Method for manufacturing industrial and civil pipeline

A production method and pipeline technology, applied in the direction of pipes, siphons, pipe components, etc., can solve the problems of low efficiency, long cycle, high cost, etc., and achieve the effect of saving matching area, improving anti-vibration ability, and large adjustable deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

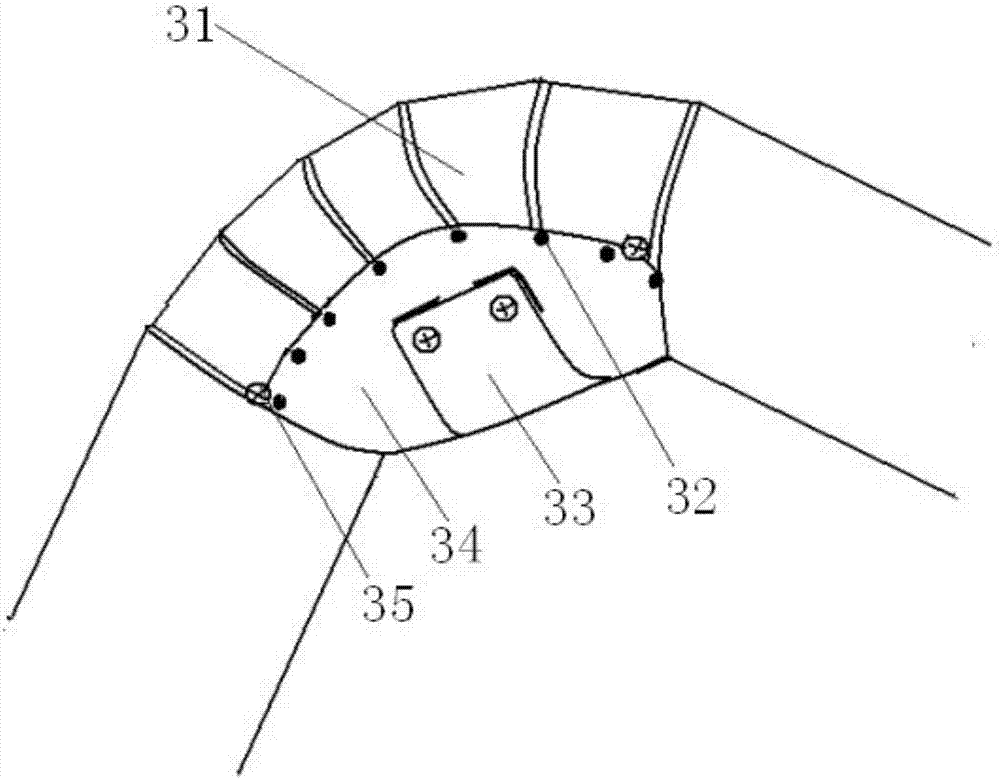

[0013] The invention provides a method for manufacturing industrial and civil pipelines, the specific scheme is:

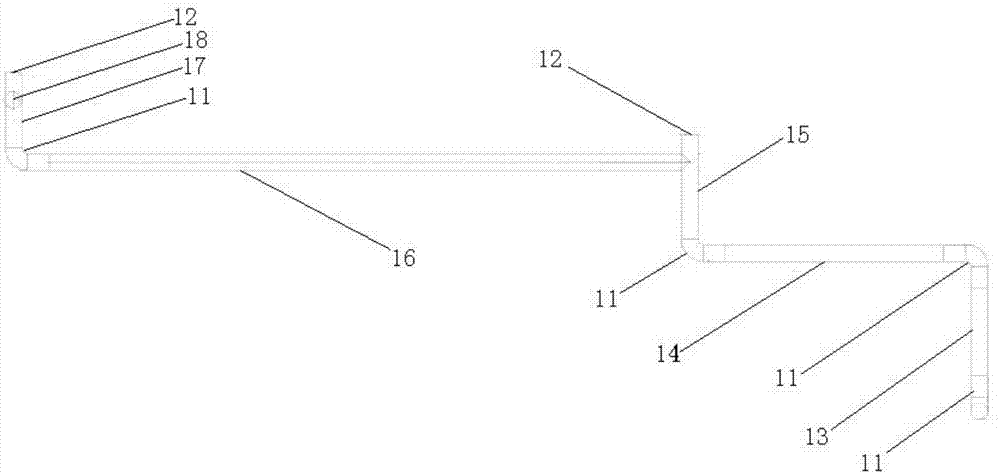

[0014] Make the first-stage pipeline, specifically to make five straight pipe sections, which are straight pipe section 1 13, straight pipe section 2 14, straight pipe section 3 15, straight pipe section 4 16, and straight pipe section 5 17; make three arc sections 11, and then Connect straight pipe section 1 13 with straight pipe section 2 14, straight pipe section 2 14 and straight pipe section 3 15, straight pipe section 4 16 and straight pipe section 5 17 with arc section 11; straight pipe section 3 15 and straight pipe section 4 16 by splicing The mode connection of straight pipe section three 15 ends is installed stuffy cover 12, and the end of straight pipe section five 17 is installed stuffy cover 12.

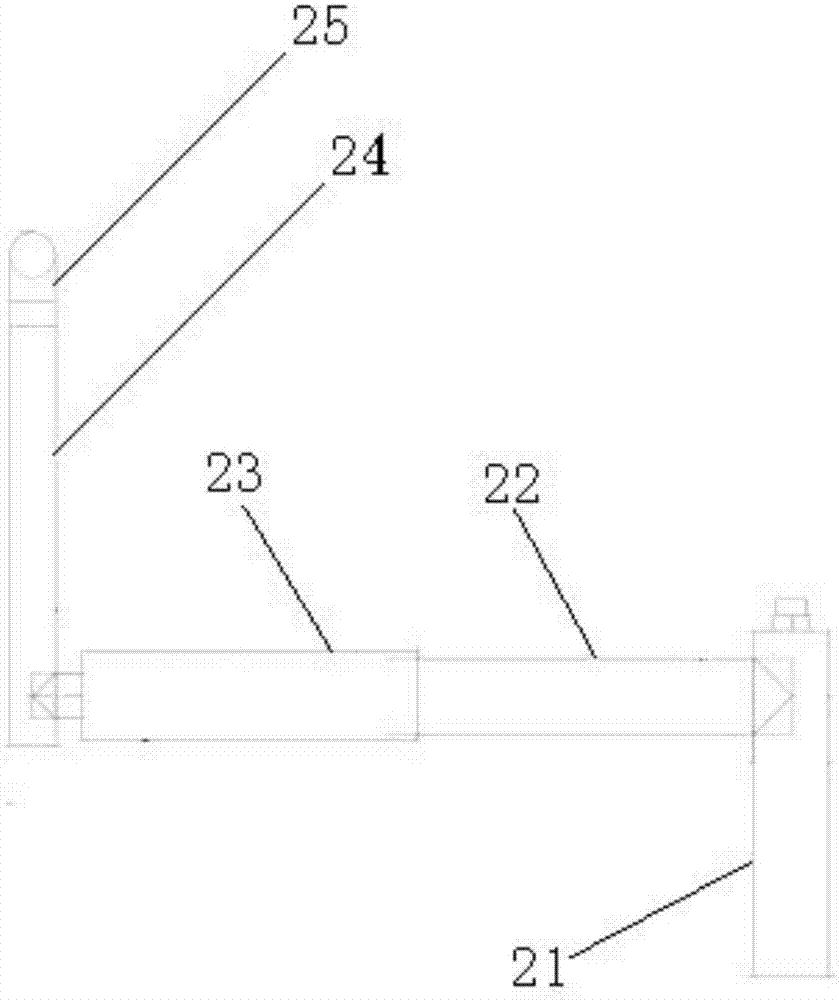

[0015] Make the second pipeline, specifically for making three straight pipe sections, respectively straight pipe section six 21, straight pipe section sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com