Preparation method of methyl oleate

A technology of methyl oleate and fatty acid methyl ester, which is applied in the field of preparation of methyl oleate, can solve the problems of poor safety, high energy consumption, complicated process, etc., and achieve the effects of full reaction, increased output, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

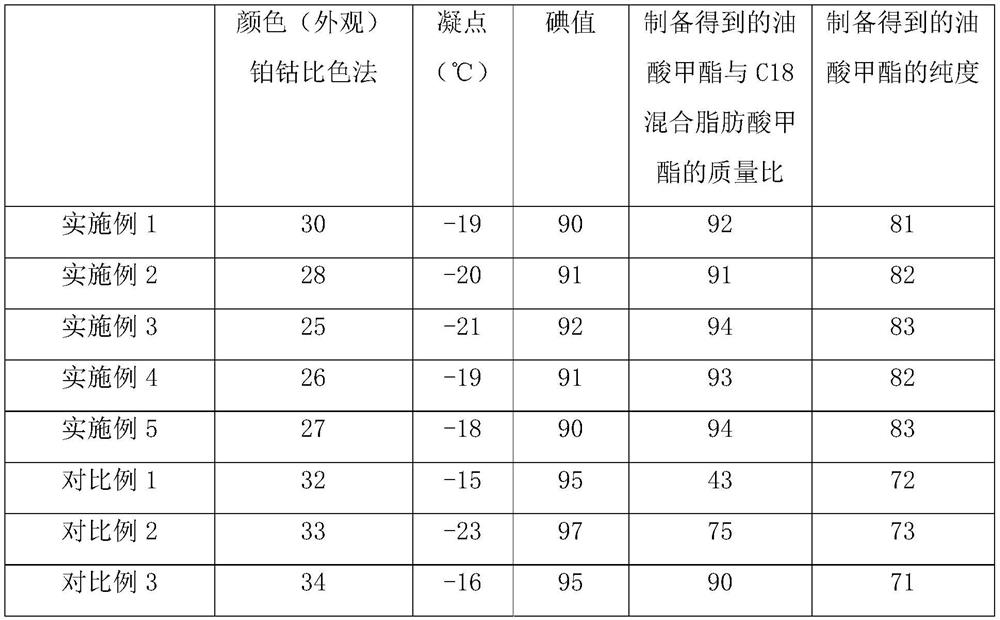

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of methyl oleate, comprises the steps:

[0028] Pump the C18 mixed fatty acid methyl ester (the content of methyl oleate in the C18 mixed fatty acid methyl ester is 40%, the content of methyl linoleate is 55%, and the content of methyl stearate is 5%) into the hydrogenation reactor, and add granules Nickel-lead powder with a density of 38 μm (nickel-lead ratio is 1:1), the amount of nickel-lead powder added is 1‰ of C18 mixed fatty acid methyl ester), stir evenly, and the stirring speed is 80 rpm;

[0029] Turn on the self-circulation pump of the hydrogenation reactor, inhale excess hydrogen through the Venturi jet port, and then add hydrogen to the C18 mixed fatty acid methyl ester through the static mixer circulation, (the amount of hydrogen added is 3‰ of the C18 mixed fatty acid methyl ester ) at 40°C under normal pressure, and react for 4 hours to obtain crude methyl oleate. If the temperature exceeds 40°...

Embodiment 2

[0033] The present embodiment provides a kind of preparation method of methyl oleate, comprises the steps:

[0034] Pump the C18 mixed fatty acid methyl ester (the content of methyl oleate in the C18 mixed fatty acid methyl ester is 48%, the content of methyl linoleate is 50%, and the content of methyl stearate is 2%) into the hydrogenation reactor, and add the granules Nickel-lead powder with a density of 48 μm (nickel-lead ratio is 1:0.3), the addition of nickel-lead powder is 3‰ of C18 mixed fatty acid methyl ester), stir evenly, and the stirring speed is 60 rpm;

[0035] Turn on the self-circulation pump of the hydrogenation reactor, inhale excess hydrogen through the Venturi jet port, and then add hydrogen to the C18 mixed fatty acid methyl ester through the static mixer circulation, (the amount of hydrogen added is 10‰ of the C18 mixed fatty acid methyl ester ) at 20°C under normal pressure, and react for 12 hours to obtain crude methyl oleate. If the temperature exceeds...

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of methyl oleate, comprises the steps:

[0040]Pump the C18 mixed fatty acid methyl ester (the content of methyl oleate in the C18 mixed fatty acid methyl ester is 45%, the content of methyl linoleate is 45%, and the content of methyl stearate is 10%) into the hydrogenation reactor, and add the granules Nickel-lead powder with a density of 42 μm (the ratio of nickel-lead to 1:0.6), the addition of nickel-lead powder is 2‰ of C18 mixed fatty acid methyl ester), stir evenly, and the stirring speed is 70 rpm;

[0041] Turn on the self-circulation pump of the hydrogenation reactor, inhale excess hydrogen through the Venturi jet port, and then add hydrogen to the C18 mixed fatty acid methyl ester through the static mixer circulation, (the amount of hydrogen added is 6‰ of the C18 mixed fatty acid methyl ester ) at 30°C under normal pressure, and react for 8 hours to obtain crude methyl oleate. If the temperature ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com