Preparation and molding technology of HDPE geomembrane

A molding process and geomembrane technology, used in flat products, clean hollow objects, other household appliances, etc., can solve the problems of uneven heating, low heating and melting effect, mutual stickiness, etc., to increase the residence time and improve melting. effect, the effect of improving the quality of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

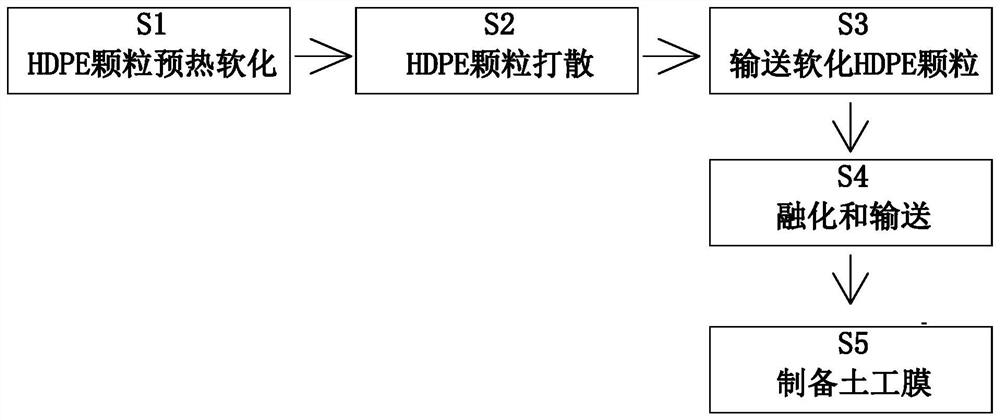

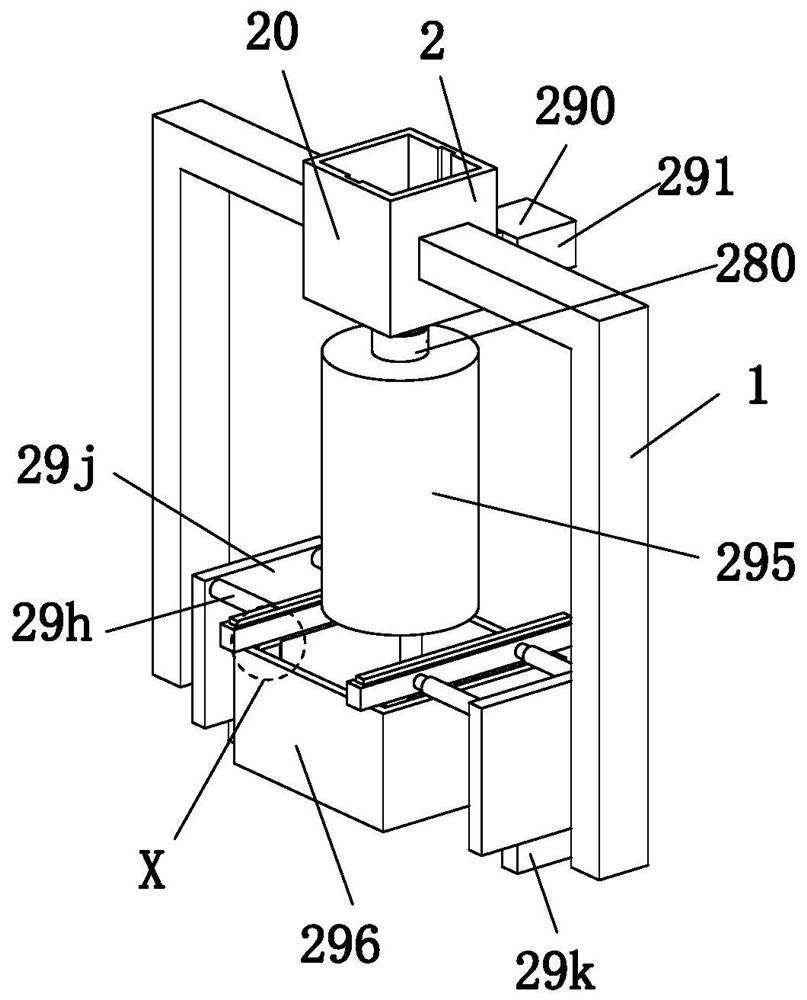

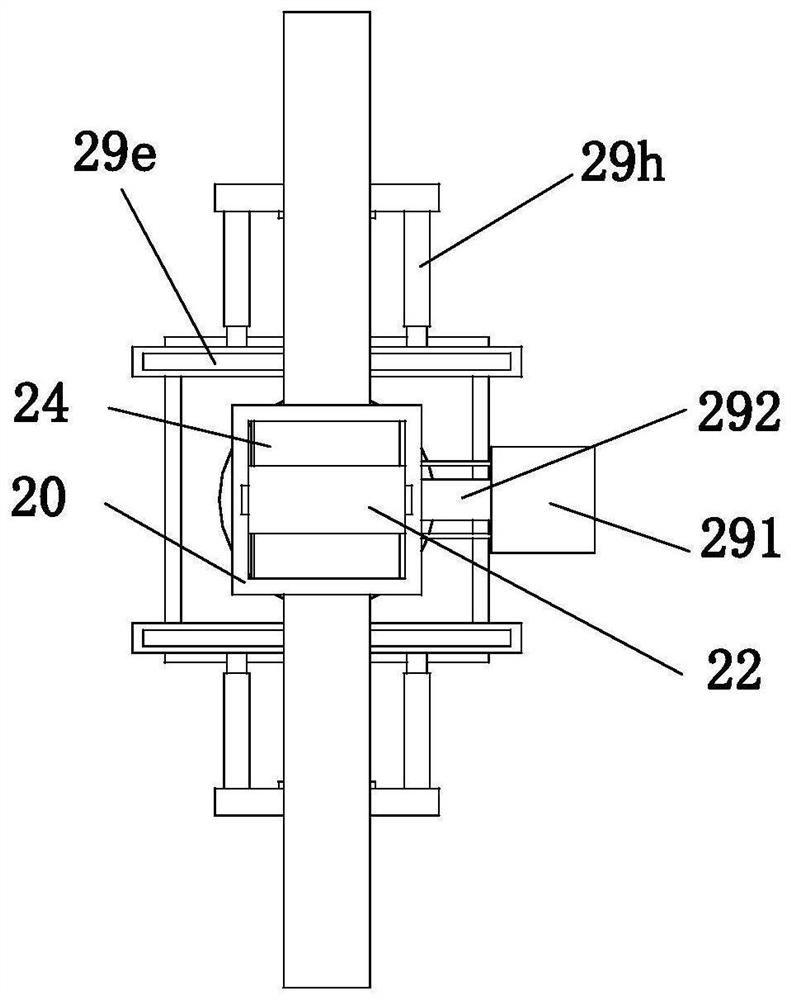

[0040] Such as Figure 1 to Figure 11 A HDPE geomembrane preparation and molding process is shown, which uses a HDPE geomembrane preparation and molding device. The HDPE geomembrane preparation and molding device includes a stand 1 and a molding mechanism 2, and the HDPE geomembrane preparation and molding device is used for HDPE geomembrane preparation. The specific molding process during molding is as follows:

[0041] S1. Preheating and softening of HDPE particles: Pour the HDPE particles into the preheating box 20 manually, and heat and soften the HDPE particles through the preheating box 20;

[0042] S2, HDPE particles are scattered: during the step S1, the two middle plates 22 are in a state of successive movement driven by the No. 1 elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com