Forming die capable of quickly discharging waste

A forming mold and fast technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to clean waste, affect the forming of parts, no waste discharge channel, etc., to achieve convenient waste discharge and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

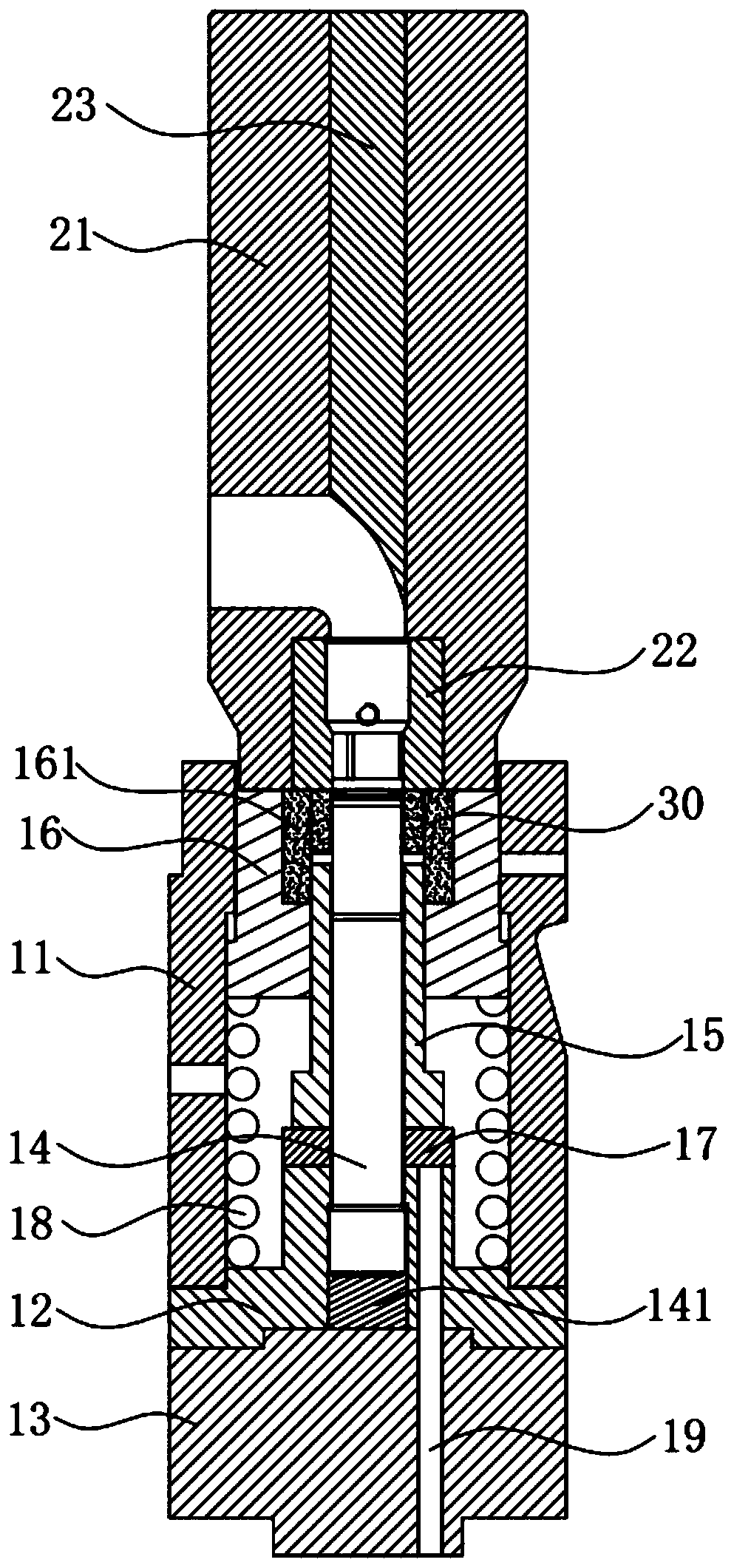

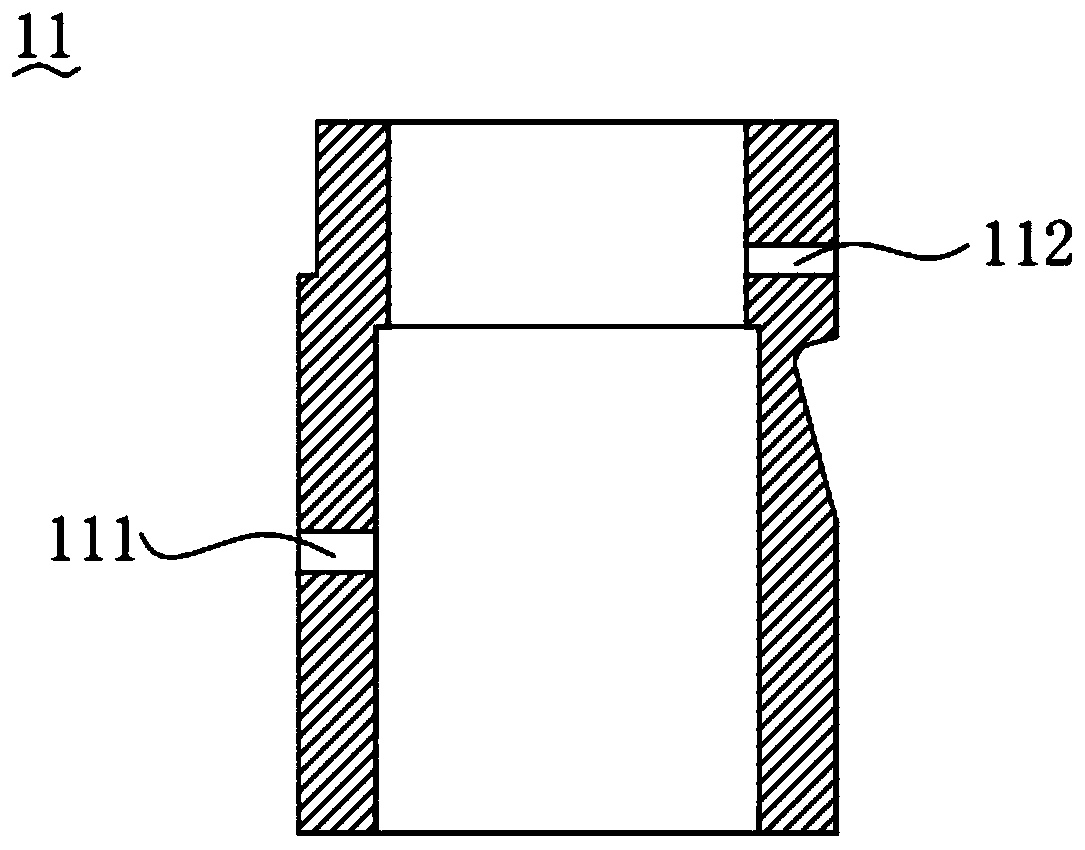

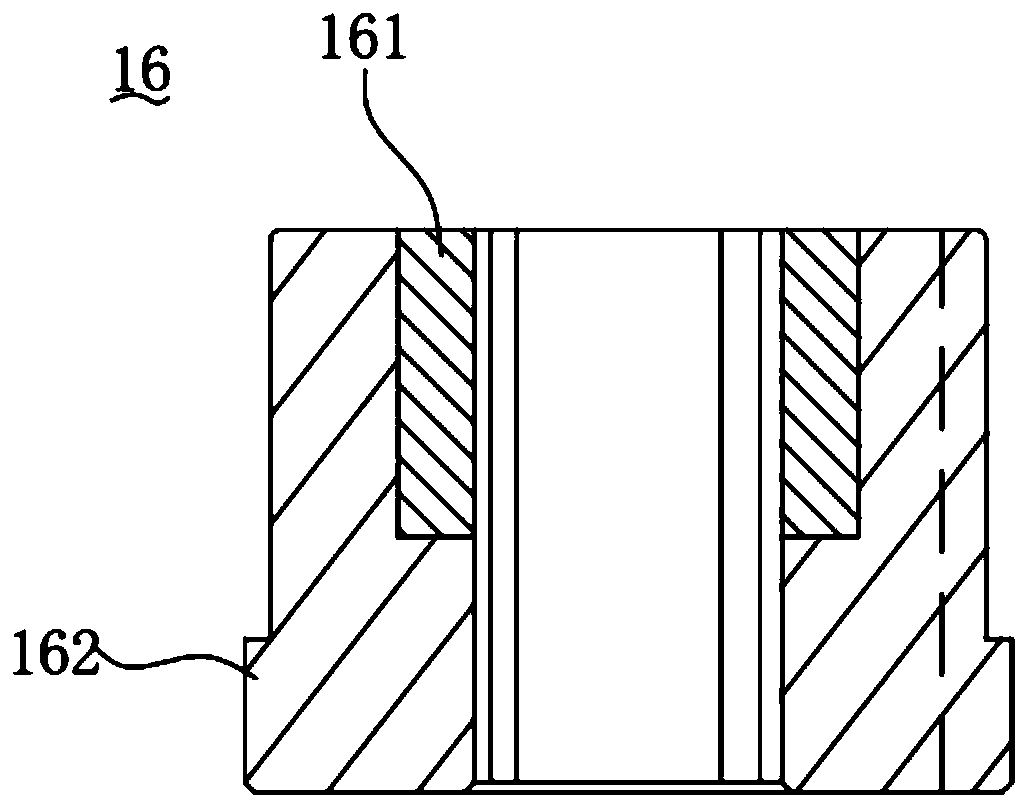

[0023] like Figure 1 to Figure 6 As shown, the present invention provides a fast waste-discharging molding die, comprising: a bottom mold shell 11 with a hollow interior and openings at the top and bottom; a bottom mold pressing rod 14 located in the hollow cavity of the bottom mold shell 11; One set is arranged on the bottom mold pressing rod 14 and is fastened on the first bottom mold rear pad 12 on the bottom open end of the bottom mold shell 11; one is fastened on the first bottom mold rear pad 12 below Two bottom mold rear pads 13; one is located in the hollow cavity of the bottom mold shell 11 and is sleeved on the bottom mold push tube 15 on the bottom mold pressure rod 14; one is located in the hollow cavity of the bottom mold shell 11 and A bottom mold core 16 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com