Bonding film and used resin thereof

A technology of film and resin layer, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of adhesive film overflow, circuit board reliability, etc., and achieve the effect of reducing the phenomenon of glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

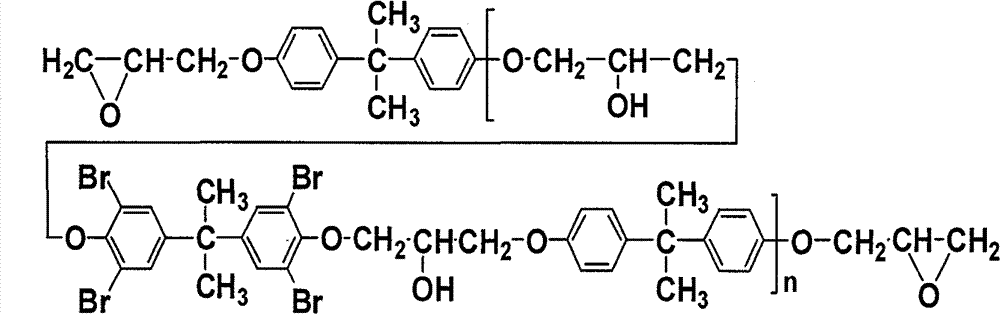

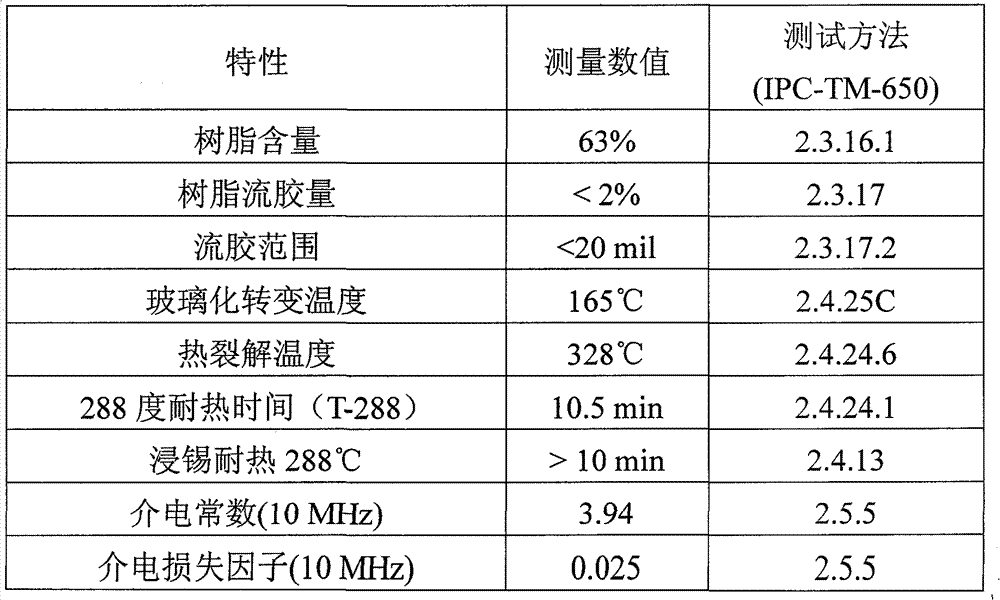

[0012] At present, the epoxy resin is used as the main material to make the adhesive film, and the adhesive film is used as the bonding interface of the soft and hard board. In order to reduce the phenomenon of glue overflow, rubber components or rubber-modified epoxy resins are added to the impregnated resin. Among them, the weight ratio of the rubber component or the rubber-modified epoxy resin to the unmodified main epoxy resin must be greater than 0.3, so as to change the fluidity of the unmodified main epoxy resin and reduce the glue overflow phenomenon , but it also causes the thermal stability of the adhesive film made by impregnation with this impregnated resin to deteriorate and the expansion characteristics to change, resulting in the deformation of the soft and hard boards in the thermocompression process of bonding the soft and hard boards.

[0013] In addition, there is often a significant difference in polarity between the solvent properties of the epoxy resin wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com