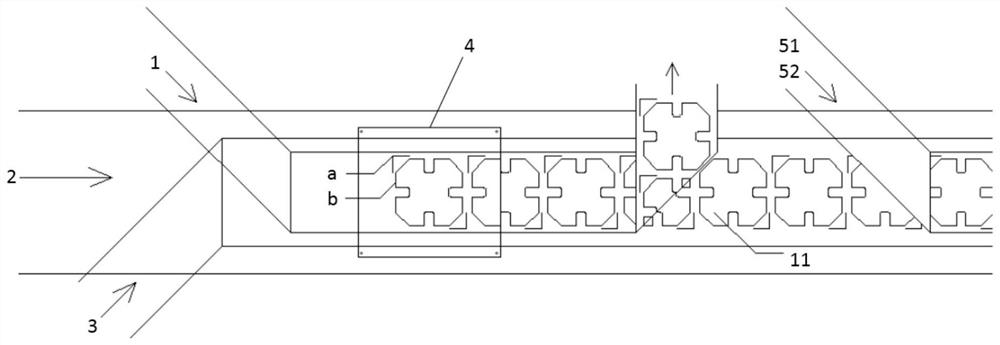

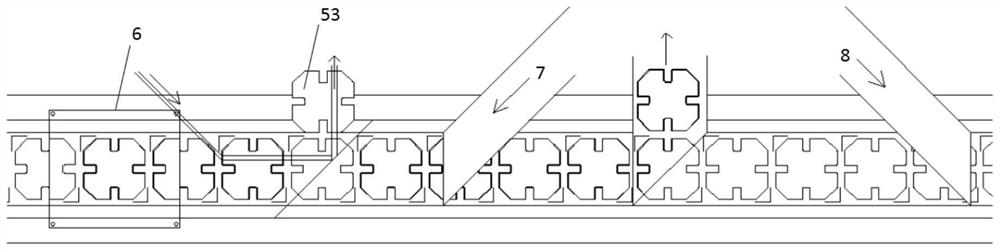

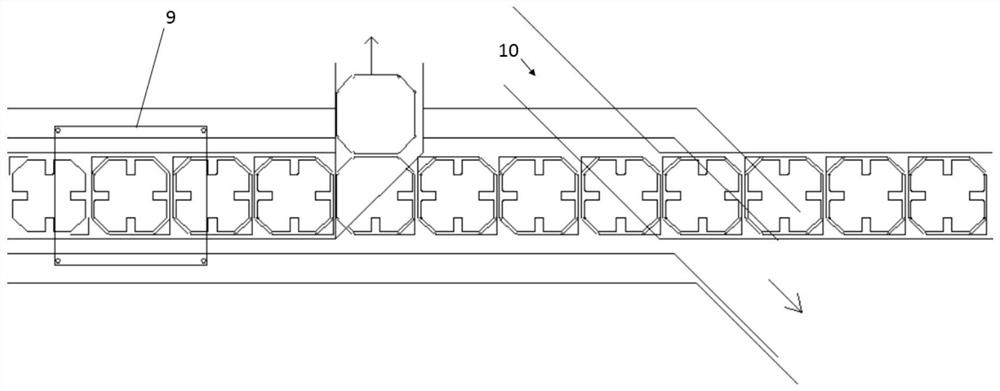

Production system of hollow special-shaped double-faced adhesive tape die-cutting part

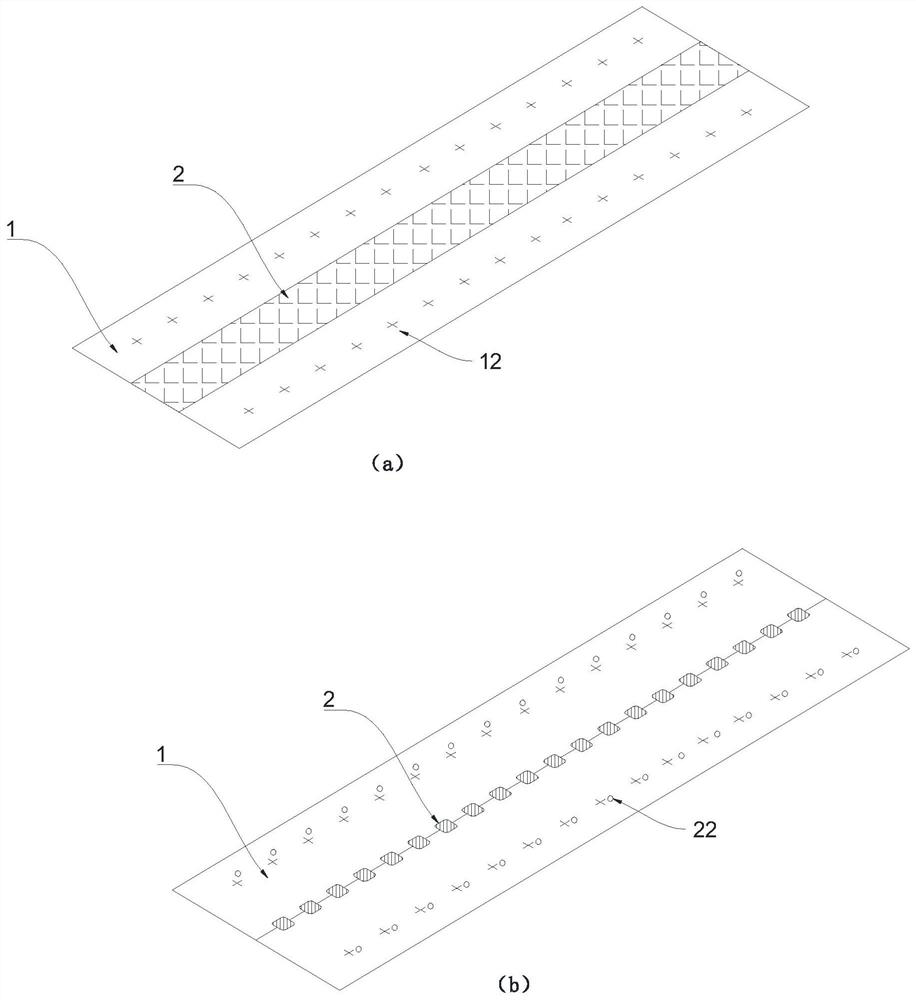

PendingCN112829427AEasy dischargeDoes not cause displacementLamination ancillary operationsAdhesive articlesPunchingRelease liner

The invention relates to a production system of a hollow special-shaped double faced adhesive tape die-cutting part, which is characterized in that the system comprises a pre-primary-punching laminating unit, a primary punching die-cutting unit, a pre-secondary-punching laminating unit, a secondary punching die-cutting machine (6), a secondary punching waste discharge unit, a ternary punching die-cutting unit and a die-cutting part receiving unit. After passing through the pre-primary-punching laminating unit, a low-viscosity protective film (1) and a low-viscosity bottom film (3) are respectively laminated above and below a handle release film (2); a first-stage material belt is formed after the first-stage material belt is punched by the primary punching die-cutting unit, then the first-stage material belt passes through the pre-secondary-punching laminating unit, the secondary punching die-cutting machine (6), the secondary punching waste discharge unit, the ternary punching die-cutting unit and the receiving unit to form hollow special-shaped double-faced adhesive tape die cutting part, and the product is wound. Compared with the prior art, the system has the advantages of more efficient waste discharge, reduction of the reject ratio of products and the like.

Owner:上海昊佰智造精密电子股份有限公司

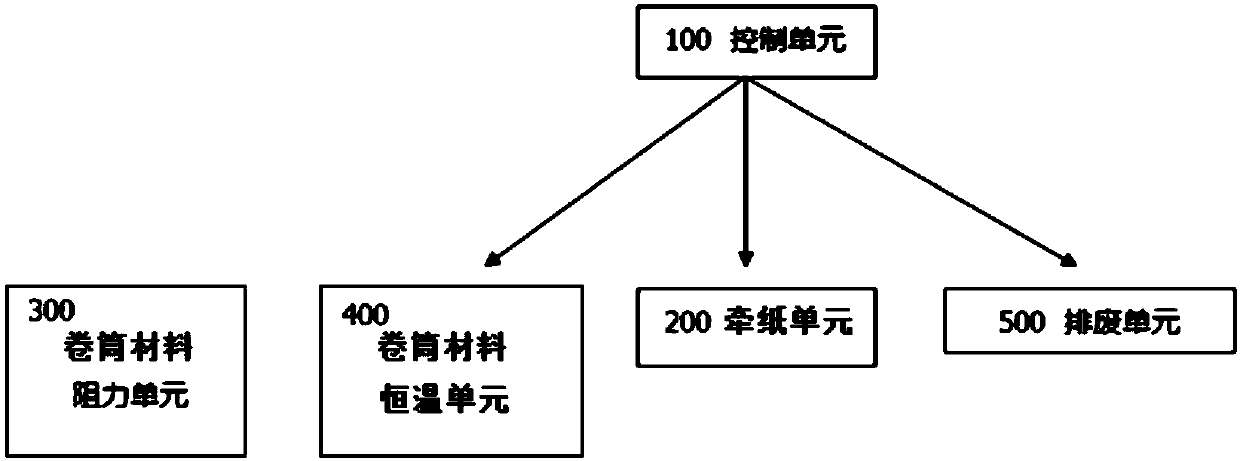

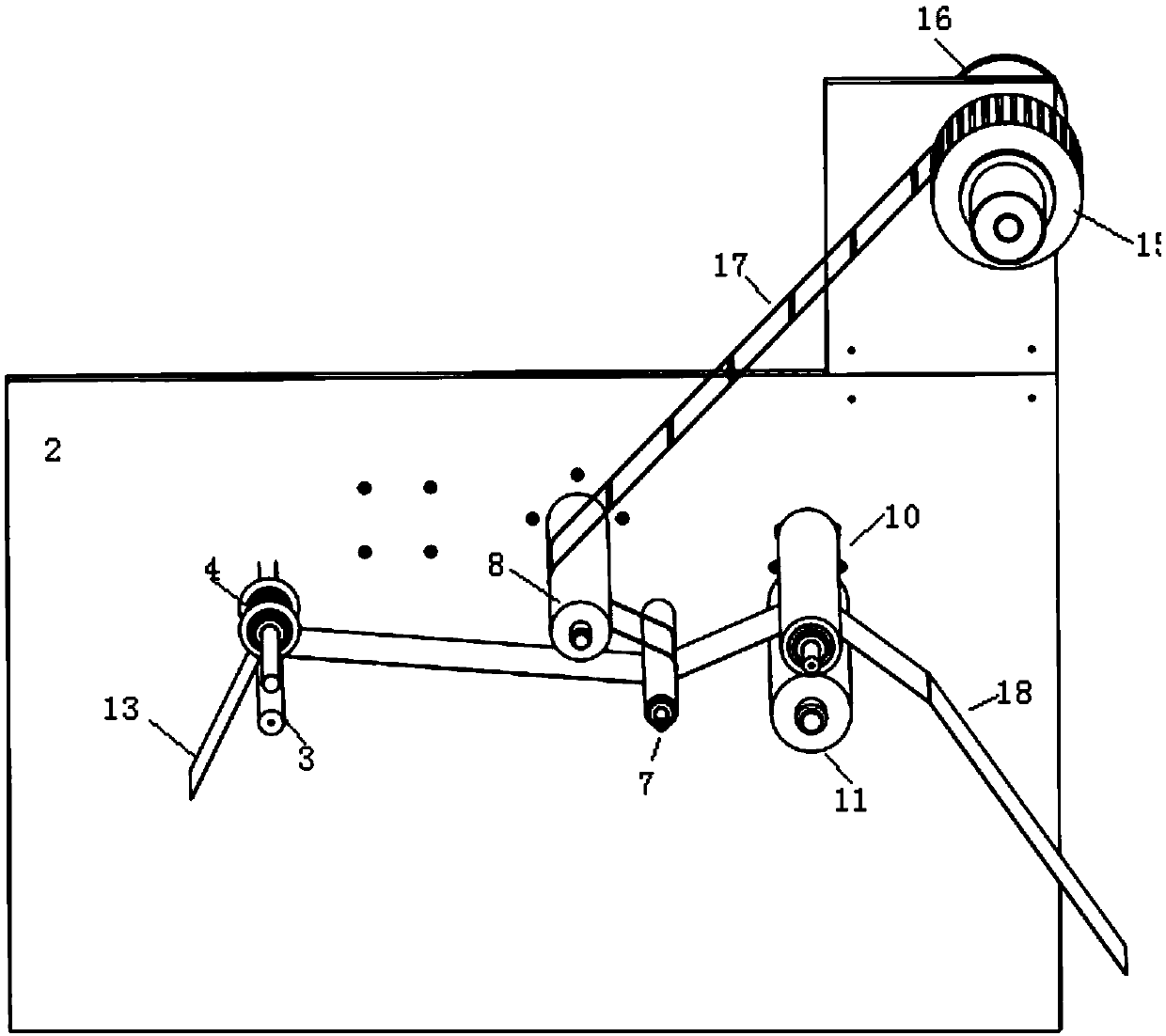

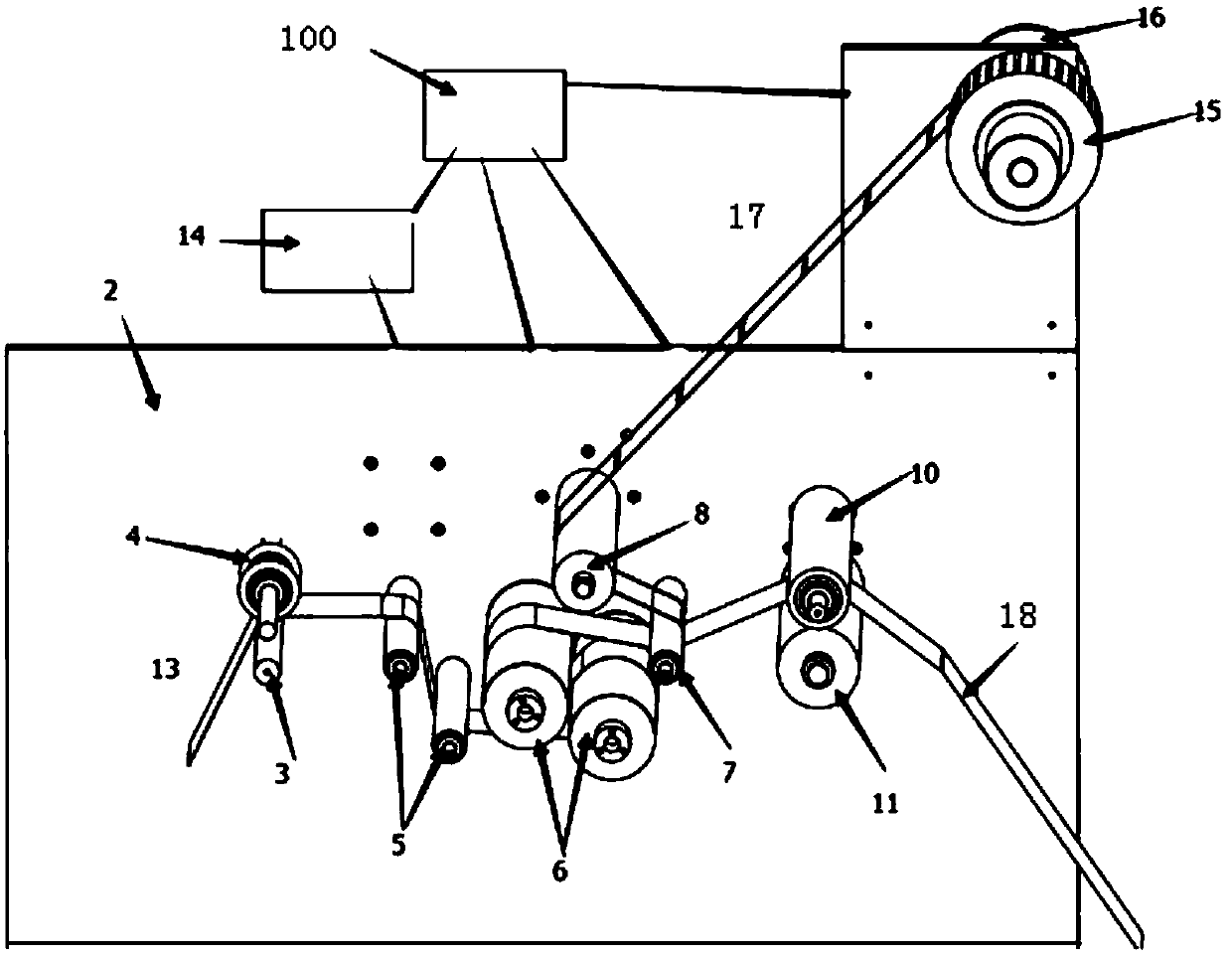

Adhesive sticker die-cutting machine with constant temperature waste discharge function

InactiveCN110653870ALow viscosityControl unit controls viscosityMetal working apparatusAdhesiveControl cell

The invention discloses an adhesive sticker die-cutting machine with the constant temperature waste discharge function. The adhesive sticker die-cutting machine with the constant temperature waste discharge function comprises a supporting plate. A paper traction unit, a rolled material resistance unit and a waste discharge unit are installed on the supporting plate. The paper traction unit and thewaste discharge unit are both connected with a control unit. A rolled material constant temperature unit is arranged on the supporting plate and located in front of the position where the adhesive sticker rolled material enters the waste discharge unit. The rolled material constant temperature unit comprises a temperature sensor, a pair of front guide rollers and a heating device, for instance, apair of heating rollers as the heating device, wherein the temperature sensor and the heating device are both connected with the control unit. According to the adhesive sticker die-cutting machine with the constant temperature waste discharge function, by arranging the rolled material constant temperature unit between a traction roller and a resistance press roll, when to-be-discharged waste enters a die-cutting waste discharge stage, the to-be-discharged waste has a constant temperature, so that the adhesiveness of adhesive is constant, and stripping and waste discharge are easy; and the problem that in the prior art, die-cutting waste discharge is low in reliability is solved, and the production efficiency is improved correspondingly.

Owner:柏志强 +1

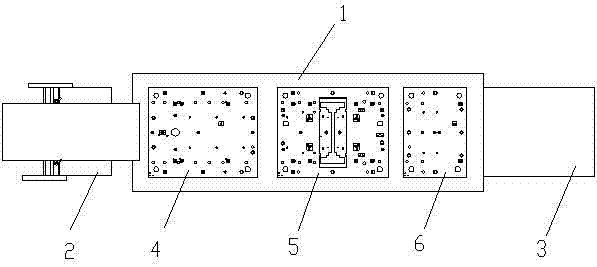

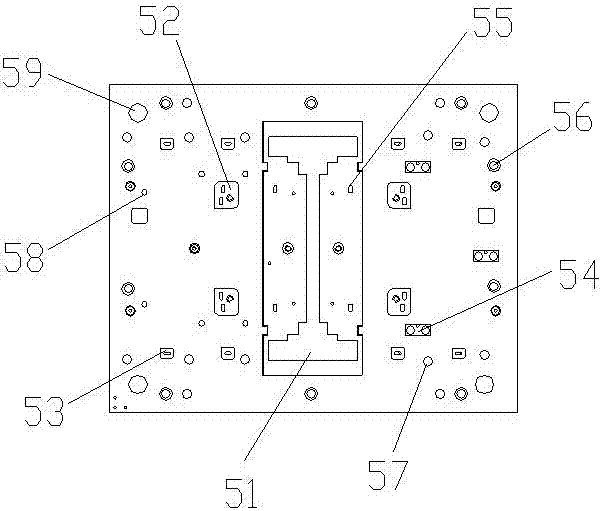

Automatic molding equipment for lamp base plates

The invention discloses automatic molding equipment for lamp base plates. The automatic molding equipment comprises a base, a first lower mold, a second lower mold and a third lower mold are fixedly arranged on the surface of the base, the three lower molds are provided with multiple kinds of molding punching holes in different shapes, and the molding punching holes comprise the first molding punching hole, the second molding punching hole, the third molding punching hole, the forth molding punching hole and the fifth molding punching hole; the second lower mold is further provided with a detachable dumbbell-shaped punching plate, and the upper and lower ends of the dumbbell-shaped punching plate are provided with symmetrical step parts; an upper mold is arranged above the base and is provided with puncher pins corresponding to the molding punching holes and the dumbbell-shaped punching plate in position and shape; and a feeding mechanism is arranged at the front end of the base, and a receiving material conveying belt is arranged at the back end of the base.

Owner:苏州申达洁净照明股份有限公司

Plastic bag sealing device and method and packaging equipment

InactiveCN113525793AAvoid blowingEasy to blow outWrapper twisting/gatheringElectric machineryStructural engineering

The invention discloses a plastic bag sealing device, which comprises a central pivot rod, a first connecting rod, a second connecting rod, a first moving plate, a second moving plate, a telescopic air cylinder, a movable cutter set, a fixed cutter set, an air suction pipe, a driving motor and a transmission assembly; the lower sides of the two ends of the first moving plate and the second moving plate are movably connected to a rack through sliding rails, the ends of the pivot rod are rotatably connected through a bearing seat, a swing rod is fixedly arranged on the central pivot rod, and connecting holes are arranged at the two ends of the swing rod; one end of the first connecting rod is hinged to a connecting hole of the swing rod, and the other end of the first connecting rod is hinged to the first moving plate; one end of the second connecting rod is hinged to the other connecting hole of the swing rod, and the other end of the second connecting rod is hinged to the second moving plate; and the telescopic air cylinder is installed on the second moving plate, the movable cutter set is movably connected to the second moving plate through the sliding rails, and the fixed cutter set is fixedly arranged on the first moving plate. The plastic bag sealing device provided by the invention has the advantages of being efficient in sealing and smooth in sealing.

Owner:杨陈燕

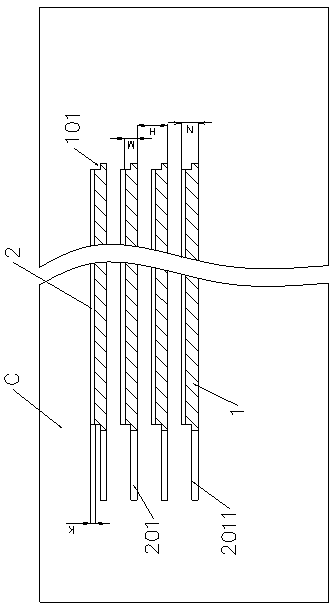

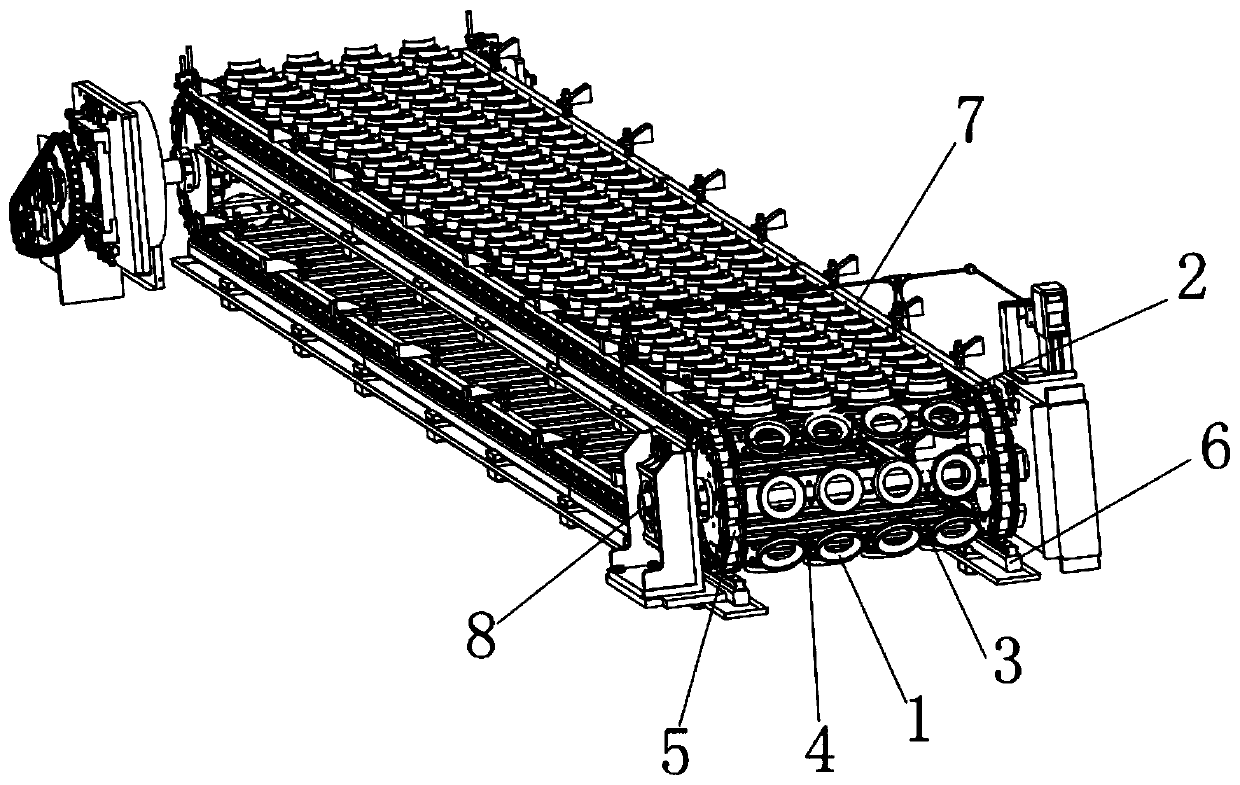

Lug laser cutting device, workbench assembly and lug laser cutting method

PendingCN108284279ACutting does not affectImprove stabilityLaser beam welding apparatusLaser cuttingEngineering

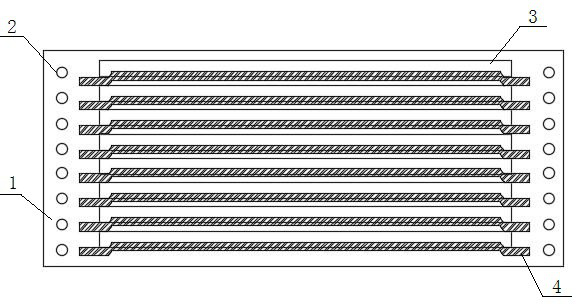

The invention discloses a lug laser cutting device, a workbench assembly and a lug laser cutting method. The workbench assembly comprises an upper air channel plate and a lower air channel plate. Theupper air channel plate is arranged above the lower air channel plate. An interval space allowing the lug to pass is reserved between the upper air channel plate and the lower air channel plate. The bottom face of the upper air channel plate and the top face of the lower air channel plate are each provided with multiple air holes. The upper air channel plate and the lower air channel plate blow air into the interval space through the multiple air holes so as to remove dust. When the workbench assembly cuts the lug, the upper air channel plate and the lower air channel plate blow air to the interval space so as to remove dust, the stability of a conveyed pole plate in the interval space can be improved at the same time, shake of the pole plate in the cutting process is restrained, and therefore an out-of-focus laser and other phenomena can be avoided.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Forming die capable of quickly discharging waste

The invention discloses a forming die capable of quickly discharging waste. The forming die capable of quickly discharging waste comprises a bottom die shell, a bottom die pressing rod, a first bottomdie rear pad, a second bottom die rear pad, a bottom die push pipe, a bottom die core, a flat wire spring, a plurality of elongated rods, and a punching die shell, wherein the bottom die shell is hollow and the top and the bottom of the bottom die shell are open; the bottom die pressing rod is positioned in the hollow cavity of the bottom die shell; the first bottom die rear pad sleeves the bottom die pressing rod and is fixedly fastened on the open end of the bottom of the bottom die shell; the second bottom die rear pad is fixedly fastened below the first bottom die rear pad; the bottom diepush pipe is positioned in the hollow cavity of the bottom die shell and sleeves the bottom die pressing rod; the bottom die core is positioned in the hollow cavity of the bottom die shell and sleeves the bottom die push pipe; the flat wire spring is pressed between the bottom die core and the first bottom die rear pad; the plurality of elongated rods vertically penetrating through the first bottom die rear pad and the second bottom die rear pad to be used for pushing the bottom die push pipe; and the punching die shell is provided with a waste discharge channel. The forming die capable of quickly discharging waste has the advantages of being simple in structure and capable of conveniently discharging waste.

Owner:XINBANG METAL PROD KUNSHAN

A kind of manufacturing method of asynchronous adhesive tape facing the rubber surface

The invention provides a method for making an asynchronous adhesive tape facing the rubber surface. The steps include: compounding the A film on the stripping film, cutting and discharging the waste by a sleeve cutter of the first mold; compounding the compound double-sided adhesive tape on the A film On the film, the bottom adhesive of the composite double-sided adhesive is in contact with the upper surface of the A film, and the upper adhesive is exposed; then it enters the sleeve cutting machine equipped with a second mold, and the cutting edge of the second mold is aligned with the upper adhesive of the composite double-sided adhesive ; Feed the B film through the asynchronous feeding wheel, and perform asynchronous cutting. The cut B film is compounded on the top of the composite double-sided adhesive tape; finally, the entire surface is directly compounded. In the sleeve cutting machine, it is directly cut, the waste frame is discharged, and the product is finally formed. The process of the present invention is to directly expose the double-sided adhesive to the direction of the mold, and directly form it through a sleeve cutting production line, which is convenient for waste discharge, high in product precision, and meets the needs of subsequent mass production; the process of the present invention can improve work efficiency, save material costs, and improve Product yield.

Owner:NANJING GRANDEUR TECH

A kind of cutting method without base material double-sided adhesive tape

ActiveCN111113497BAvoid squeezingAvoid flowLamination ancillary operationsLaminationAdhesive materialsMaterials science

The invention discloses a method for cutting double-sided adhesive tape without a base material, which comprises the following steps: S1. Composite a backing film above a carrier tape, and use a round knife to cut the carrier tape and the backing film in the center along the product area to form A straight gap; S2. Lay double-sided adhesive without base material in the product area of the carrier tape, use a round knife to cut along the gap cut in S1, and obtain a double-sided adhesive material without base material of a determined shape; S3. Composite transfer film on the non-substrate double-sided adhesive material, use a round knife to cut the non-substrate double-sided adhesive material, and trim the arrangement of the non-substrate double-sided adhesive material; then remove the support along the gap in two steps The bottom film, the double-sided adhesive material without substrate is attached to the product area of the transfer film. The invention provides a cutting method without a base material double-sided adhesive tape without a knife mark. The obtained base material double-sided adhesive material is not easy to be deformed, is not easy to fall off, and can be quantitatively produced.

Owner:DONGGUAN LINGYI PRECISION MFG TECH CO LTD

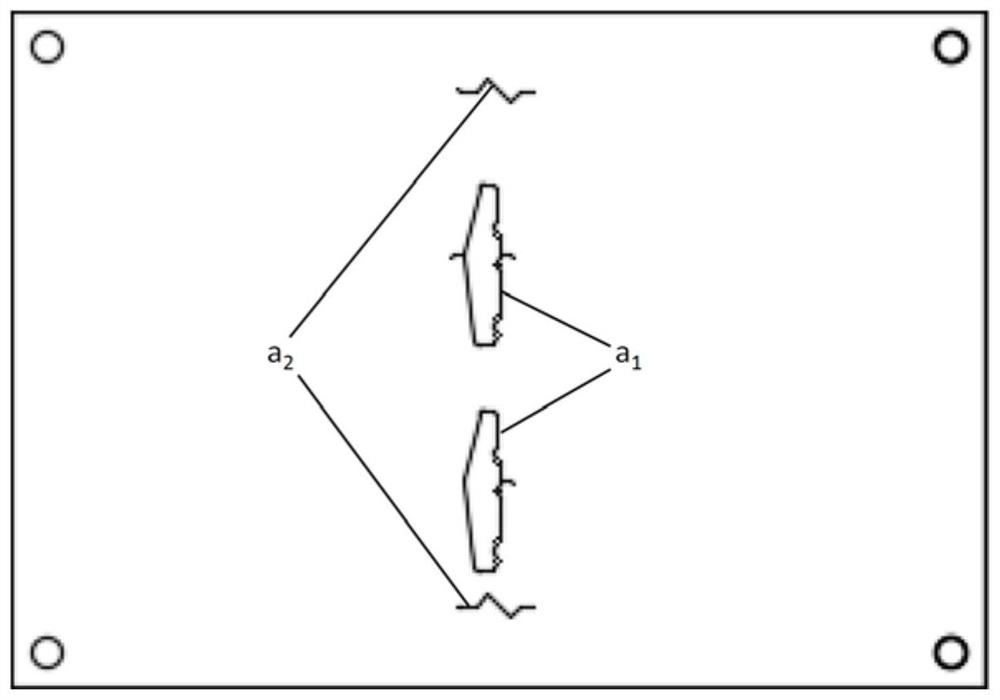

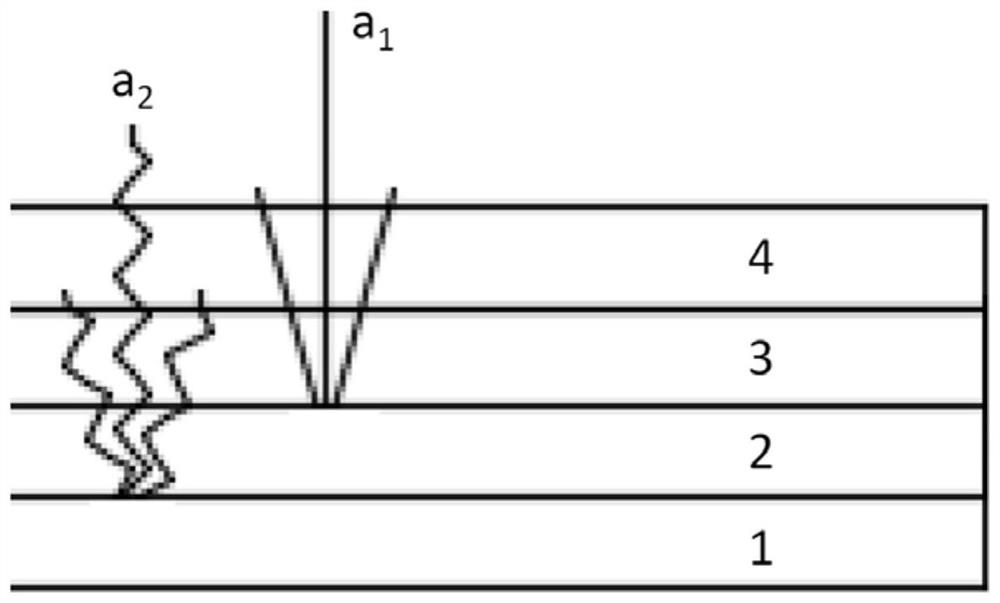

A die-cutting process of flat plate knife removal

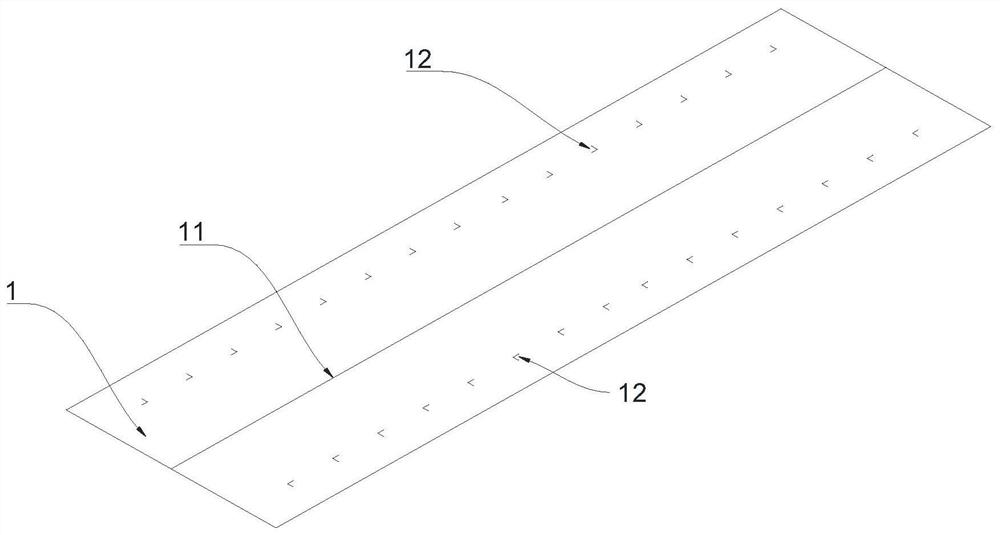

ActiveCN110238906BEasy to processImprove processing yieldMetal working apparatusTectorial membraneHorizontal pitch

The present invention aims at the problem that the die-cut frame in the prior art is easy to produce embossing, etc., and provides a flat-plate die-cutting process, which is used for the die-cutting of the frame of the protective film product, and is characterized in that: according to the line characteristics and the According to the process requirements, the frame of the protective film product is split into N knife lines along the line trend. Correspondingly, the knife die used for die-cutting the protective film product is provided with N blades for cutting the N knife lines. The N blades are arranged equidistantly along the horizontal direction, and the distance between two adjacent blades is recorded as the column spacing a1, and the column spacing a1 is equal to the horizontal spacing a0 between adjacent two protective film products, for The moving step s of the material tape of the die-cutting protective film product on the die-cutting machine is equal to the column spacing a1; wherein, N>1 and N is an integer. The present invention effectively reduces the probability of embossing and crushing of products obtained by die-cutting by removing the knife, and greatly improves the yield rate of the process.

Owner:郑州领胜科技有限公司

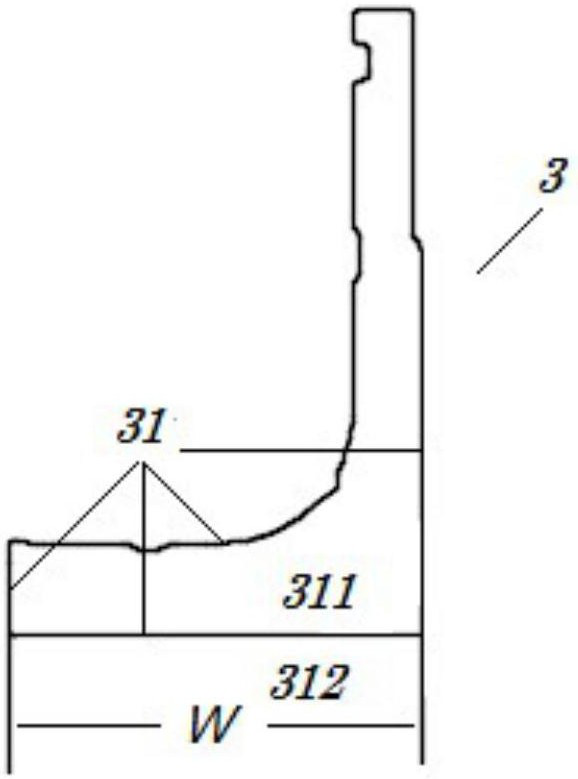

Processing technology with handle mylar

ActiveCN111098357BGuaranteed sizeConvenient waste disposalMetal working apparatusFilm baseStructural engineering

The present invention provides a processing technology with a handle Mylar, which includes the following steps: S1, first punching the release film, forming the contour of one side edge of the handle area on the release film, and passing the punching through the sleeve. method to form a positioning hole; S2, compound Mylar on the release film, position the Mylar and the release film based on the positioning hole, and punch the Mylar and the release film for the second time to form the release film at one time. Draw the contour of the finished product and the contour of the remaining edges of the handle area compounded on the Mylar finished product; S3. Exclude the corresponding Mylar waste on the handle area and the release film waste outside the contour of the Mylar finished product. The processing technology of the mylar with handle of the present invention achieves the purpose of not only cutting out the release film handle, but also ensuring the size of the mylar and good waste discharge by punching and cutting the release film and the mylar separately. For various types of Mylar with this structure, high-precision products can be produced by using this process, and the processing difficulty is greatly reduced.

Owner:深圳安洁电子有限公司

Packaging bag blowing device and method and sealing equipment

InactiveCN113525794AAvoid blowingEasy to blow outWrapper twisting/gatheringElectric machineryStructural engineering

The invention discloses a packaging bag blowing device, which comprises a guide frame, a linear bearing, a lifting plate, an inclined supporting column, a blowing column, a stepping motor, a synchronous belt assembly, an air inlet seat, a control air cylinder and an air suction frame; the guide frame is fixedly arranged on a rack, a cylindrical shaft is arranged in the middle of the guide frame, the linear bearing is movably matched on the cylindrical shaft, the lifting plate is installed on the linear bearing, a connecting channel is arranged on one side of the lifting plate, the inclined supporting column is arranged on the other side of the lifting plate, and the blowing column is installed at the lower end of the inclined supporting column; a slim hole is arranged in the side of the blowing column; the air inlet seat is mounted at the lower end of the guide frame, the control cylinder is mounted at the upper end of the air inlet seat, and a telescopic end of the control cylinder is provided with a blocking piece; and the air suction frame is fixed to the rack, two rectangular material containing holes are arranged in the middle of the air suction frame and located directly below the blowing column, and a row of air suction holes are arranged in the periphery of each rectangular material containing hole. The packaging bag blowing device provided by the invention has the advantages of being efficient in bag blowing, reliable in fixation and convenient to bag.

Owner:杨陈燕

Efficient four-shaft tapping machine facilitating waste discharge

InactiveCN112809445AConvenient waste disposalImprove the safety of useThread cutting machinesDispersed particle filtrationAir pumpInjection air

The invention discloses an efficient four-shaft tapping machine facilitating waste discharge. The efficient four-shaft tapping machine comprises a bottom plate, a special-shaped protection plate and a fixed support, wherein a first chute is arranged in the top of the bottom plate; a first sliding block is movably arranged at the top of the first chute; a waste recycling box is fixedly connected to the top of the first sliding block; a connecting rod is fixedly arranged at the end of the waste recycling box; and a grip is fixed to the side of the connecting rod. According to the efficient four-shaft tapping machine facilitating waste discharge, an air pump is started, the air pump conveys air to the position of an air injection gun, and the air injection gun conducts air injection cleaning on a workbench and an object; through the special-shaped protection plate formed a fixed block, a connecting column and a fixing bolt, waste chips are effectively prevented from being blown to the ground or eyes of workers; and through the arrangement of a special-shaped supporting plate and an electric push rod, the air injection gun can more comprehensively clean the object and the workbench, the influence of the waste chips on screwing of a next object is greatly avoided, and then the use safety of the tapping machine is improved.

Owner:金良军

A production process of a sheet label

ActiveCN109532185BQuality assuranceConvenient waste disposalLamination ancillary operationsLaminationProcess engineeringWaste material

The invention discloses a production process for a sheet-shaped label. The production process comprises the following steps: (1) shearing: shearing release backing paper into a sheet-shaped structure;(2) film lamination: laminating a PP film onto each sheet of release backing paper; (3) cut-shaping of the release backing paper: placing a film-laminated release backing paper sheet into a positioning-hole cut-molding seat, and subjecting the surface of the release backing paper sheet to positioning-hole cut-molding; (4) PP film cut-molding: rotating a positioning-hole cut-molded surface material for 180 degrees, placing the surface material into a surface material cut-molding seat, and subjecting the PP film to shape cut-molding; (5) discharging of waste materials: discharging a waste surface material through a manner of manual peeling, wherein a positioning-hole waste material cut off from the release backing paper is taken away during discharging of the waste surface material by utilizing the adhesion force of the waste surface material; and (6) material collection: after the waste materials are discharged, stacking and collecting the obtained surface material. Through changing ofa cut-molding process, and by adoption of a separate cut-molding manner of the front and back surfaces of the surface material, the positioning-hole waste material cut off from the release backing paper is taken away together with a peeled PP film waste material during discharging of waste materials, so the quality of cut-molding can be guaranteed, and waste discharging is convenient.

Owner:KUNSHAN HUAGUAN TRADEMARK PRINTING

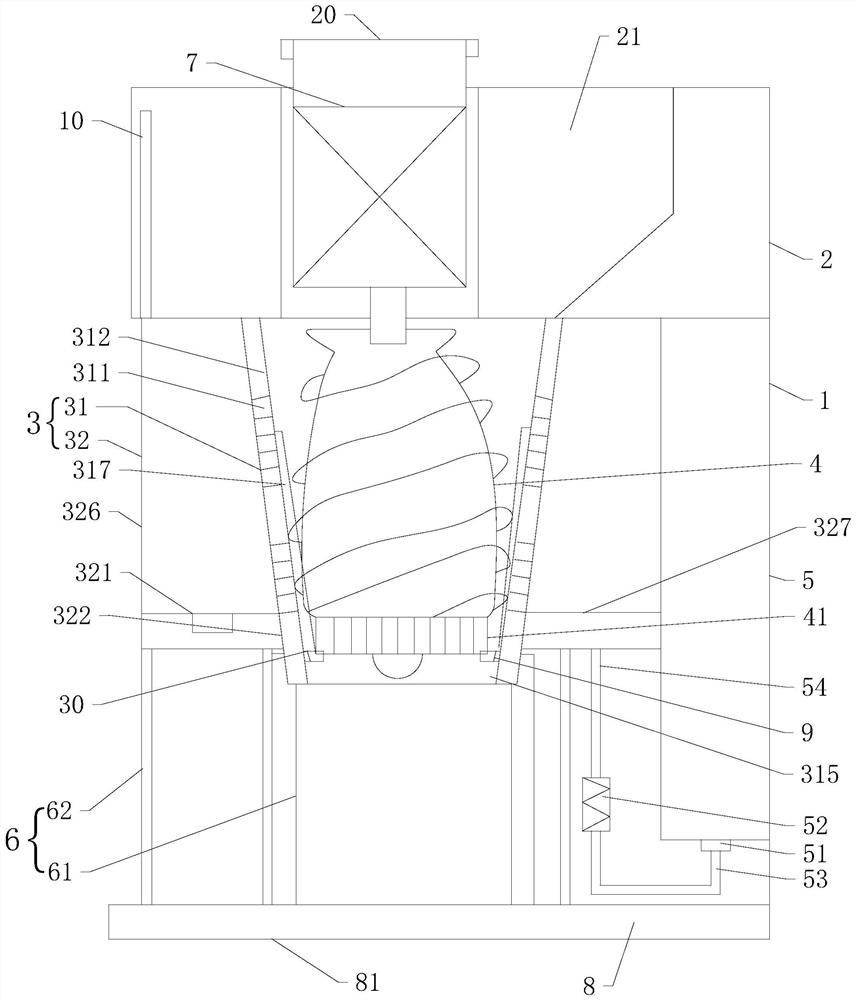

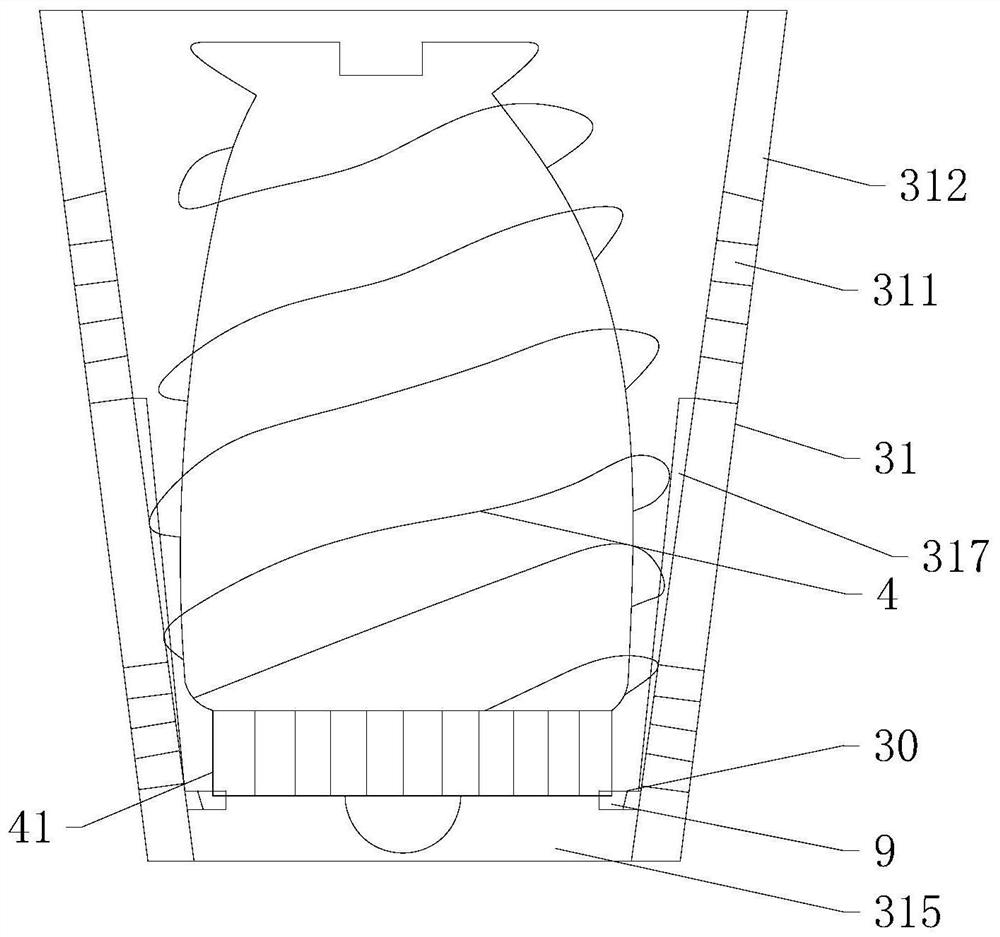

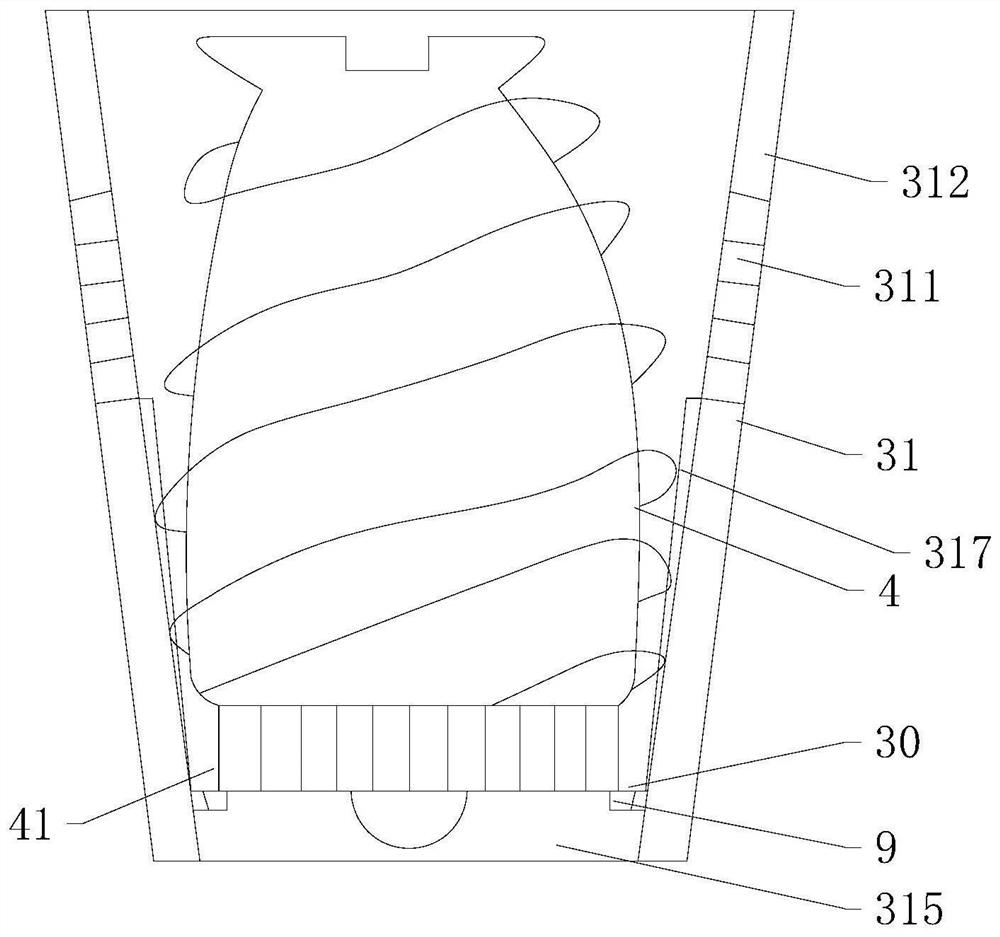

Control method of multifunctional food processor

PendingCN114847744AGuaranteed rotation effectConvenient waste disposalStrainersProcess engineeringMechanical engineering

The invention provides a control method of a multifunctional food processor, the food processor comprises a juice squeezing container and a screw rod arranged in the juice squeezing container, the food processor is characterized in that the bottom of the juice squeezing container is provided with a waste discharge channel, the screw rod is driven to be at a first working position for closing the waste discharge channel, and the screw rod rotates in the juice squeezing container; and the driving screw rod is located at a second working position for opening the waste discharging channel, and waste discharging work is conducted through the waste discharging channel. The screw can be switched between two working positions in the juicing or cleaning working process, operation is convenient, the juice yield of fruit and vegetable juice or soybean milk made through the control method is higher, and the residue and juice separation effect is good; when the control method is used for executing cleaning work, the cleaning effect is good, automatic cleaning can be achieved, and during automatic cleaning, the cleaning work is simpler, and cleaning is more thorough.

Owner:JOYOUNG CO LTD

A knife roller blade limit and waste discharge device

The invention relates to a knife roller blade limiting and waste discharging device, and belongs to the field of engraving molds. The device comprises a knife roller and is characterized by further comprising a blade detachably mounted on the surface of the knife roller, the blade comprises a first blade inclined side, an inclined blade top side and a second blade inclined side, the first blade inclined side and the second blade inclined side are arranged in parallel, and the inclined blade top side is connected with the first blade inclined side and the second blade inclined side; the two ends of the blade are provided with a first moving limiting block which moves in the extension direction parallel to the rotating axis of the knife roller and a second moving limiting block which vertically moves; the lower end of the blade is connected with a heating block; and compared with the prior art, the knife roller blade limiting and waste discharging device has the beneficial effects that the blade can be detached, blades of different sizes can be limited, through heating, the blade heats, and therefore welding is achieved, roller cutting is also achieved, and waste discharge is facilitated.

Owner:坂崎雕刻模具(昆山)有限公司

Production method of die-cutting foam rubber without knife marks

The invention relates to a die cutting production method for a cut mark-free cotton adhesive tape . According to the method, a bottom film needs not to be replaced and waste is discharged conveniently, and the obtained cotton adhesive tape is free of burrs, cut marks and excessive glue. The production method comprises the following steps: feeding a laminated die obtained by laminating an isolatingfilm and the bottom film and the cotton adhesive tape without body paper step by step into a clearance machine for die cutting, wherein the cotton adhesive tape and the laminating die are stepped once after die cutting every time; cutting the middle main body part of the cotton adhesive tape by a lower cross cutter line, and forming a cotton adhesive tape unit, the width of which is equal to thestepping distance of the cotton adhesive tape, in the vertical direction of the middle main body part of the cotton adhesive tape during stepping every time and adhering the cotton adhesive tape unitto the surface of the isolating film; starting to calculate the die cutting number of times and the stepping number of times from 0 after stepping some time, encircling the cutting line of the middlemain body part of the isolating film by an upper cross cutter line and a side cutter line during (N+1)th die cutting and the cutting line of the middle main body part of the isolating film during Nthdie cutting after stepping for N times to form an isolating film unit; and discharging waste in the periphery of the isolating film unit.

Owner:成都冠佳科技有限公司

Small size sheet die cutting process

ActiveCN110978129BImprove efficiencyReduce dosageMetal working apparatusWaste materialIndustrial engineering

The invention provides a small-size sheet die-cutting process, which includes the following steps: S1, attaching the material tape to the carrier film, and transporting it to the downstream for the first die-cutting; S2, performing the second die-cutting through the first row of knives One-time die-cutting to form the first profile of the small-size sheet; S3, remove the first waste area; S4, convey the carrier film and its feeding belt after the first die-cut to the downstream for the second die-cut Cutting; S5, carry out the second die-cutting by the second row of knives to form the second profile of the small-size sheet, and form the finished product of the small-size sheet through the formed first profile and the second profile; S6, exclude the second waste area. The invention realizes the step-by-step molding of the product and synchronous waste discharge through the steps of twice die-cutting and waste discharge, which is beneficial to waste discharge and prevents the occurrence of the problem of chip dropping. In addition, while improving the efficiency of the die-cutting process, it also reduces the amount of the carrier film and reduces the cost of the process.

Owner:深圳安洁电子有限公司

A double-sided adhesive die-cutting waste discharge device used on a die-cutting machine

ActiveCN113321038BGuaranteed continuityConvenient waste disposalArticle deliveryWebs handlingAdhesiveSprayer

The invention discloses a double-sided adhesive die-cutting waste discharge device used on a die-cutting machine, relates to the technical field of double-sided adhesive die-cut waste discharge, comprising: a discharge roller, the discharge roller is used for continuously supplying double-sided adhesive Assembly, the double-sided adhesive assembly includes release paper and release paper-substrate; die-cutting mechanism, used for die-cutting the double-sided adhesive assembly, so that it can be separated into continuous double-sided adhesive waste and two parts of the continuous double-sided adhesive finished product; the stripping roller group two is used to peel off the double-sided adhesive waste and the double-sided adhesive finished product, wherein the double-sided adhesive finished product is received by the finished product located above it and the lower film supply roller, the lower film supply roller is used to continuously supply the lower film, and the lower film enters the stripping point of the stripping roller group two after being guided by the guide roller three, and is combined with the double-sided adhesive waste The bottom of the film is bonded to form a reinforced waste; and, the bonding side of the lower film is sprayed by the sprayer one to realize water bonding.

Owner:SUZHOU TIANLIDA ADHESIVE PROD CO LTD

Knife roller blade limiting and waste discharging device

ActiveCN106078919AConvenient waste disposalAchieve weldingMetal working apparatusPulp and paper industry

The invention relates to a knife roller blade limiting and waste discharging device, and belongs to the field of engraving molds. The device comprises a knife roller and is characterized by further comprising a blade detachably mounted on the surface of the knife roller, the blade comprises a first blade inclined side, an inclined blade top side and a second blade inclined side, the first blade inclined side and the second blade inclined side are arranged in parallel, and the inclined blade top side is connected with the first blade inclined side and the second blade inclined side; the two ends of the blade are provided with a first moving limiting block which moves in the extension direction parallel to the rotating axis of the knife roller and a second moving limiting block which vertically moves; the lower end of the blade is connected with a heating block; and compared with the prior art, the knife roller blade limiting and waste discharging device has the beneficial effects that the blade can be detached, blades of different sizes can be limited, through heating, the blade heats, and therefore welding is achieved, roller cutting is also achieved, and waste discharge is facilitated.

Owner:坂崎雕刻模具(昆山)有限公司

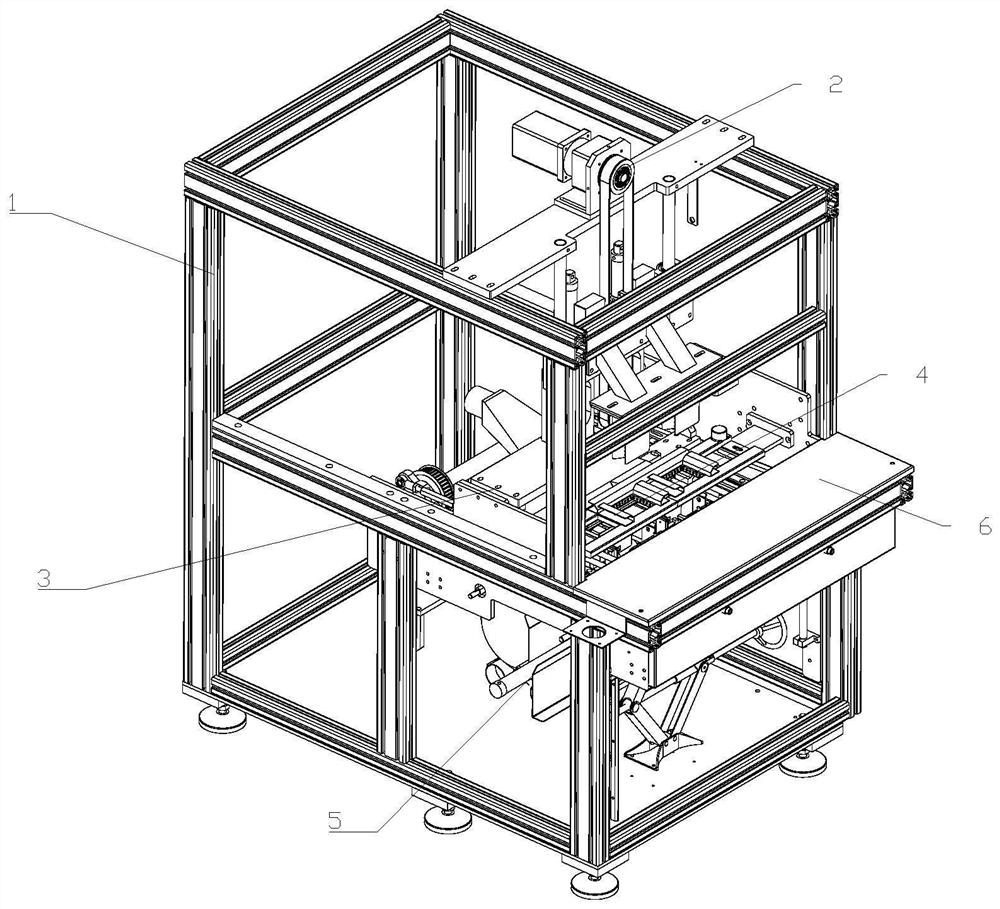

A wire rope winding device

ActiveCN105460817BEasy to rewindConvenient waste disposalWinding mechanismsGear wheelElectric machinery

The invention relates to a steel wire rope winding device. The steel wire rope winding device comprises a spool device, spool fixing devices, a bracket and a driving device, wherein the spool device comprises a spindle, a gear of which the side center of a circle is fixedly perpendicular to one end of the spindle, four rectangular connecting plates which are circumferentially distributed along the spindle at equal intervals, a side plate which is connected to the other end of the spindle and four fan-shaped plates; the spool fixing devices are fixed to both opposite sides of the bracket, the spool fixing devices are formed by sliding shafts, shaft sleeves and locking pins which are used for the sliding shafts to be axially positioned in the shaft sleeves, and the sliding shafts are assembled in blind holes in both ends of the spindle, so that the spool device is positioned; the driving device is fixed to the bracket and is driven to be engaged with the gear by a motor, so as to drive the gear to rotate, so that a steel wire rope is wound. According to the steel wire rope winding device, the expansion and contraction of the fan-shaped plates in the radial direction of the gear are realized by utilizing the displacement of the fan-shaped plates in the radial direction of the gear, the winding and waste discharge of the steel wire rope are realized by utilizing the removable side plate, and the winding and waste discharge of steel wire ropes of various sizes can be conveniently and quickly completed, so that the labor intensity is reduced, and additionally, the working efficiency is improved.

Owner:HANGANG GRP HANBAO IRON & STEEL +1

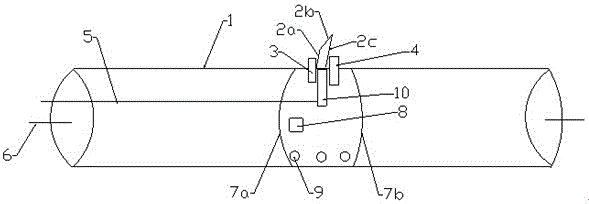

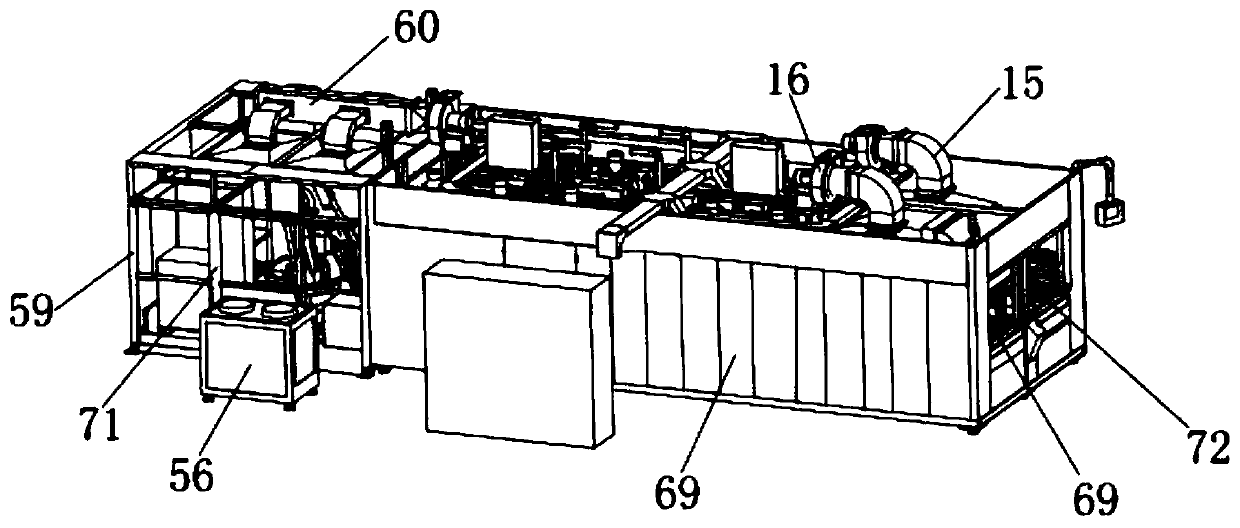

Device and method for dipping of copper wire winding of automobile generator stator

ActiveCN108832784BEasy to collectConvenient waste disposalManufacturing dynamo-electric machinesCopper wireExhaust fumes

The invention discloses a device and method for varnishing a copper wire winding of an automobile generator stator. The device comprises a preheating transmission mechanism, an overall structure framecontaining high temperature furnaces, a varnishing device and a gelling and curing transmission mechanism after varnishing, wherein the preheating transmission mechanism before varnishing and the gelling and curing transmission mechanism after varnishing pass through the overall structure frame containing the high temperature furnaces side by side to be assembled together; and the varnishing device is connected with the overall structure frame containing the high temperature furnaces. The transmission mechanism disclosed by the invention achieves the effect of zero damage to a product in thetransmission process through a stable placement structure. According to the device and the method, the effect of zero damage to the product in the transmission process is achieved. A transporting technology, a baking technology and a varnishing technology for a product are separated in the technological process, so that an exhaust gas generated from volatilization of an insulating paint is easierto collect and thorough exhaust treatment is facilitated. Through the baking mode, of forming hot air circulation through heating air, of air drying components, the temperature of high-temperature regions is more uniform, meanwhile, the heat transfer efficiency of the air is significantly improved and the gelling and curing process quality is improved.

Owner:湖南中伟智能制造有限公司

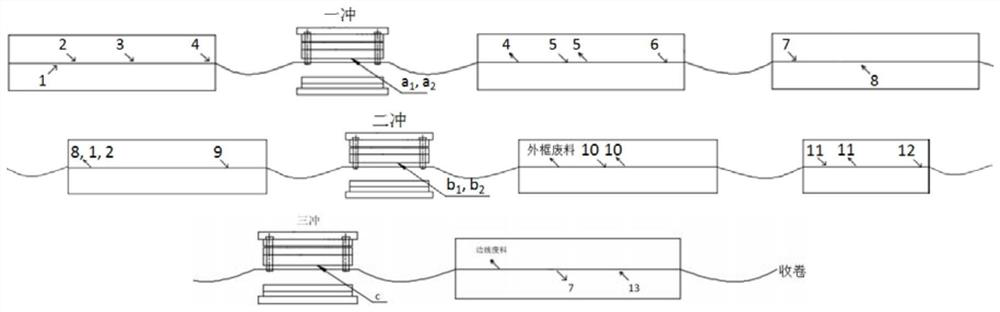

Manufacturing method of vertical die cutting piece with irregular double-glue area

PendingCN114378900AConvenient waste disposalSmooth waste dischargeMetal working apparatusEngineeringAdhesive

The invention relates to a manufacturing method of a vertical die cutting piece with an irregular double-glue area. The method comprises the following steps that (1) a first-stage material belt is attached; (2) primary punching die cutting and waste discharging; (3) attaching a secondary material belt: sequentially attaching a handle film (6) and a second single-sided adhesive (7) to the double-sided adhesive (3), then attaching a silica gel belt (8) to the lower part of the single-sided adhesive (1), overturning the material belt, discharging the silica gel belt (8), the single-sided adhesive (1) and the bottom film (2), and attaching a cover film (9) to the double-sided adhesive (3) to form the secondary material belt; (4) secondary punching die cutting and waste discharging; (5) laminating a third-stage material belt; (6) third-time punching die cutting and waste discharging; and (7) laminating and rolling the die-cutting piece product: laminating partition paper (13) below the handle film (6) to form a vertical die-cutting piece with an irregular double-glue area, and rolling the vertical die-cutting piece. Compared with the prior art, the invention has the advantages of no displacement of the double faced adhesive tape, low product reject ratio and the like.

Owner:昊佰电子科技(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com