Cleaning agent used for ultrasonic spraying and preparation method and using method thereof

A cleaning agent and ultrasonic technology, applied in the field of field cleaning, can solve problems such as affecting the cleaning process, cleaning agent overflow, and increasing hidden dangers in the working environment, achieving good cleaning effect and fast oil softening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for a cleaning agent for ultrasonic spraying, comprising the following steps:

[0027] Step 1. Add 3.5g of sodium pyrophosphate into distilled water, stir and dissolve completely to obtain a solution;

[0028] Step 2: Add 4g of EH-9 and 3g of LF-305 to the solution in Step 1, stir to dissolve completely and mix well, and set the volume to 100 parts by mass of cleaning agent. Among them, EH-9 can be purchased from Dow Chemical in the United States, and LF-305 can be purchased from BASF in Germany.

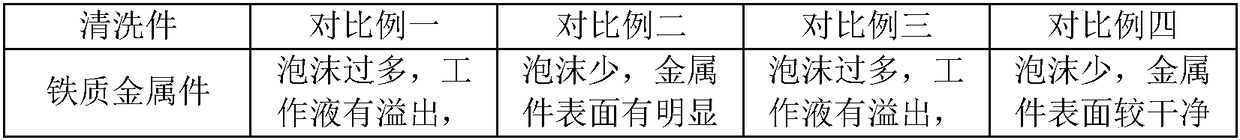

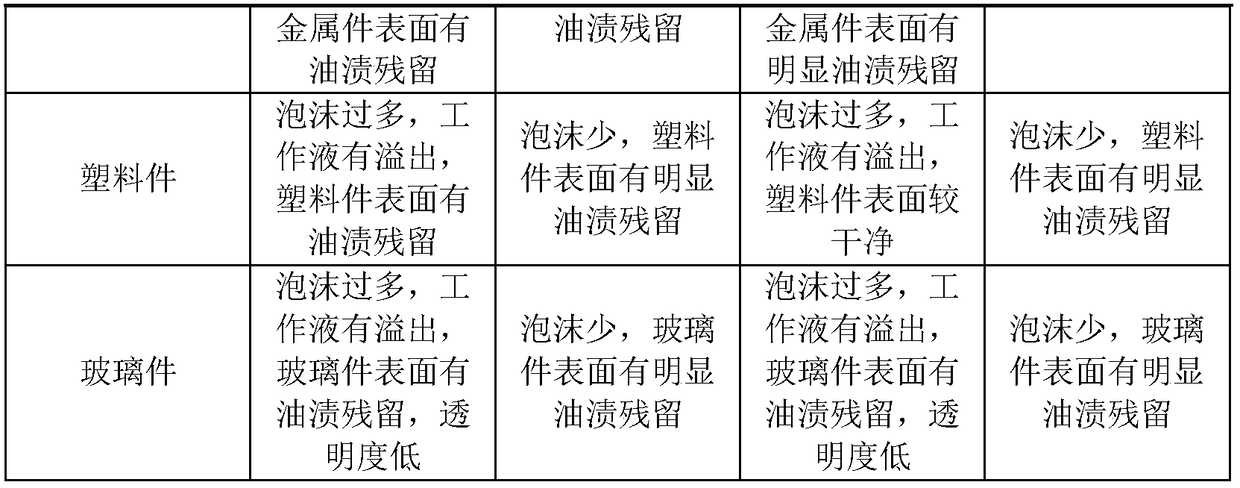

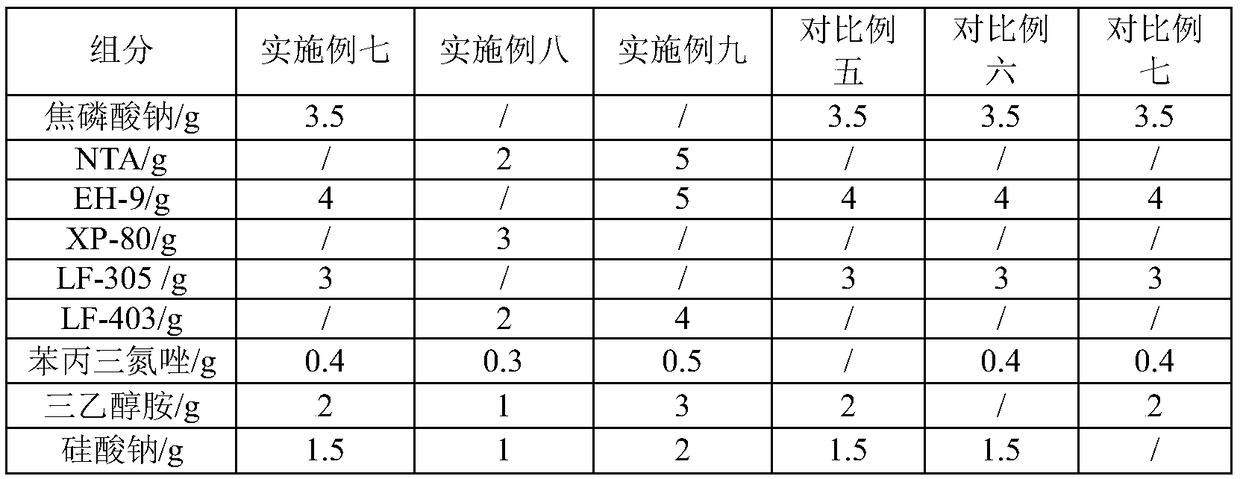

[0029] Cleaning agent test method: make a standard test piece with reference to the test piece of the national recommended standard GB / T35759-2017, and then clean it on the ultrasonic spray dual-purpose cleaning equipment. The spray pressure is set at 0.5Mpa for cleaning and rinsing. Dry after rinsing, and visually test whether the dirt on the surface of the sheet is cleaned. The results are shown in Table 1 below:

[0030] temperature

[003...

Embodiment 2

[0033] A preparation method for a cleaning agent for ultrasonic spraying, comprising the following steps:

[0034] Step 1. Add 2g of NTA into distilled water, stir to dissolve completely, and obtain a solution;

[0035] Step 2. Add 3g XP-80 and 2g LF-403 to the solution in step 1, stir to dissolve completely and mix well, and set the volume to 100 parts by mass of cleaning agent. Among them, XP-80 can be purchased from BASF of Germany, and LF-403 can be purchased from BASF of Germany.

[0036] Cleaning agent test method: make a standard test piece with reference to the test piece of the national recommended standard GB / T35759-2017, and then clean it on the ultrasonic spray dual-purpose cleaning equipment. The spray pressure is set at 0.5Mpa for cleaning and rinsing. Dry after rinsing, and visually test whether the dirt on the surface of the sheet is cleaned. The results are shown in Table 2 below:

[0037] temperature

[0038] It can be clearly drawn from the abov...

Embodiment 3

[0040] A preparation method for a cleaning agent for ultrasonic spraying, comprising the following steps:

[0041] Step 1. Add 5g of NTA into distilled water, stir and dissolve completely to obtain a solution;

[0042] Step 2: Add 5g of EH-9 and 4g of LF-403 to the solution in Step 1, stir to dissolve completely and mix well, and set the volume to 100 parts by mass of cleaning agent.

[0043] Cleaning agent test method: make a standard test piece with reference to the test piece of the national recommended standard GB / T35759-2017, and then clean it on the ultrasonic spray dual-purpose cleaning equipment. The spray pressure is set at 0.5Mpa for cleaning and rinsing. Dry after rinsing, and visually test whether the dirt on the surface of the sheet is cleaned. The results are shown in Table 3 below:

[0044] temperature

[0045] It can be clearly drawn from the above table that the optimum temperature in this embodiment is 60-75°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com