A kind of tile double-glass component production process

A double-glass component and production process technology, applied in glass/slag layered products, layered products, electrical components, etc., can solve the problems of easy-to-generate cells, breakage, etc., and achieve convenient push, reduce air, and melt degree. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail in conjunction with specific inventions below.

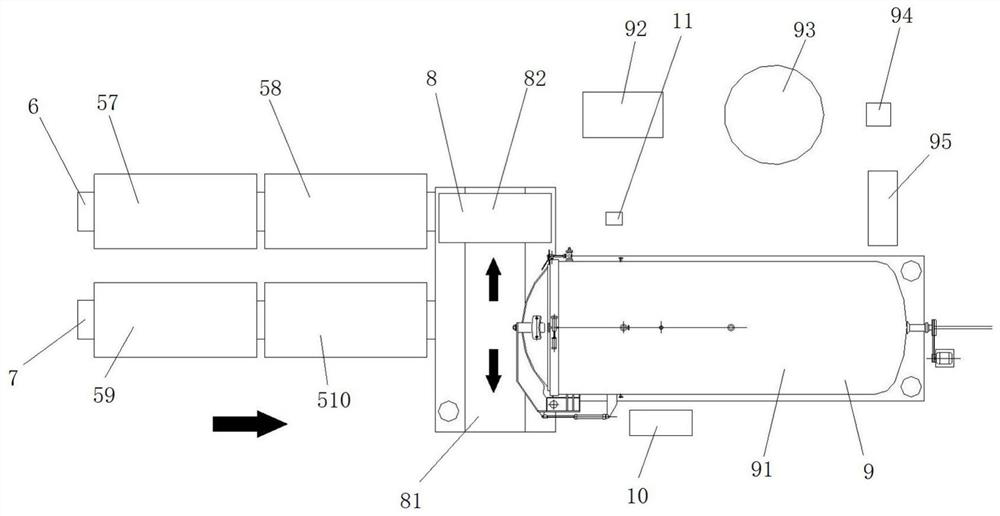

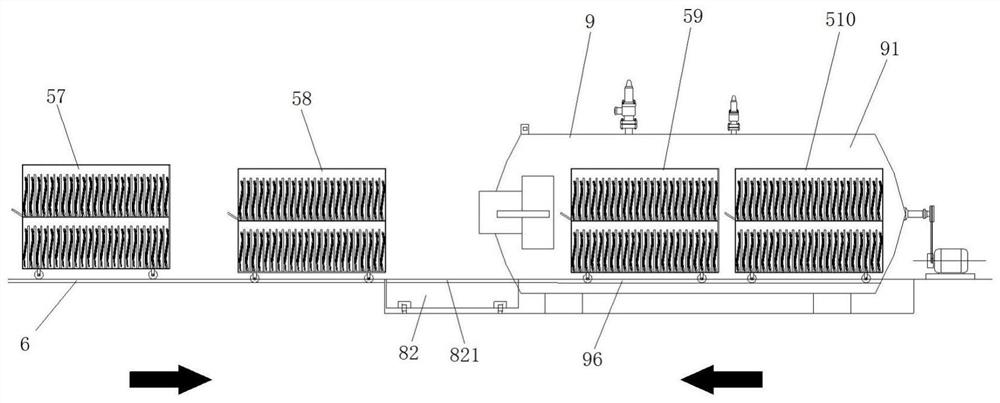

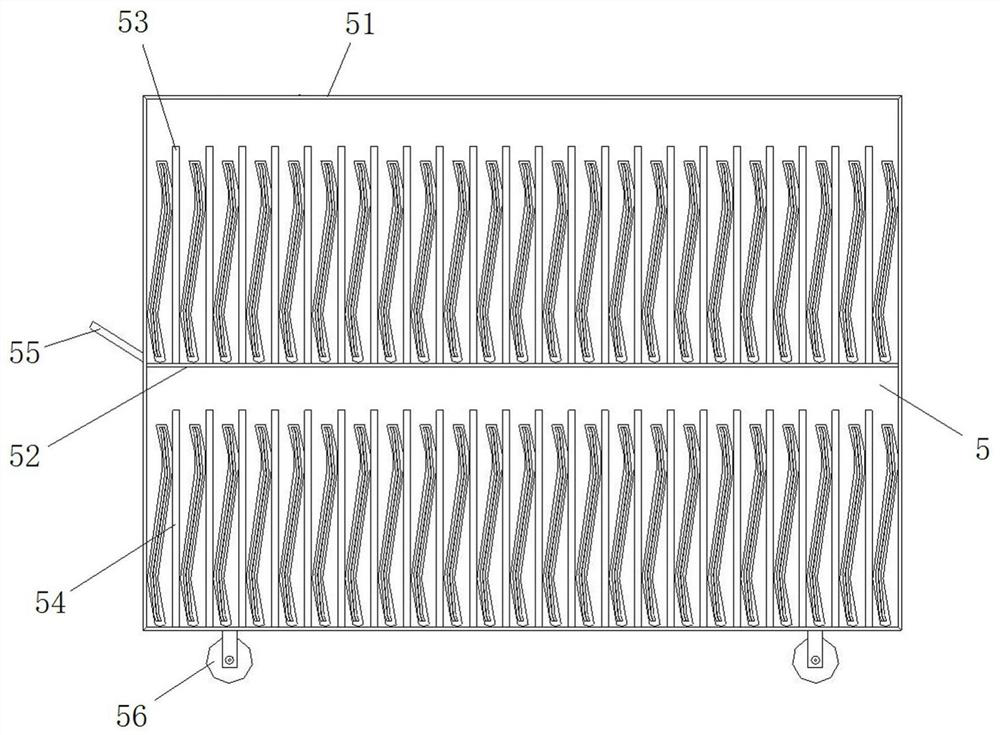

[0044] A production process for tiled double-glass components, combining Figure 1 to Figure 6 As shown, the production system of the tile double-glass module production process includes a kettle car 5, a vacuum mechanism, an air pressure kettle 9 and a driving mechanism.

[0045] Preliminary combination of stacked tiles and double glass components Figure 4 to Figure 6 As shown, it includes the upper curved tile glass 1, the front PVB film, the battery assembly 3, the reverse PVB film and the lower curved tile glass 2 stacked in sequence. The battery assembly 3 is formed by welding a plurality of battery strings through bus ribbons, and the battery string is formed by connecting multiple battery slices through welding ribbons. PVB strips are placed around the cells to buffer the pressure of the glass on the cells and protect the cells. In addition, when the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com