Hot air/laser edge sealing strip back-coated with thermoplastic polyester elastomer (TPEE) polymer material

An elastomeric polymer, thermoplastic polyester technology, used in furniture accessories, film/sheet adhesives, furniture parts, etc. It can reduce the problems of easy pollution and other problems, so as to reduce the glue overflow and jamming defects, improve the waterproof effect, and improve the smoothness of the surface layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

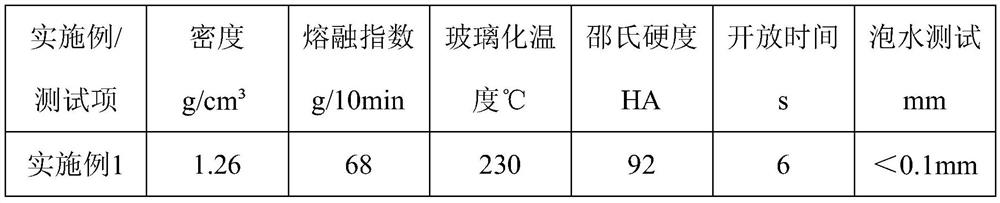

Examples

Embodiment 1

[0042] Adopt the following steps to prepare edge banding for furniture:

[0043] S1, using PVC material, made of 2mm sheet substrate through co-extrusion process;

[0044] S2, setting an ink layer on one side of the sheet substrate;

[0045] S3, the ink layer is passed through UV varnish;

[0046] S4. Roll coating on the other side to set up a PU cohesive layer, and then scrape or stick to set up a 0.1mm modified TPEE polymer back-coating layer to obtain an edge banding strip.

[0047] Here, in terms of mass percentage, the modified material used in the modified TPEE polymer back coating layer is modified by blending 0.5% toner, 0.5% laser absorber and 99% thermoplastic polyester elastomer polymer .

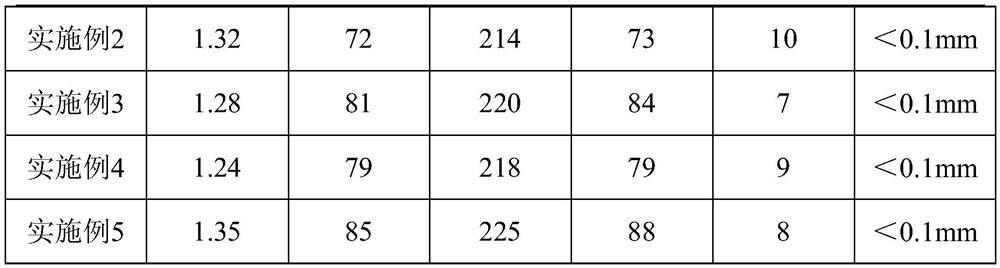

Embodiment 2

[0049] Adopt the following steps to prepare edge banding for furniture:

[0050] S1. ABS material is used to make 1.5mm sheet substrate through co-extrusion process;

[0051] S2, setting an ink layer on one side of the sheet substrate;

[0052] S3, the ink layer is passed through UV varnish;

[0053] S4. On the other side, first roll coat to set up a PU cohesive layer, and then scrape or stick to set up a 0.8mm modified TPEE polymer back-coating layer to obtain an edge banding strip.

[0054] Here, in terms of mass percentage, the modified material used in the modified TPEE polymer back coating layer is modified by blending 1% toner, 0.3% laser absorber and 98.7% thermoplastic polyester elastomer polymer .

Embodiment 3

[0056] Adopt the following steps to prepare edge banding for furniture:

[0057] S1. Using PP material, the 4mm sheet substrate is made by co-extrusion process;

[0058] S2, setting an ink layer on one side of the sheet substrate;

[0059] S3, the ink layer is passed through UV varnish;

[0060] S4. Roll coating on the other side to set up a PU cohesive layer, and then scrape or stick to set up a 0.12mm modified TPEE polymer back-coating layer to obtain an edge banding strip.

[0061] Here, in terms of mass percentage, the modified material used in the modified TPEE polymer back coating layer is modified by blending 2% toner, 0.7% laser absorber and 97.3% thermoplastic polyester elastomer polymer .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com