Die cutting method convenient for detection

A die-cutting and die-cutting technology, applied in the field of die-cutting that is easy to detect, can solve the problems of reducing the yield rate, affecting product quality, lack of lubrication, etc., to reduce the generation of air bubbles, reduce the phenomenon of glue overflow, and reduce the defect rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

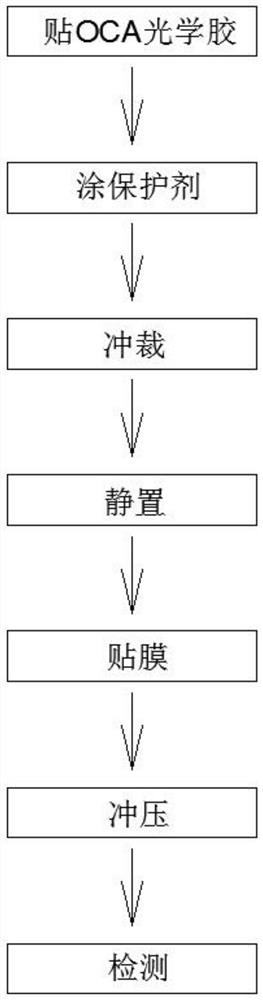

[0022] Example 1: Reference figure 1 , a kind of die-cutting method that is easy to detect is characterized in that, comprises the blanking mold that is used for this method, and described blanking mold comprises mold body and marking device, and described mold body has the same cutting tool as preset shape ;

[0023] Steps include:

[0024] (1). Paste OCA optical glue, place OCA optical glue on the heavy release film, and stick them together by a laminating machine to form a composite film;

[0025] (2). Apply protective agent, and coat a layer of uniform degumming protective agent on the upper surface of the composite film;

[0026] (3). Punching, using a punching die to punch out the composite film, punching out the OCA optical adhesive layer into a plate with the same preset shape, and leaving a detection mark on the composite film through the marking device;

[0027] In this embodiment, the projection of the marking device on the composite film is outside the maximum d...

Embodiment 2

[0032] Embodiment 2: Different from Embodiment 1, in this embodiment, the detection of step (7) is judged by the optical detection device. Analyze and judge product images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com