Cushion material for hot-press and use of the same

A buffer material and hot press technology, applied in the direction of press, lamination, lamination device, etc., can solve the problems of glue overflow, buffer material overflow, uneven thickness of laminated board, etc., to achieve uniform thickness and reduce glue overflow. Situation, effect of dimensional stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

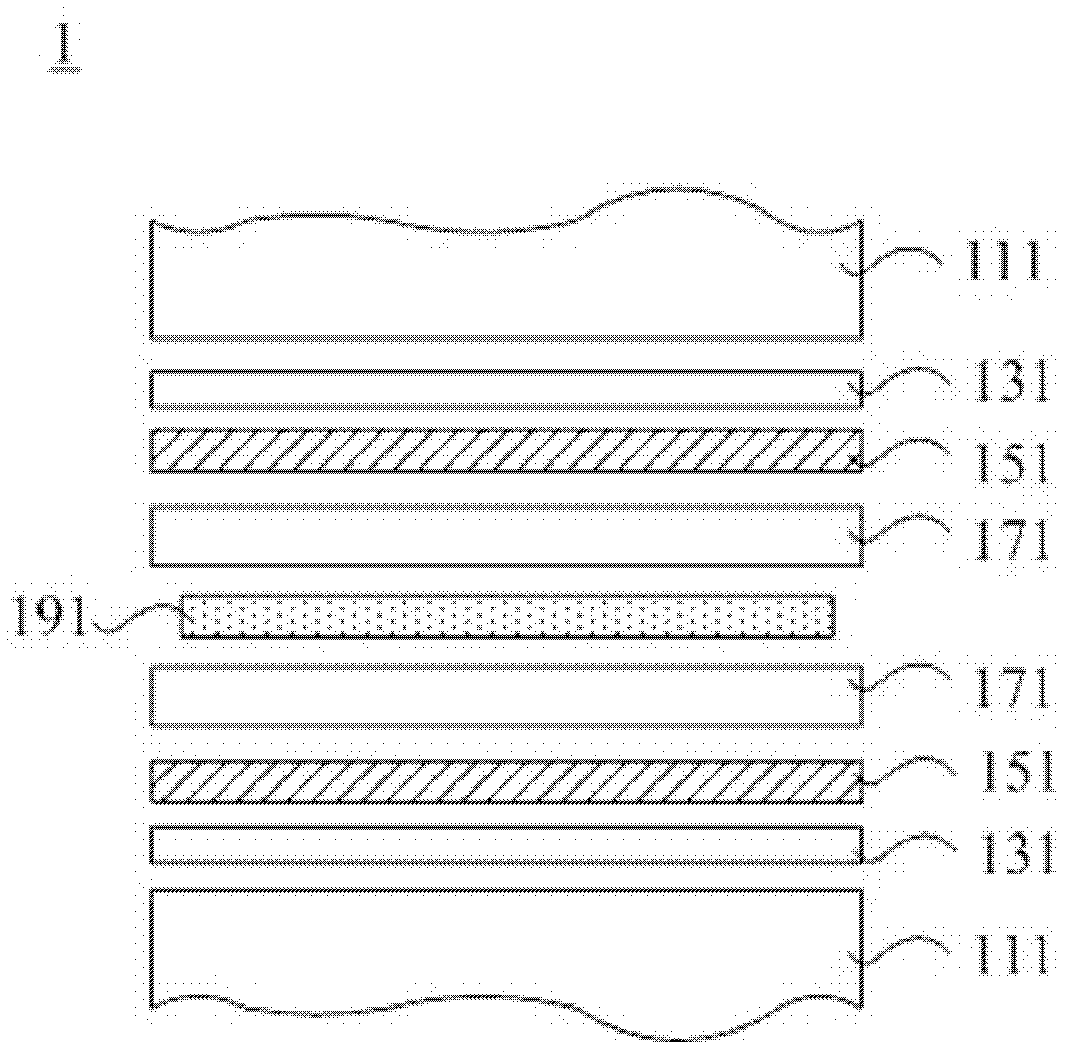

[0038] A fiber web made of MPIA fibers is used as a base material, and PPTA fibers are used alone as a fiber material. By means of steps such as opening, blending, lapping, carding, and pre-needle-punching, a pre-needle-punched cushioning sheet is formed. Afterwards, several buffer sheets were laminated, and processed by needle-punching, hot-pressing and singeing with 46,500 needles to form a basis weight of about 1600 grams per square M buffer material 1. The thermal conductivity coefficients of the buffer material 1 at 20°C and 160°C were measured respectively, and the results were 0.0915 W / m·K and 0.2651 W / m·K respectively.

Embodiment 2

[0040] A layer of MPIA fibers with a thickness of about 75 microns is covered on both sides of the buffer material 1 to obtain the buffer material 2 .

Embodiment 3

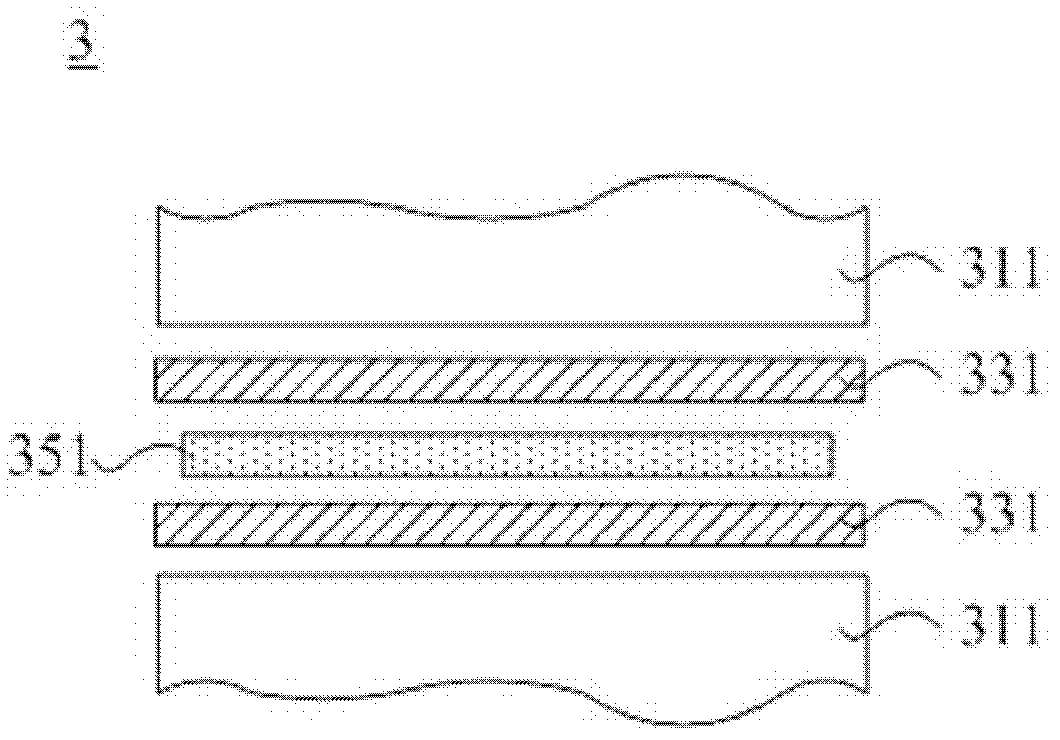

[0042] The steps of Example 1 were repeated to prepare buffer material 3, except that 90% by weight of PP TA fibers and 10% by weight of MP IA fibers were used as fiber materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal degradation temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com