Preparation method of rigid-flex printed circuit board with blind groove

A technology of rigid-flex boards and blind slots, which is applied in multi-layer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problems that rigid-flex boards can't achieve the effect, and blind slots can't be combined with rigid-flex boards at the same time. Achieve the effect of simple operation, high efficiency and reducing glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

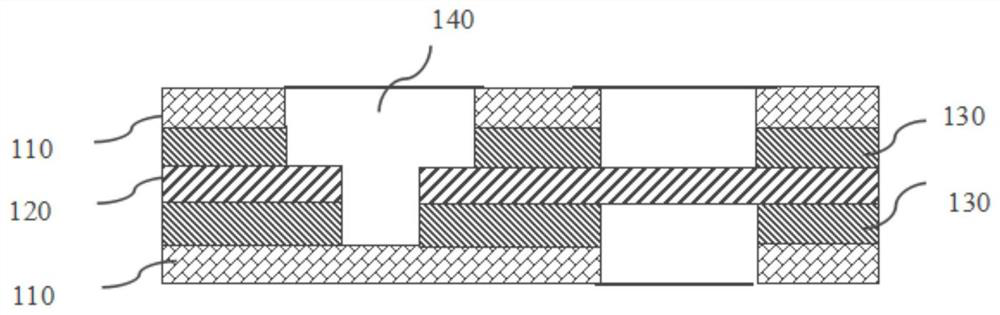

[0038] A rigid-flex combination plate with blind slots, the structure of the combination plate is shown in figure 1 , from top to bottom, followed by a rigid board 110, a prepreg 130, a flexible board 120, a prepreg 130, and a rigid board 110, and the combined board has a blind slot 140 spanning the rigid board and the flexible board.

[0039] The preparation method of the rigid-flex board comprises the following steps:

[0040] The expansion and contraction of the flexible board is measured for the first time to obtain the expansion and contraction coefficient of the covering film, and then the covering film is grafted on the flexible board and pressed together, and then the expansion and contraction of the flexible board is measured for the second time, and finally the deflection is milled out. The position of the blind groove on the sex plate;

[0041] (1) Take the flexible board, cut the material, make the inner layer circuit on the flexible board, and check the quality o...

Embodiment 2

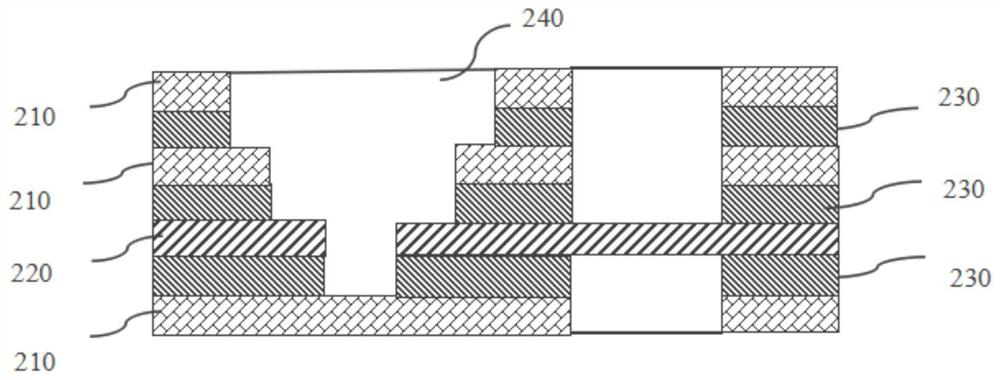

[0048] A rigid-flex combined board with blind slots, see the structure of the combined board figure 2 , from top to bottom, followed by rigid board 210, prepreg 230, rigid board 210, prepreg 230, flexible board 220, prepreg 230, rigid board 210, the combination board has a blind slot 240 spanning the rigid and flexible boards.

[0049] The preparation method of the rigid-flex board comprises the following steps:

[0050] (1) Take the flexible board, cut the material, make the inner layer circuit on the flexible board, and check the quality of the PCB circuit pattern through optical scanning; measure the expansion and contraction of the flexible board for the first time to obtain the expansion and contraction of the cover film Coefficient, film exposure, gold-plated protection for the bottom of the blind groove, film removal, blackening, grafting cover film, quick pressing, and baking board; then perform a second expansion and contraction measurement on the flexible board to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com