A repair system and method for alleviating radial rubber overflow of active tire molds

A technology for tire active mold and rubber spillage, which is applied to household appliances, other household appliances, tires, etc., can solve the problems of tires failing to meet process requirements, increasing the gap between pattern blocks, affecting product stability, etc., to overcome mold deformation. And the effect of high repair cost, increased interference, easy assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

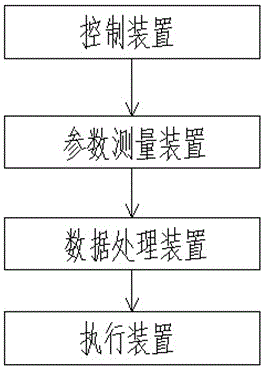

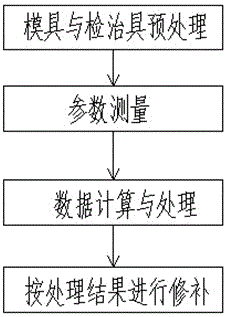

[0025] Such as figure 1 As shown, a repair system for alleviating the radial rubber overflow of active tire molds, including a control device, a parameter measurement device for measuring data, a data processing device and an execution device, the control device controls the connection measurement device and the execution device, and the measurement The output end of the device is electrically connected to the input end of the data processing device, and the output end of the data processing device is electrically connected to the execution device;

[0026] The data processing device includes a data memory and a data processor, the data memory is used to store the set reference value, and the data processor is used to calculate and process the data measured by the parameter measuring device; then transmit the processing result to the execution device; the repair system also Includes a display screen for displaying data and data calculation processing.

[0027] The working pri...

Embodiment 2

[0029] The rest are the same as the above embodiments, except that the parameter measuring device is a gap measuring instrument and / or a laser distance measuring instrument.

Embodiment 3

[0031] The rest are the same as in Embodiment 1, except that the control device is a PLC or an industrial computer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com