Glue dispensing method and device

A technology of glue dispensing and glue dispensing machine, which is applied to devices and coatings that apply liquid to the surface, which can solve problems such as pollution, glue overflow and residual glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

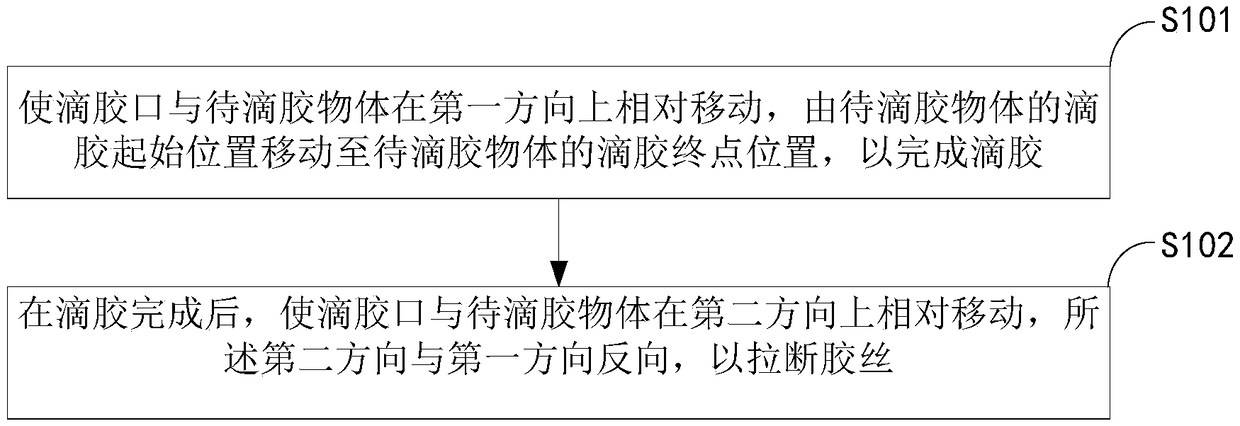

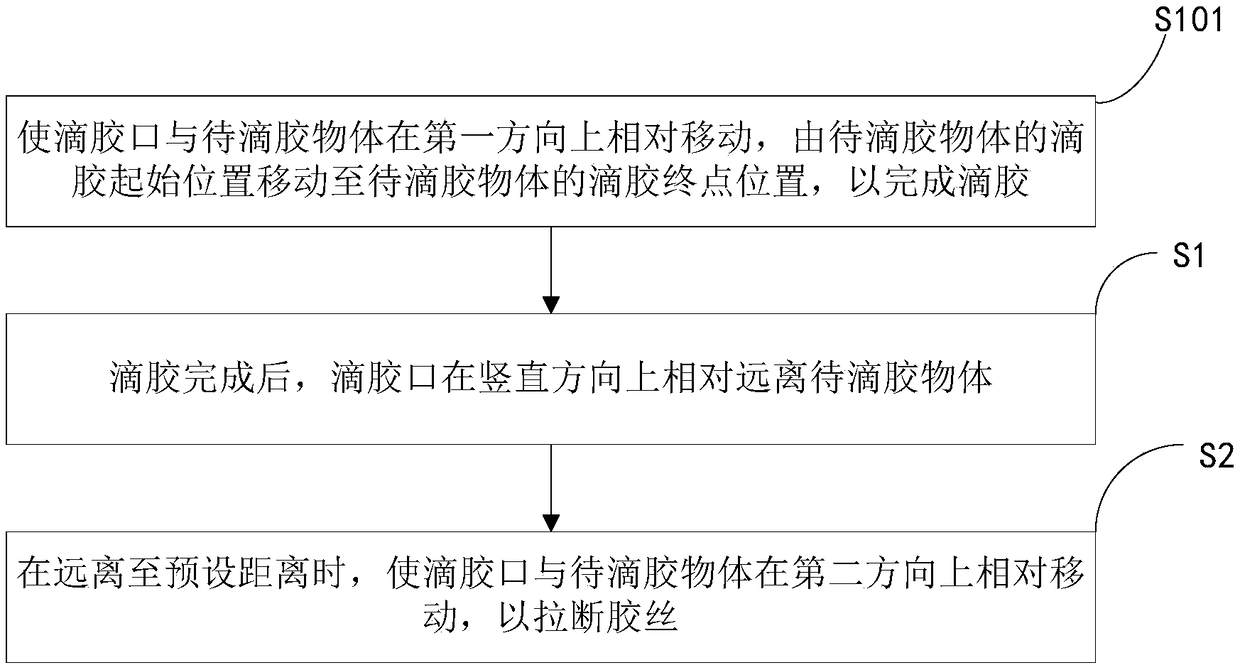

[0067] see Figure 2 to Figure 3 As shown, the present embodiment provides a kind of glue dropping method, and described method comprises:

[0068] Step S101: Make the dispensing port and the object to be dispensed relatively move in a first direction, from the dispensing start position of the dispensing object to the dispensing end position of the dispensing object, so as to complete the dispensing.

[0069] It can be understood that this step can be realized in two ways: the object to be dispensed is stationary, and the relative movement between the dispense port and the object to be dispensed is realized by driving the dispense port to move; Drive the object to be dispensed to move, and realize the relative movement between the dispenser port and the object to be dispensed.

[0070] In this step, the relative moving speed between the glue dispensing port and the object to be dispensed is not greater than 200mm / s, and the dispensing speed of the glue dispensing port is 90mm...

Embodiment 2

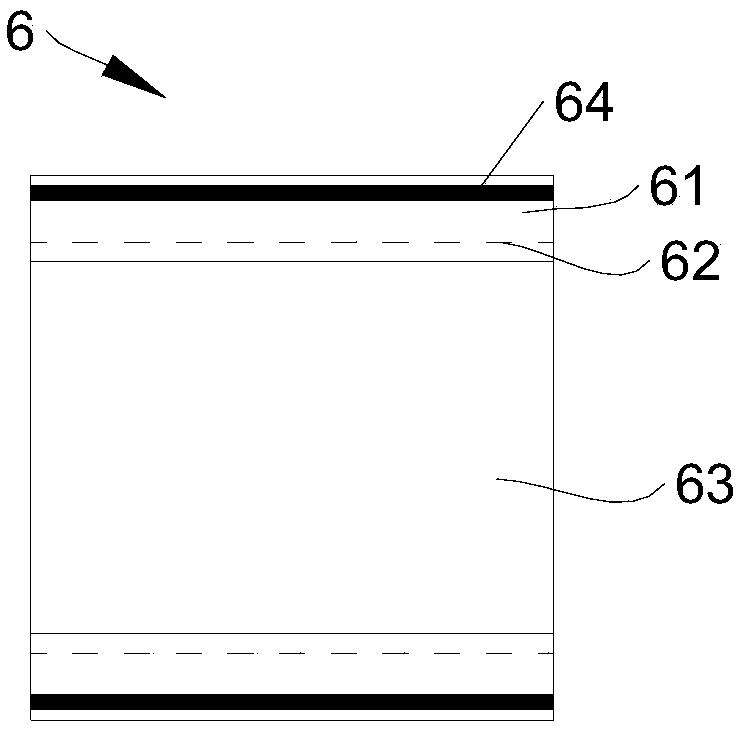

[0086] Such as Figure 4-6 As shown, this embodiment provides a glue dispensing device, which can realize the glue dispensing method described in Embodiment 1. For the convenience of description, this embodiment takes the realization of the edge sealing of the battery cell as an example for illustration.

[0087] The glue dispensing device in this embodiment includes a glue dispensing machine, a first driving mechanism 3 , a third driving mechanism 4 , a second driving mechanism 5 and an angle adjusting mechanism 2 .

[0088] Wherein, the glue dispensing machine 1 is provided with a glue dispensing port, and the glue dispensing machine 1 is provided with a heat shield 11 .

[0089] The angle adjustment mechanism 2 can realize the adjustment of the glue dispensing port of the dispensing machine; the first driving mechanism 3 can drive the dispensing machine to move along the first direction or the second direction, and the second driving mechanism 5 can drive the dispensing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com