Die cutting production method for cut mark-free cotton adhesive tape

A production method and technology of foam glue, which is applied in metal processing and other directions, can solve the problems of difficult foam tape die-cutting, easy deformation of products, overflow of glue, etc., so as to avoid colloid detachment and delamination, and reduce the use of auxiliary materials , Reduce the effect of overflow glue phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

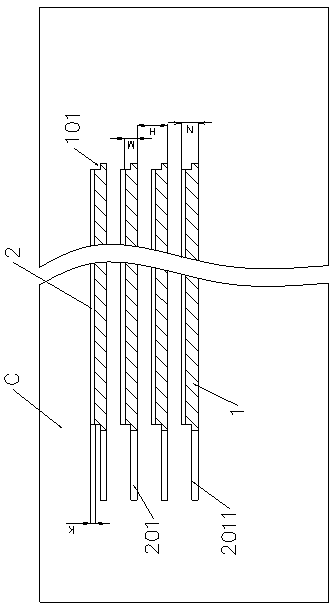

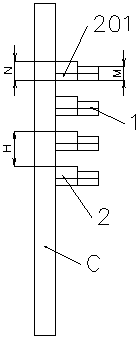

[0024] see figure 1 , 2 The foam glue shown is composed of tape units arranged at intervals on the base film C, and the tape unit includes a foam glue unit 1 and an isolation film unit 2 . The foam glue unit 1 has cutouts 101 on the upper left and right sides. The isolation film unit 2 is located between the base film C and the foam rubber unit 1 , and its left side part extends out of the foam rubber unit to form a tearing hand 201 , the upper edge 2011 of the tearing hand is flush with the bottom of the cutout 101 . The width of foam rubber unit 1 (at the widest point) M=1.75mm, the width of isolation membrane unit 2 (at the widest point) N=1.8mm, the lower edge of the foam rubber unit is flush with the lower edge of the isolation membrane unit, and the foam The upper edge of the glue unit is 0.05mm lower than the upper edge of the isolation membrane unit. The distance between tape units is H=4.4mm. The thickness of the foam glue unit is about 1 mm, and the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com