Patents

Literature

59results about How to "Reduce glue overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

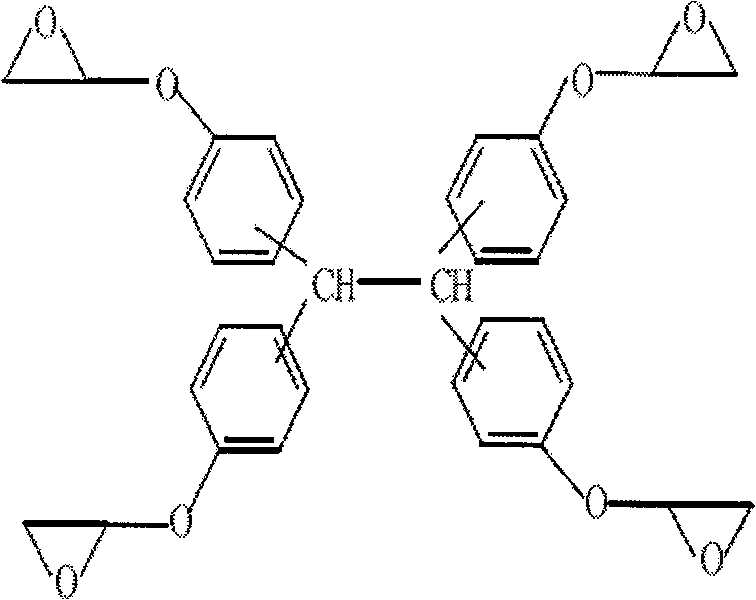

Siliconless fire-retardant type quick solidifying covering film for flexible circuit and its preparation method

InactiveCN1537906AGuaranteed stabilityLower volatility pointLiquid surface applicatorsEpoxy resin coatingsEpoxyElastomer

A flame-retarded quickly solidified silicon-free covering film for flexible circuit contains brominated epoxy resin, liquid phenolic epoxy resin, high-activity low-viscosity epoxy resin, acrylate copolymer, diaminodiphenyl sulfone (or methane), aluminium hydroxide, Sb2O3, and toluene / acetone. Its advantages are high adhesion and fire resistance.

Owner:SHENZHEN DANBOND TECH

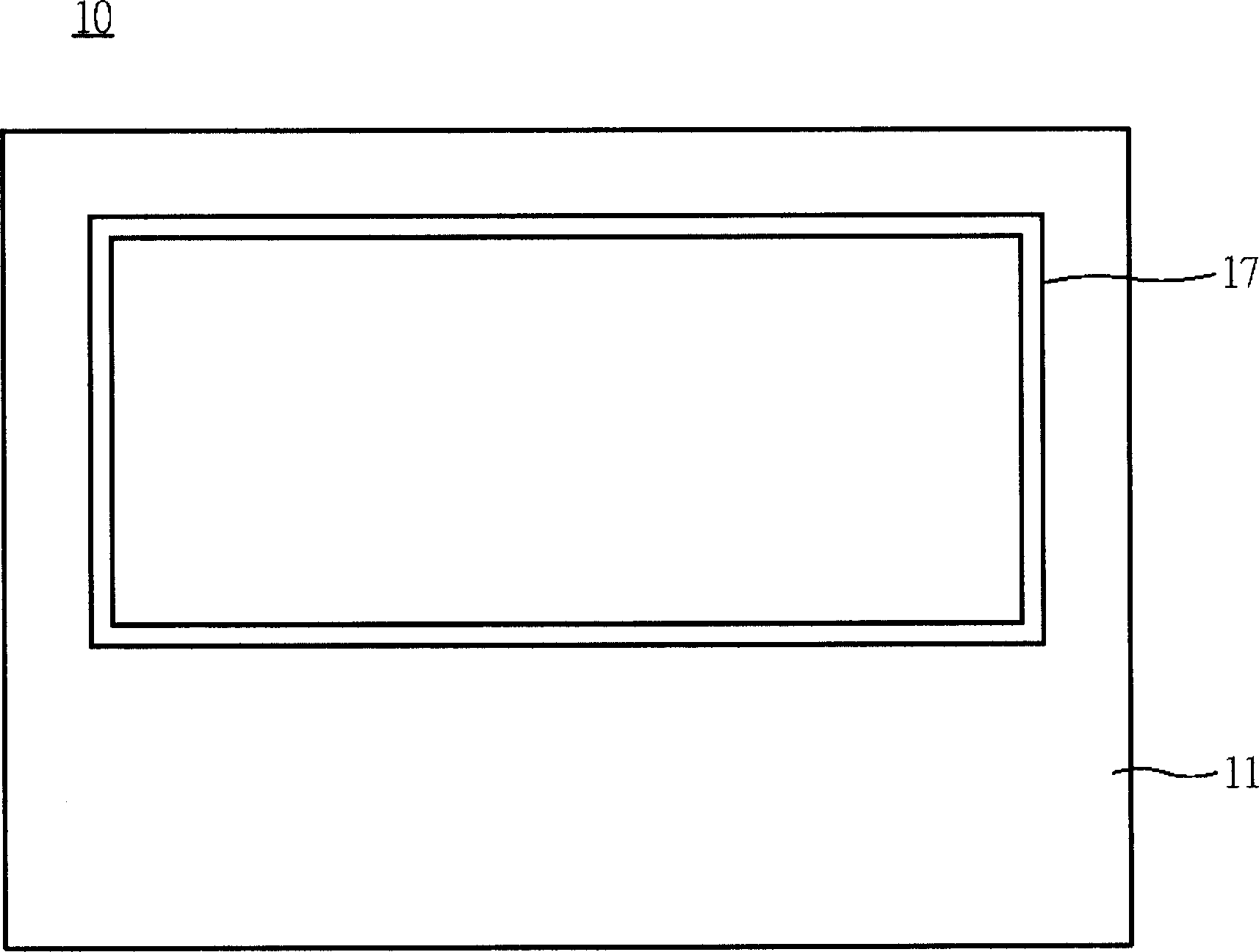

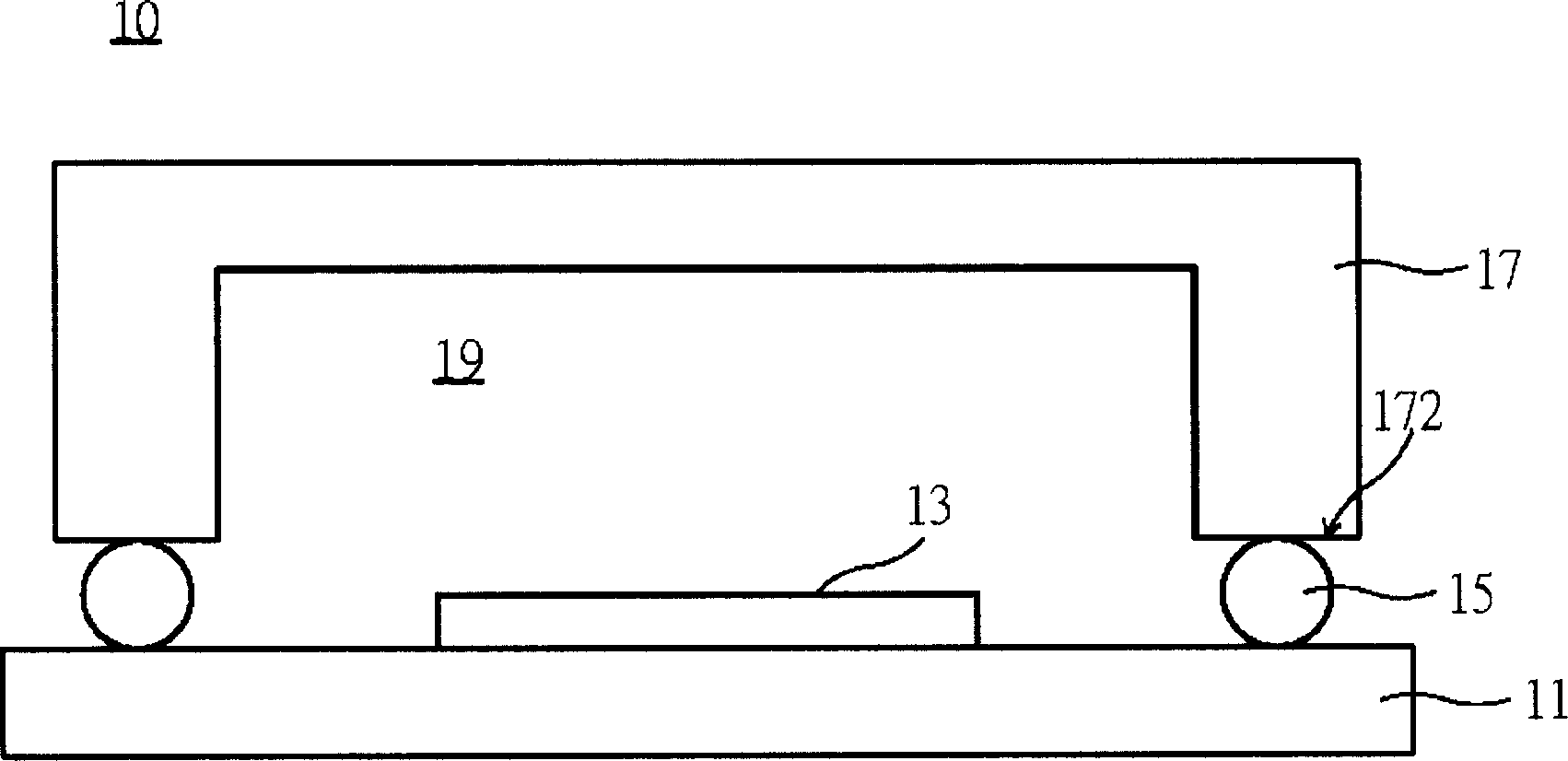

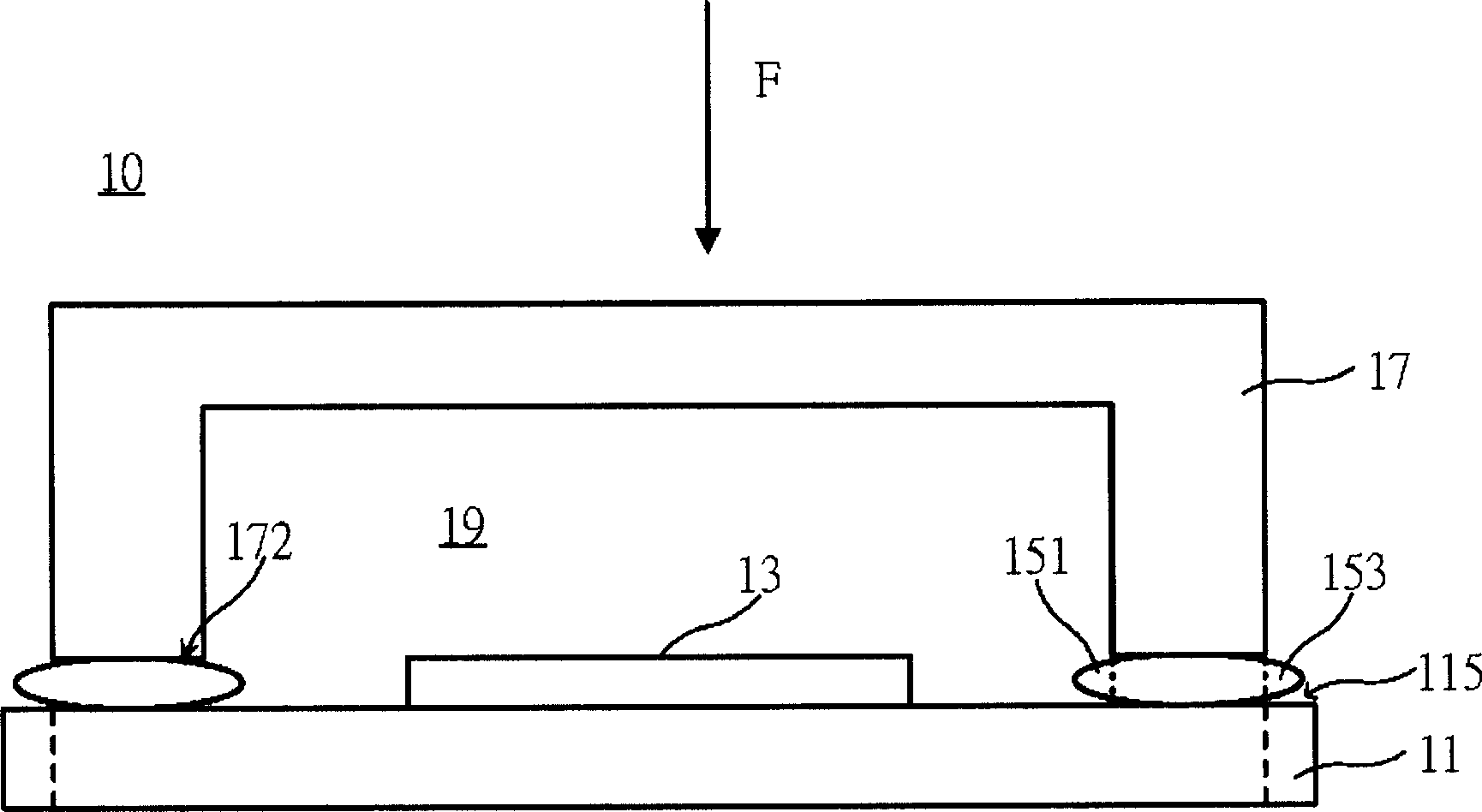

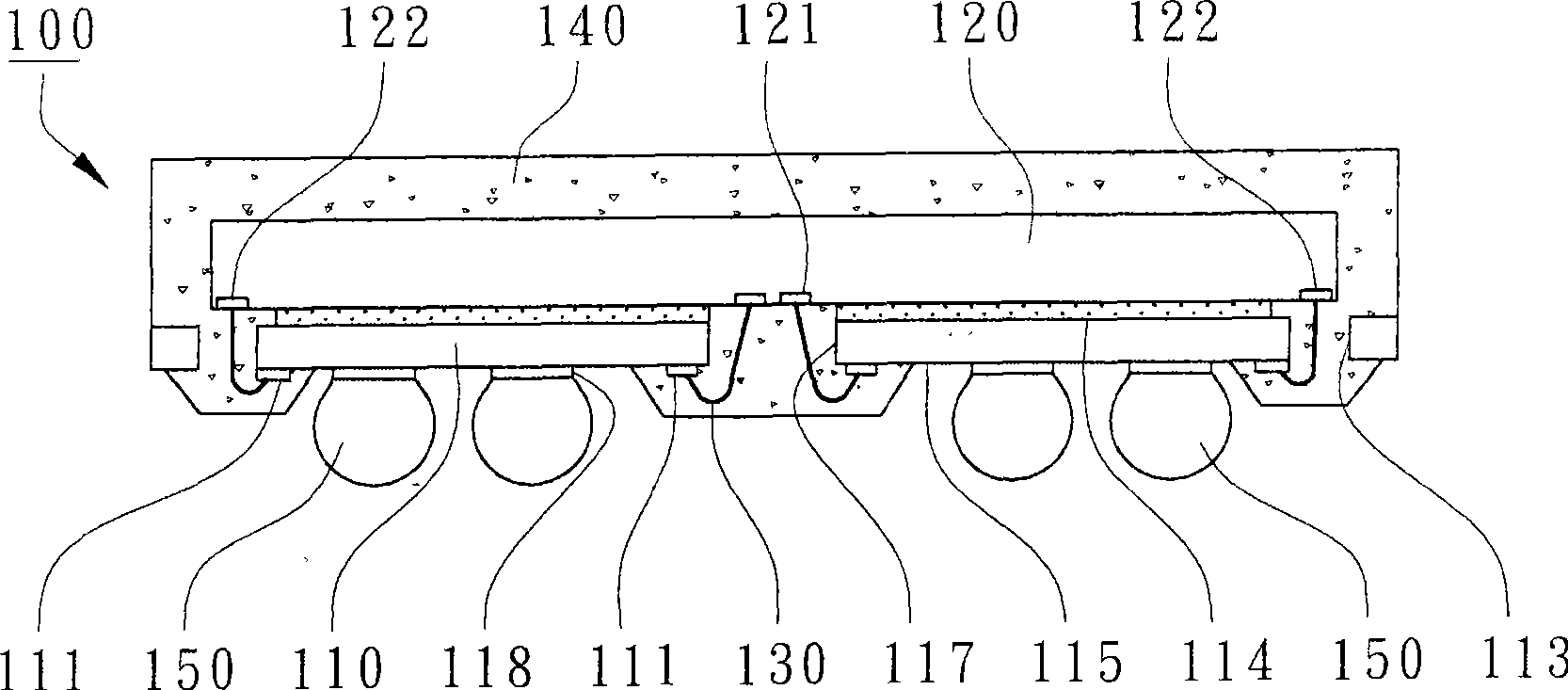

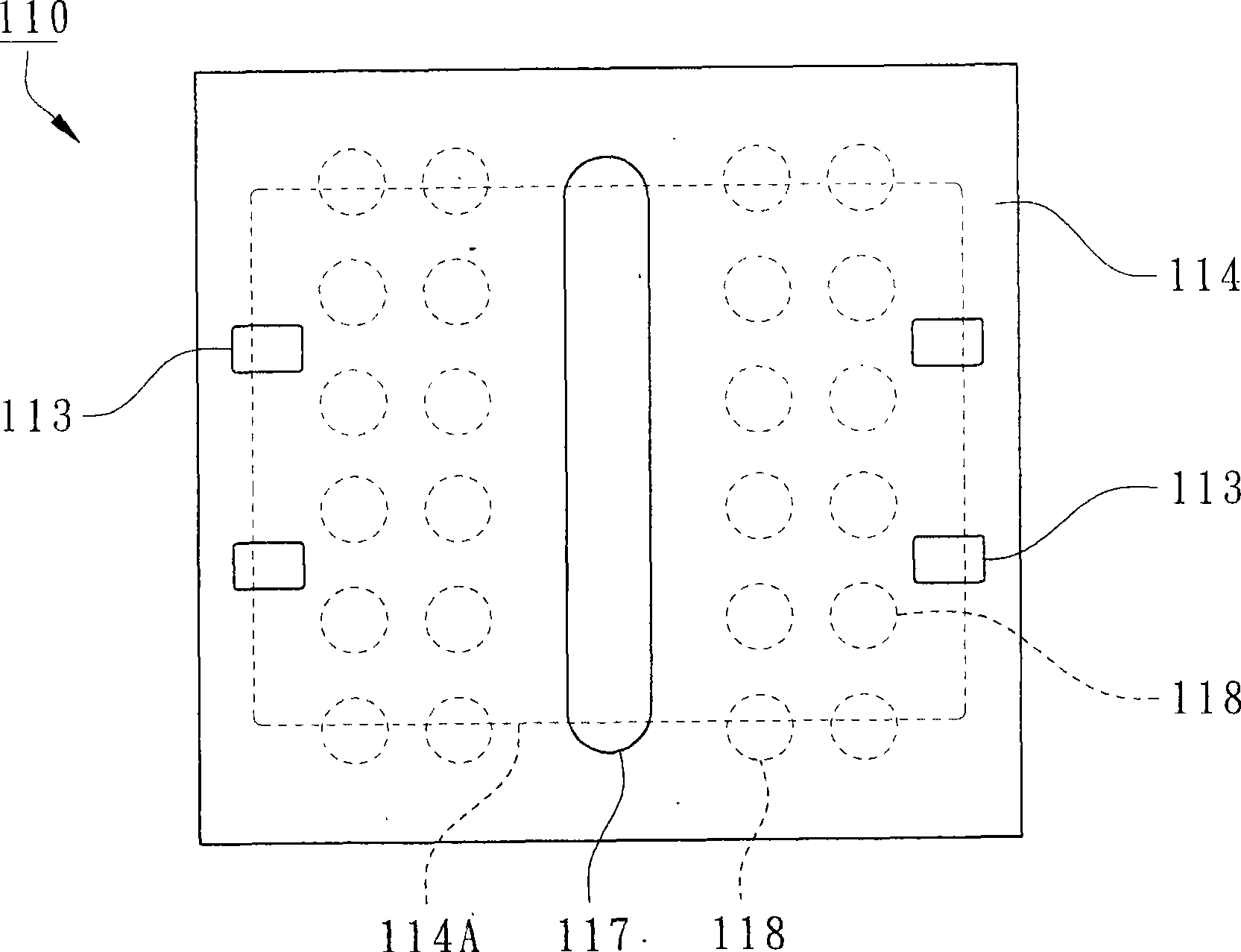

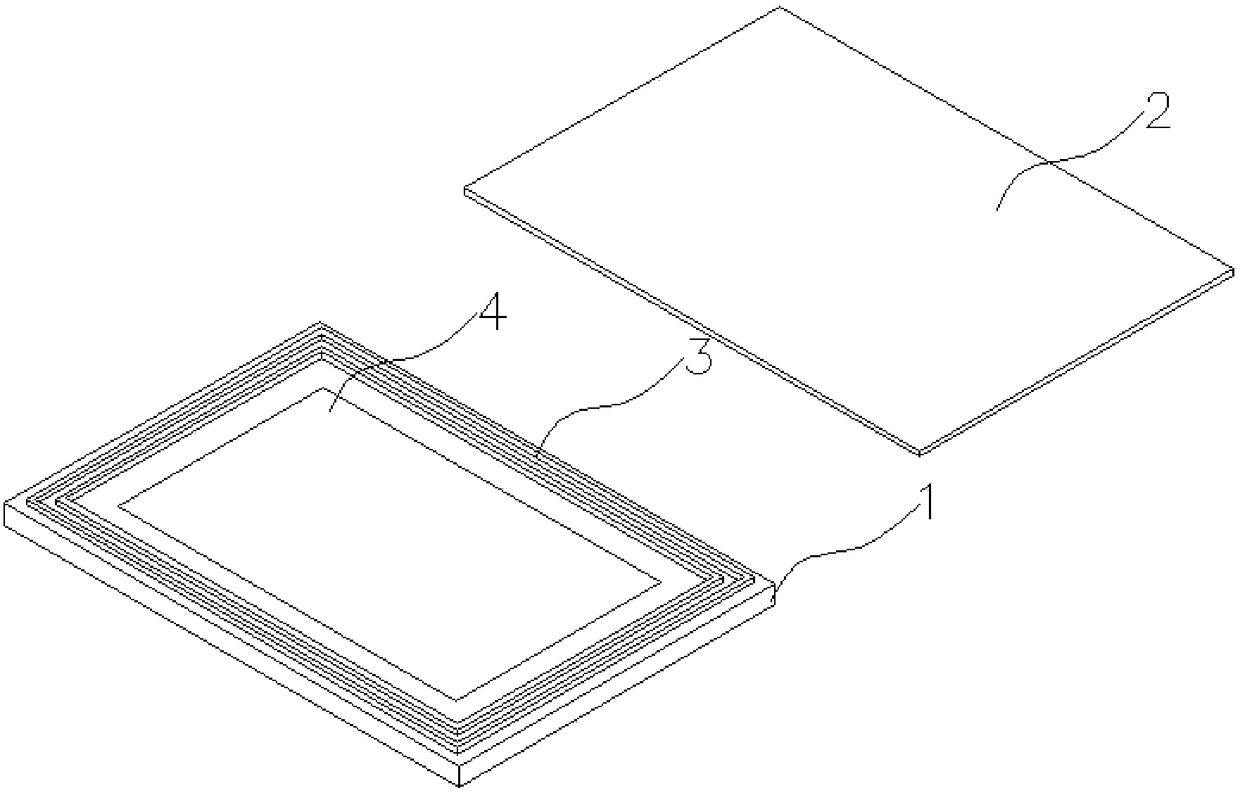

Structure for packaging organic electroluminescence device

InactiveCN1652647AImprove production yieldImprove production efficiencyElectroluminescent light sourcesSolid-state devicesEngineeringAgglutination

Encapsulation structure for organic electroluminescence device (OELD) includes following parts and structures: base plate and OELD on the base plate; encapsulation cover plate above the base plate in use for covering the OELD; multiple partition walls are setup at glue spreading region; A sealing glue regions are formed between two adjacent partition walls naturally. Agglutination glue is accommodated inside sealing glue regions. Thus, encapsulation cover plate through agglutination glue is agglutinated on the base plate. The invention raises superior rate and manufacturing efficiency and quality of product, as well as reduces glue flooding so as to be in favor of mass manufacture of the product.

Owner:UNIVISION TECHNOLOGY

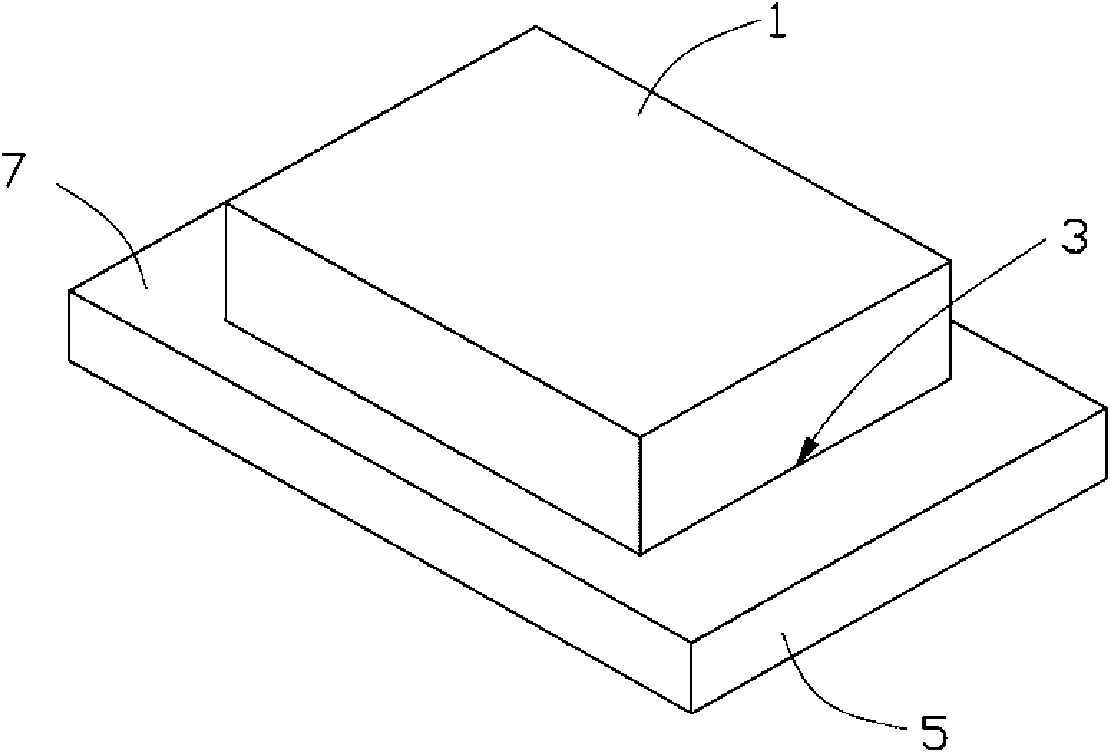

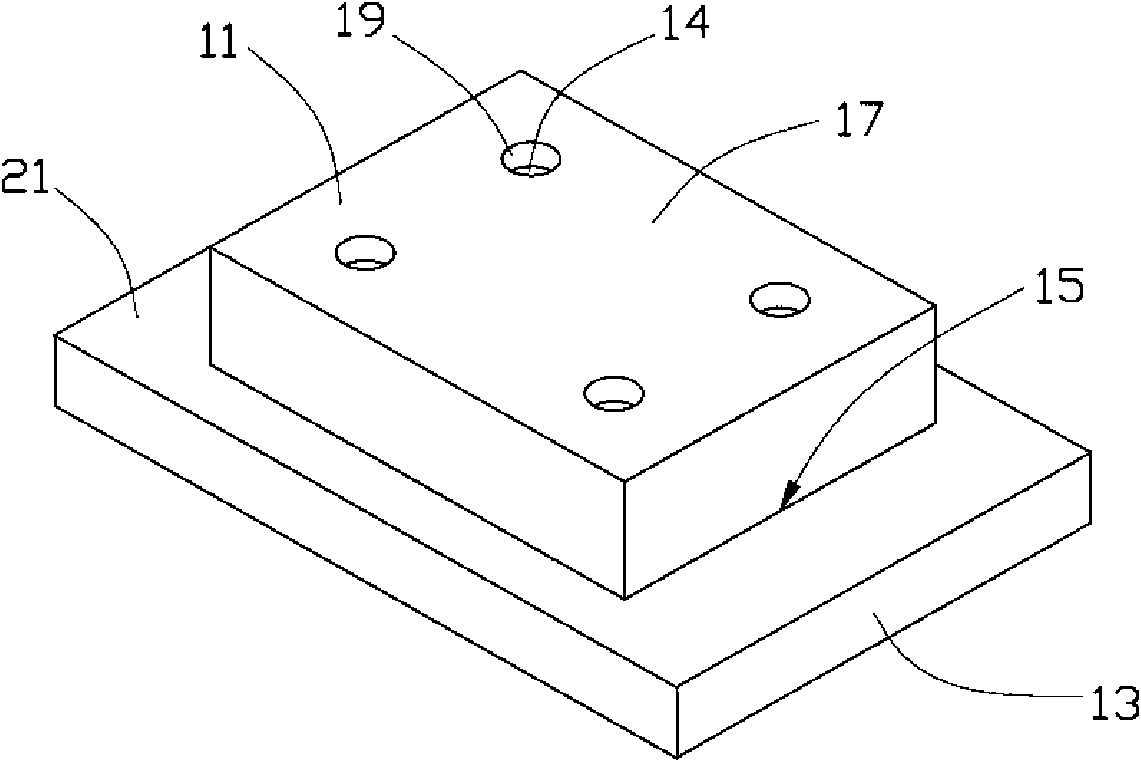

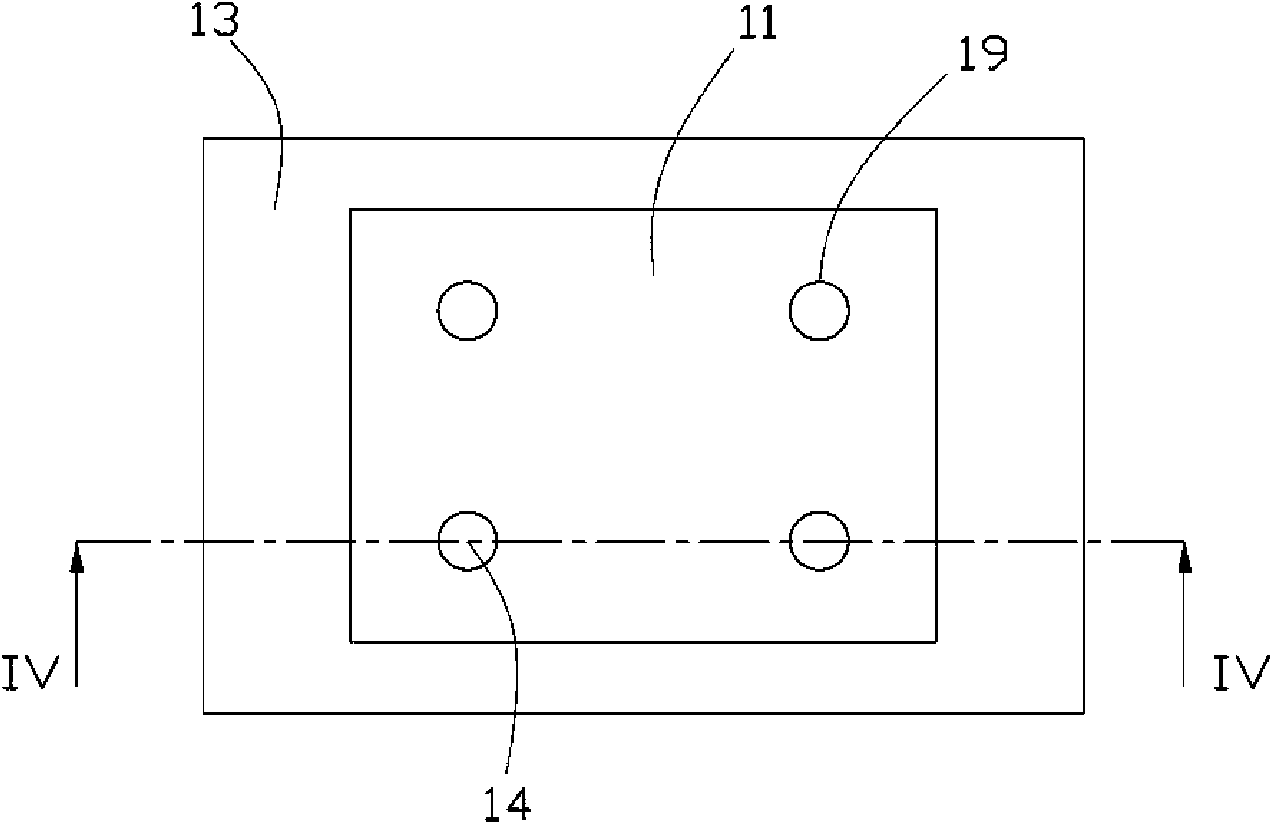

Agglutinating member and agglutinating method

InactiveCN101526172AHigh precisionAvoid manufacturing schedule impactAdhesive processesSheets/panelsAgglutinationColloid

An agglutinating member comprises a first member, a second member and glue by which the first member and the second member are connected. The first member comprises a first junction surface, a sizing surface and a sizing channel. The second member comprises a second junction surface which corresponds to the first junction surface. The glue is sized from the sizing channel, flows to the second junction surface of the second member, and enables the two members to be agglutinated by the inner wall of the sizing channel and the second junction surface. Because of the existence of the sizing channel, the surplus micro glue can stay in the sizing channel, thereby the probability of glue overflow is reduced, and the precision of the agglutination of the members is enhanced. The invention also provides an agglutinating method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

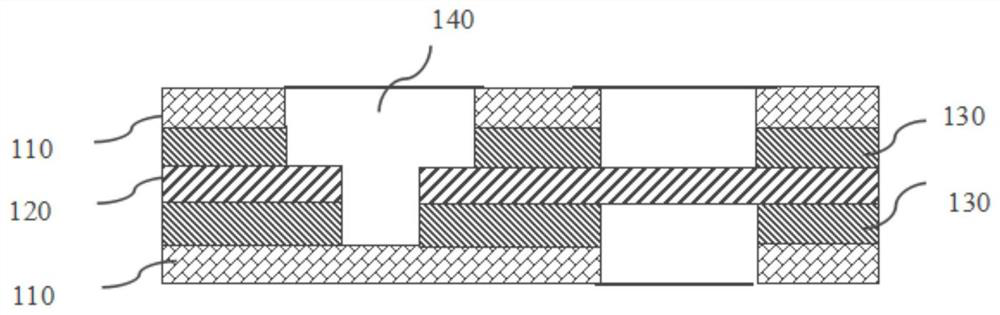

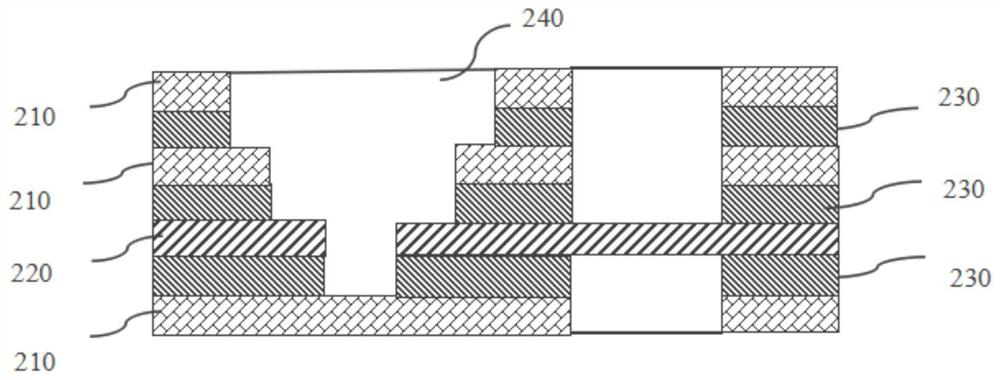

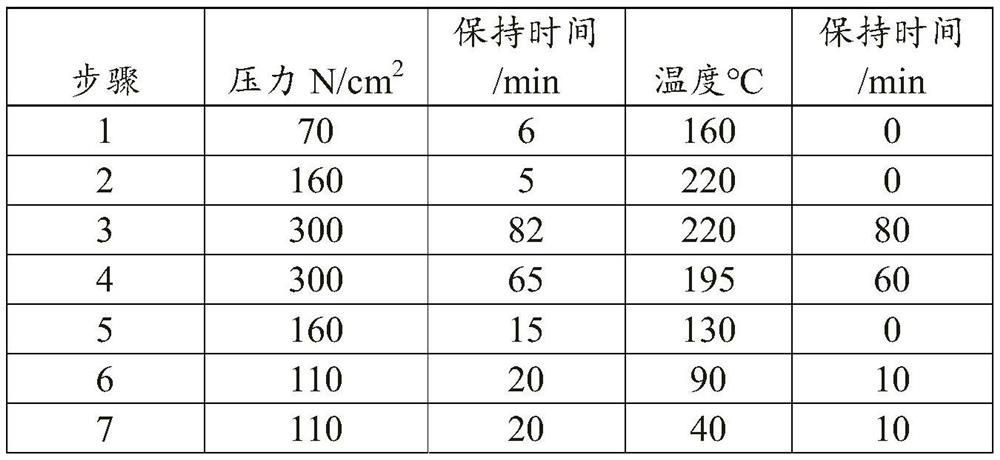

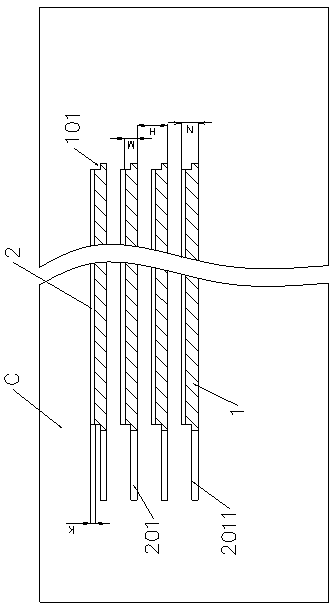

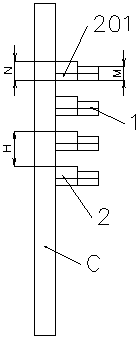

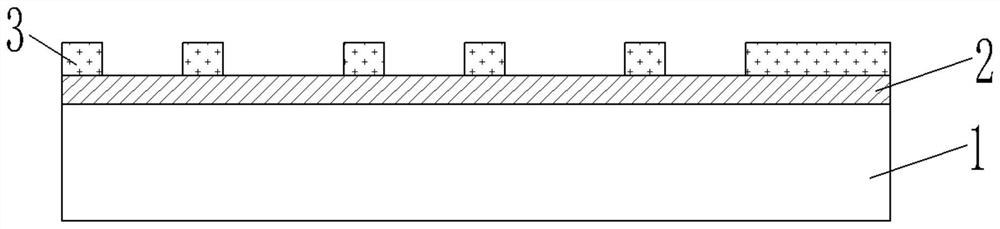

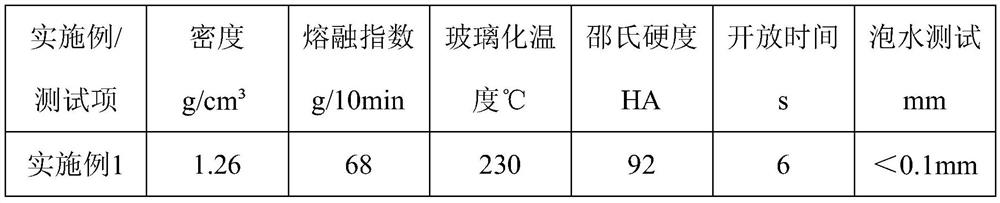

Preparation method of rigid-flex printed circuit board with blind groove

ActiveCN111683473ARealize the combinationEasy to pressMultilayer circuit manufactureStructural engineeringMechanical engineering

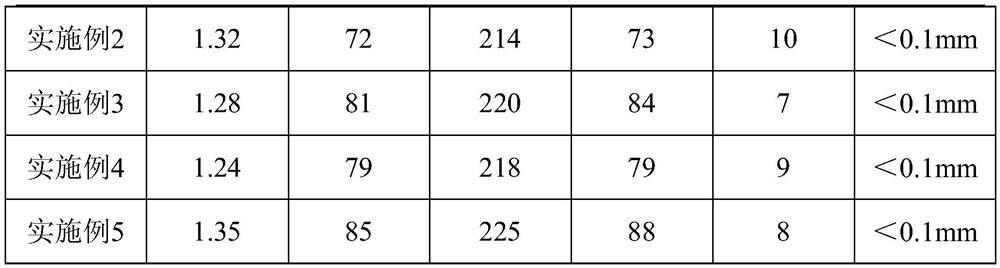

The invention belongs to the technical field of printed circuit boards, and discloses a preparation method of a rigid-flexible printed circuit board with a blind groove. The method comprises the following steps: (1) manufacturing a flexible board, and milling the position of the blind groove on the flexible board; (2) manufacturing a rigid plate, and milling the position of a blind groove in the rigid plate; (3) manufacturing prepregs, and milling blind groove positions and flexible areas on the prepregs; (4) stacking the rigid plate prepared in the step (2), the prepreg prepared in the step (3) and the flexible plate prepared in the step (1) in a staggered manner, respectively plugging blocking films in blind grooves of the rigid plate, the flexible plate and the prepreg, and performing laminating; (5) manufacturing an outer layer circuit; (6) performing hole milling and cover opening. By adopting the preparation method of the rigid-flex printed circuit board, the rigid-flex printed circuit board with the blind groove spanning over can be prepared, and the combination of the blind groove and the rigid-flex printed circuit board is realized; and the prepared rigid-flex printed circuit board has the blind slot excessive glue of less than or equal to 0.5 mm and the flatness of less than or equal to 0.1 mm.

Owner:珠海杰赛科技有限公司 +1

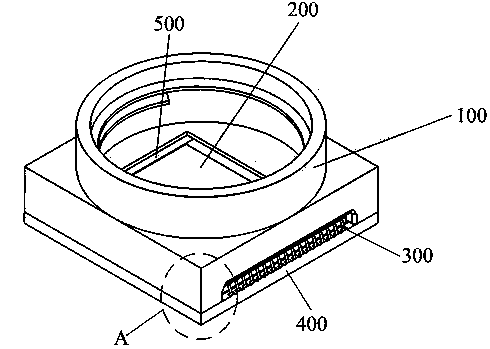

Lens module

The invention belongs to the technical field of optics, and discloses a lens module. The lens module includes a lens and a barrel which are connected with each other, a glue groove is formed between the lens and the barrel, a collision avoidance groove is formed in the side wall of the barrel, the bottom of the collision avoidance groove is angled with the central axis of the barrel, and the distance between the bottom of the collision avoidance groove and the central axis of the barrel decreases gradually in the direction close to the lens. According to the lens module, the collision avoidance groove is formed in the side wall of the barrel, which makes it easy for a rubber needle to extend into the glue groove and inject a glue, and the case that the glue overflows on the surfaces of thelens and the barrel is reduced, thereby improving the cleanliness and aesthetics of the lens module; the glue can enter the glue groove completely for the bonding between the lens and the barrel, theglue is sufficient, which enhances the bonding firmness effect, and the torsion of the lens after glued is large, which reduces the deviation and defocusing of the lens in the actual use process, thereby improving the imaging quality.

Owner:GUANGZHOU LUXVISIONS INNOVATION TECH LTD

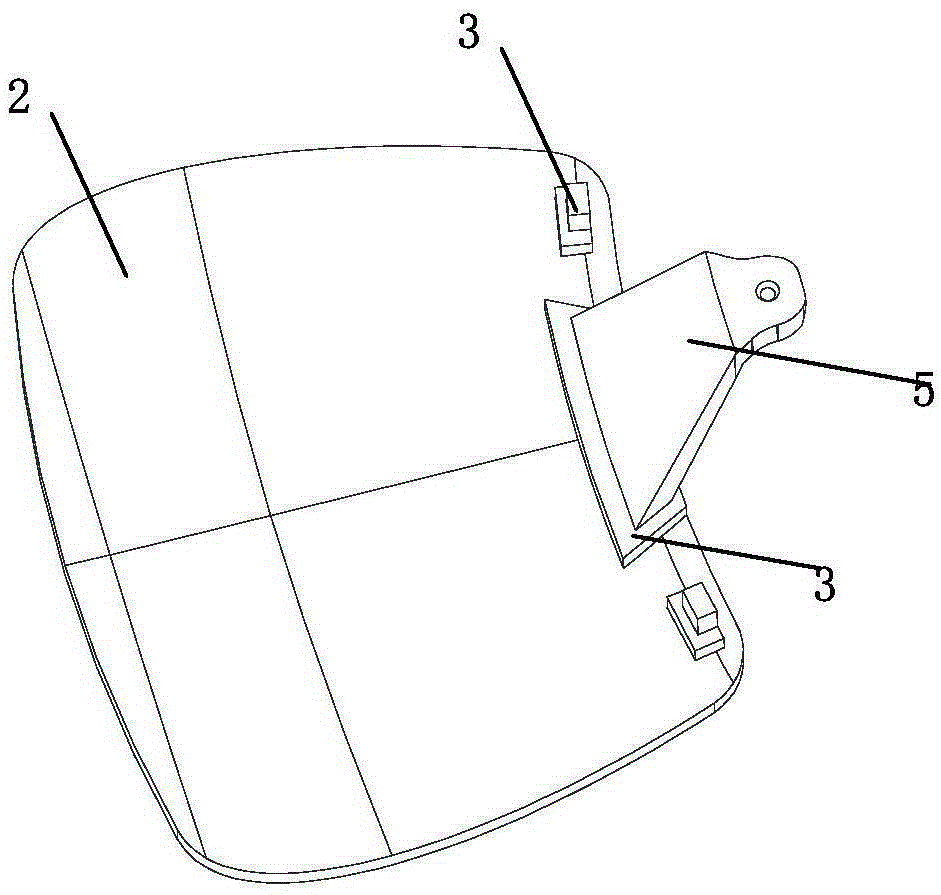

Assembling structure of camera module and assembling method for reducing dimension of camera module

PendingCN109286735ASmall sizeImprove support strengthTelevision system detailsColor television detailsImage sensorPrinted circuit board

The invention relates to an assembling structure of a camera module and an assembling method for reducing dimension of the camera module. The camera module comprises a lens barrel frame, an image sensor chip and a printed circuit board. At least one side of the lens barrel frame is provided with a gap. Partial sidewall of the lens barrel frame is eliminated, thereby realizing a purpose of reducingthe dimension of the camera module.

Owner:GALAXYCORE SHANGHAI

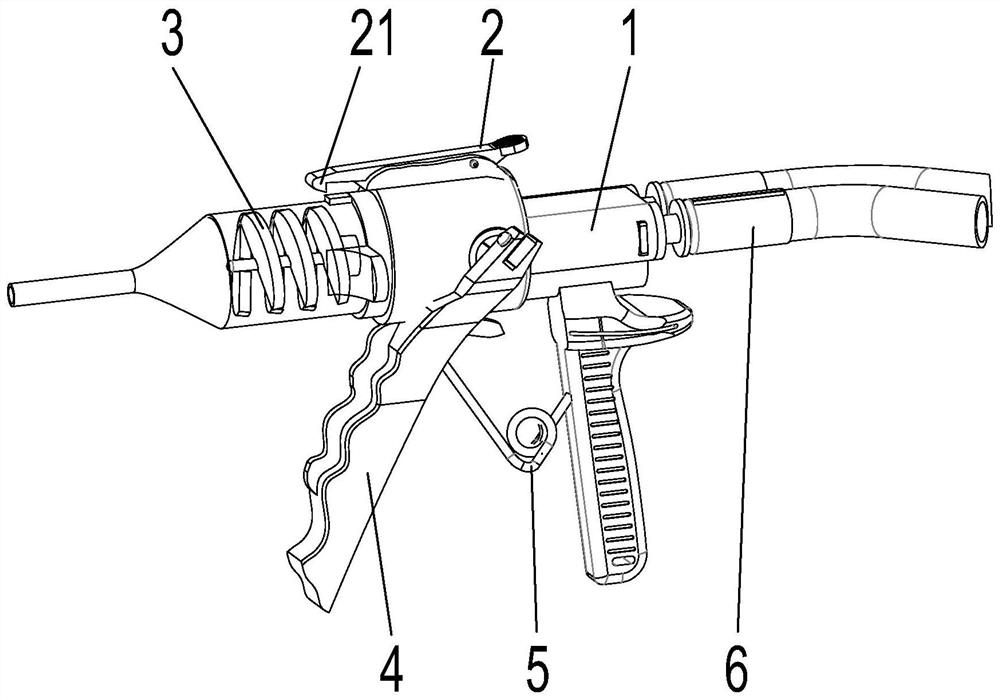

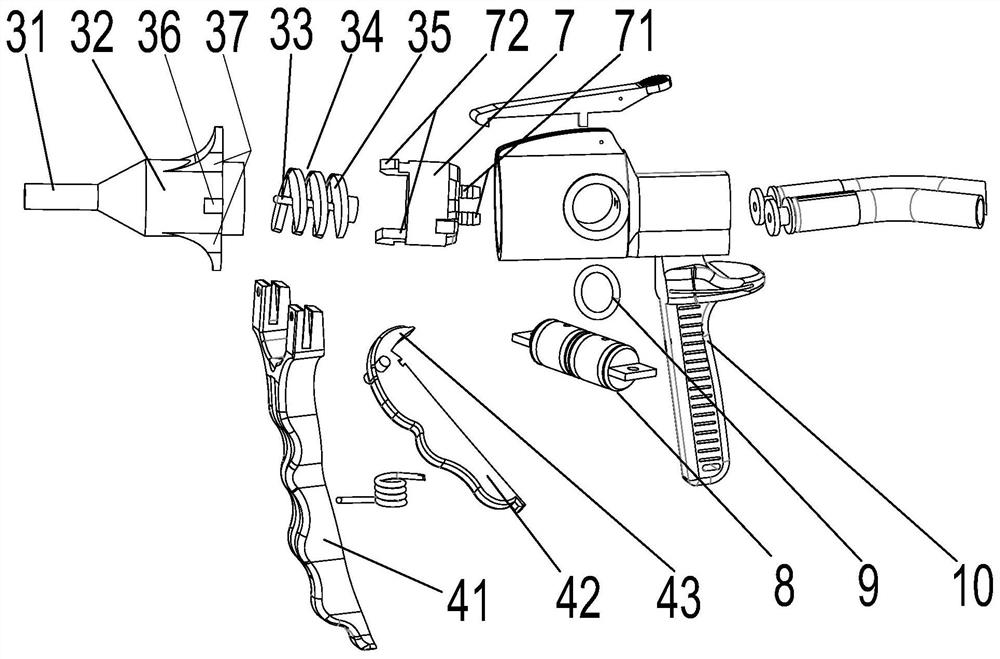

Two-in-one spray gun

PendingCN111992351AShorten the timeImprove efficiencyLiquid spraying apparatusStructural engineeringNozzle

The invention relates to a two-in-one spray gun. The two-in-one spray gun comprises a gun body, a trigger and a conveying pipe connected to the rear portion of the gun body, wherein the front portionof the gun body is detachably connected with a nozzle mechanism. In order to facilitate replacement of the nozzle mechanism, a lock catch mechanism for locking the nozzle mechanism and the gun body isarranged between the nozzle mechanism and the gun body. The nozzle mechanism comprises a cylindrical and hollow shell. A connecting cover is arranged at the end, close to the gun body, of the shell.A conical funnel-shaped nozzle is arranged at the end, away from the gun body, of the shell. Compared with the prior art, the two-in-one spray gun has the advantages that raw materials and the gun body are separated, the structural size of the two-in-one spray gun is reduced, and operation is more flexible; an unlocking device at the trigger prevents misoperation; a nozzle consumable part is rapidly replaced through one key, and the efficiency is improved during continuous operation; and the whole components are simple and easy to machine, assemble, disassemble and clean.

Owner:三江开源有限公司

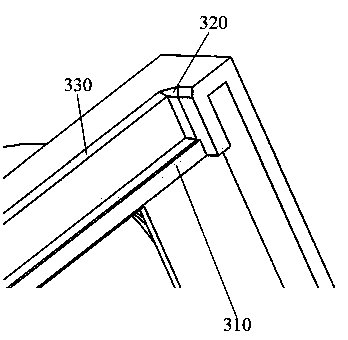

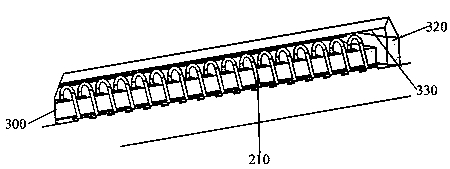

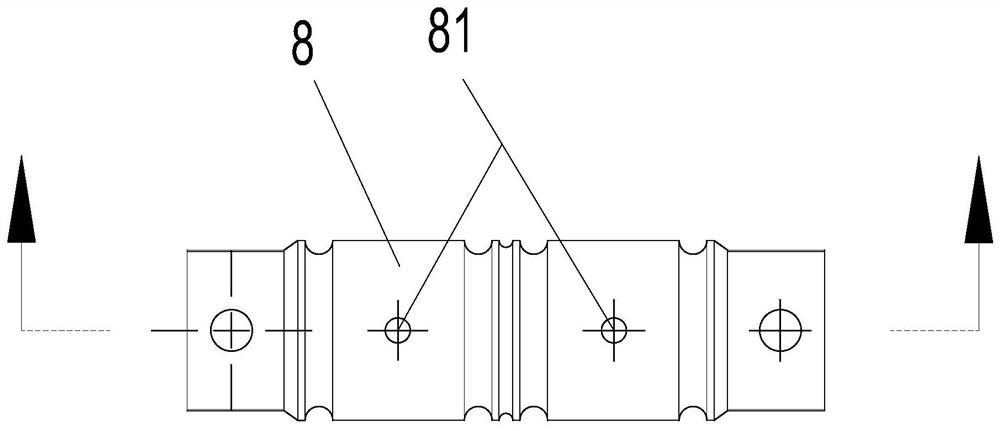

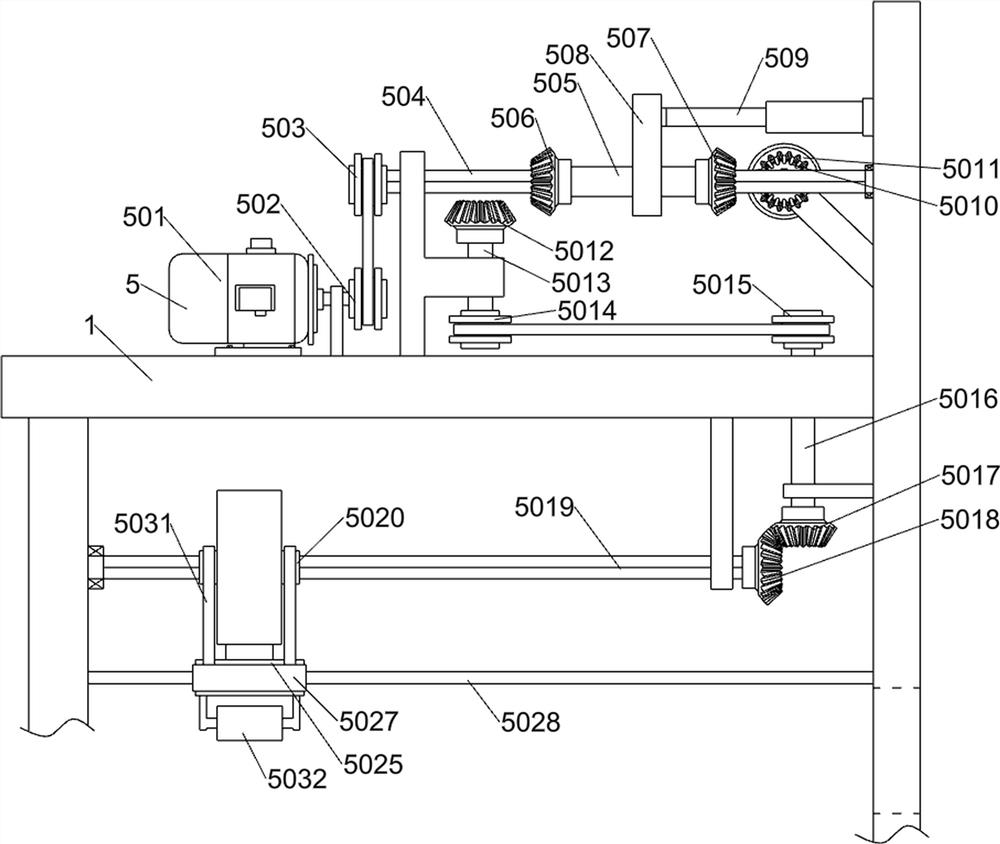

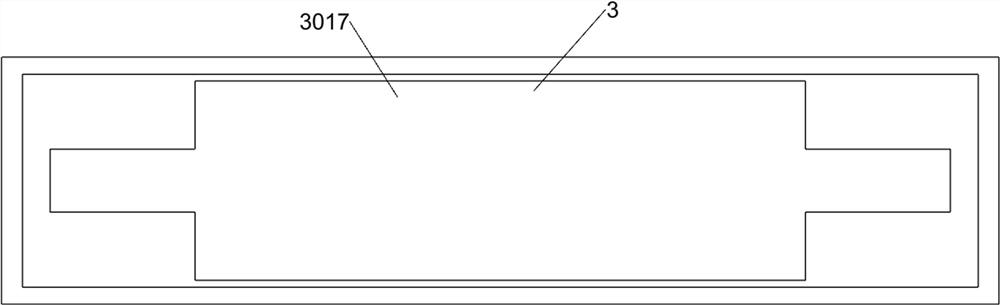

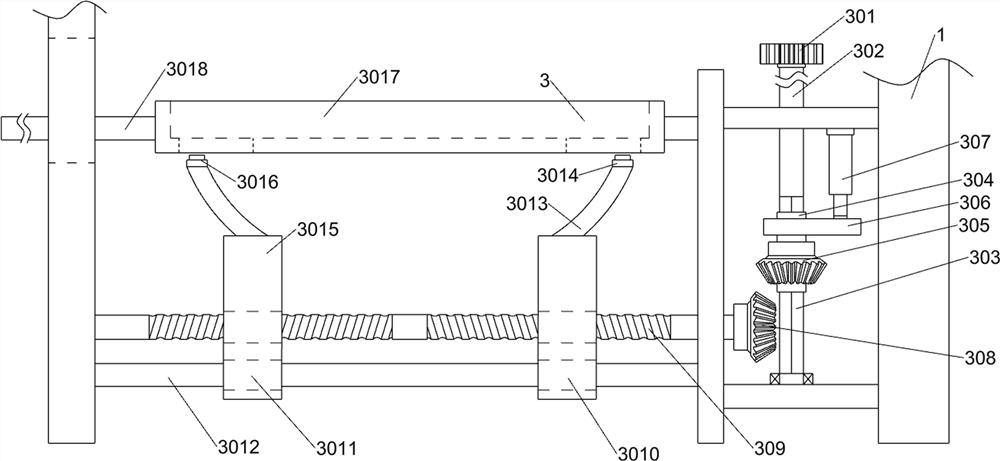

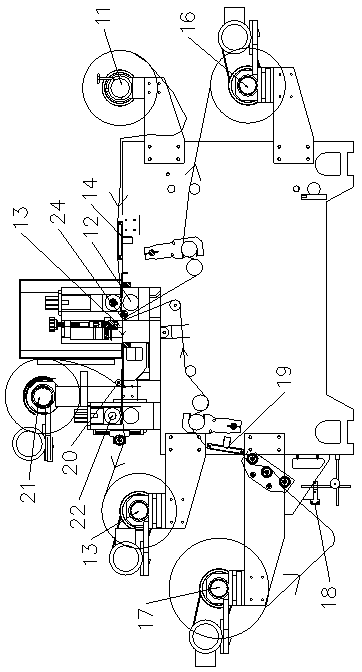

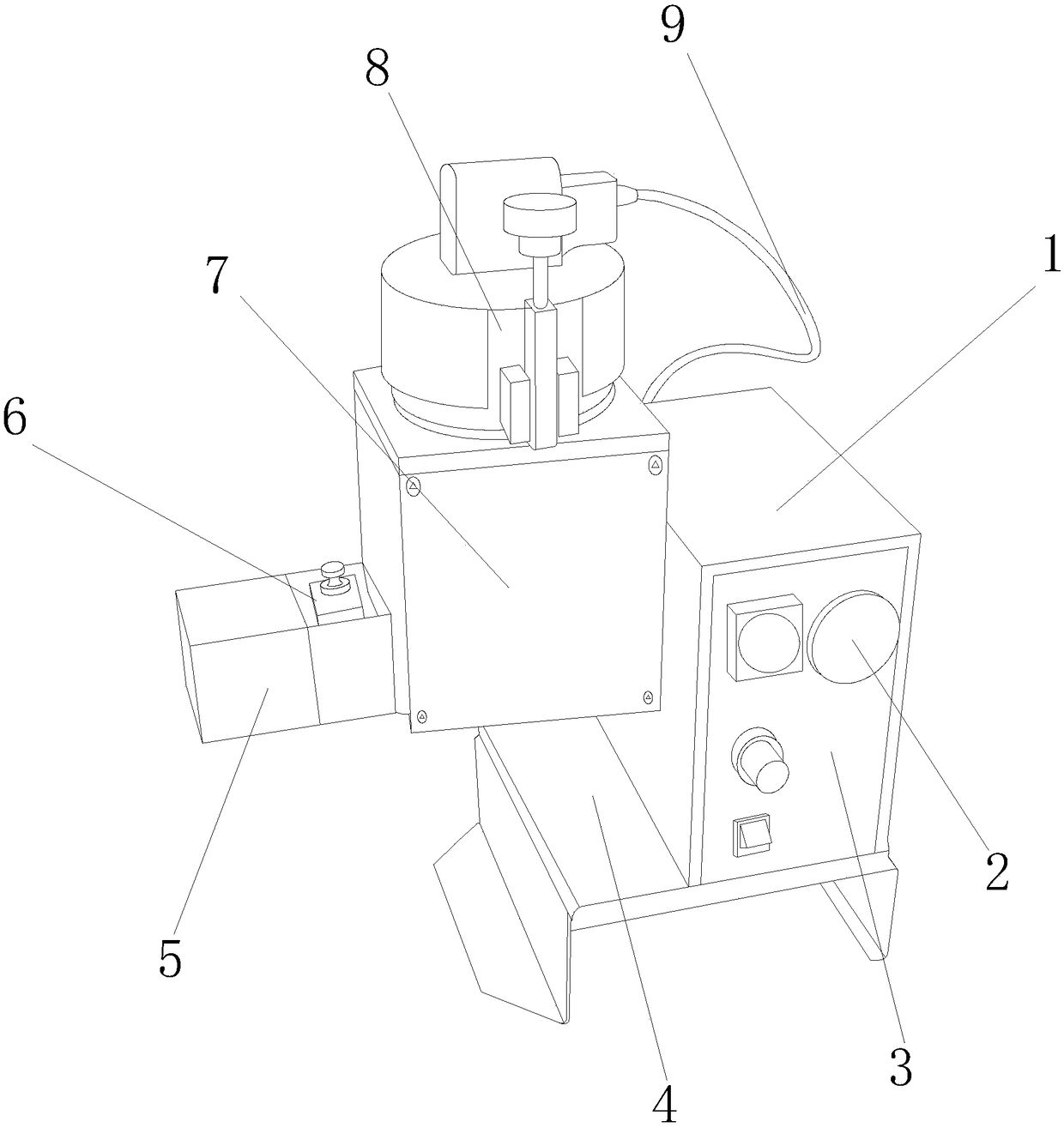

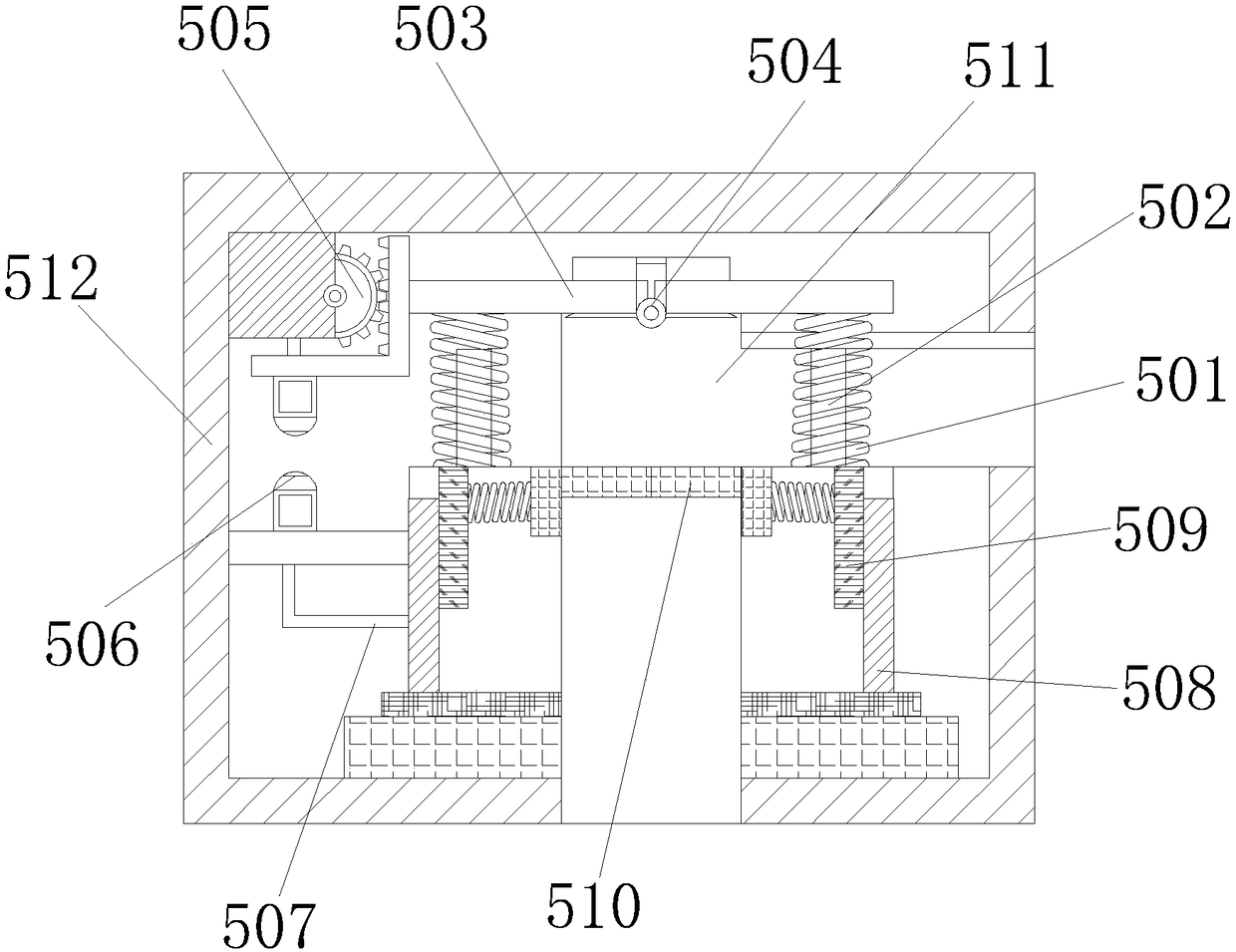

Bent gluing type automobile filter element machining device

ActiveCN112934601AGood adhesionReduce glue overflowLiquid surface applicatorsLaminationAdhesive glueStructural engineering

The invention relates to the field of automobile filters, in particular to a bent gluing type automobile filter element machining device. The technical problem to be solved is to provide the bent gluing type automobile filter element machining device. According to the technical scheme, the bent gluing type automobile filter element machining device comprises a working frame plate, a control display screen, a bending system, a gluing system and the like; and the control display screen is connected with the working frame plate. The bent gluing type automobile filter element machining device achieves the effects that a filter element is bent and then glued, glue can stay on the upper surface of filter paper, the glue is automatically and evenly spread through automatic spreading of the filter paper, glue overflowing is reduced, meanwhile, the pressing direction of cloth is perpendicular to the wrinkle direction of the filter paper, the bonding force of the cloth is enhanced, and glue flowing is avoided.

Owner:安徽钰铭汽车配件有限公司

Die cutting production method for cut mark-free cotton adhesive tape

The invention relates to a die cutting production method for a cut mark-free cotton adhesive tape . According to the method, a bottom film needs not to be replaced and waste is discharged conveniently, and the obtained cotton adhesive tape is free of burrs, cut marks and excessive glue. The production method comprises the following steps: feeding a laminated die obtained by laminating an isolatingfilm and the bottom film and the cotton adhesive tape without body paper step by step into a clearance machine for die cutting, wherein the cotton adhesive tape and the laminating die are stepped once after die cutting every time; cutting the middle main body part of the cotton adhesive tape by a lower cross cutter line, and forming a cotton adhesive tape unit, the width of which is equal to thestepping distance of the cotton adhesive tape, in the vertical direction of the middle main body part of the cotton adhesive tape during stepping every time and adhering the cotton adhesive tape unitto the surface of the isolating film; starting to calculate the die cutting number of times and the stepping number of times from 0 after stepping some time, encircling the cutting line of the middlemain body part of the isolating film by an upper cross cutter line and a side cutter line during (N+1)th die cutting and the cutting line of the middle main body part of the isolating film during Nthdie cutting after stepping for N times to form an isolating film unit; and discharging waste in the periphery of the isolating film unit.

Owner:成都冠佳科技有限公司

Technology for coating conductive resin and plastics through liquid silica gel

The invention discloses a technology for coating conductive resin and plastics through liquid silica gel. The contact parts of a plastic element and a conductive piece are bonded; a positioning hole is formed in the plastic element, a positioning plug pin is arranged on the conductive piece, the positioning plug-pin is inserted into the positioning hole to be fixed, and the processed plastic piece is placed in a die to be positioned and fixed; die assembly, injection, curing and die opening are carried out, and after forming, the die is opened and a formed product is obtained; edges are torn so as to cut off abundant edges and corners of the formed product. Through glue adhesion, the positioning hole is matched with the positioning plug pin, and stable connection of the plastic element, a silicon gel plate and the conductive piece is guaranteed. The technology can greatly reduce waste materials, precision of products is controlled easily, materials do not need to be specially processed, the production process is simplified, and accordingly the aims of reducing production cost, improving product quality and reducing labor cost are achieved.

Owner:SHENZHEN KAIWO TECH CO LTD

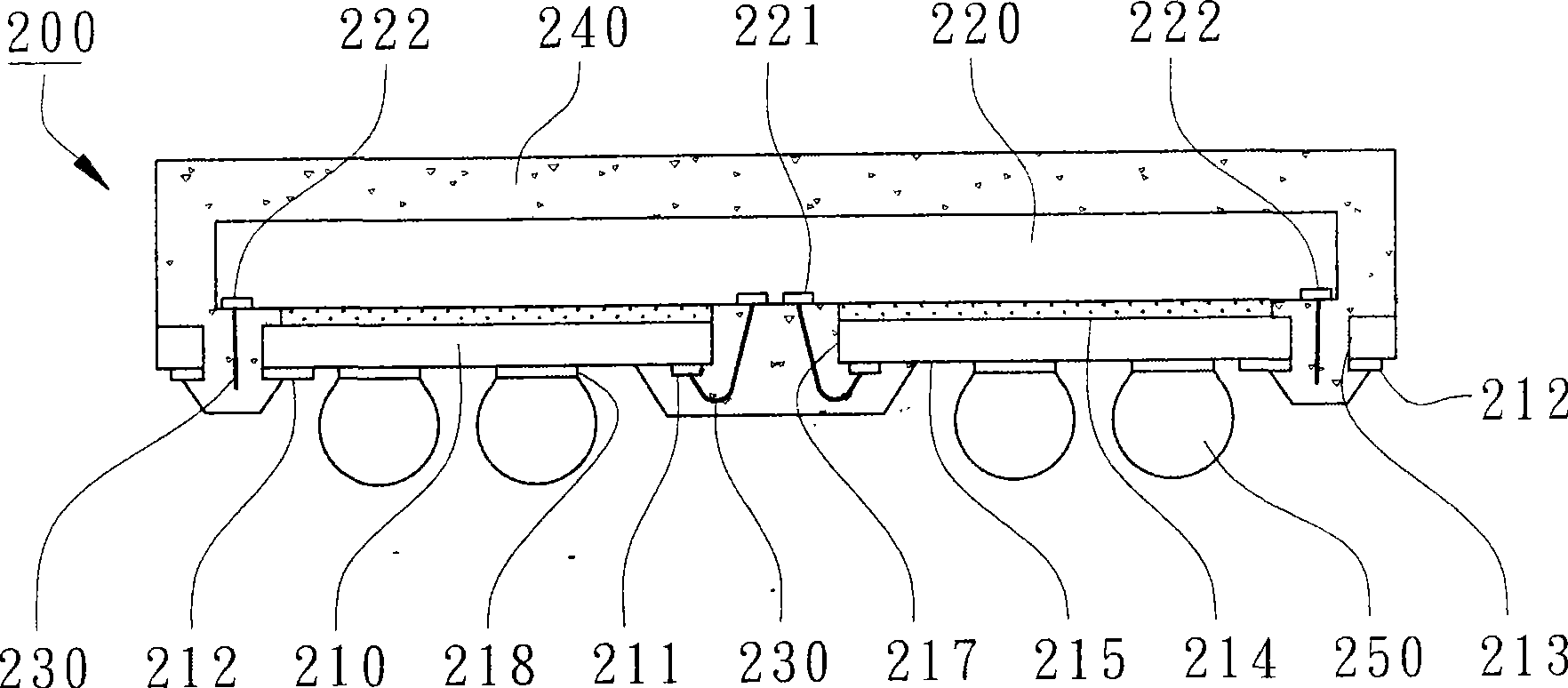

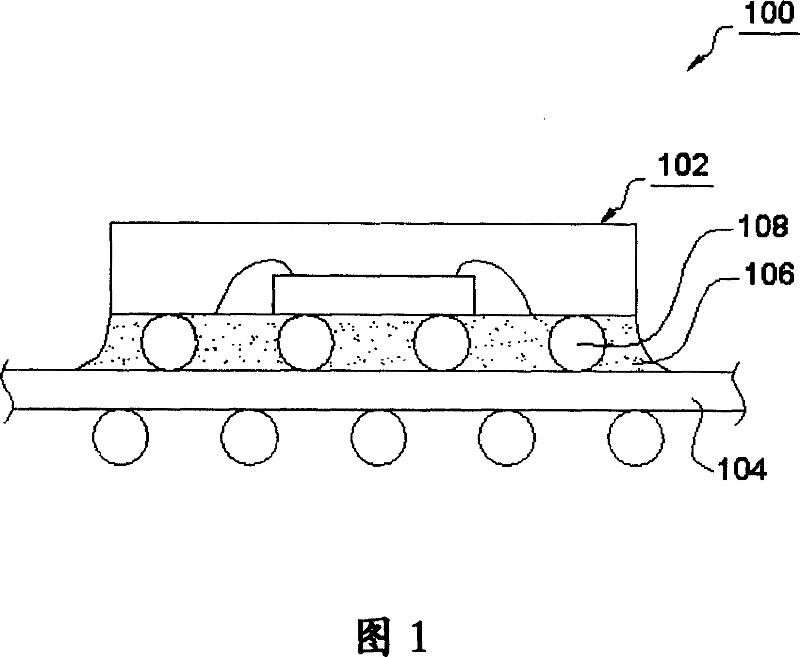

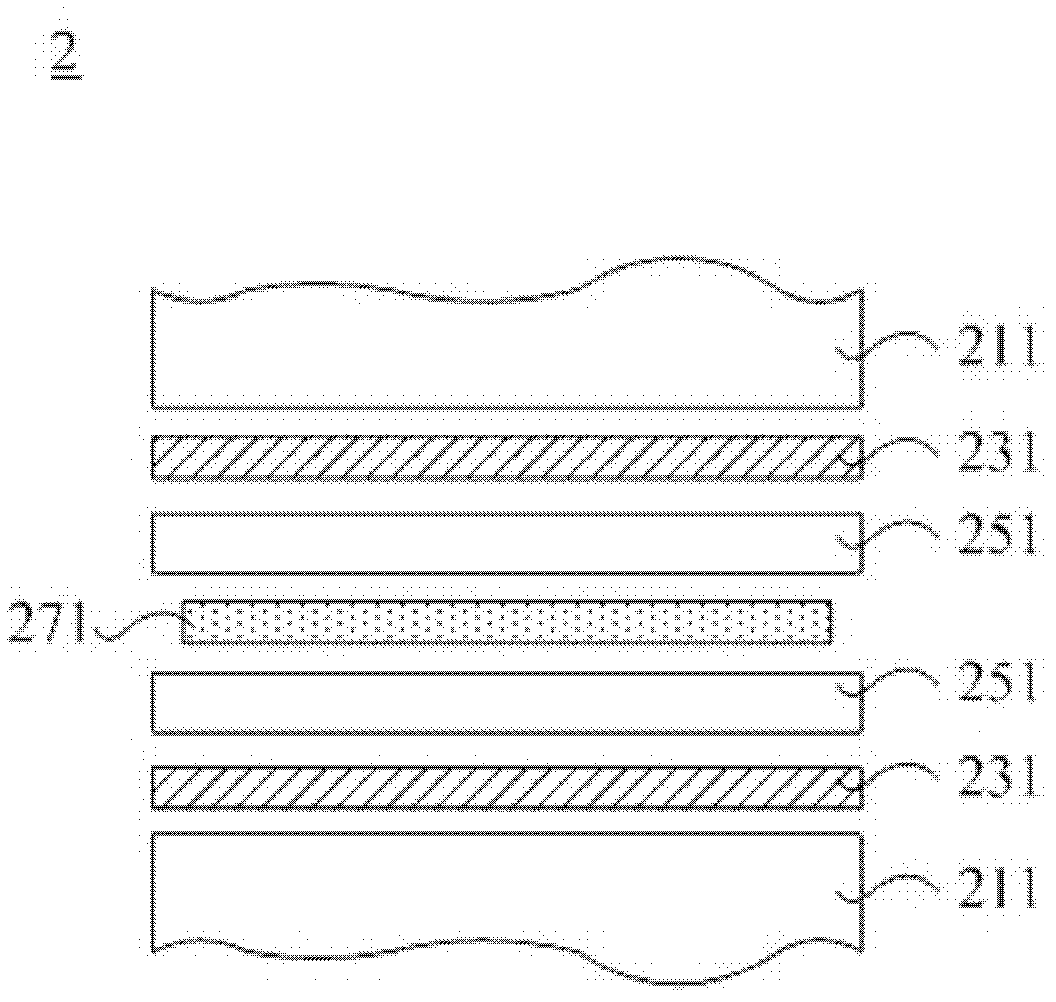

Semiconductor encapsulation conformation and used substrate thereof

InactiveCN101471314AReduce the chance of breakageImprove thermal stress resistanceSemiconductor/solid-state device detailsSolid-state devicesColloid bodiesSemiconductor package

The invention relates to a semiconductor packaging structure and base plate used thereby. The semiconductor packaging structure comprises a base plate which has a plurality of signal joint-fingers, a fictitious metal graph and at least a peripheral notch groove penetrating the base plate, a chip which is arranged on the base plate and has a plurality of welding cushions, a plurality of electrically connected elements for connecting the welding cushions of the chip and the signal joint-fingers of the base plate, and a sealed colloid body which is to seal the electrically connected elements and is filled in the peripheral notch groove. The fictitious metal graph extends the trimming to the peripheral notch groove and is electrically insulated from the signal joint-fingers, the base plate has a plurality of signal joint-fingers, the fictitious metal graph and at least a peripheral notch groove penetrating the base plate. Because the peripheral notch groove is favorable for mold flow to fill and reduce the excessive glue of mold seals and the shape of the trimming of the fictitious metal graph to the peripheral notch groove, the invention can inhibit the lateral warping amplitude of the base plate, lower the fracture probability produced by the base plate, and enhance the thermal stress resistance of the peripheral notch groove under the circulation of temperature, thereby avoiding the surface or the lateral sides of the chip from damaging.

Owner:POWERTECH TECHNOLOGY

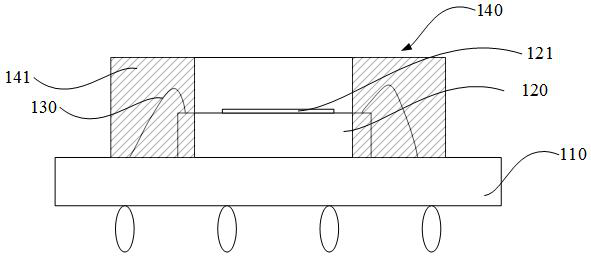

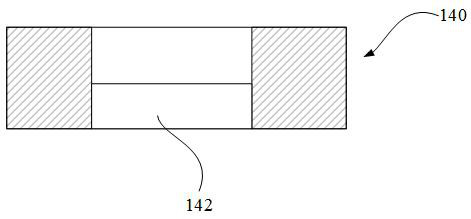

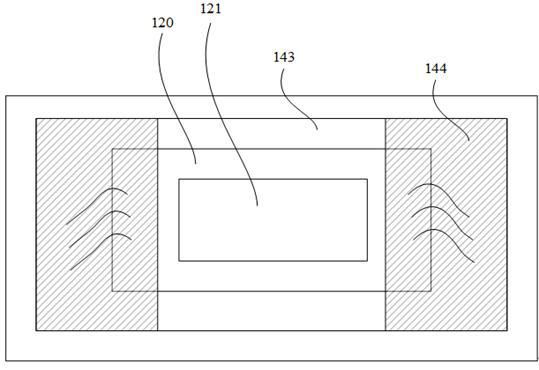

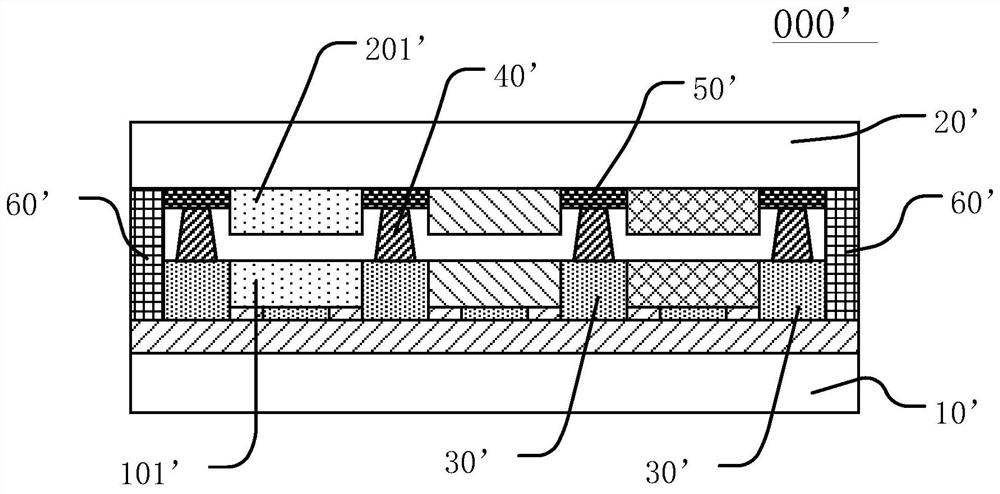

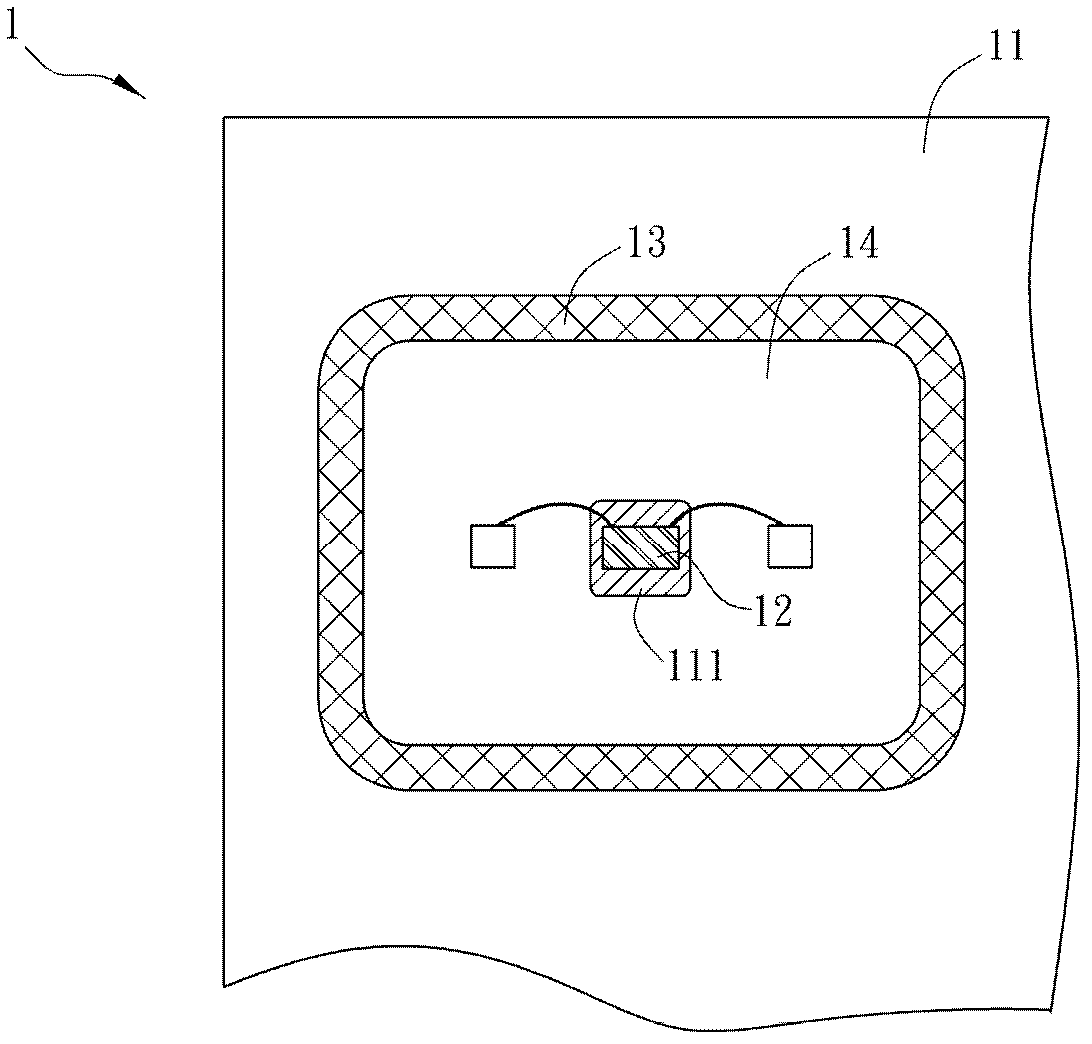

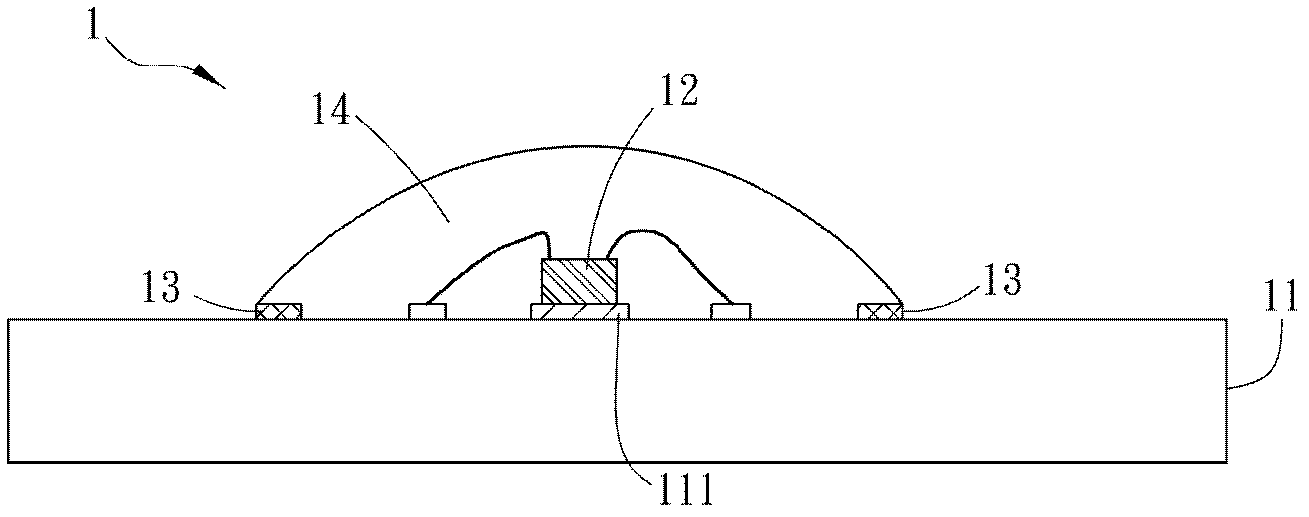

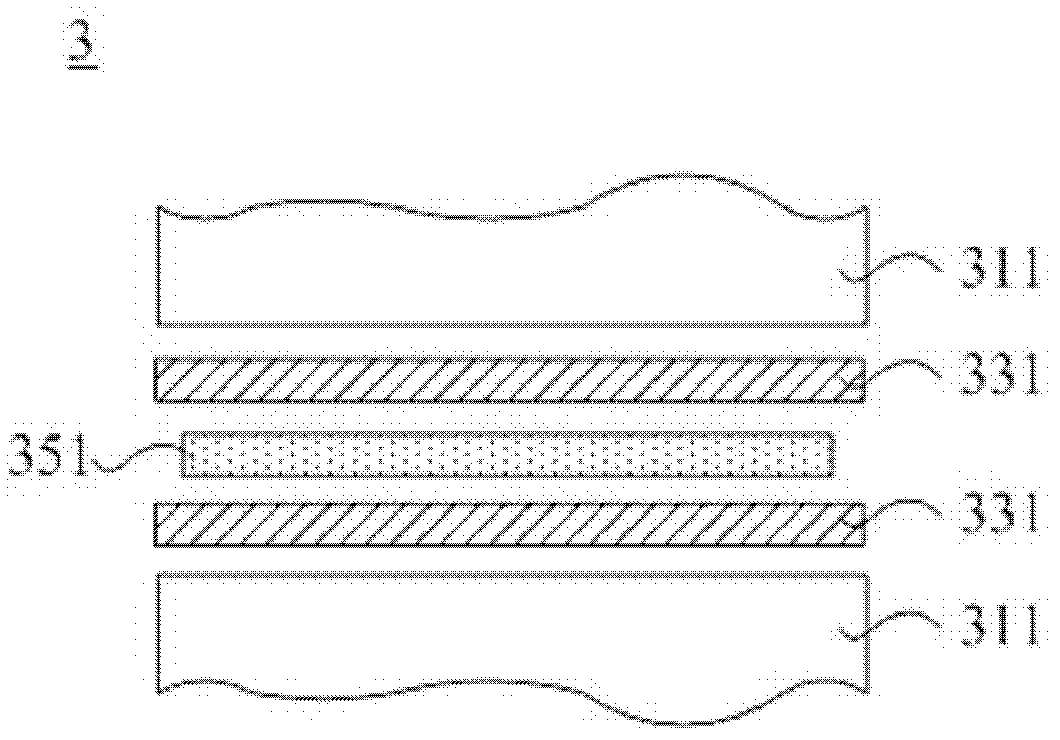

Sensor packaging structure and packaging method

ActiveCN111739901AImprove yieldAvoid defectsSolid-state devicesRadiation controlled devicesEngineeringMechanical engineering

The invention provides a sensor packaging structure and a packaging method, and belongs to the technical field of semiconductors. The sensor packaging structure comprises: a substrate, wherein a sensing chip is arranged on the surface of the substrate, the working area of the sensing chip faces one side far away from the substrate, the circuit of the sensing chip is connected with the circuit of the substrate through a binding wire, a first accommodating groove is formed in the plate surface of a packaging cover plate, the first accommodating groove is filled with an insulating colloid, the packaging cover plate is arranged on the side, provided with the sensing chip, of the substrate in a covering mode, the binding wire is contained in the first accommodating groove so as to be embedded with the insulating colloid, the insulating colloid is used for bonding the packaging cover plate to the substrate, a second accommodating groove is formed in the side, close to the sensing chip, of the packaging cover plate, and the sensing chip is contained in the second accommodating groove. The invention aims to provide the sensor packaging structure and the packaging method, so that the binding wire connected between the sensing chip and the substrate can be well arranged and protected, the yield of the packaging structure is improved, and the packaging cost is reduced.

Owner:FOREHOPE ELECTRONICS NINGBO CO LTD

Coating device and coating method thereof

InactiveCN111482328AImprove packaging yieldPrevent overflowPretreated surfacesCoatingsAdhesiveMechanical engineering

The invention discloses a coating device and a coating method thereof. The coating device comprises a machine table, a coating member, an ultraviolet curing device and a baffle plate, wherein the machine table is used for carrying a to-be-coated panel, and the first surface of the to-be-coated panel is in contact with the machine table; the coating member is used for coating the side edge of the panel with a coating adhesive; the ultraviolet curing device is used for curing the coating adhesive on a target side edge of the panel; and the baffle plate is in contact with the second surface of the to-be-coated panel to prevent the coating adhesive from overflowing to a display area of the panel when the coating member coats the target side edge of the panel. By arranging the baffle plate in ato-be-coated area of a display panel before coating, an adhesive overflowing phenomenon in the coating process is reduced, so that the packaging yield of the display panel is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

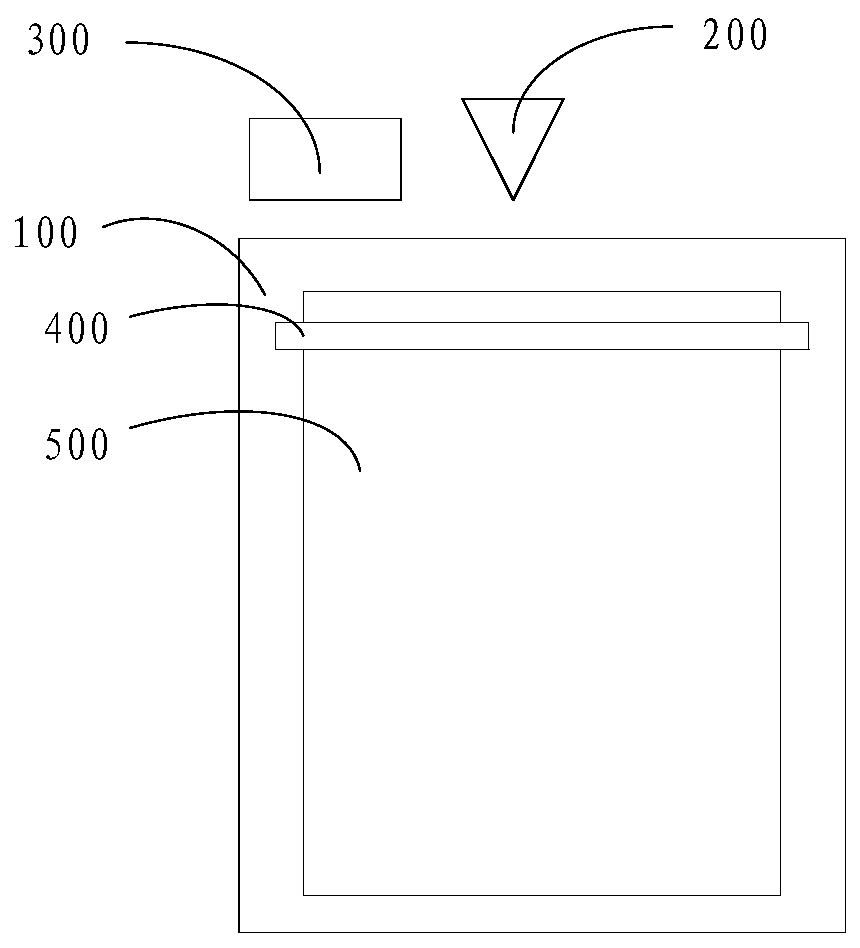

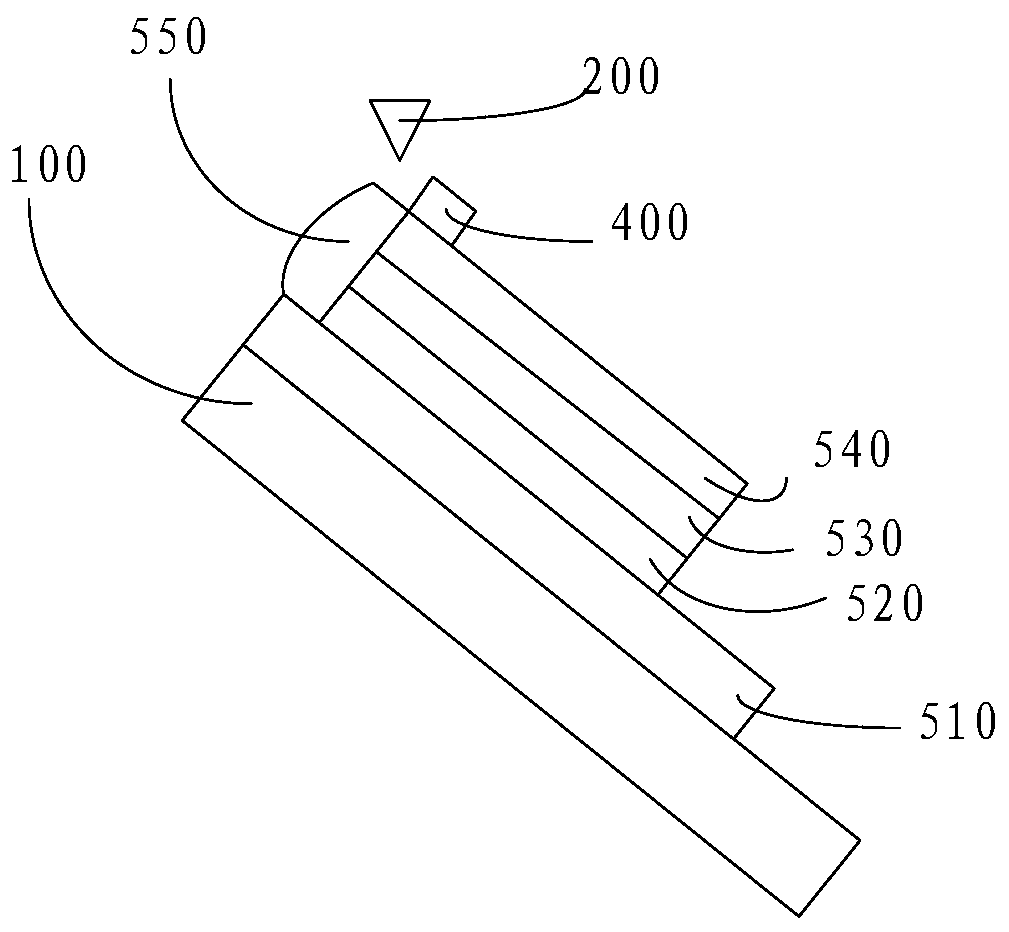

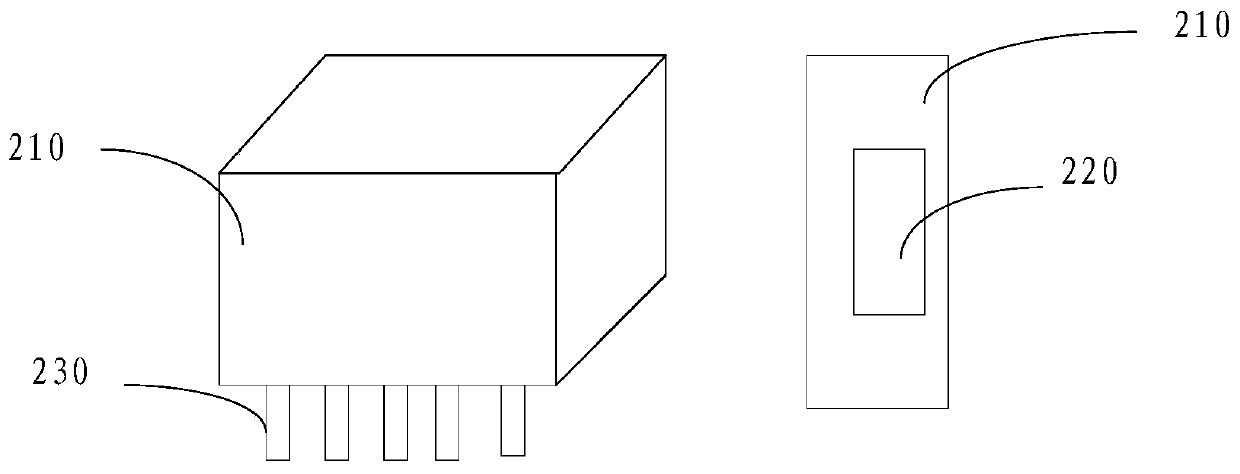

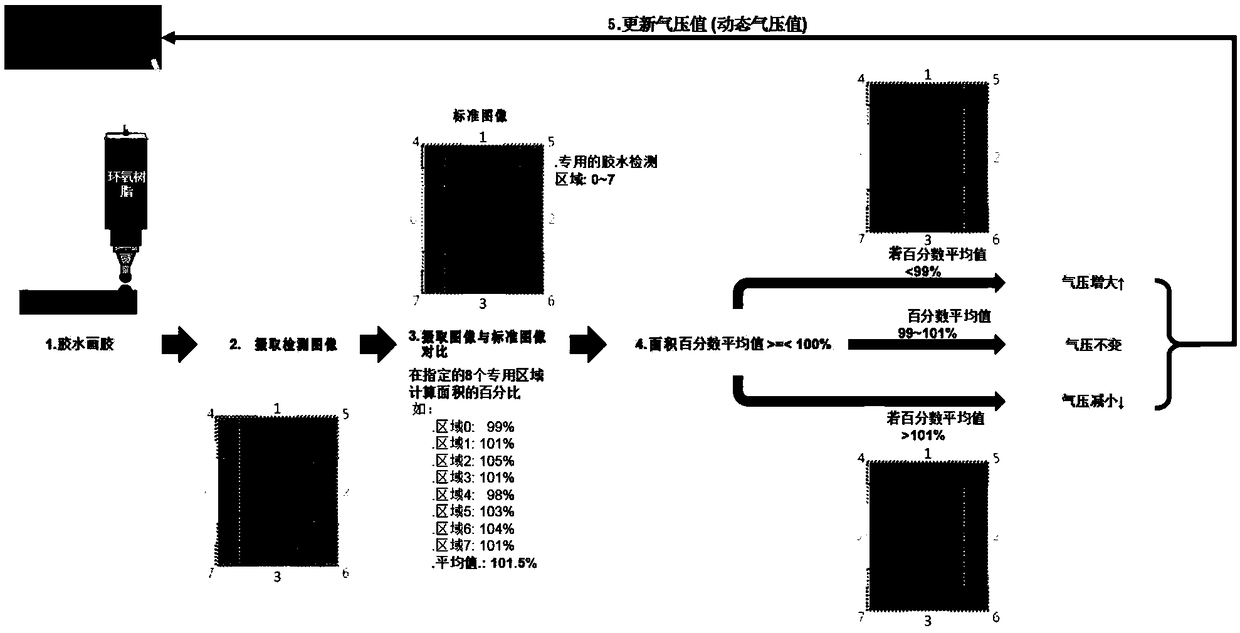

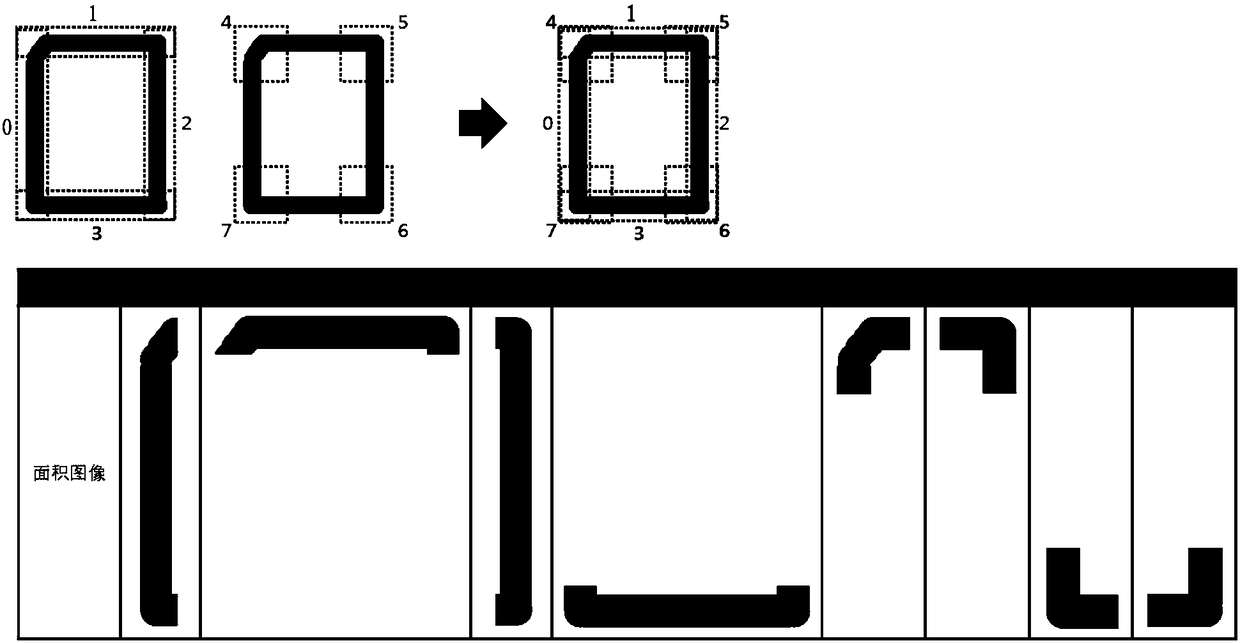

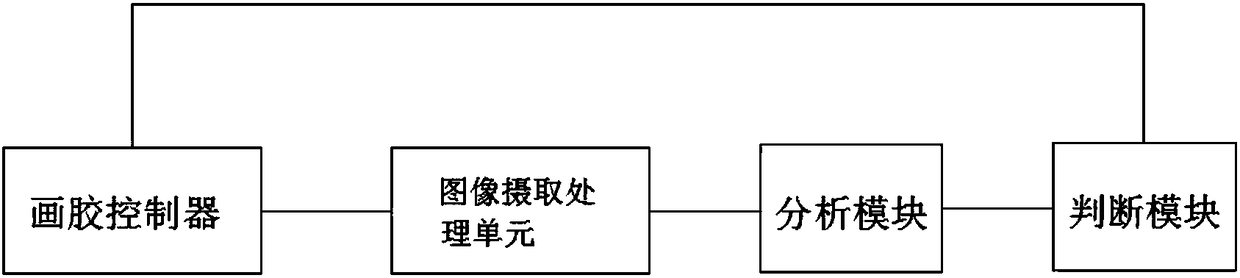

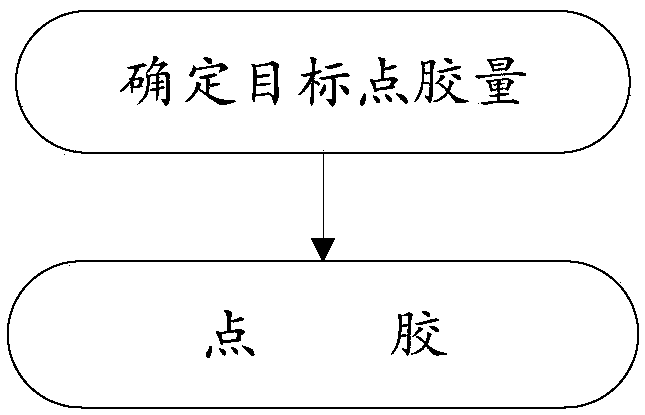

Method and system for dynamically controlling HTCC (high temperature co-fired ceramic) plate back epoxy resin glue quantity

ActiveCN108453009AReduce sheddingAccurate analysisLiquid surface applicatorsCoatingsEpoxyCamera lens

The invention relates to a method and system for dynamically controlling the HTCC (high temperature co-fired ceramic) plate back epoxy resin glue quantity. The method comprises the following steps that 1, square-shaped epoxy resin glue is dispensed at the HTCC plate back part by a glue dispensing controller; 2, the square-shaped epoxy resin glue is divided into eight (0 to 7) area regions; 3, theshot 0-7 area region and the corresponding standard 0-7 area regions are compared to obtain the area percent of each region; the average percent is obtained; 4, if the average percent is smaller than99 percent, a pressure boosting instrument is given out; if the average percent is greater than or equal to 99 percent but is smaller than or equal to 101 percent, the instrument is not given out; ifthe average percent is greater than 101 percent, a pressure reduction instrument is given out; 5, the air pressure value is updated for dynamically controlling the epoxy resin glue outlet quantity; the square-shaped epoxy resin glue is divided into the eight (0-7) area regions and is then compared with the standard image for comparison to obtain the average value. The epoxy resin glue area of eachregion of the glue dispensing route is comprehensively considered and analyzed; the accurate data support is provided for the subsequent product dynamic glue quantity control; poor phenomena such asglue overflow and camera lens falling are reduced.

Owner:东莞高伟光学电子有限公司

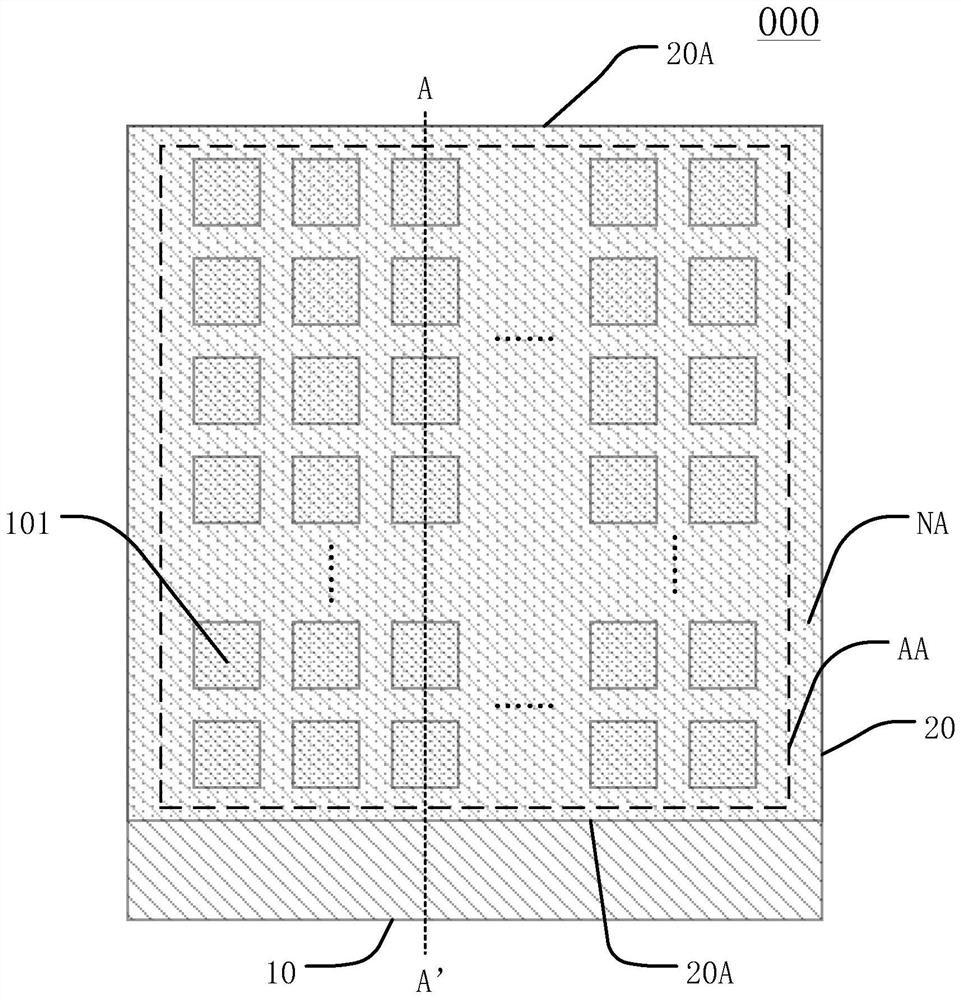

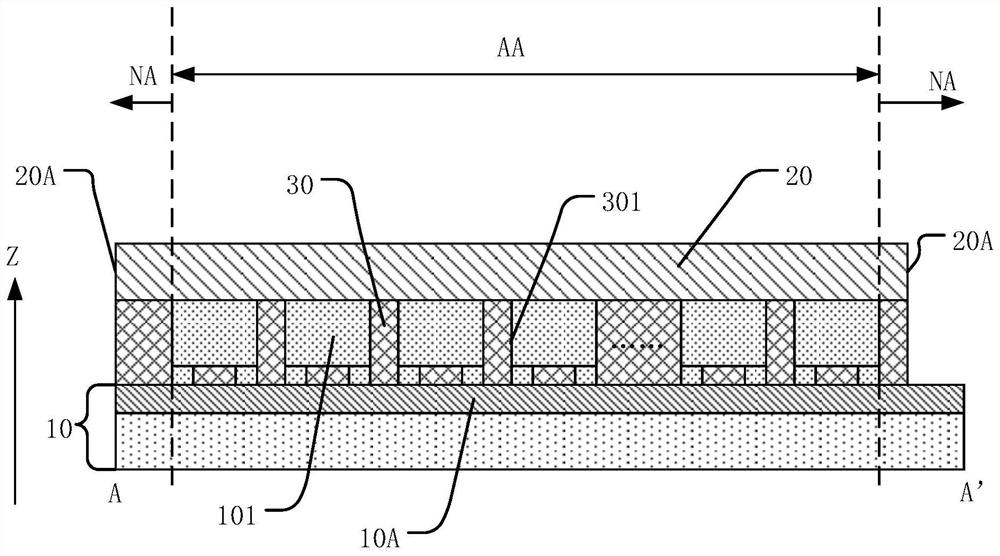

Display device and manufacturing method thereof

PendingCN113725248AAchieve fitReduce typesSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention discloses a display device and a manufacturing method thereof, and belongs to the technical field of display. The display device comprises a first substrate and a second substrate which are oppositely arranged, wherein the side, which faces the second substrate, of the first substrate comprises a plurality of light-emitting elements; an adhesive layer is filled between the first substrate and the second substrate, and the first substrate and the second substrate are attached through the adhesive layer; and at least part of the adhesive layer extends to the edge position of the second substrate in the direction parallel to the plane where the first substrate is located. The manufacturing method of the display device is used for manufacturing the display device. The manufacturing method comprises the steps of providing a first substrate; sequentially arranging light-emitting elements and an adhesive layer on the first substrate; and providing a second substrate, wherein the first substrate and the second substrate are attached through the adhesive layer, and at least part of the adhesive layer extends to the edge position of the second substrate. According to the invention, the process steps are reduced, the manufacturing cost is reduced, the process efficiency is improved, and the product yield can be improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

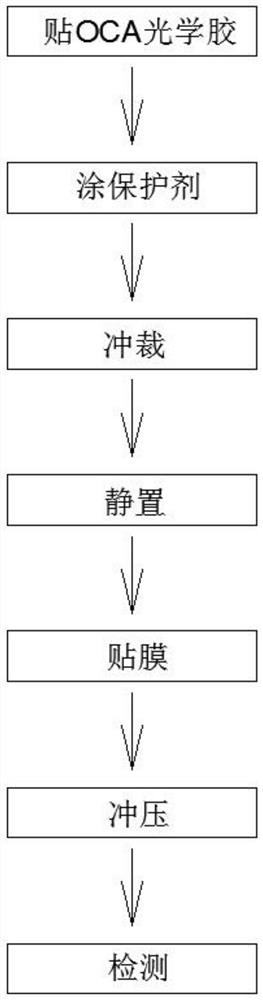

Die cutting method convenient for detection

InactiveCN112388732AReduce generationEasy to separateMetal working apparatusFilm/foil adhesive release linersComposite filmAdhesive belt

The invention relates to a die cutting detection process. The die cutting detection process comprises the following steps that an OCA (Optically Clear Adhesive) is placed on a heavy release film, andthe OCA and the heavy release film are laminated together through a laminating machine to form a composite film; the upper surface of the composite film is coated with a layer of uniform degumming protective agent; the composite film is stamped by using a blanking die, an OCA layer is blanked into a proper shape, and a detection mark is left on the composite film through a marking device; the composite film obtained in the previous step is stood for 15 minutes; a light release film is put on the upper surface of the composite film, and the light release film and the composite film are laminated through the laminating machine to form a finished film; the finished film is stamped by using a forming die, and a product is stamped and formed; and the machined product is detected; The degummingprotective agent is added in the film laminating process, bubbles are reduced, and the separation of the product and an adhesive tape is facilitated; and the die cutting effect of the product is directly judged by observing whether the product has the detection mark or not, other equipment is not needed for measurement, and defective products can be directly found.

Owner:东莞艾塔极新材料科技有限公司

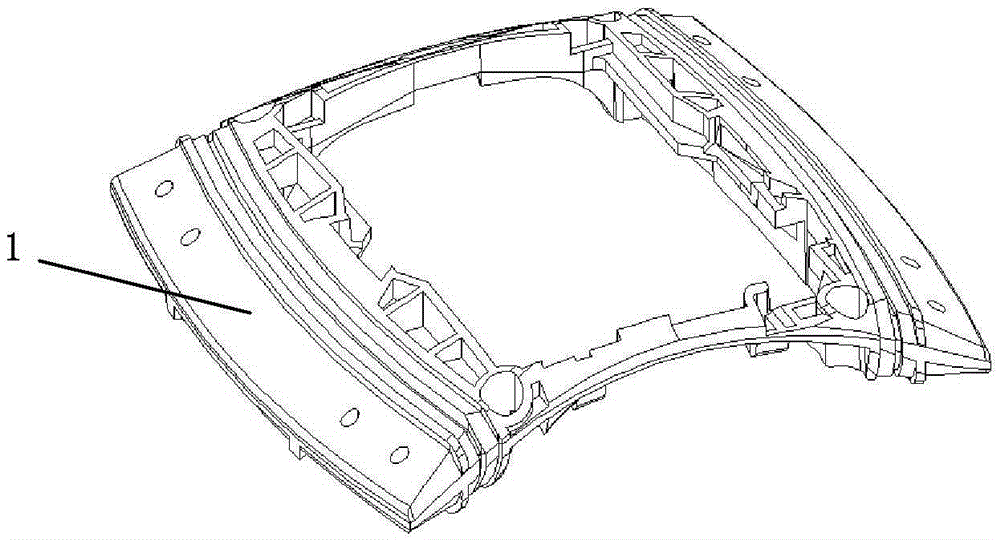

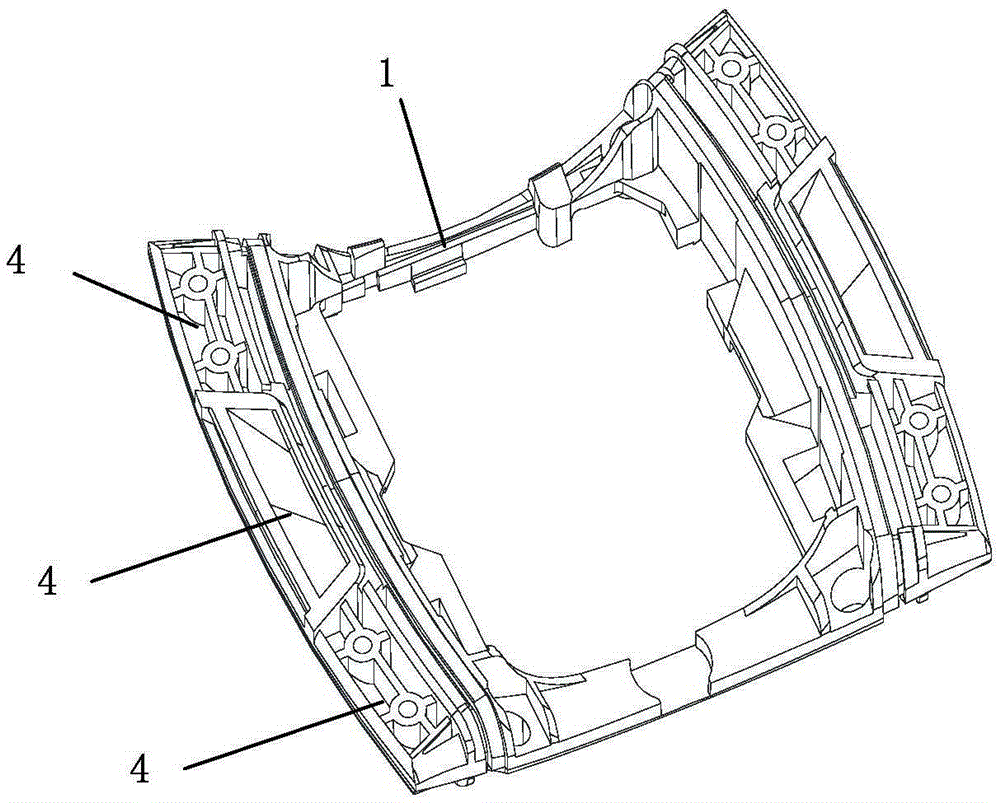

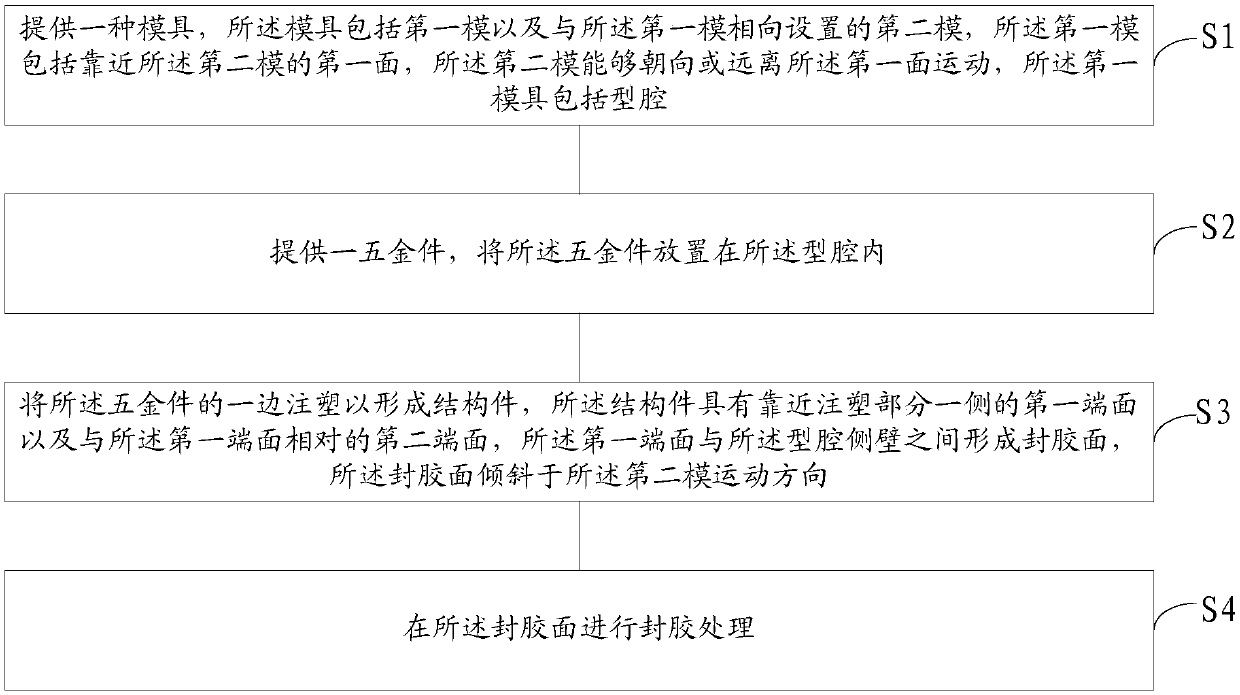

Manufacturing method of structural part, mold, shell and electronic equipment

ActiveCN110900945AImprove qualityReduce glue overflowDomestic articlesInjection mouldingMechanical engineering

The embodiment of the invention provides a manufacturing method of a structural part, a mold, a shell and electronic equipment. The method comprises a step of providing a first mold which comprises afirst mold body and a second mold body opposite to the first mold body, wherein the first mold body comprises a first surface close to the second mold body, the second mold can move towards or away from the first surface, and the first mold comprises a cavity, a step or providing a hardware piece and placing the hardware piece in the cavity, wherein one side of the hardware piece is subjected to injection molding to form the structural part, the structural part is provided with a first end face close to one side of an injection molding part and a second end face opposite to the first end face,a glue sealing face is formed between the first end face and a side wall of the cavity, the glue sealing face inclines to the movement direction of the second mold, and glue sealing treatment is conducted on the glue sealing face. Glue overflowing can be reduced during the injection molding of the structural part, and the quality of the structural part is improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

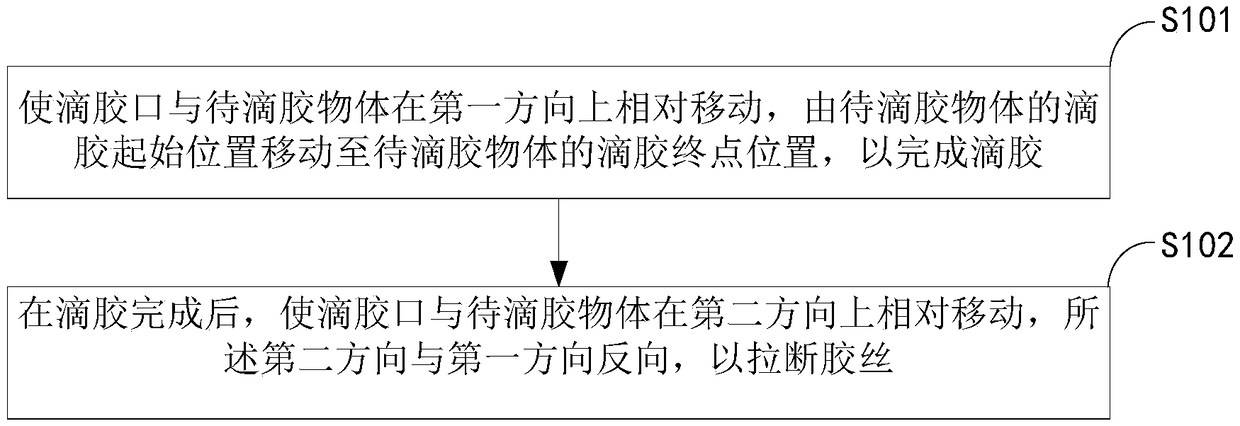

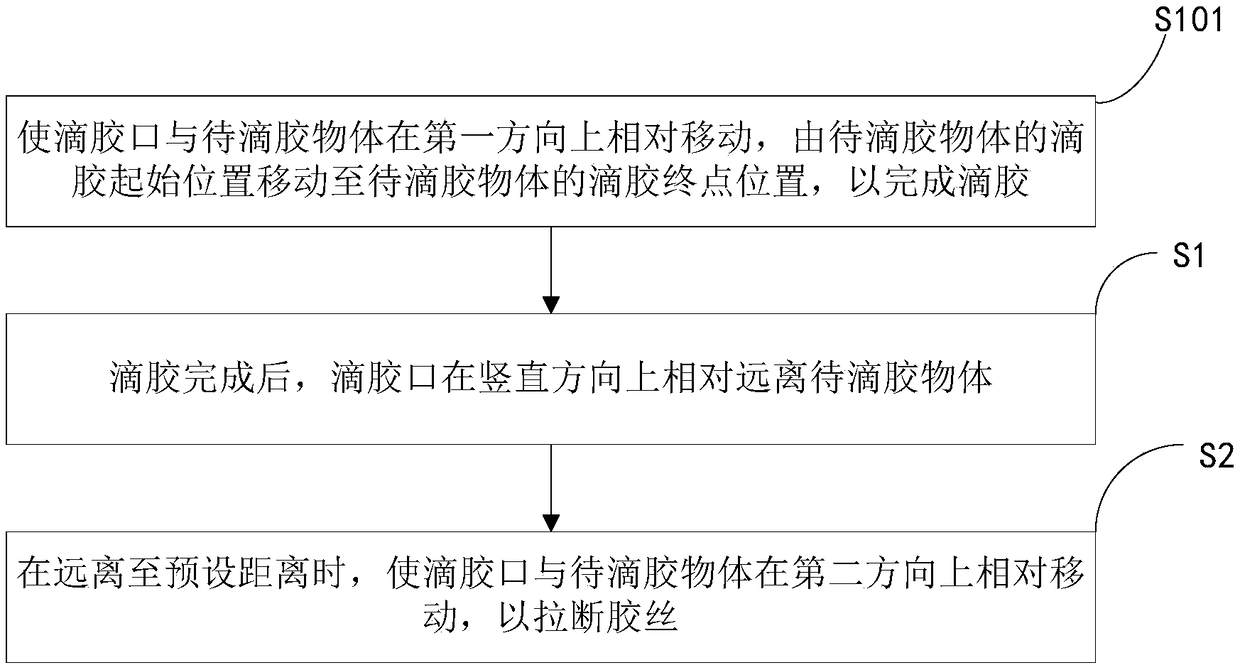

Glue dispensing method and device

PendingCN108970908ADoes not cause overflowNo pollutionLiquid surface applicatorsCoatingsMechanical engineeringBattery cell

The invention relates to the technical field of battery cell edge sealing glue dispensing, and discloses a glue dispensing method and device. The glue dispensing method specifically comprises the following steps that a glue dispensing port and an object to be subjected to glue dispersing are enabled to move relative to each other in the first direction and are enabled to move from the initial position of glue dispensing of the object to be subjected to glue dispersing to the final position of glue dispensing of the object to be subjected to glue dispersing so as to complete glue dispensing; and after glue dispensing is completed, the glue dispersing port and the object to be subjected to glue dispersing are enabled to move relative to each other in the second direction, and the second direction is opposite to the first direction so as to pull and break glue wires. According to the glue dispensing method and device, glue overflow and glue residues cannot be generated in the glue wire pulling and breaking process, in addition, glue droplets can drop onto glue tape when the glue wires are pulled and broken, and pollution to other equipment caused by glue can be further avoided.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Photovoltaic cell with frontside busbar tape on narrow front busbars

InactiveCN107980179ANarrow widthReduce dosagePhotovoltaic energy generationSemiconductor devicesElectrical batteryBusbar

The present disclosure relates to photovoltaic ("PV") solar cell comprising a frontside busbar tape in electrical contact with narrow front busbars (e.g., silver busbars). A single frontside busbar tape may be in electrical contact with a single narrow front busbar or with a dual set of narrow front busbars. The disclosure also relates to modified gridlines and methods of enhancing the electricalconnection between gridlines and narrow busbars and busbar tape on a solar PV cell.

Owner:3M INNOVATIVE PROPERTIES CO

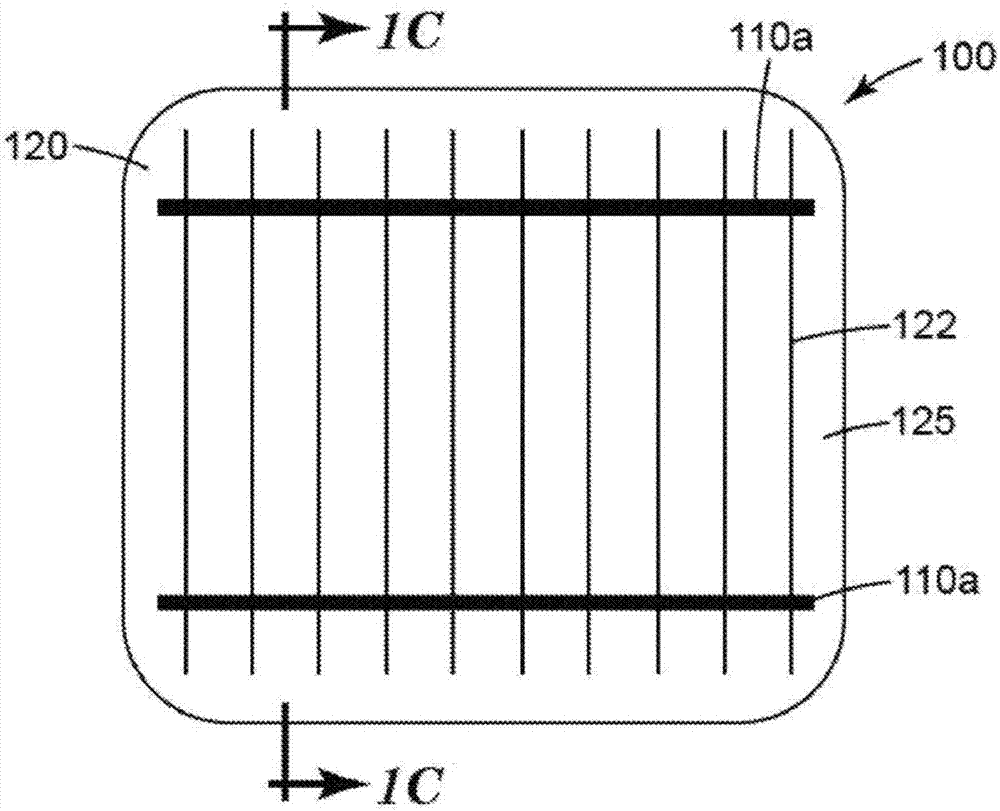

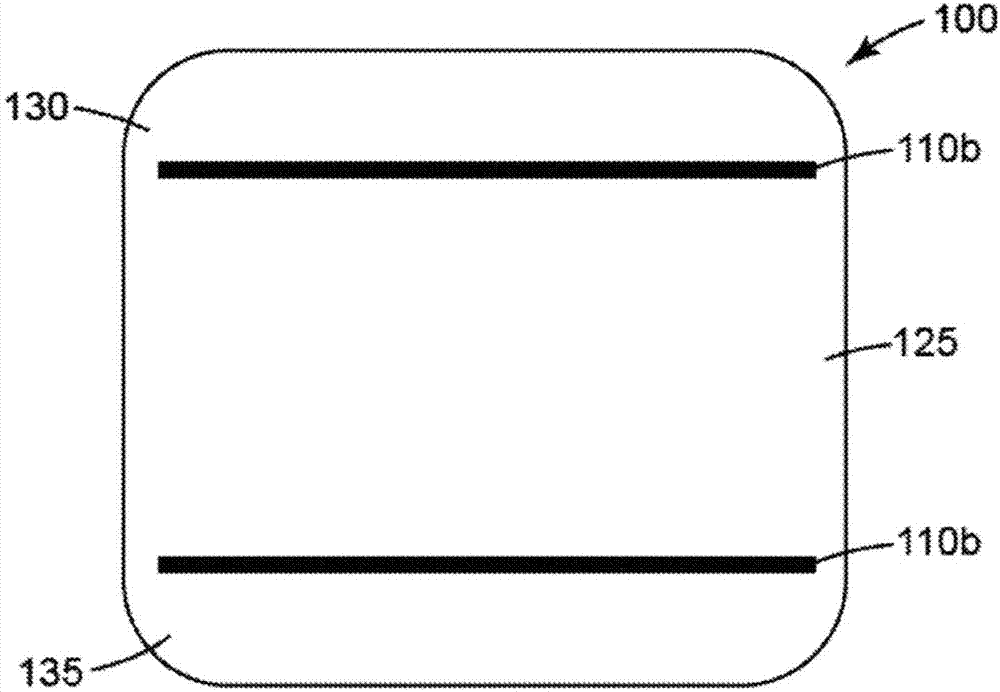

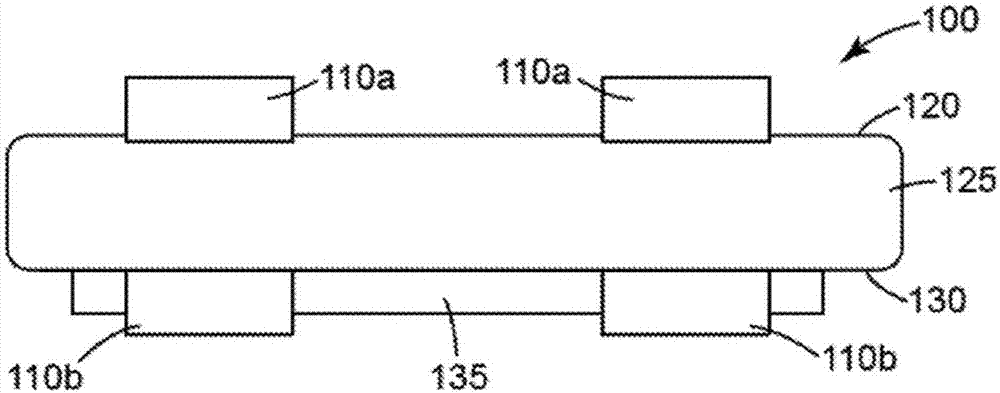

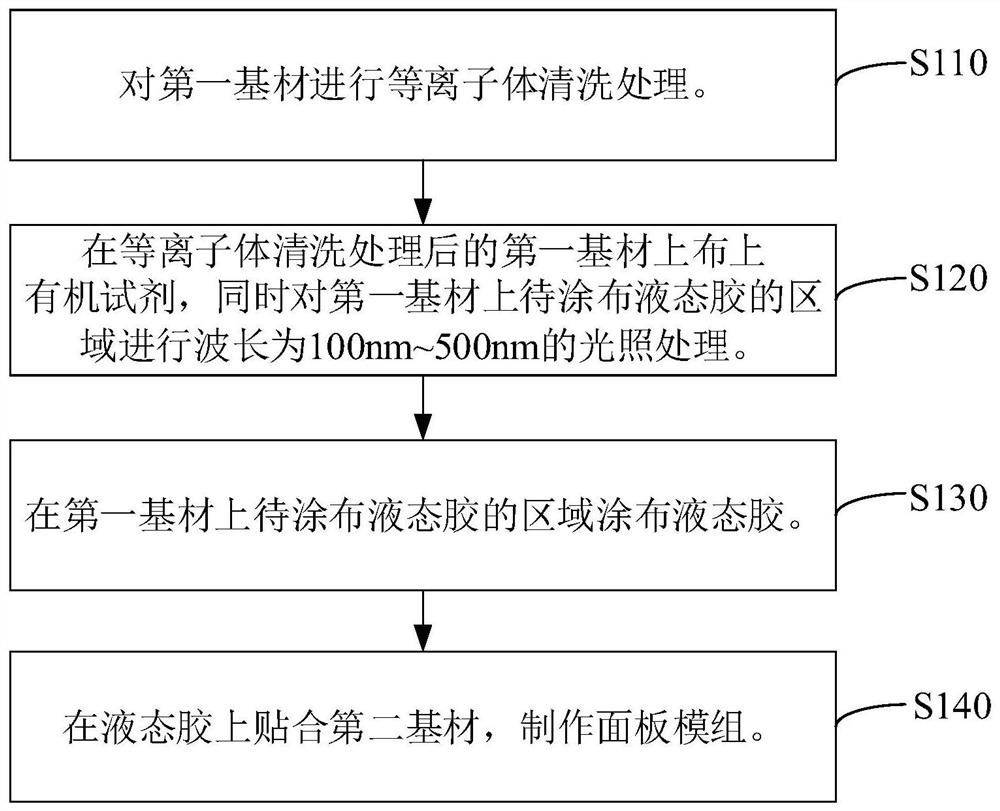

Manufacturing method of panel module

ActiveCN112693210AHigh surface energyImprove adhesionLamination ancillary operationsSynthetic resin layered productsOrganic baseDouble bond

The invention relates to a manufacturing method of a panel module. The manufacturing method of the panel module comprises the following steps of carrying out plasma cleaning treatment on a first base material, wherein the first base material is an organic base material, distributing an organic reagent on the first base material subjected to plasma cleaning treatment, meanwhile, enabling the area, to be coated with the liquid glue, of the first base material to be subjected to illumination treatment with the wavelength ranging from 100 nm to 500 nm, wherein the structure of the organic reagent contains double bonds and hydrophilic groups, coating the area to be coated with the liquid glue on the first base material with the liquid glue, and enabling a second base material to be attached to the liquid glue, and manufacturing the panel module. According to the manufacturing method of the panel module, excessive glue can be reduced, the adhesive force between the liquid glue and the first base material can be improved, and the phenomenon that the liquid glue is stripped from the first base material due to small adhesive force is avoided.

Owner:INTERFACE TECH CHENGDU CO LTD +3

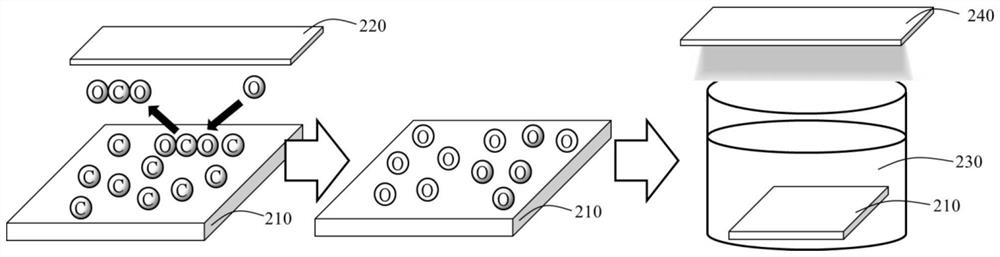

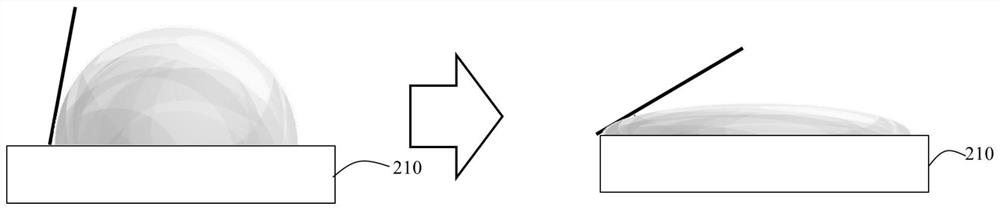

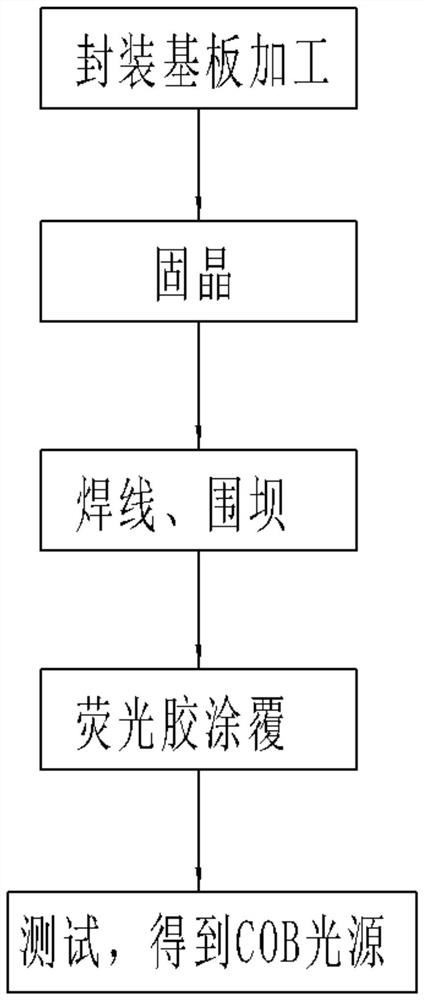

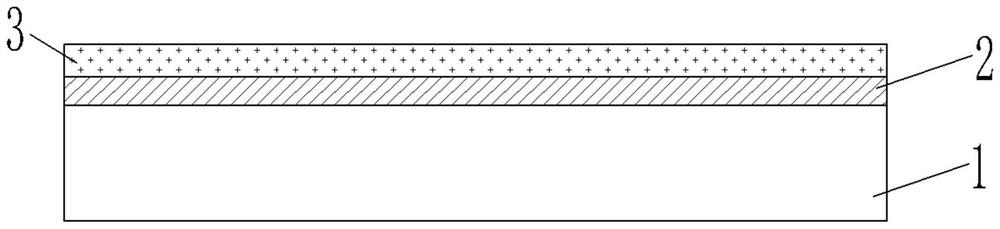

Manufacturing method of intelligent full-color toning COB light source

The invention discloses a manufacturing method of an intelligent full-color toning COB light source. The intelligent full-color toning COB light source comprises a packaging substrate, a COB chip and solid crystal glue. When the packaging substrate is prepared, an original solid crystal area is creatively set into a plurality of transverse die bonding grooves and longitudinal die bonding grooves, the sizes of the transverse die bondinggrooves and the longitudinal die bonding grooves are consistent with the sizes of the COB chip needing to be glued, meanwhile, the grooves are formed in the die bonding grooves, and after glue is dispensed in the die bonding grooves subsequently, the die bonding glue can enter the grooves, so that the glue overflowing condition can be reduced to a great extent, the die bonding glue is not prone to covering the side edge of the COB chip during glue joint, and the electric leakage condition is avoided. The COB light source prepared by the invention is high in light emitting efficiency and uniform in light emitting, the side edge of the COB chip is not coated with glue in the preparation process, the die bonding glue does not overflow, and the COB light source is high in yield and reliability, excellent in light emitting effect and higher in practicability.

Owner:ZHUHAI HONGKE OPTOELECTRONICS

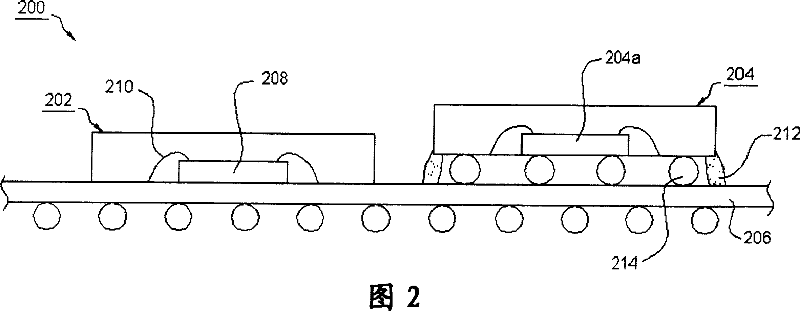

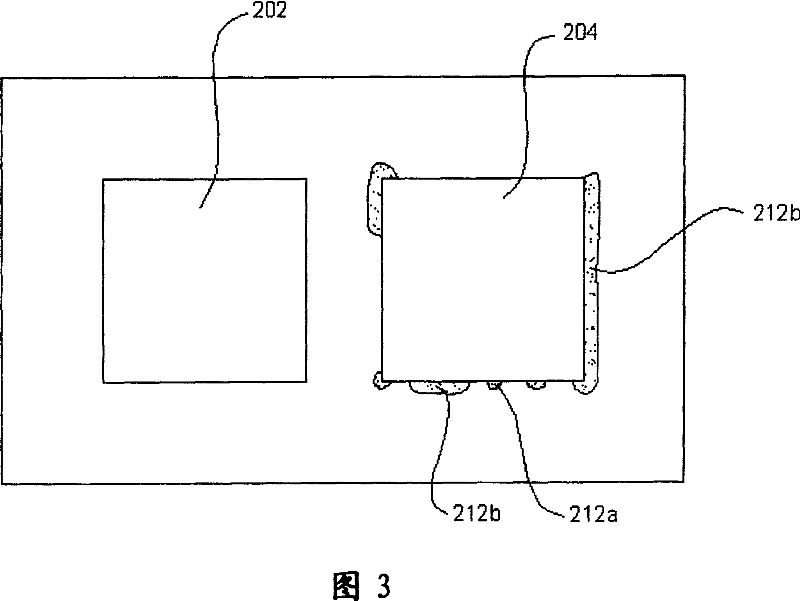

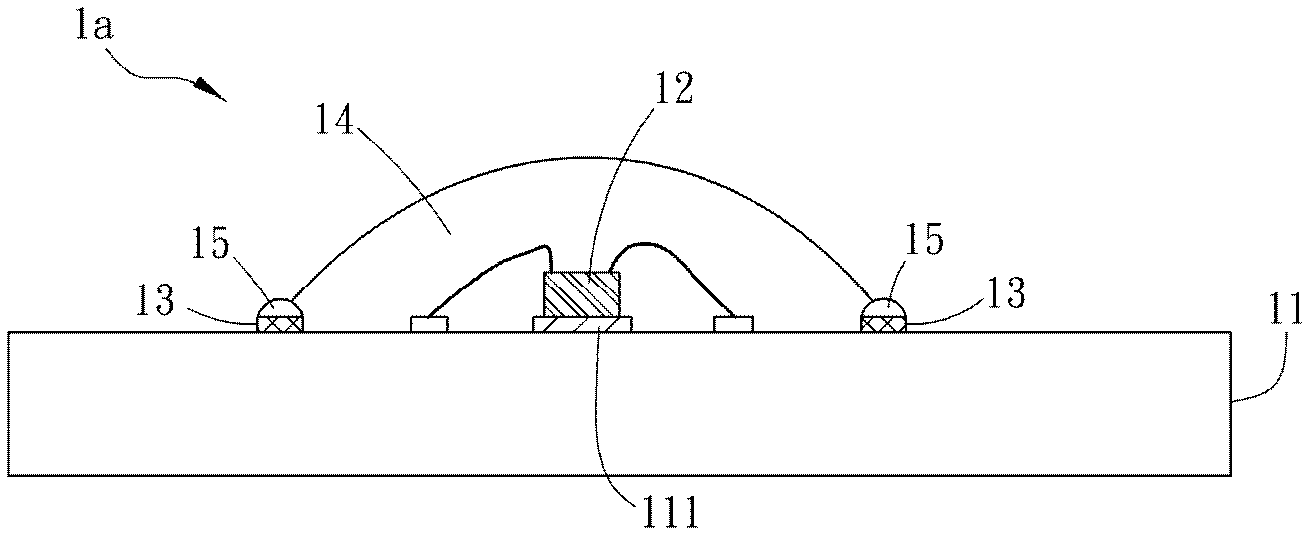

Semiconductor packing structure and production thereof

ActiveCN100356534CReduce consumptionReduce glue overflowSemiconductor/solid-state device detailsSolid-state devicesSemiconductor componentsElectrical conductor

Owner:ADVANCED SEMICON ENG INC

Light emitting device and manufacturing method thereof

InactiveCN102867903ADoes not reduce light output angleReduce glue overflowSolid-state devicesSemiconductor devicesEffect lightEngineering

A light emitting device comprises a substrate, at least one light emitting diode core, a sealing adhesive positioning layer and a first packaging adhesive body. The substrate is provided with a core setting area, the light emitting diode cores are arranged in the core setting area, the sealing adhesive positioning layer is arranged on the substrate, and at least part of the first packaging adhesive body covers the light emitting diode cores and contacts with the adhesive positioning layer. By the aid of the light emitting device, light emitted from the light emitting diode cores can be prevented from being blocked, and lighting effect can be enhanced.

Owner:GIO OPTOELECTRONICS CORP

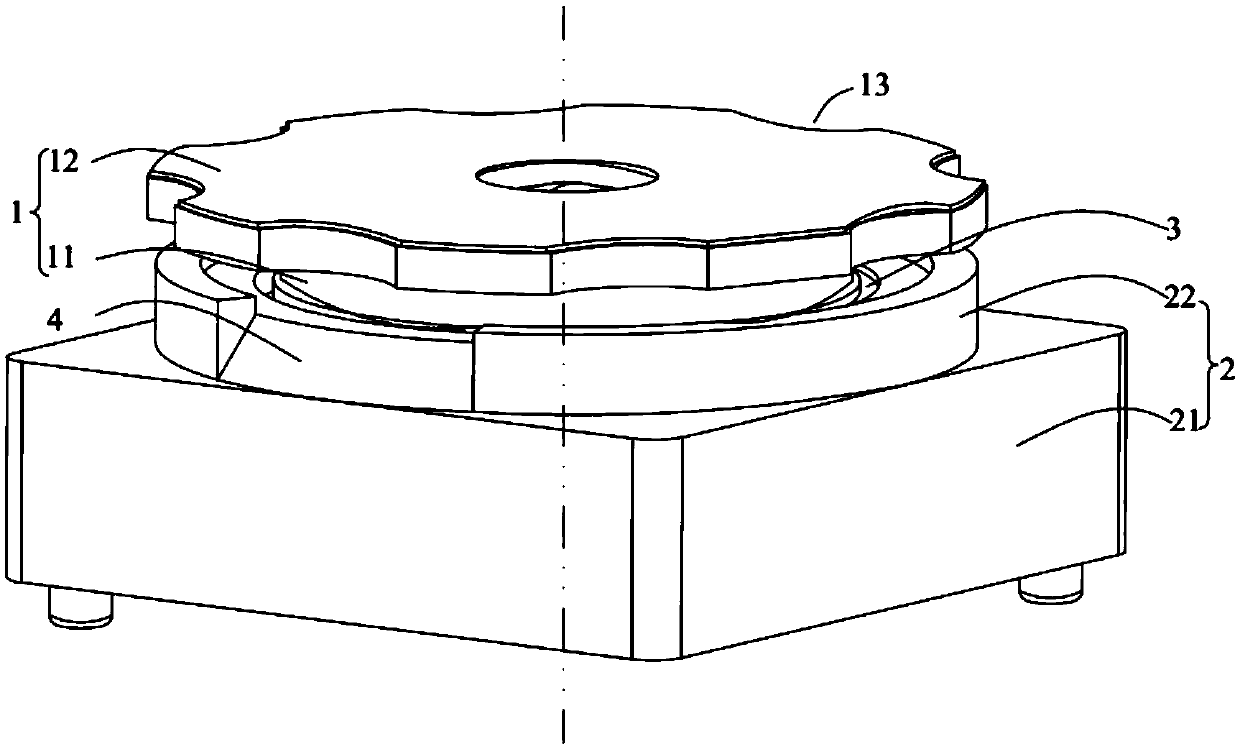

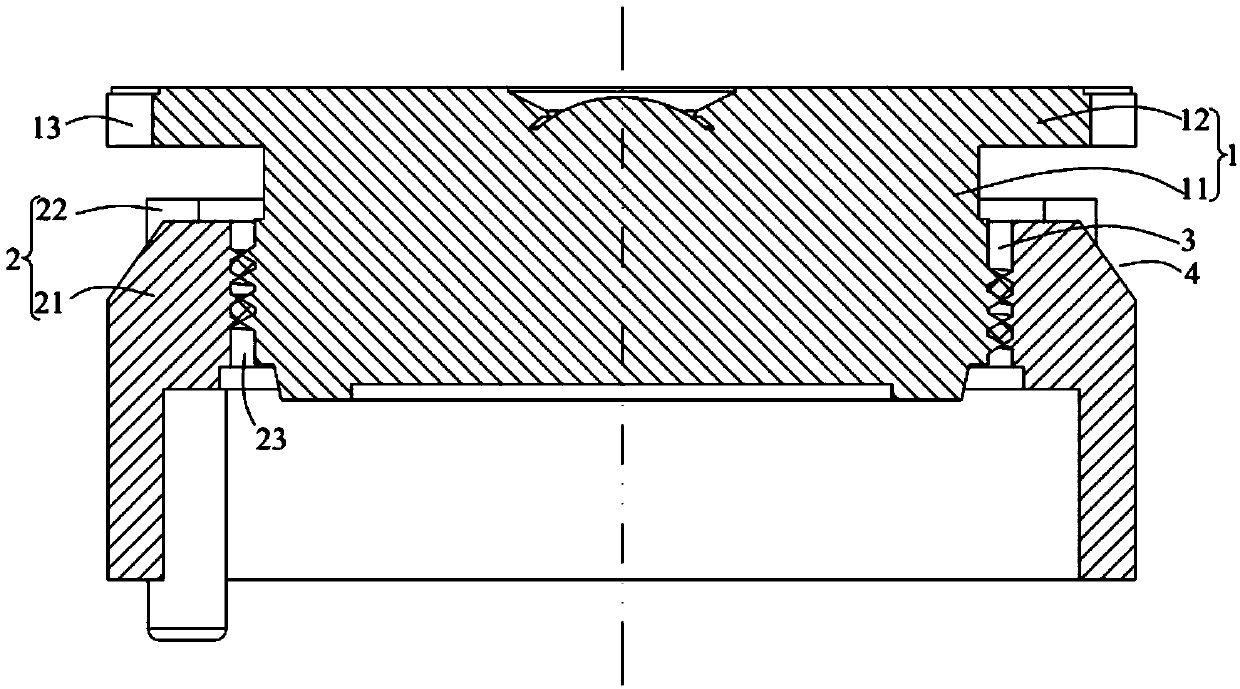

Cushion material for hot-press and use of the same

ActiveCN103009765AReduce glue overflowUniform thicknessLaminationLamination apparatusFiberKraft paper

Owner:TECH ADVANCE IND

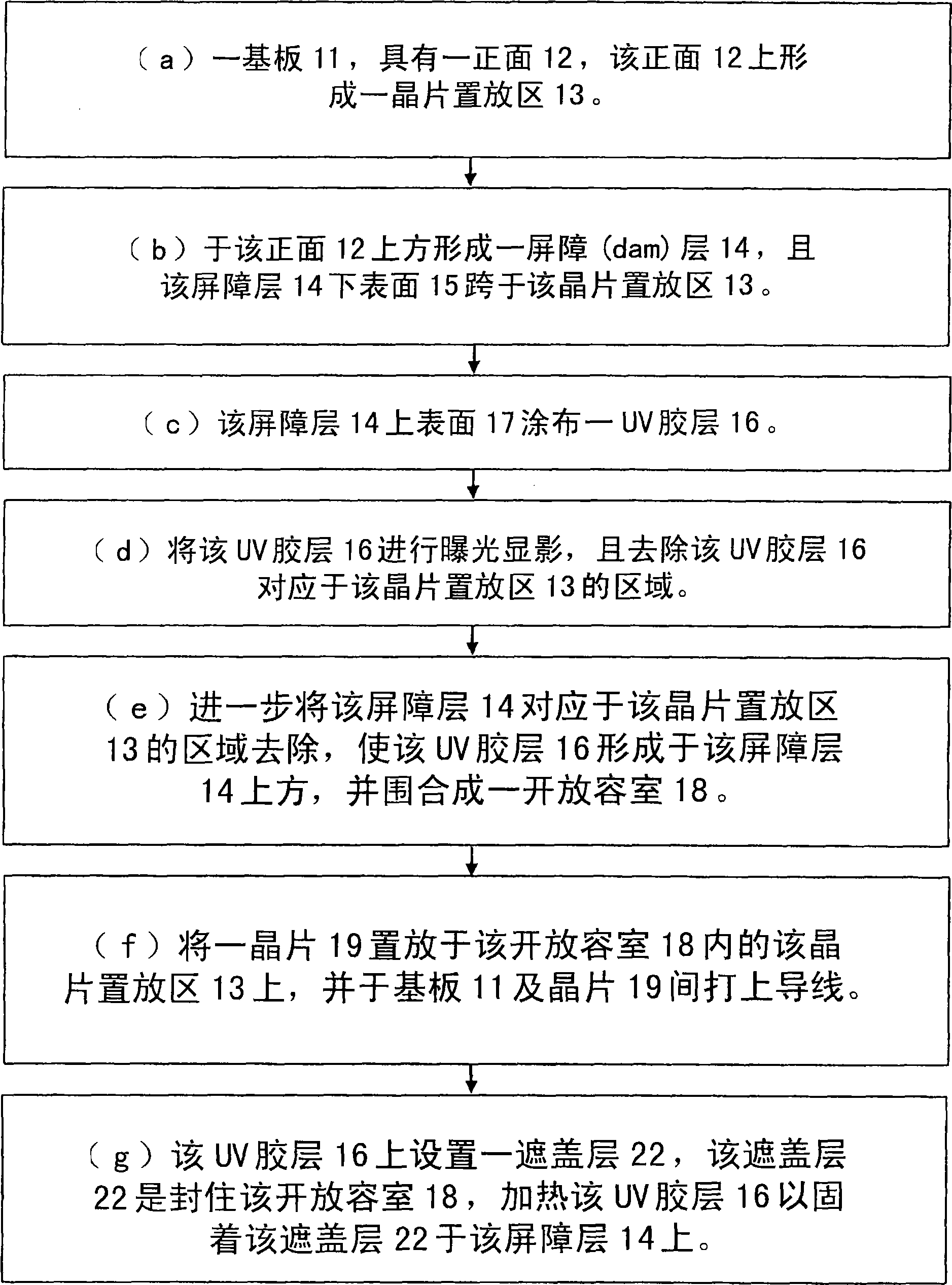

Method for packaging semiconductor with cavity

InactiveCN101546712AReduce glue overflowLow costSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor package

The invention relates to a method for packaging a semiconductor with a cavity, which comprises the following steps of: a, providing a substrate of which the front side has a chip accommodating area; b, forming a barrier layer above the front side; c, coating a UV adhesive layer on the upper surface of the barrier layer; d, removing an area, corresponding to the chip accommodating area, in the UV adhesive layer; e, further removing an area, corresponding to the chip accommodating area, in the barrier layer; f, arranging a chip on the chip accommodating area in an open accommodating chamber and molding an wire on the chip to electrically connect the chip and the substrate; and g, arranging a cover layer on the UV adhesive layer and heating the UV adhesive layer to fix the cover layer on the barrier layer. The design of the invention can reduce glue overflow generated during the packaging of the semiconductor considerably; and the method can be implemented by the prior art without increasing equipment purchase cost.

Owner:LINGSEN PRECISION INDS

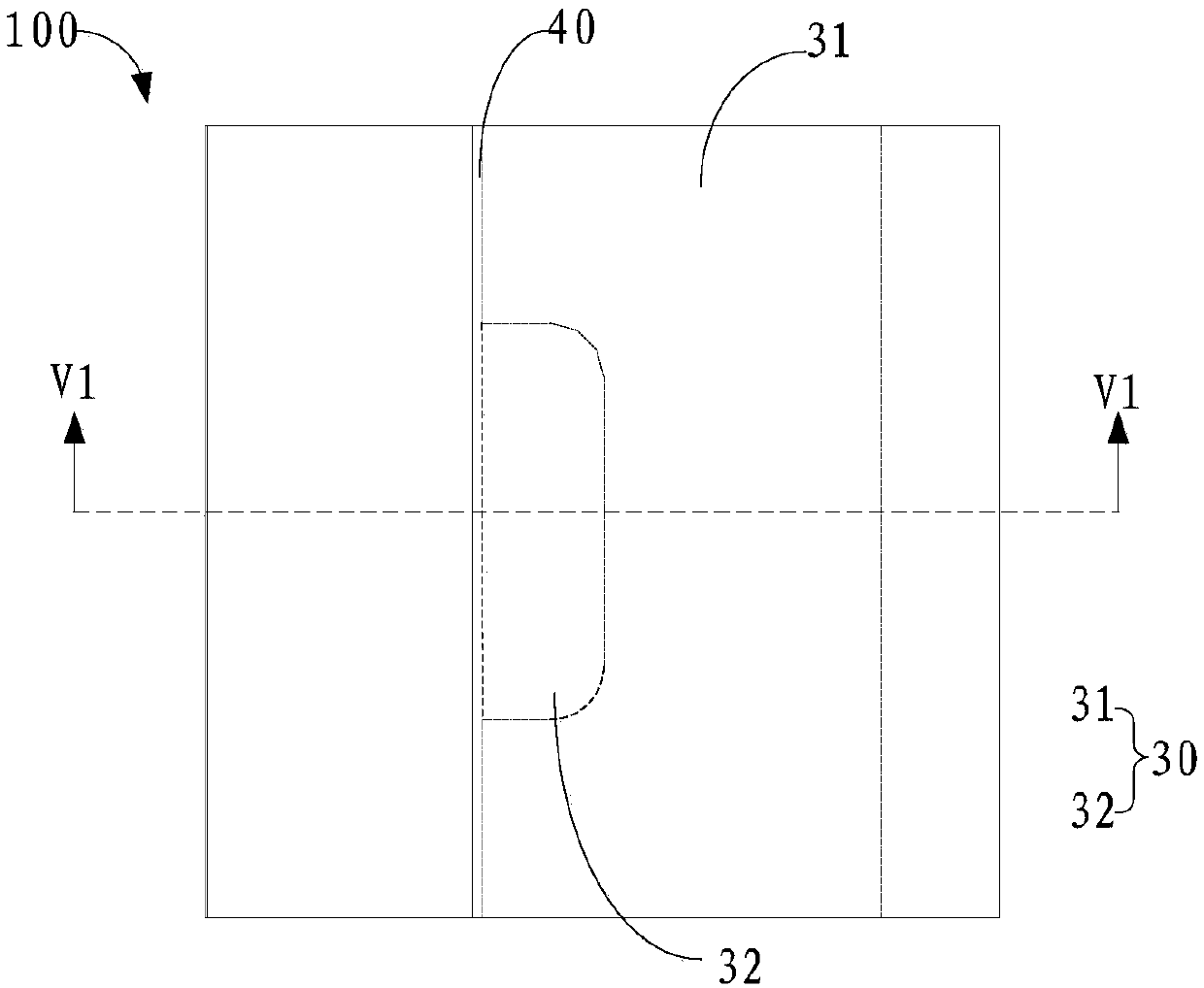

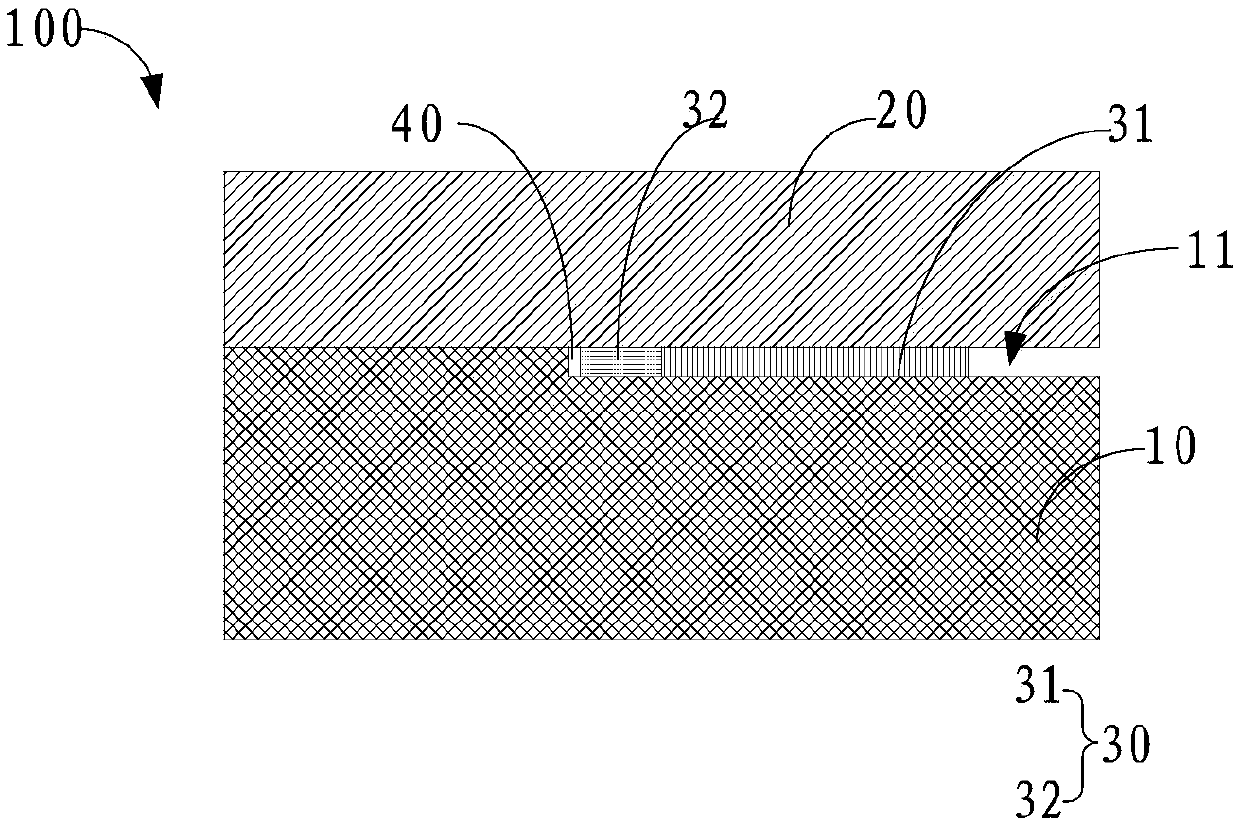

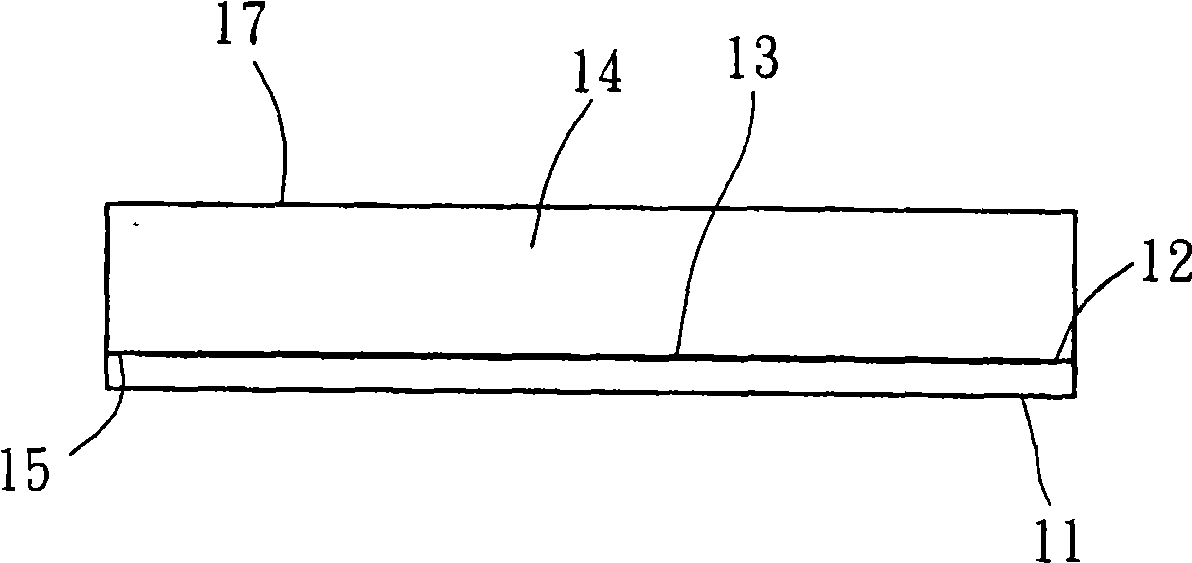

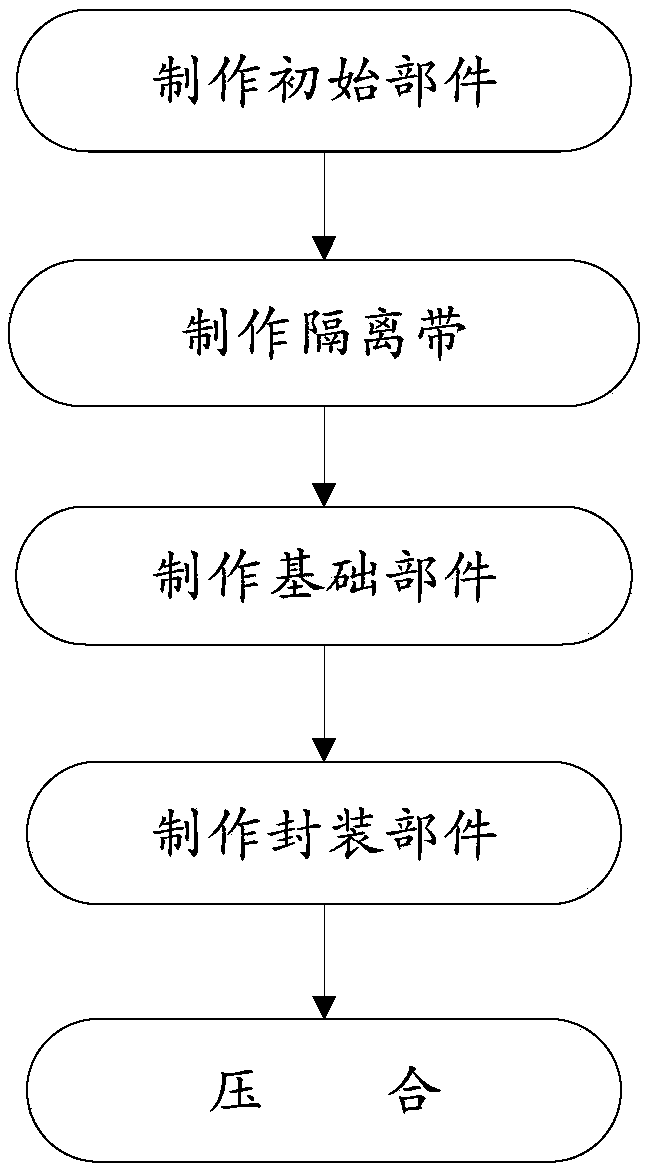

Ultra-thin OLED screen body and manufacturing process thereof

ActiveCN108172606ASolve the technical problems of overflowing glueImprove yieldSolid-state devicesSemiconductor devicesManufacturing engineering

The invention provides an ultra-thin OLED screen body and a manufacturing process thereof. Based on the technical scheme provided by the invention, in the specific structure of the ultra-thin OLED screen body provided by the invention, due to the existence of two parallel isolation strips, a broadening area of dispensing can be limited after the two parallel isolation strips are laminated, therebyeffectively solving the excessive glue problem in the prior art and improving the product yield; and based on the technical scheme, compared with the prior art, the manufacturing process of the ultra-thin OLED screen body provided by the invention has the advantages that the isolation strips are prepared on the same layer as insulating layers or isolation columns, so that the process steps are greatly simplified, and the production efficiency is improved.

Owner:GUAN YEOLIGHT TECH CO LTD

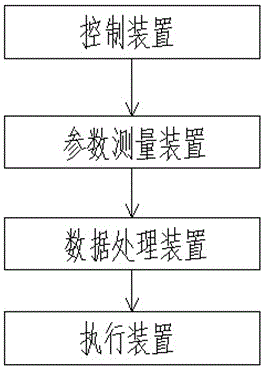

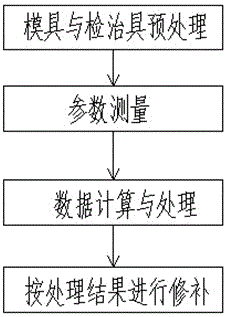

A repair system and method for alleviating radial rubber overflow of active tire molds

ActiveCN104227043BEasy to assembleEasy to adjustAuxillary equipmentTyresNational standardData memory

The invention discloses a repair system for relieving excessive glue of a tire segment mold. The repair system comprises a control device, a parameter measuring device, a data processing device and an executing device. The parameter measuring device is used for measuring data, the control device is in control connection with the measuring device and the executing device, an output end of the measuring device is electrically connected with an input end of the data processing device, and an output end of the data processing device is electrically connected with the executing device; the data processing device comprises a data storage and a data processor, the data storage is used for storing set standard data, the data processor is used for computing and processing the data measured by the parameter measuring device, and then processing results of the data processor are transmitted to the executing device. The invention further discloses a repair method. The repair system and the repair method have the advantages that various dimensions of products manufactured by the aid of the repair system and the repair method can meet requirements of national standards, the mold repair efficiency can be improved, the repair cost can be reduced, and skill requirements of the segment mold on staffs can be lowered.

Owner:KENDA RUBBER CHINA

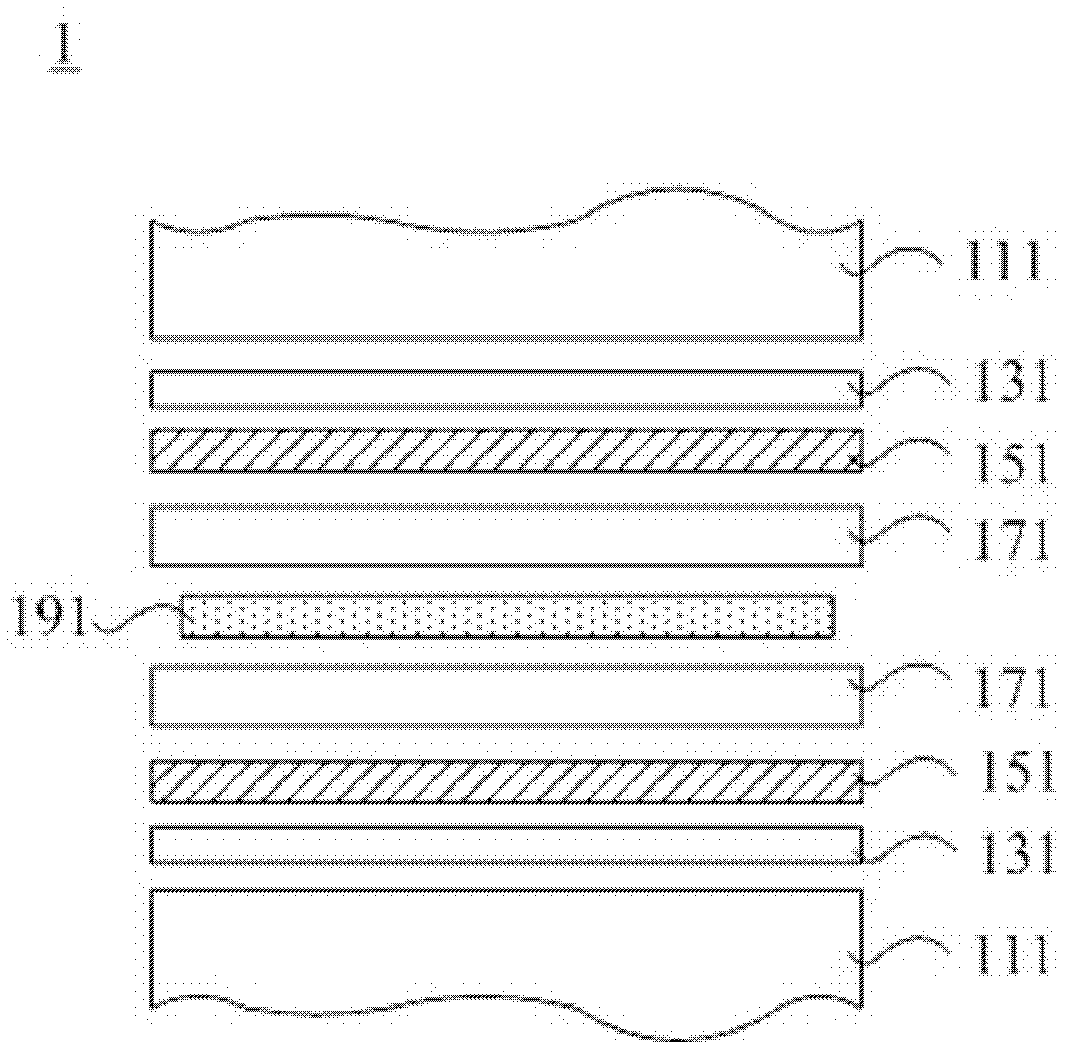

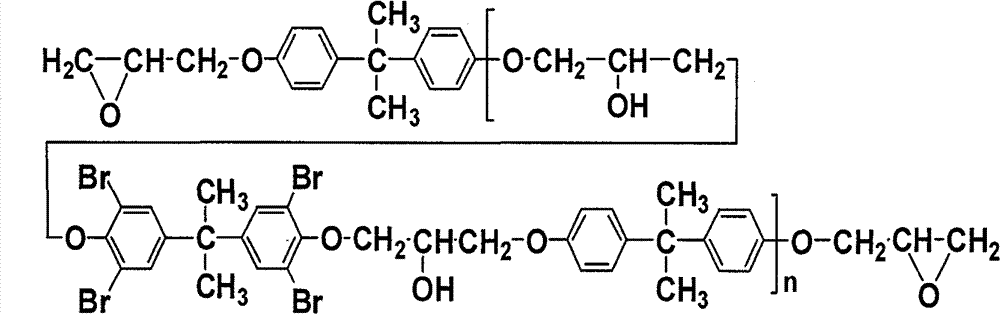

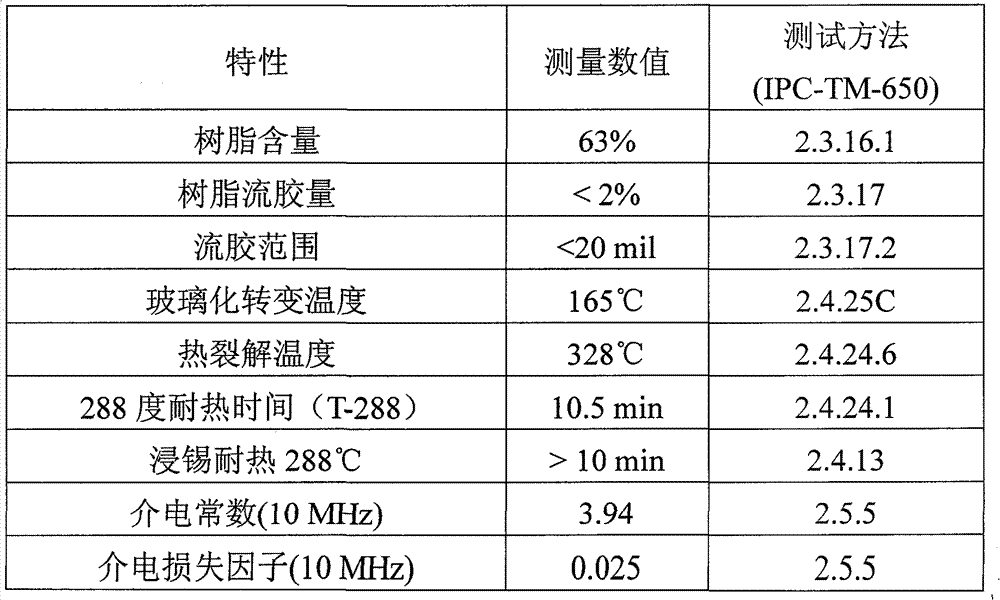

Bonding film and used resin thereof

ActiveCN101768328BEasy to manufactureReduce glue overflowPrinted circuit detailsEpoxy resin adhesivesEpoxyGlass fiber

The invention relates to a resin composition which is provided with brominated epoxy resin, carbamate modified copolyester, a hardener and a solvent. The invention also relates to a bonding film which comprises glass fiber cloth and a resin layer, wherein the resin layer is distributed on the glass fiber cloth, and the resin layer is provided with the resin composition.

Owner:ITEQ WUXIELECTRONICS TECH

Equipment for injecting glue into bottle caps

InactiveCN108819060AReduce glue overflowImprove product qualityDomestic articlesBottle capElectromagnet

The invention discloses equipment for injecting glue into bottle caps. The equipment structurally comprises a control machine case, an operation button, an operation panel, a base, an overflow cuttingdevice, a discharging pipe, a glue injection box, a sol box and a glue pipe. The control machine case is perpendicular to the rear end of the glue injection box. The operation button is embedded andinstalled in the outer wall of the operation panel. The equipment for injecting the glue into the bottle caps is structurally provided with the overflow cutting device, when the equipment is started and used, the bottle caps enter an armature from a material pipe, a half gear is used for rotationally driving an upper top plate to move downwards, when the upper top plate moves downwards, a cuttingtool embedded in the upper top plate trims the bottle caps, bearing columns are used for fixing the descending height of the upper top plate, and after cutting is finished, the upper top plate continuously descends, a lower contact is connected, an electromagnet is powered on through the contact, the armature is attracted, and the bottle caps above the armature fall down and are collected. By means of the device, the situation of glue overflow of the manufactured bottle caps can be reduced, and the product quality is improved.

Owner:徐美琴

Hot air/laser edge sealing strip back-coated with thermoplastic polyester elastomer (TPEE) polymer material

PendingCN114369419AReduce glue overflowReduce jam defectsFilm/foil adhesivesFittingPolyesterPrinting ink

The invention relates to the technical field of edge bands, in particular to a thermoplastic polyester elastomer (TPEE) polymer material back-coated hot air / laser edge band which comprises a UV gloss oil layer, a printing ink layer, a plastic base material layer, a joining layer PU and a modified TPEE polymer back-coated adhesive layer which are sequentially arranged from top to bottom. By adopting the modified TPEE polymer back coating adhesive layer, the problem of heat resistance is solved from the aspect of materials, the defects of adhesive overflowing and material blocking of the edge sealing strip are reduced, and the production efficiency is improved. The product percent of pass is improved and the reject ratio is reduced. The appearance attractiveness is improved, the surface smoothness is improved, and the surface hardness is improved. The product heat resistance is improved. Compared with an existing material, the processing temperature error-tolerant rate is improved, and processing in a small temperature range is not needed. The crystallization efficiency is improved, the cooling effect is accelerated, and the opening time is shortened. The edge sealing quality effect is improved, the zero-glue-line effect is achieved, and the viscous force of the edge strip and the plate is improved.

Owner:惠州市华富新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com