Bent gluing type automobile filter element machining device

A processing device and filter technology, which is applied to the surface coating liquid device, lamination device, coating, etc., can solve the problems of difficult dust, reducing the bonding force between cloth and filter paper, and reducing the filtration efficiency of filter paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

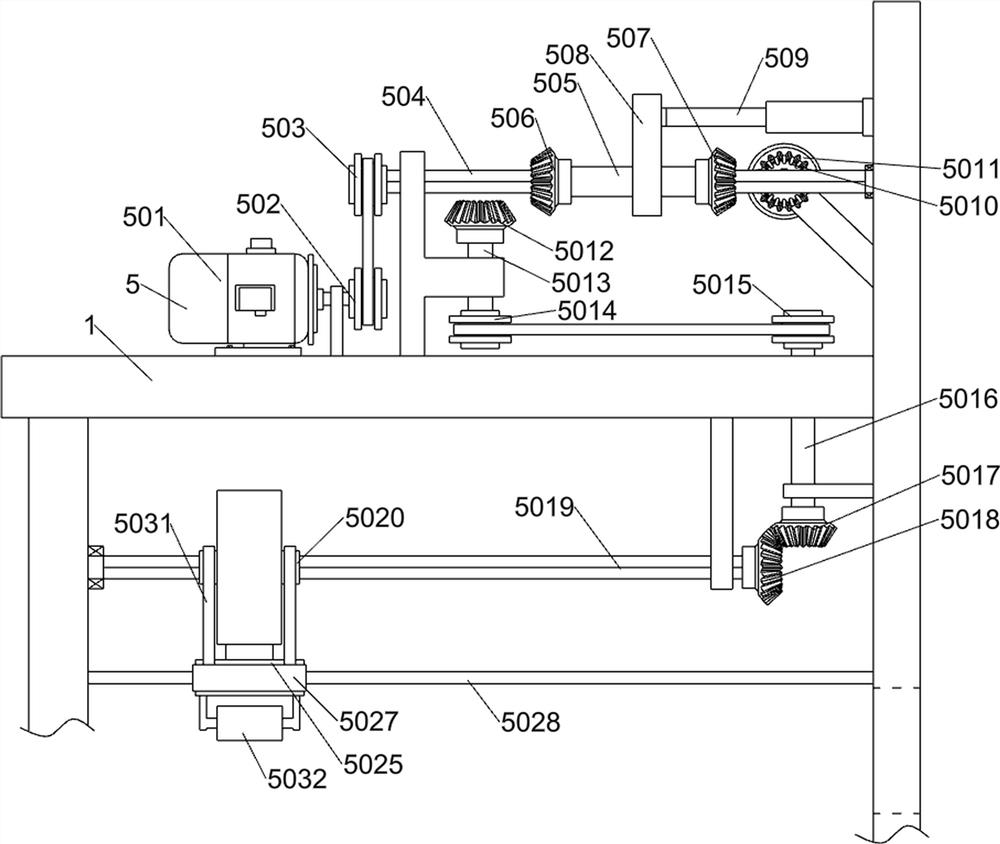

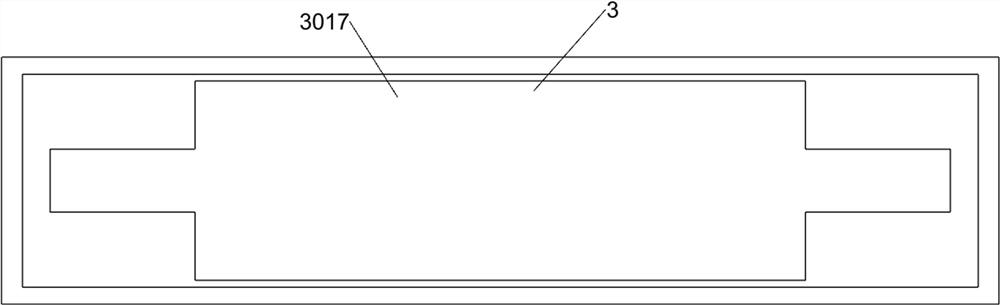

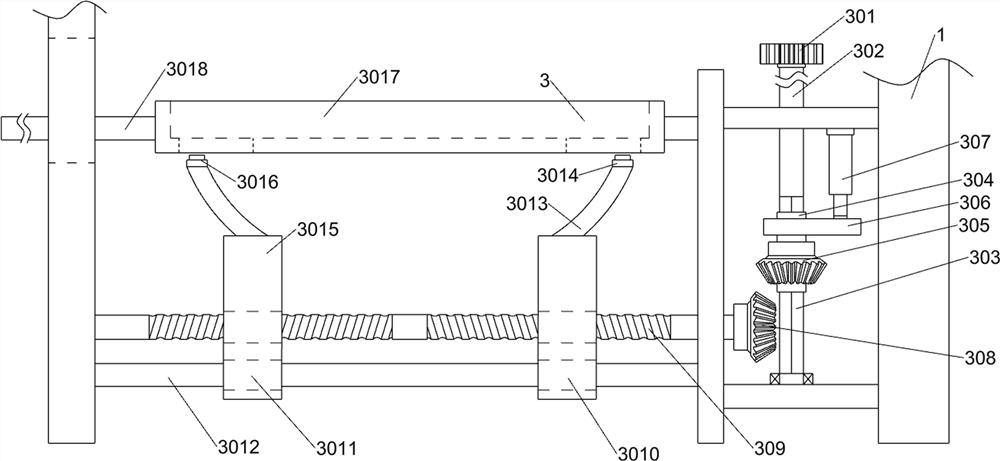

[0103] A curved glue-coated automotive filter element processing device, such as Figure 1-6 As shown, it includes a working frame 1, a control display 2, a bending system 3, a glue application system 4 and a spreading system 5; the control display 2 is connected to the working frame 1; the bending system 3 is connected to the working frame 1 is connected; the gluing system 4 is connected with the working frame 1, and the gluing system 4 is connected with the bending system 3; the spreading system 5 is connected with the working frame 1, and the spreading system 5 is connected with the gluing system 4.

[0104] Working process: When using the device, fix the device horizontally on the working plane, connect the external power supply, and the operator will adjust the device as a whole through the control display screen 2, first debug the device, and start working after the debugging is completed. Place the filter element in the bending system 3, drive the gluing system 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com