Two-in-one spray gun

A two-in-one, spray gun technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of frequent replacement of raw materials, limited flexibility, overflow, etc., to reduce the time for replacing raw materials, expand the scope of use, and improve the quality of the gun body light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

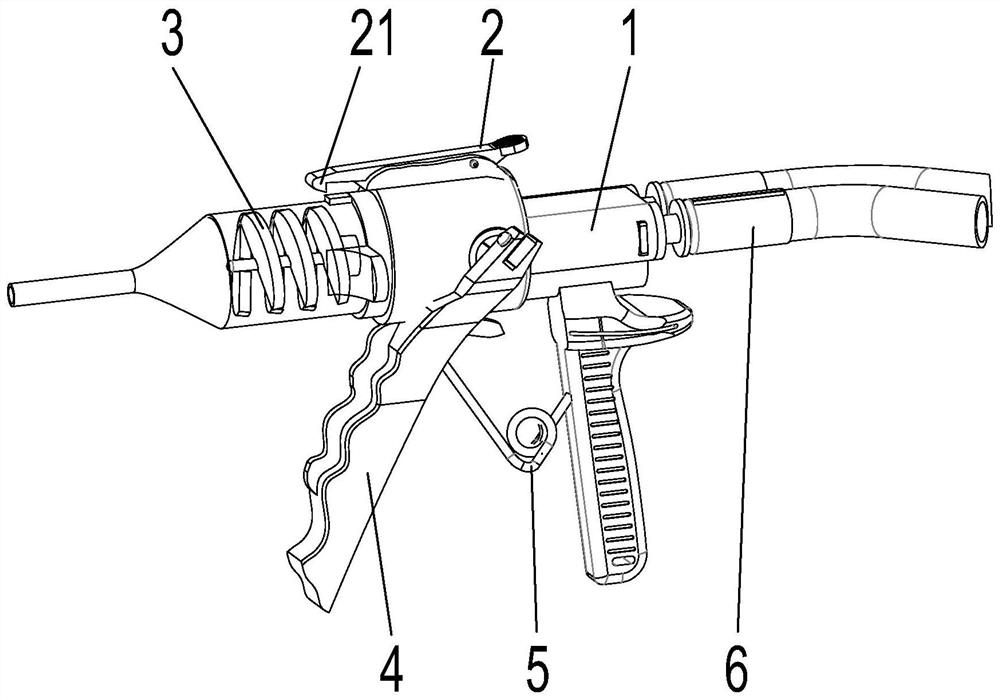

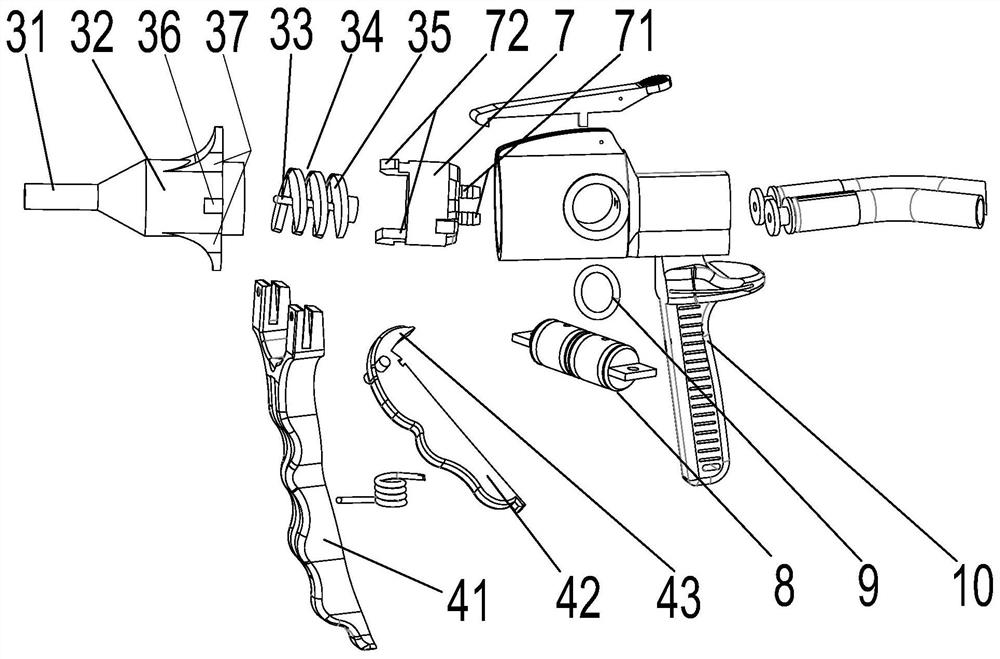

[0032] Such as figure 1 , 2 , 3, a two-in-one spray gun mainly includes a gun body 1, a nozzle mechanism 3, a trigger 4 and two delivery pipes 6 fixedly connected to the rear end of the gun body 1.

[0033] The nozzle mechanism 3 is detachably mounted on the front of the gun body 1. Specifically, the main body of the nozzle mechanism 3 is a cylindrical and hollow shell 32, and one end of the shell 32 close to the gun body 1 is detachably snapped together. A coupling cover 7, the end of the housing 32 away from the gun body 1 is integrally formed and extended to form a conical funnel-shaped nozzle 31.

[0034] In the inside of the housing 32, there is a mixing part 34 arranged axially along the housing 32. The mixing part 34 is vertically fixed to the coupling cover 7. The mixing part 34 is mainly composed of a central axis 33, The stirring piece 35 spirally surrounds along the central axis 33, and the stirring piece 35 is arranged in a semicircle.

[0035] In order to make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com