Mould for manufacturing glass container

A glass container and mold technology, which is applied in the field of molds for making glass containers, can solve problems such as inconsistencies, and achieve the effects of smooth molding, saving resources, and reducing the matching area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

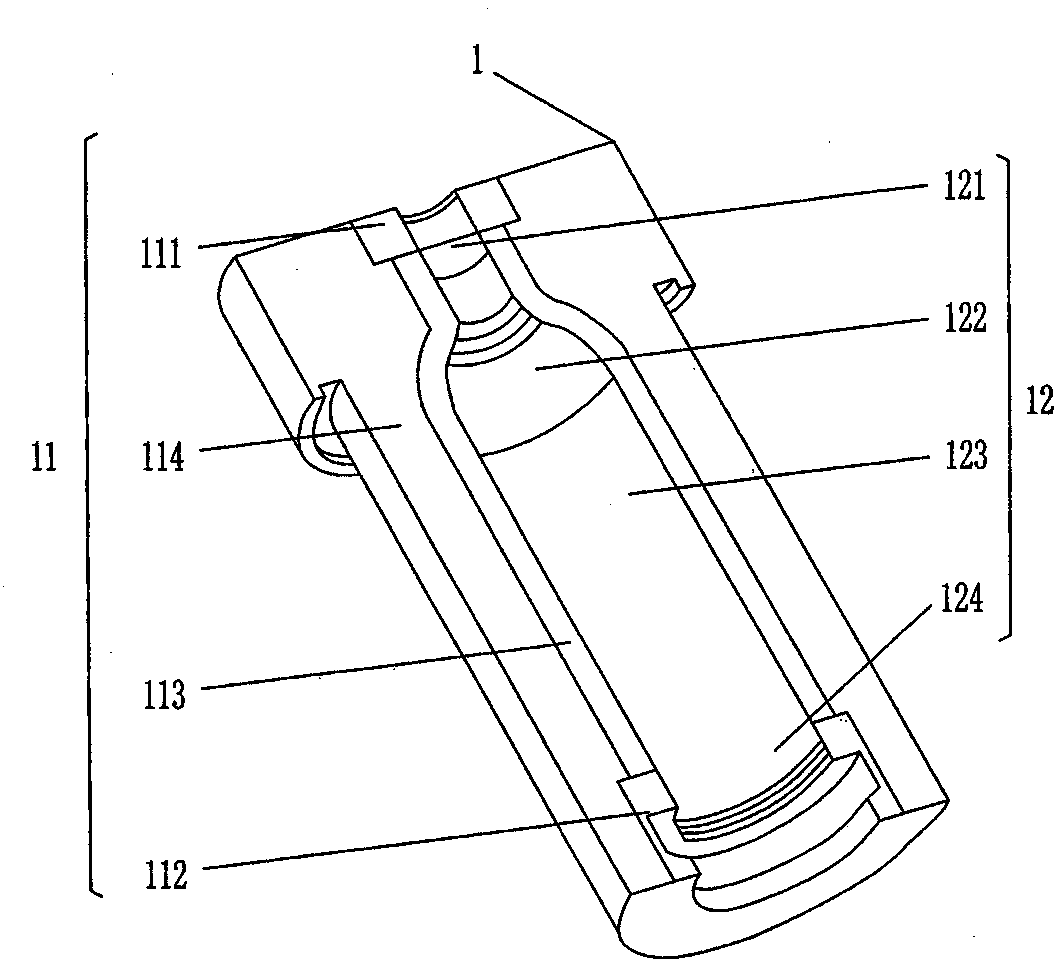

[0011] see figure 1 , since the shape of a pair of bottle half molds 1 is the same, only one bottle half mold 1 is shown in the figure, and the inner side of the bottle half mold 1 faces the side of the other bottle half mold 1 in the use state A pair of seam surfaces 11 are formed, and the pair of seam surfaces 11 are located on both sides of the bottle mold cavity 12 in the height direction, wherein: the bottle mold cavity 12 is composed of a bottle neck cavity 121, a neck shoulder cavity 122, a bottle body cavity 123 and a bottle bottom cavity. 124 are formed together (belonging to common knowledge), and the seam surface 11 includes the bottle mouth fitting area 111 corresponding to the mouth of the bottle neck cavity 121 and the middle fitting area 113 corresponding to the mouth of the bottle body cavity 123. , Corresponding to the bottle bottom matching area 112 at the mouth of the bottle bottom cavity 124 and the peripheral matching area 114 located in the middle matc...

Embodiment 2

[0014] The figure is omitted, only the height of the surface of the middle matching area 113 is changed to be 0.5 mm lower than the surface of the bottle mouth and bottle bottom matching areas 111 and 112, and the height of the surface of the peripheral matching area 114 is changed to be higher than that of the middle matching area 113. The surface is 0.1 mm lower, and the width of the middle matching area 113 is changed to 15 mm, and the rest are the same as the description of Embodiment 1.

Embodiment 3

[0016] The figure is omitted, only the height of the surface of the middle matching area 113 is changed to be 0.9 mm lower than the surface of the bottle mouth and bottle bottom matching areas 111 and 112, and the height of the surface of the peripheral matching area 114 is changed to be higher than that of the middle matching area 113. The surface is 1 mm lower, and the width of the middle matching area 113 is changed to 7 mm, and the rest are the same as the description of Embodiment 1.

[0017] The mold obtained by the above-mentioned Examples 1-3 was handed over to the glass container manufacturer for trial in the state that the applicant took strict confidentiality measures. 2 times longer service life), thus confirming the technical effect described by the applicant .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com