A double-sided adhesive die-cutting waste discharge device used on a die-cutting machine

A waste discharge device and double-sided adhesive technology, which is applied in the directions of transportation and packaging, thin material processing, and delivery of objects, can solve the problems of waste discharge failure, double-sided adhesive waste breakage, low efficiency, etc., and achieve anti-break attachment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

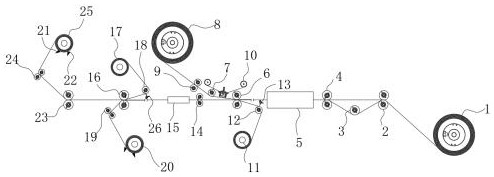

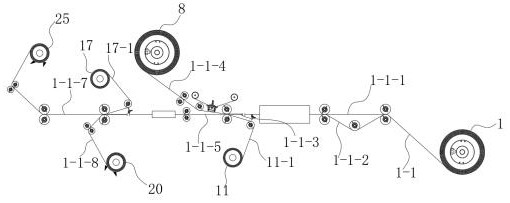

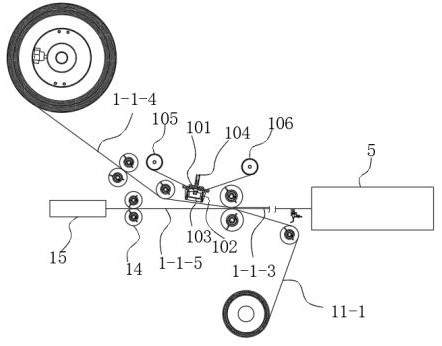

[0037] see Figure 1~4 , the present invention provides a double-sided adhesive die-cutting waste discharge device used on a die-cutting machine, comprising:

[0038] Discharge roller 1, described discharge roller 1 is used for continuously supplying double-sided adhesive tape assembly 1-1, and described double-sided adhesive tape assembly 1-1 includes release paper 1-1-1 and release paper-substrate 1-1-2; It should be noted that, if Figure 4 , in the embodiment of the present invention, the double-sided tape assembly 1-1 is named as two parts, that is, the release paper 1-1-1 and the release paper-substrate 1-1-2, wherein the release paper- The substrate includes another release paper and the substrate, and the upper and lower surfaces of the substrate are pre-applied with glue;

[0039] Die-cutting mechanism 5 for die-cutting the double-sided adhesive assembly 1-1 so that it can be separated into continuous double-sided adhesive waste 1-1-3 and continuous double-sided adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com