Label production technology with automatic waste discharge function

A production process and labeling technology, applied in the direction of cardboard items, etc., can solve the problems of heavy workload, mistakes, damaged products, etc., and achieve the effect of facilitating overall waste disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-Figure 5 As shown, a label production process that can automatically discharge waste includes the following steps:

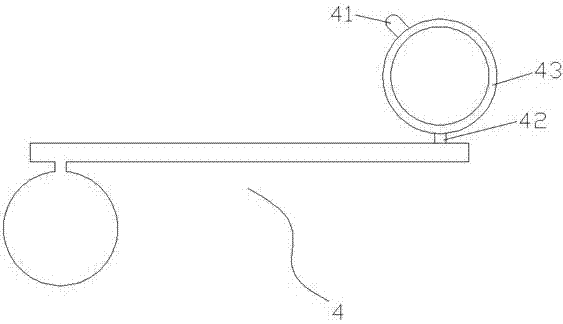

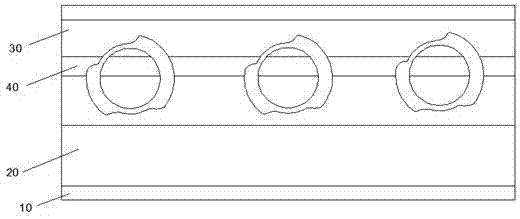

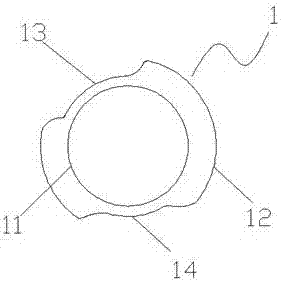

[0025] (1) Paste the mopp film 10 on the release base paper, and paste a layer of low-adhesive film 20 on the upper surface of the mopp film 10, and the area to be cut between the mopp film 10 and the low-adhesive film 20 is provided with a strip The first Marathon tape 40, the position of the first Marathon tape 40 pasting is as figure 2 As shown; (2) Die-cut the low-mucosa 20 and the first Marathon tape 40 using the first knife die 1, cut out a round hole on the low-mucosa 20, and put the low-mucosa 20 waste around the hole together with the The first Marathon tape cut off by the die is removed together. In this waste discharge process, a second Marathon tape is pasted on the area where the round hole is located on the low m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com