Patents

Literature

77results about How to "Fast softening speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colloidal electrolyte formula for lead-acid storage battery

ActiveCN101908649AStrong water retentionEliminate passivationFinal product manufactureLead-acid accumulators constructionPolyethylene glycolPhosphoric acid

The invention discloses a colloidal electrolyte formula for a lead-acid storage battery, comprising the following components in percentage by weight: 0.8-10 percent of fumed silica, 0.4-0.8 percent of polyethylene glycol, 0.03-0.6 percent of bismuth trioxide, 0.05-0.3 percent of antimonous oxide, 0.05-0.5 percent of stannous sulfate, 0.3-1 percent of phosphoric acid, 0.5-2 percent of anhydrous sodium sulfate, 25-40 percent of sulfuric acid and 50-60 percent of water. The invention has the advantages that: after using a colloidal electrolyte of the invention, with regard to the lead-calcium alloy storage battery, the phenomenon that a common colloidal electrolyte cannot adapt to a lead-calcium alloy storage battery can be effectively improved, the early-stage capacity attenuation effect of the lead-calcium alloy battery can be improved, the deep electrical discharge cycle life, the low-temperature heavy-current charging and discharging performances and the rechargeable performance after being discharged of the lead-calcium battery can be further enhanced, the use safety of the battery can be improved and the overall use cost of the battery can be reduced.

Owner:CHAOWEI POWER CO LTD

Oil composition and method for preparing same

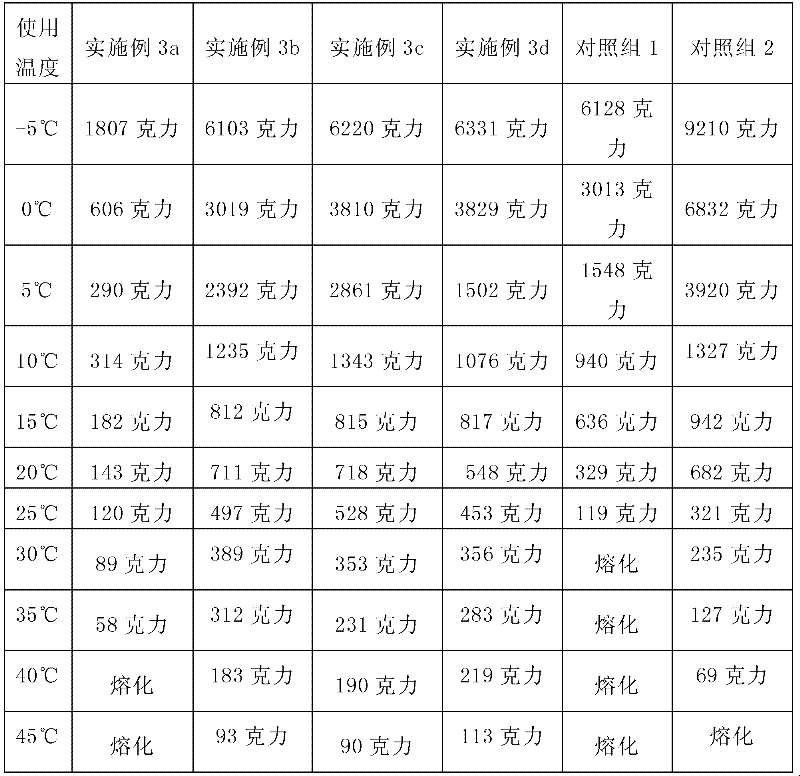

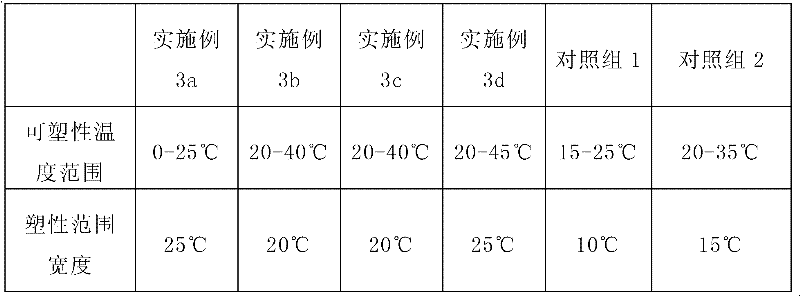

InactiveCN102524423AWide plasticity temperature rangeImprove cold resistanceBakery productsEdible oils/fats production/working-upOil and greaseChemical composition

The invention relates to an oil composition and a method for preparing the same. The oil composition contains lard oil and palm type oil, wherein the iodine value of the lard oil is 60-70gI / 100g, the melting point of the lard oil is 30-42 DEG C, the iodine value of the palm type oil is 8-35 gI / 100g, and the melting point of the palm type oil is 50-60 DEG C. The oil composition disclosed by the invention can be used for various plastic oil products comprising margarine, shortening and the like and has the advantage of wide plastic temperature range.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Softener for thick salix integra and preparation method of softener

ActiveCN103659979AImprove toughnessSmoothReed/straw treatmentWood impregnation detailsEthylenediamineBetaine

A softener for thick salix integra is made from raw materials in parts by weight as follows: 5-7 parts of ethylenediamine, 4-5 parts of tartaric acid, 4-5 parts of coco-betaine, 1-2 parts of decyl polyglucoside, 4-5 parts of ammonium dihydrogen phosphate, 10-12 parts of dandelion, 4-6 parts of chrysanthemum, 10-12 parts of coptis chinensis, 3-4 parts of camphor tree bark, 6-8 parts of povidone iodine,3-4 parts of an assistant and 100 parts of water. According to the softener, the ethylenediamine, the tartaric acid and multiple surfactants are used, so that the softener is high in permeation speed, high in softening speed and even in softening; the salix integra is good in toughness and touches smooth, and the weaving efficiency can be improved; and Chinese herbal medicines such as the camphor tree bark and the like as well as the povidone iodine are used, so that salix integra is smooth in surface, mould-proof and free of worms. The softener is applicable to softening of the thicker salix integra.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

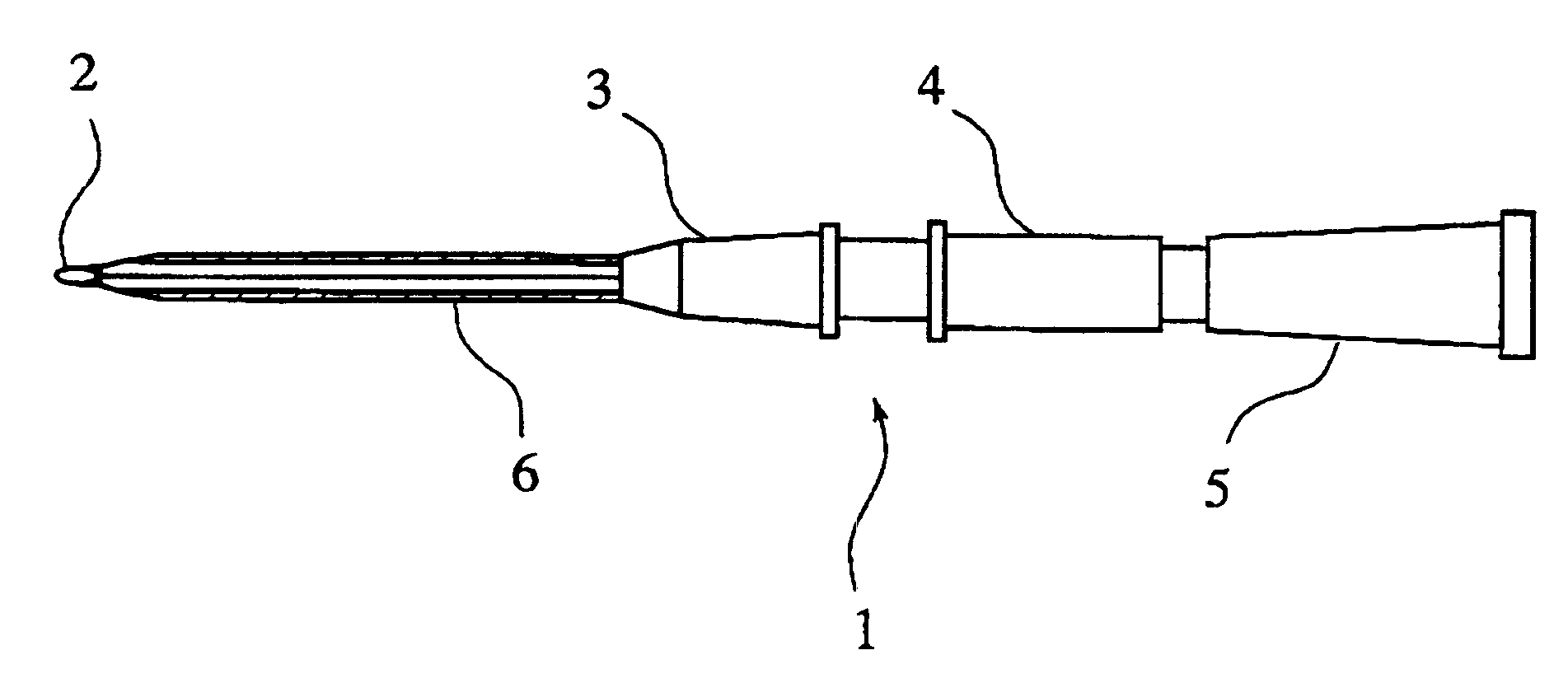

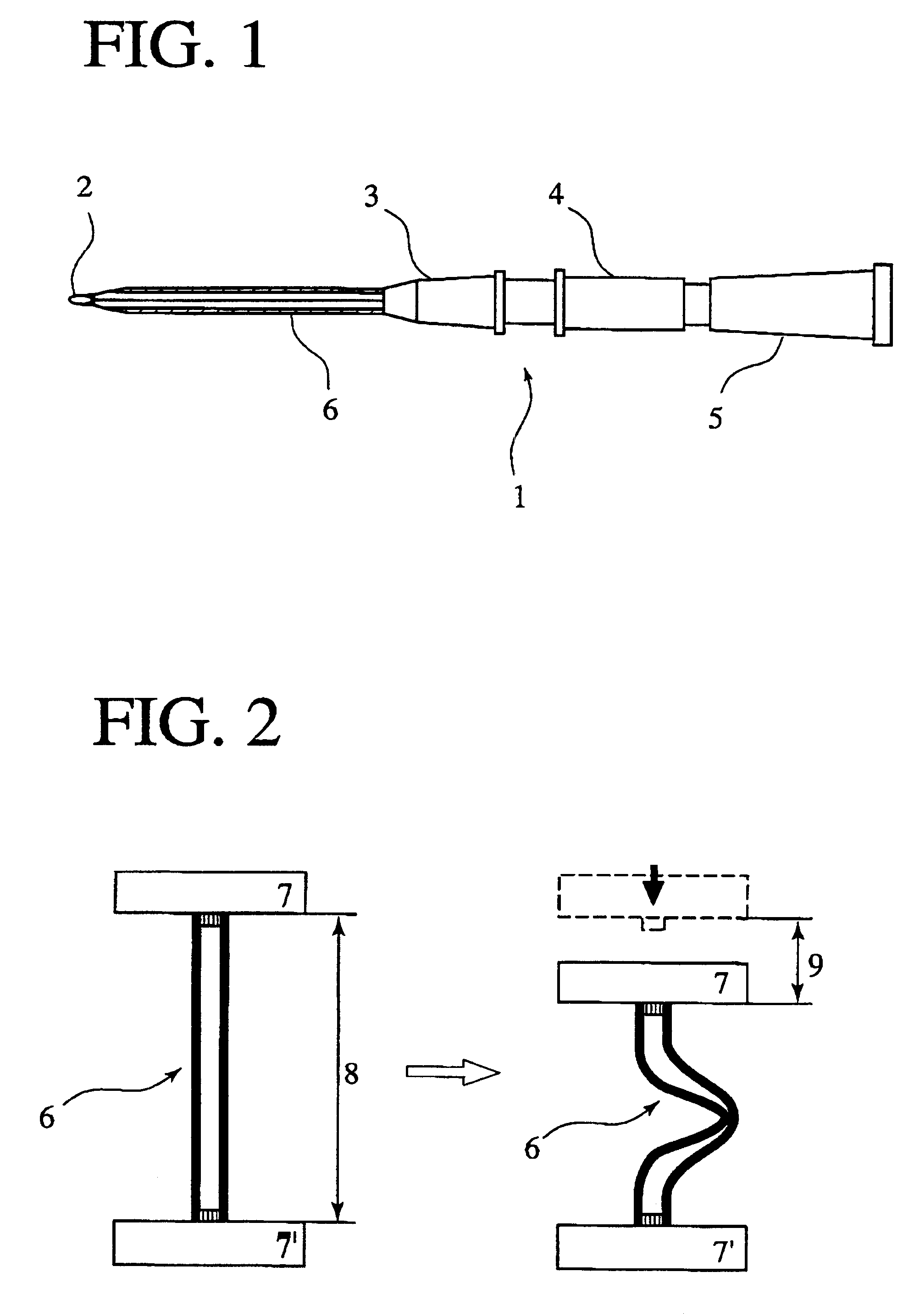

Indwelling catheter

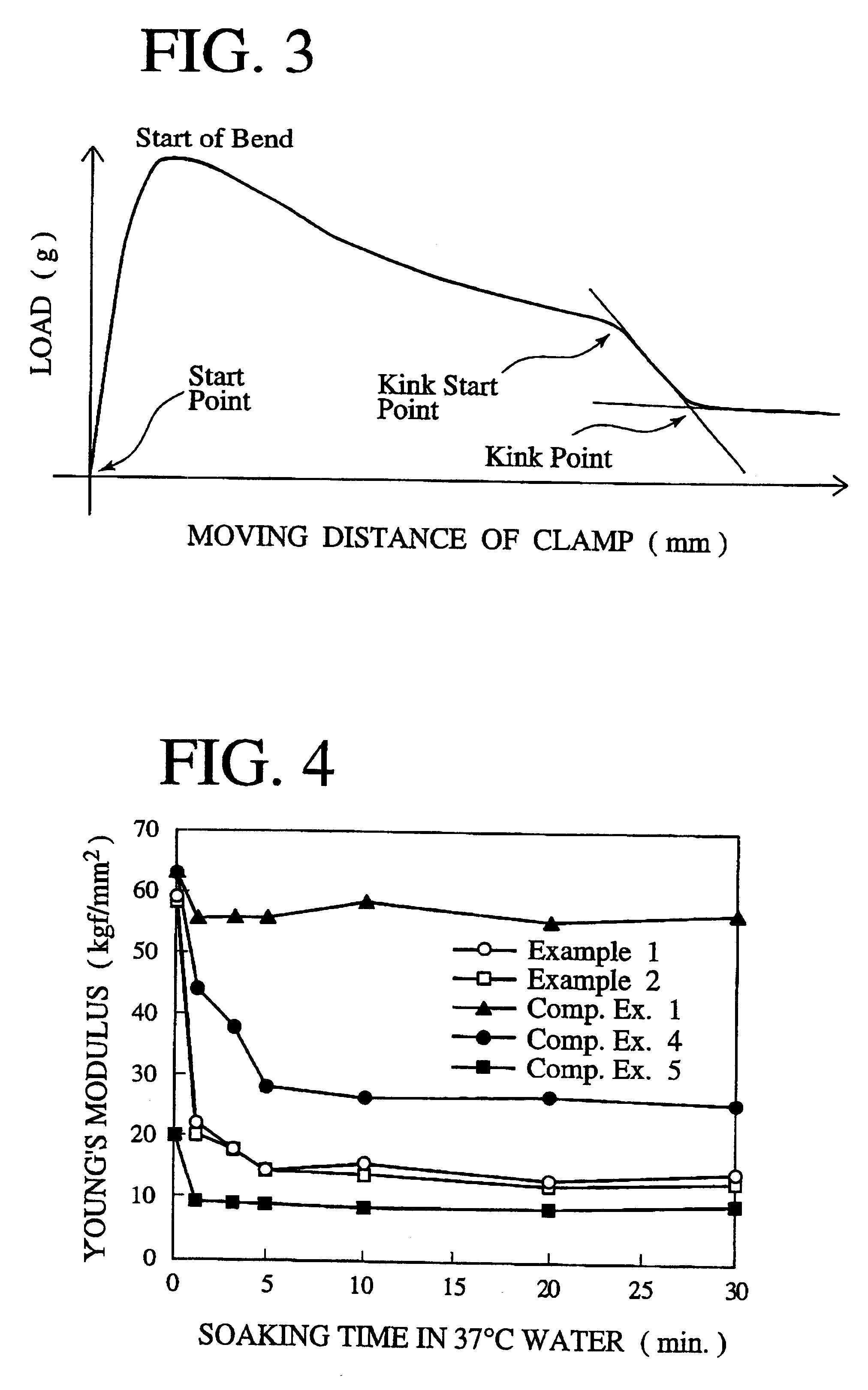

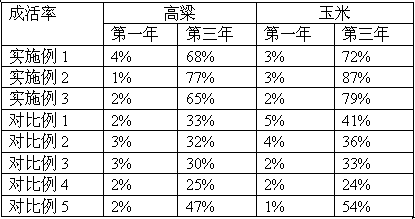

InactiveUS6342047B1Increase stiffnessModulus is reducedCatheterIntravenous devicesDynamic storageYoung's modulus

An indwelling catheter is made of a blend of a plurality of polyurethane resins containing polyglycols having different molecular weights, or a polyurethane resin containing a plurality of polyglycols having different molecular weights. It shows a dynamic storage modulus of 1 GPa or more under a dry condition at 25° C. and decrease in dynamic storage modulus when changed from a dry condition at 25° C. to a wet condition at 37° C., a decrease percentage of the dynamic storage modulus being less than 60% at the elapsed time of 20 seconds and 60% or more at the elapsed time of 1 minute after placed under the wet condition at 37° C. Its Young's modulus is 50 kgf / mm2 or more under a dry condition at 25° C., which reduces to 25 kgf / mm2 or less within 5 minutes when placed under a wet condition at 37° C.

Owner:TERUMO KK

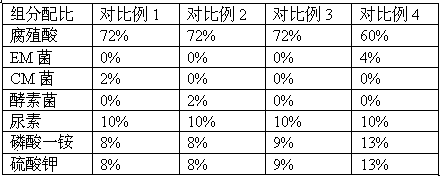

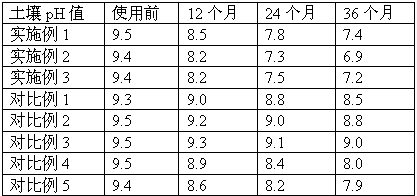

Salt and alkali decomposing biological bacterial fertilizer

PendingCN103613452AImprove pHLower pH temperatureFertilising methodsFertilizer mixturesNitrogen fertilizerChemistry

The invention relates to a salt and alkali decomposing biological bacterial fertilizer. The salt and alkali decomposing biological bacterial fertilizer is prepared through the following components by mass percentage: 65 to 80% of humic acid, 1 to 4% of EM bacteria, 5 to 15% of nitrogenous fertilizer, 5 to 11% of phosphatic fertilizer, and 5 to 11% of potash fertilizer. The salt and alkali decomposing biological bacterial fertilizer is prepared by the following steps: (1) mixing and uniformly agitating humic acid and EM bacteria, and fermenting for 72 to 96 hours at a temperature of 20 to 30 DEG C until the number of beneficial bactera in the mixture per kg is less than 20 million, thus obtaining a fermented material; and (2) adding nitrogenous fertilizer, phosphatic fertilizer and potash fertilizer to the fermented material obtained in the step (1); and uniformly mixing to obtain the salt and alkali decomposing biological bacterial fertilizer. The salt and alkali decomposing biological bacterial fertilizer is subjected to site-directed experience of three years in Ninghe County, Tianjin; the salt and alkali decomposing biological bacterial fertilizer added to the soil of which the pH (Power Of Hydrogen) is below 10 can decrease the pH of the soil by about 0.8 averagely each year; and after the salt and alkali decomposing biological bacterial fertilizer is used in three consecutive years, the pH of soil can reach a normal level, and as a result, the rate of survival of crops is greatly increased.

Owner:高世磊

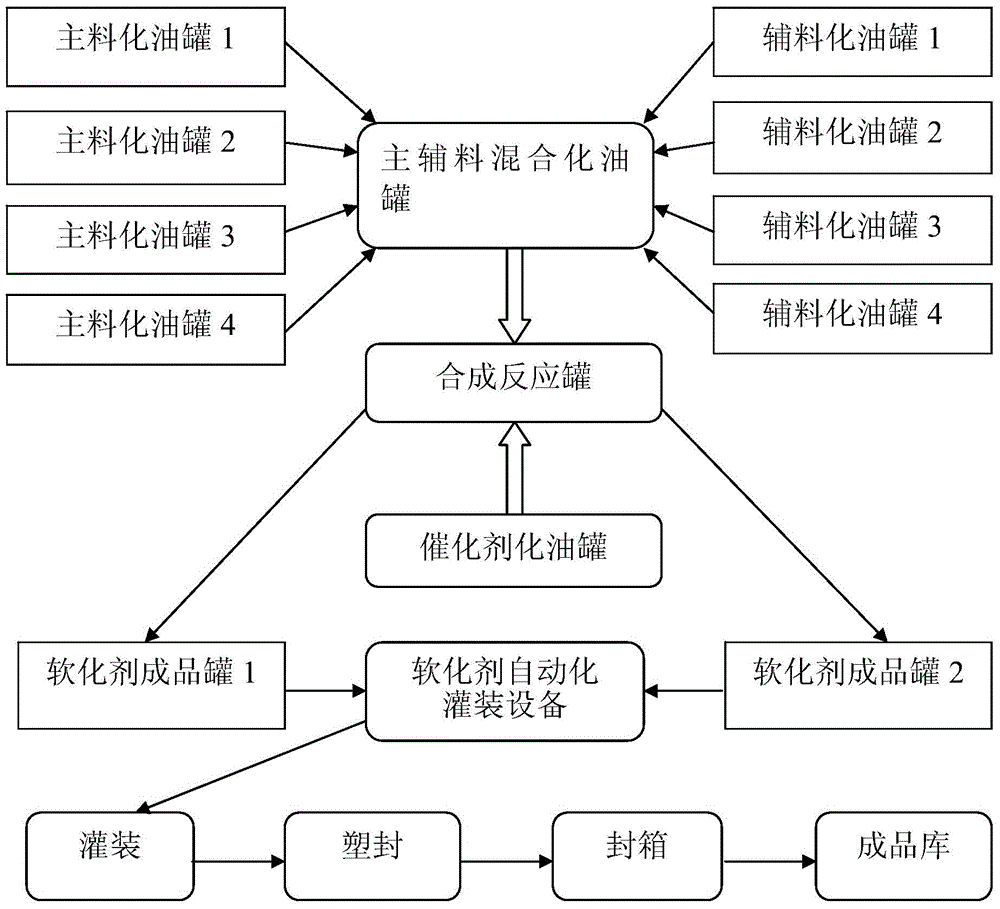

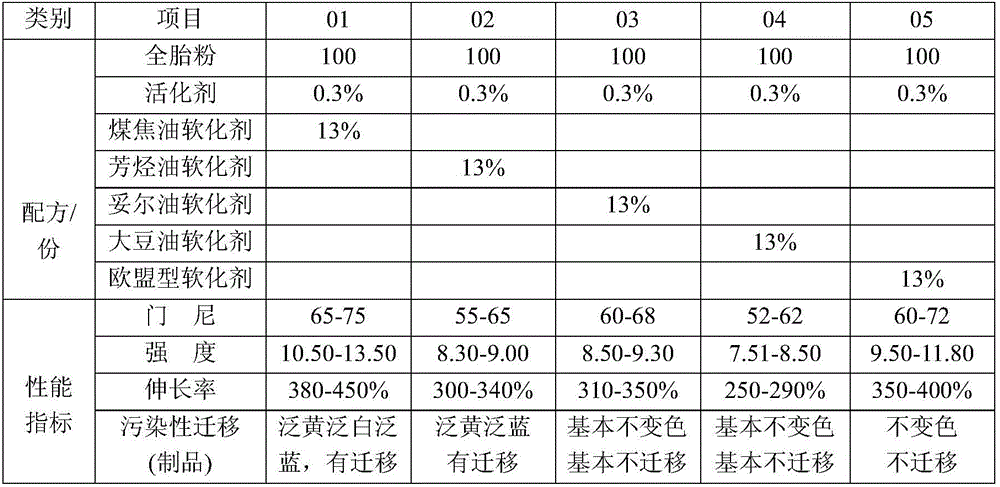

Reclaimed rubber softening agent and preparation method thereof

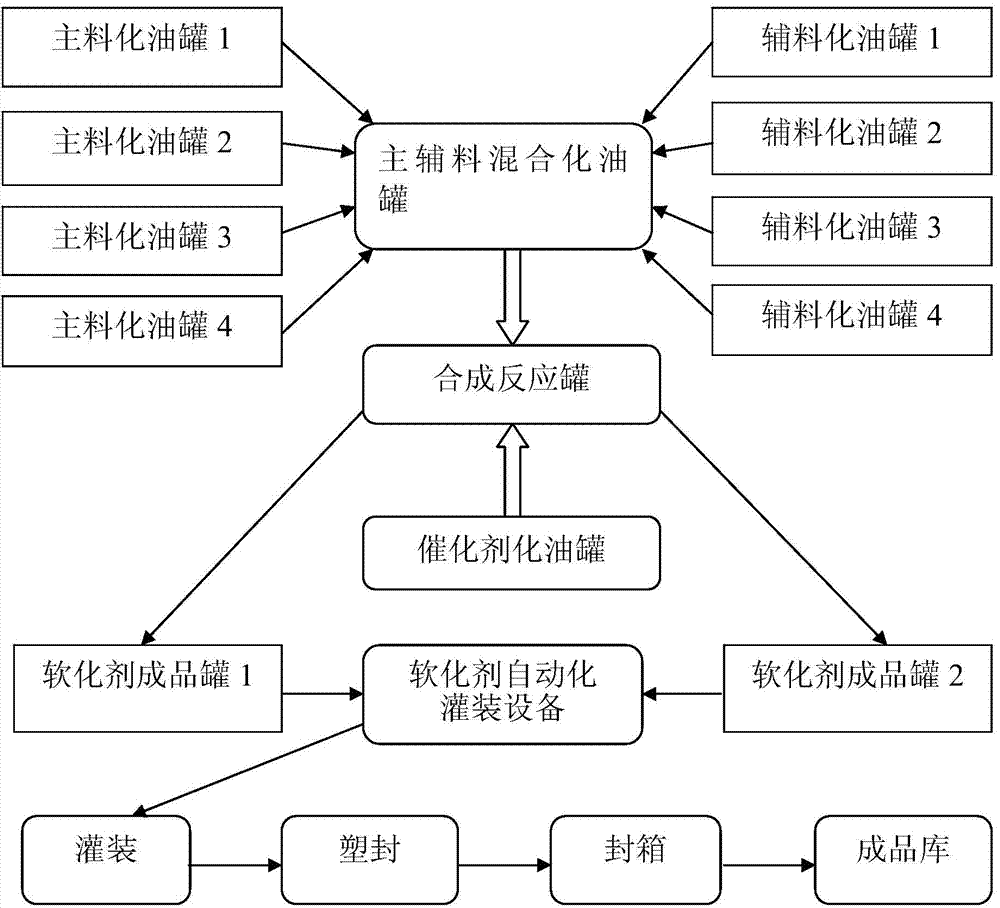

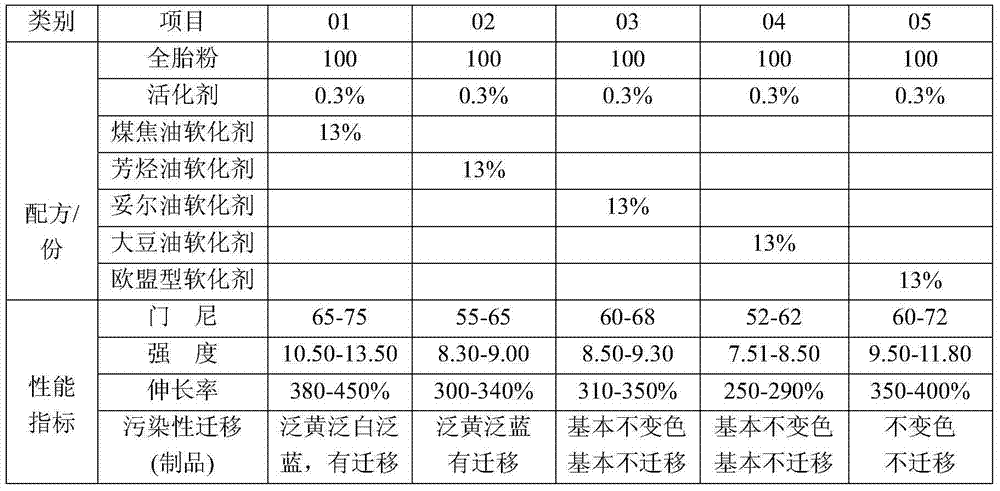

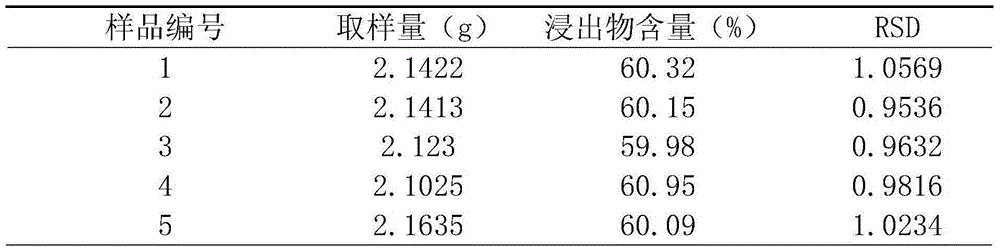

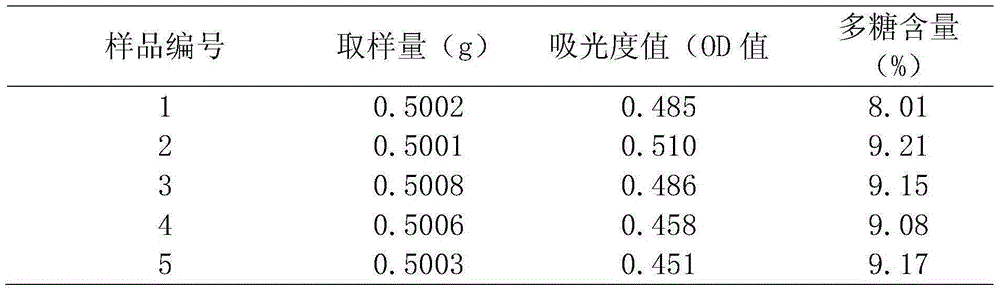

The invention provides a reclaimed rubber softening agent. The reclaimed rubber softening agent is obtained by reacting a softening agent main material with a softening agent auxiliary in the presence of a catalyst; the softening agent main material comprises a natural vegetable oil ingredient, while the softening agent auxiliary comprises a natural biochemical oil ingredient, and the catalyst is a phthalate; the natural vegetable oil ingredient is a natural vegetable oil and / or natural vegetable oil foots; the natural biochemical oil ingredient is a natural biochemical oil and / or natural biochemical oil foots. The reclaimed rubber softening agent is a composite product prepared by compounding the natural vegetable oil and the biochemical oil and refining the mixed oil under the catalytic action of phthalate. The softening agent passes the PONY test of the international authoritative detection mechanism, meets the requirements of the European Union REACH environmental protection laws and regulations and passes the authentication of China Quality Certification.

Owner:湖南中海顺达新材料股份有限公司

Stomach nourishing hericium erinaceus tremella yogurt and preparation method thereof

The invention discloses stomach nourishing hericium erinaceus tremella yogurt. The stomach nourishing hericium erinaceus tremella yogurt is prepared from the following raw materials in parts by weight: 400 to 450 parts of fresh milk, 16 to 18 parts of tremella, 6 to 7 parts of hericium erinaceus, 4 to 5 parts of lettuce, 2 to 3 parts of fresh locust beans, 4 to 5 parts of miracle fruit, 2 to 3 parts of aristolochia impressinervis, 1 to 2 parts of fructu broussonetiae, 1 to 2 parts of rose, 1 to 3 parts of semen allii tuberose, 0.8 to 0.9 parts of gelatin, 16 to 18 parts of saccharose, 0.16 to 0.18 parts of pectinase, a suitable amount of lemon juice, a suitable amount of starter culture, and a suitable amount of water. According to the stomach nourishing hericium erinaceus tremella yogurt, the fresh milk and the tremella serve as main materials, and meanwhile, the traditional Chinese medicinal components, such as the rose, are added, so that the stomach nourishing hericium erinaceus tremella yogurt has the effects of promoting qi circulation, removing obstruction in the collateral, and regulating blood to alleviate pain; in addition, the auxiliary materials, such as the hericium erinaceus, adopted by the stomach nourishing hericium erinaceus tremella yogurt, have the functions of benefiting the five internal organs, helping digestion, tonifying spleen, nourishing stomach, and improving human immunity.

Owner:HEFEI KANGLING HEALTH TECH

Colored rice noodles and method for directly producing colored rice noodles by using granules

The invention provides colored rice noodles. The colored rice noodles are prepared from rice, water, dietary alkali, baking soda, table salt and yeast powder at a ratio of 100 to 100 to (1-3) to (1-1.8) to 3 to 1.2, wherein the rice in various colors is taken as a main raw material, water, dietary alkali, baking soda, table salt and yeast powder form a soaking solution, and rice expands after being soaked. The colored rice noodles are produced according to the following steps: taking yeast powder with amount in a formula, and dissolving by using warm water with amount being twice that of the yeast powder to form a yeast solution; taking table salt with amount in the formula, and dissolving the table salt by using warm water with amount being three times that of the table salt to form a table salt solution; taking baking soda with amount in the formula, dissolving the baking soda by using warm water with amount being twice that of the baking soda to obtain a baking soda solution; taking dietary alkali with amount in the formula, dissolving by using hot water with amount being five times that of the dietary alkali to obtain a dietary alkali solution; taking water left after consumption in the previous four steps, placing the obtained solutions into the water, and obtaining the soaking solution; taking the rice with amount in the formula, soaking in the soaking solution till the rice completely expands; and adding the soaked rice and the soaking solution into a rice-granule noodle production machine, then grinding, pressing for forming strips and extruding, thereby obtaining the colored rice noodles.

Owner:颜世恩 +1

Lily and tremella granule drink and preparation method thereof

The invention discloses a lily tremella granular beverage and a preparation method thereof. The lily tremella granular beverage is prepared from drinking purified water, a sweetener, concentrated pear juice, white fungus, lily, agar, citric acid and edible essence. The preparation process steps of the lily tremella granule beverage mainly include material preparation, pretreatment, softening, blending and posttreatment. The lily tremella granule beverage obtained in the present invention has the effects of nourishing yin and nourishing the lungs, moistening the intestines and laxative, and is especially suitable for drinking by people with yin deficiency and constipation; the preparation method of the lily tremella granule beverage provided by the present invention is simple to operate and requires less equipment , low cost and suitable for industrialized mass production.

Owner:SICHUAN JIUJIUAI FOOD

Sand-preventing method of artificial borehole wall, and material for sand prevention

ActiveCN107163926AImprove salt toleranceCalcium resistantFluid removalDrilling compositionAlkylphenolSURFACTANT BLEND

The invention discloses a sand-preventing method of an artificial borehole wall, and a material for sand prevention. The material for sand prevention comprises guide liquid, sand carrying liquid and promoting liquid which are prepared separately, wherein the guide liquid comprises the following components in percentage by weight: 0.5 to 20 percent of sodium chloride, 0.2 to 2 percent of calcium chloride, 0.1 to 1 percent of magnesium chloride, 0.2 to 4 percent of alkylphenol polyoxyethylene, 0.3 to 8 percent of an anionic surfactant capable of resisting calcium and magnesium ions and 0.01 to 6 percent of a dimethyl diallyl ammonium chloride-acrylamide-acrylic acid copolymer; the sand carrying liquid comprises the following components in percentage by weight: 0.01 to 5 percent of a dimethyl diallyl ammonium chloride-acrylamide copolymer and 0.5 to 20 percent of ammonium chloride; and the promoting liquid comprises the following components in percentage by weight: 8 to 22 percent of a penetrating agent and 18 to 35 percent of a dehydroxylation catalyst. The material for sand prevention performs sand prevention, can protect the stratum, has high sand carrying capability, reduces friction and enhances the consolidation strength, and the penetration ratio of the artificial borehole wall formed after sand prevention is more than 12 <mu>m<2>.

Owner:东营市科诺石油技术有限责任公司

Novel softening and cutting method in traditional Chinese medicine preparing process

InactiveCN105193861AHigh speedImprove uniformityPressurized chemical processPlant ingredientsWater solubleTraditional medicine

The invention discloses a novel softening and cutting method in the traditional Chinese medicine preparing process, and relates to the field of traditional Chinese medicine decoction piece preparation. According to the method, a traditional Chinese medicinal material is treated by adopting a vacuum sealed decompression softening method, the osmotic pressure inside the tissue of a traditional Chinese medicinal material can be enhanced, and the affinity between the medicinal material and water is improved; the surface color of a medicinal material softened by the method is darker than that of the original medicinal material, no water-injury or sticky phenomenon occurs, the decoction pieces have high softening speed, good effect, appropriate softness and no white or hard core in the section, and the aim that water is used up when a medicine is infiltrated can be achieved. The decoction pieces are convenient to cut, process parameters, such as water addition, moistening time and the like, in the softening step can be easily controlled, and water-soluble ingredients cannot be easily lost.

Owner:张斌

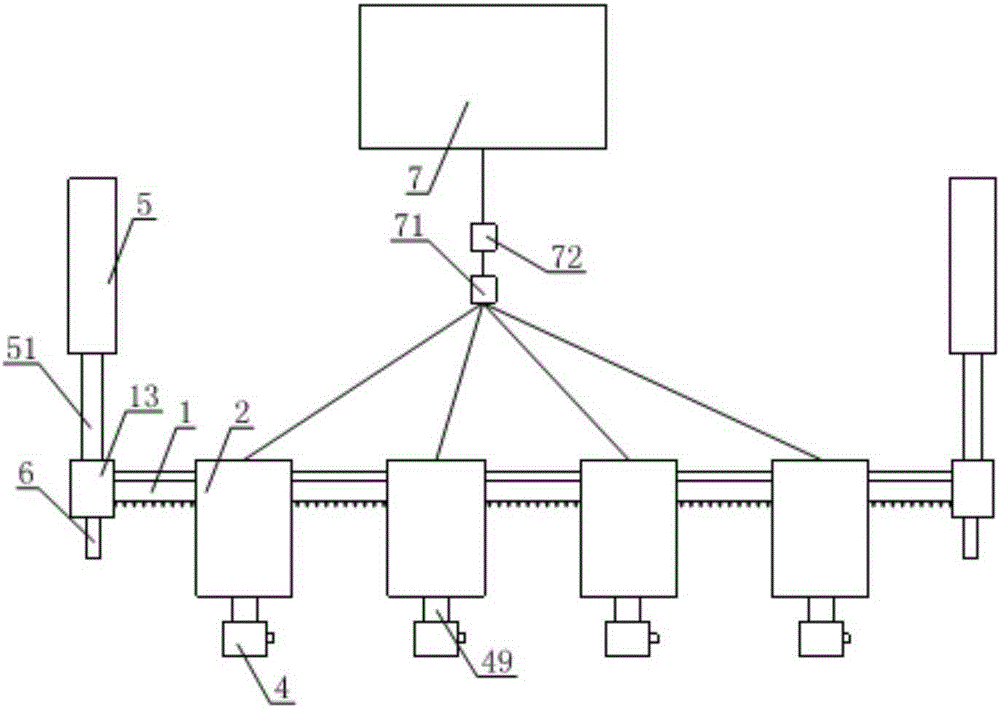

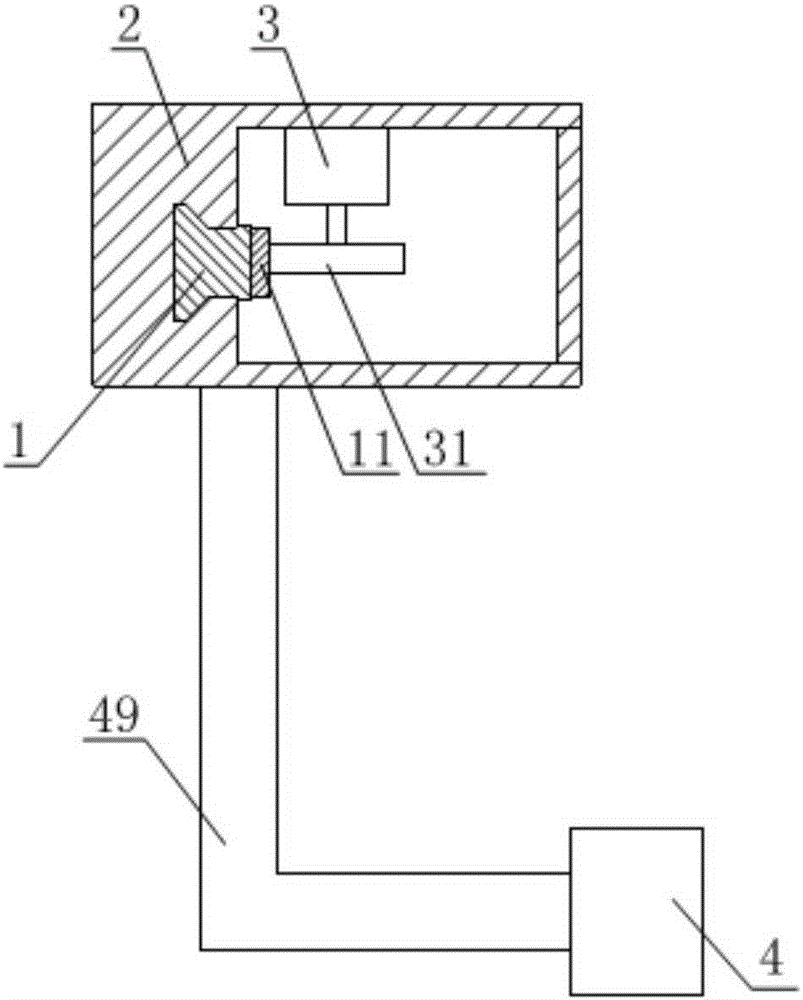

Paper explosion-preventing softening device for line pressing and molding and softening method for pressed-line crease positions of paperboards

InactiveCN105216377ANo paper burst phenomenonIncrease humidityMechanical working/deformationPaperboardPulp and paper industry

The invention discloses a paper explosion-preventing softening device for line pressing and molding and a softening method for pressed-line crease positions of paperboards. The paper explosion-preventing softening device comprises at least one nozzle, at least one transverse guide rail, transverse moving seats as many as the nozzles and drivers as many as the nozzles; the transverse moving seats are arranged on the transverse guide rails in a sliding manner; each nozzle is fixed with one transverse moving seat; the drivers are used for driving the transverse moving seats to move on the transverse guide rails to working positions. The paper explosion-preventing softening device for line pressing and molding is capable of softening surface paper, core paper, lining paper and corrugated paper at the pressed-line crease positions of the paperboards by use of high-temperature steam; the method is capable of preventing paper breaking of the paperboards during line pressing or molding.

Owner:程龙楷 +1

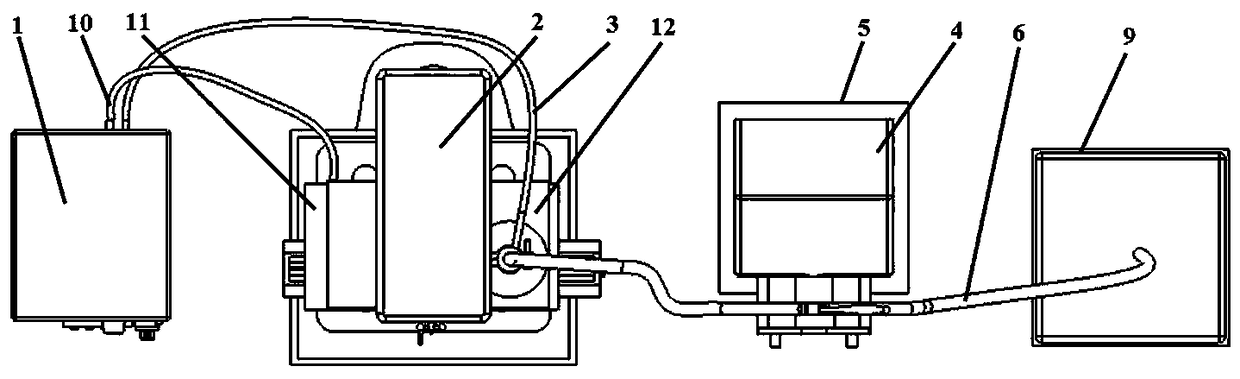

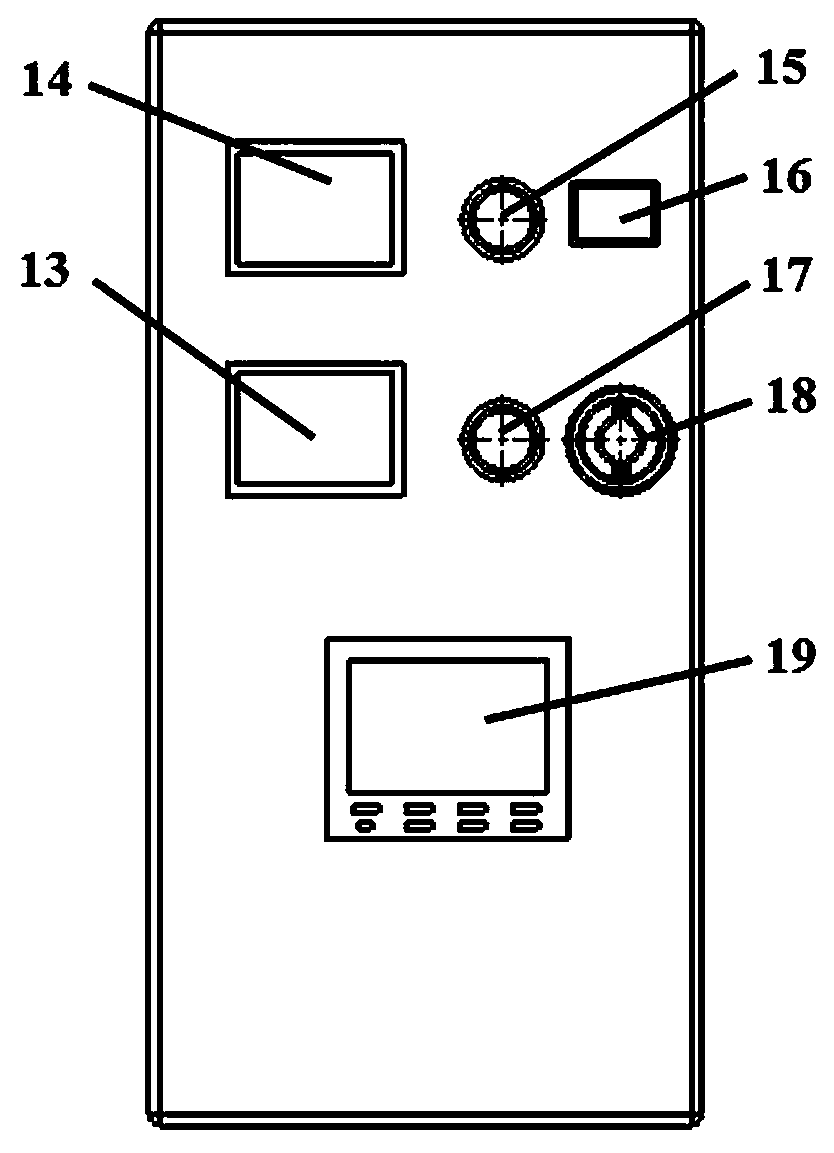

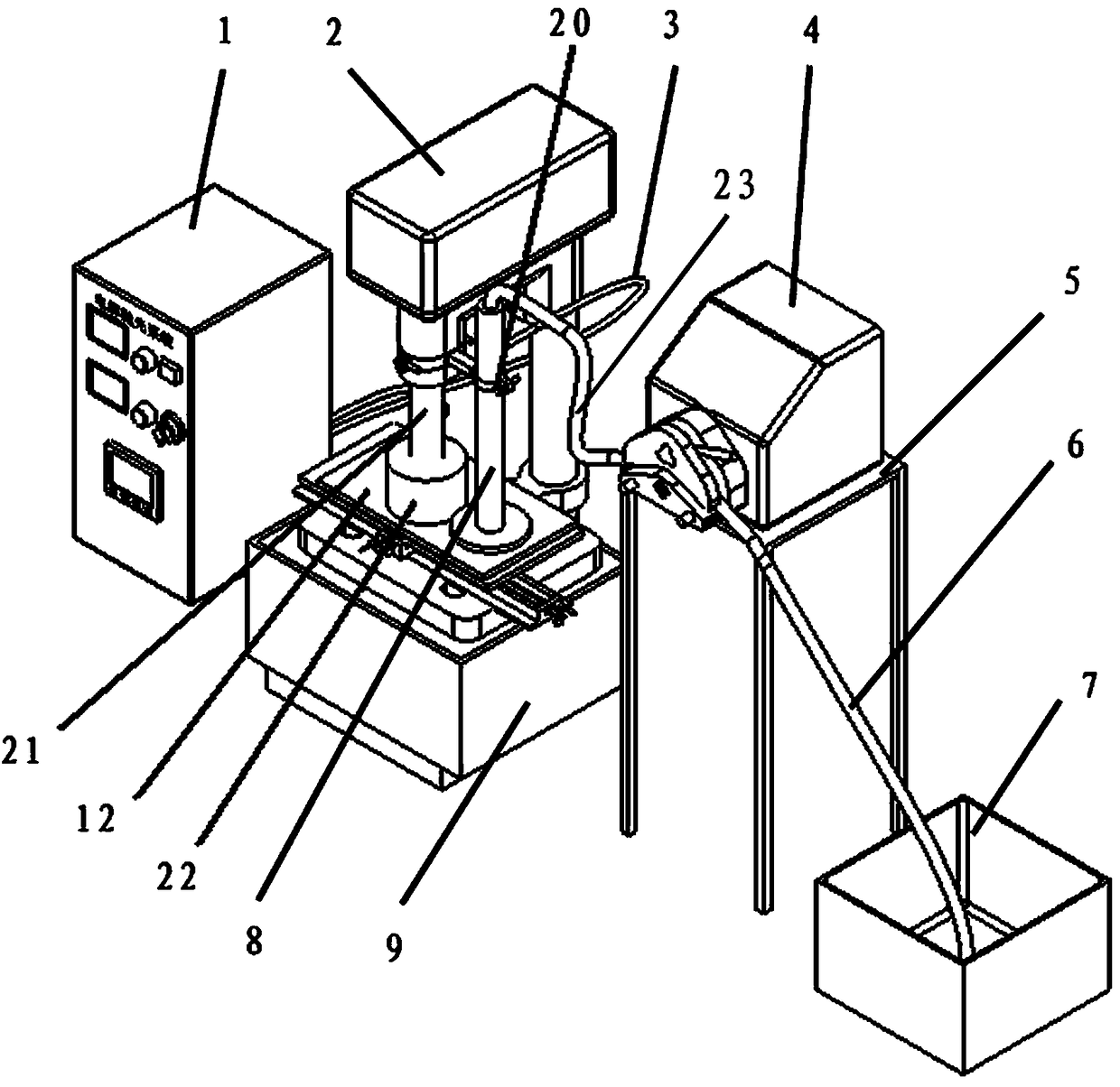

Device for carrying out combined machining on plane by electrolytic magnetic force

PendingCN108555701AHigh precisionImprove efficiencyGrinding/polishing apparatusPeristaltic pumpElectrochemistry

The invention belongs to the technical field of ultraprecision machining, and particularly relates to a device for carrying out combined machining on a plane by electrolytic magnetic force. The devicecomprises a milling machine and an adjustable horizontal workbench, and is characterized in that the milling machine is provided with a fixed clamper, electrolytic polishing equipment and magnetic force grinding equipment; the electrolytic polishing equipment comprises a hollow copper rod, a cathode line connected with the hollow copper rod, an anode line connected with a workpiece to be processed, an electrolytic polishing control system, a peristaltic pump connected with the hollow copper rod through a first silica gel pipe, and an electrolyte tank connected with the peristaltic pump through a second silica gel pipe; the magnetic force grinding equipment comprises an axial magnetic pole connected with a main shaft of the milling machine to carry out magnetic material grinding. The device makes up the deficiencies of single-type processing, the material of a workpiece surface is softened through the anode dissolution reaction of electrochemistry, so that the workpiece surface is ground by magnetic force grinding, the anode dissolution reaction of electrochemical machining can be continuously carried out, magnetic force-ground materials can be softened, and the surface accuracy ofthe machined workpiece is high.

Owner:UNIV OF SCI & TECH LIAONING

Fragrant odorless burr softening remover and preparation method thereof

The invention relates to a fragrant odorless burr softening remover and a preparation method thereof. The method comprises the following steps: preparing base stocks by separately operating a stirring tank and a reaction kettle, and then mixing the base stocks and reacting, thereby obtaining a softening remover. According to the burr softening remover prepared according to the method, the fluid can automatically flow and completely cover the plank surface; the removing effect is good; the remover can rapidly solidify; the softening speed is high; after softening, the burr can be solidified and clamped in the softening remover after solidifying; the softening remover after solidifying can be easily torn off; no residue or odor exists; the effect is excellent; the fragrant odorless burr softening remover is convenient to popularize and use.

Owner:阜南县铭钰柳木工艺品有限公司

Method for changing mouthfeel of brown rice

InactiveCN104824549ASlow down the rate of brown rice spoilageIncrease productivityFood preparationChemistryMouthfeel

The invention relates to a method for changing mouthfeel of brown rice and belongs to the field of agricultural products deep processing. The method comprises the following steps: 1) removing impurities from indica non-glutinous rice and husking so as to obtain brown rice used as a standby processing raw material; 2) preparing a mixed solution of alpha-amylase and glucoamylase at the concentration of 40-50mg / mL to be used as an enzymolysis solution for later use; 3) carrying out low temperature atomization on the prepared mixed solution from the step 2) in a high-pressure environment, and uniformly spraying the mixed solution onto the brown rice; 4) sending the processed brown rice into a constant temperature incubator to react for 1-2h; and 5) carrying out microwave drying treatment after the reaction time such that moisture of the processed brown rice is less than 15%, and packaging to obtain the modified brown rice. By the above method, mouthfeel of the brown rice is more excellent, cooking time is shortened, a cooking technology is simplified, and mouthfeel of the modified brown rice is more acceptable for people.

Owner:苏州科谷米业有限公司

Chinese wolfberry fruit and white fungus yogurt and preparation method thereof

The present invention discloses a Chinese wolfberry fruit and white fungus yogurt which is made from the following raw materials in parts by weight: 400-450 parts of fresh milk, 16-18 parts of white fungus, 5-6 parts of diced scallop, 4-5 parts of purple sweet potato full flour, 1-2 parts of seaweed powder, 4-5 parts of single cream, 7-8 parts of Chinese wolfberry fruits, 1-2 parts of burdock roots, 2-3 parts of radix salviae miltiorrhizae, 4-5 parts of Chinese yams, 0.8-0.9 part of gelatin, 16-18 parts of sucrose, 0.16-0.18 part of pectinase, a right amount of lemon juice, a right amount of fermentation agent and a right amount of water. The fresh milk and white fungus are used as main ingredient, and the radix salviae miltiorrhizae and other Chinese herbal medicinal ingredients are added at the same time, which have efficacies of clearing heart and removing restlessness, and tonifying blood and soothing mind. In addition, the used Chinese wolfberry fruits and other accessory materials have functions of lowering blood pressure and cholesterol, and preventing arteriosclerosis.

Owner:HEFEI KANGLING HEALTH TECH

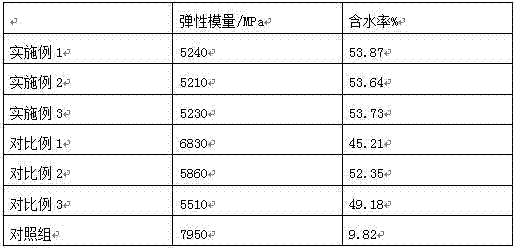

Bamboo single-plate softening method

ActiveCN107081832AFast softening speedGentle softening processRadiation/waves wood treatmentWood treatment detailsFiberUltrasonic assisted

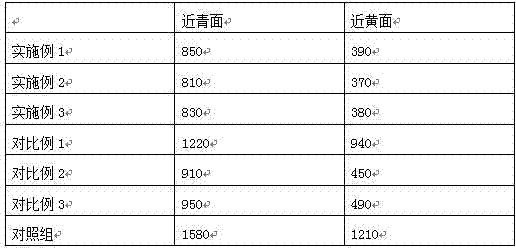

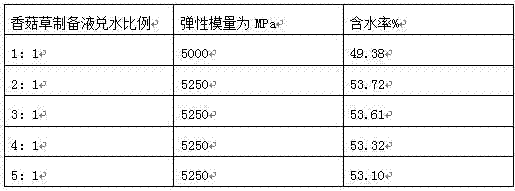

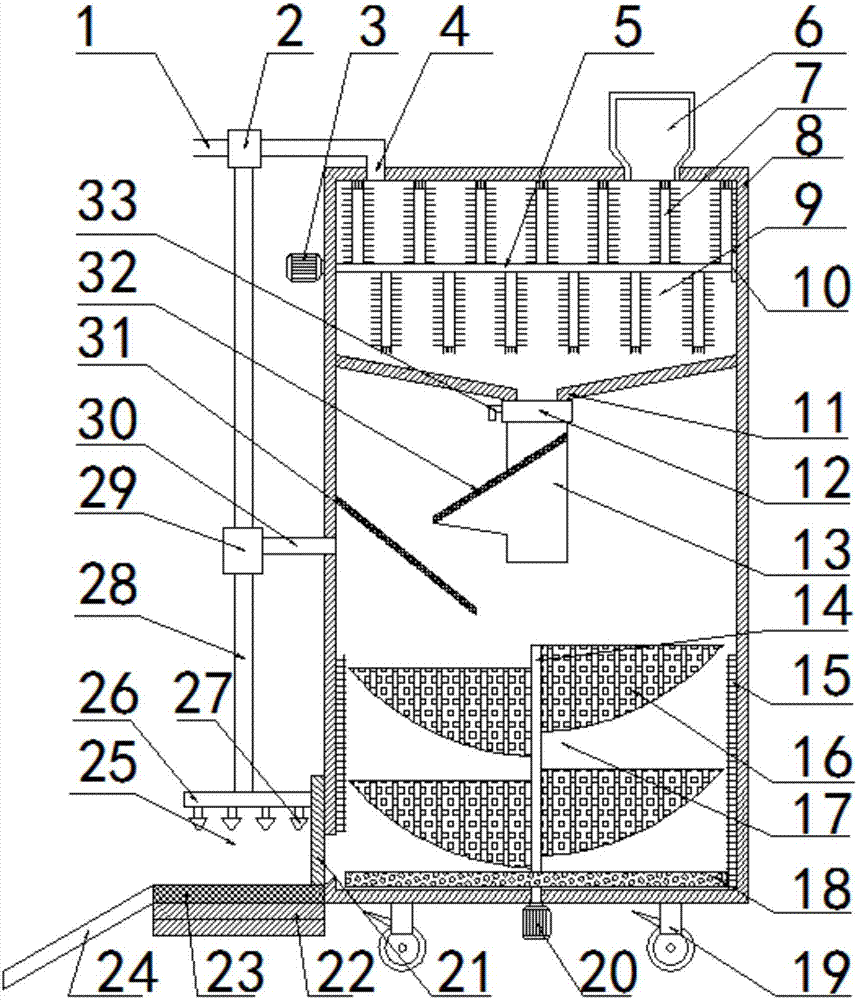

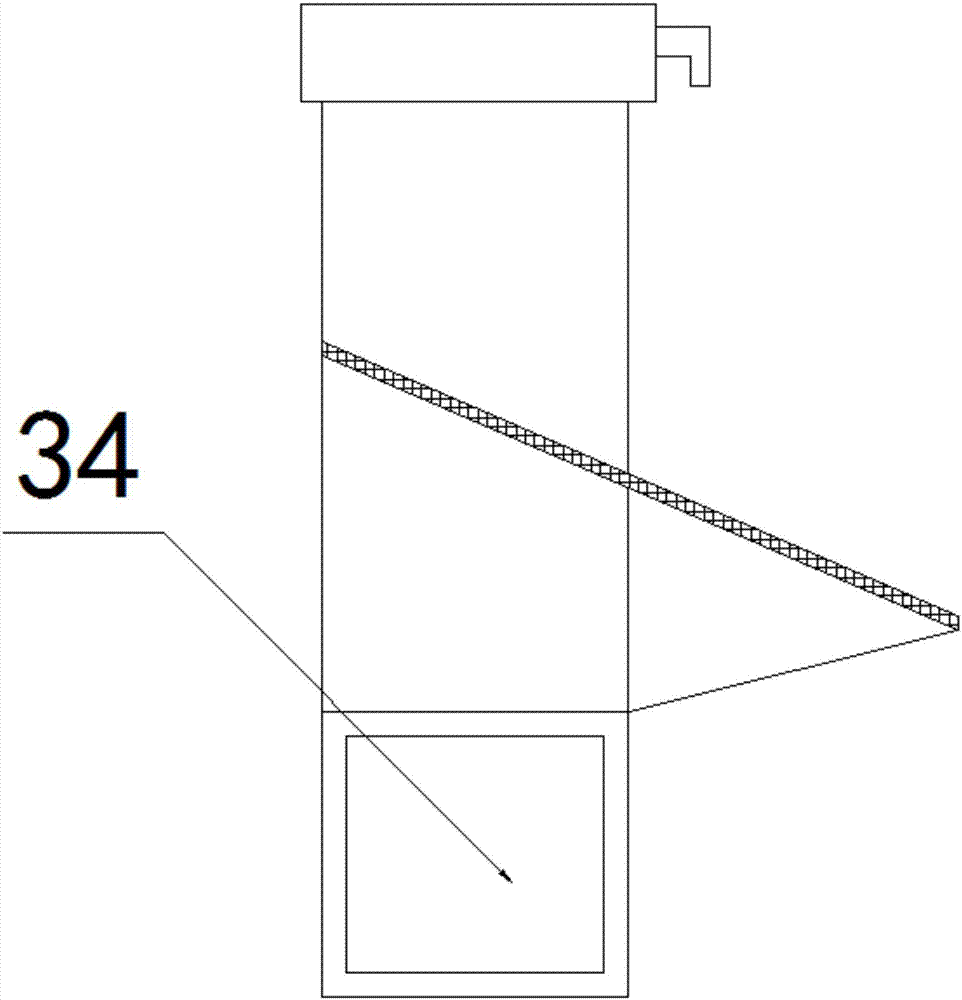

The invention discloses a bamboo single-plate softening method. The bamboo single-plate softening method comprises the steps that after a bamboo single plate is preheated, hydrocotyle vulgaris preparation liquid is adopted for being mixed with water to conduct stewing, and auxiliary treatment is conducted through ultrasonic waves. According to the bamboo single-plate softening method, the hydrocotyle vulgaris preparation liquid is adopted for being mixed with the water to conduct stewing treatment on the bamboo single plate, active ingredients in the hydrocotyle vulgaris preparation liquid can greatly increase the wood softening speed, and particularly after ultrasonic auxiliary treatment, the bamboo softening speed can be further increased; meanwhile, by adoption of the effect of the hydrocotyle vulgaris preparation liquid, the softening process of the bamboo single plate can be mild, and no damaging effect is exerted on an organization structure of the bamboo single plate; and through treatment of the bamboo single-plate softening method, water molecules can more easily enter the amorphous region of the organization of the bamboo single plate to enable fibers to be expanded, so that the elastic modulus of the bamboo single plate is remarkably decreased, the water content of the bamboo single plate is increased, and the plastic property of the bamboo single plate is improved.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

Edible mushroom and tremella yoghourt and preparation method thereof

The invention discloses edible mushroom and tremella yoghourt. The edible mushroom and tremella yoghourt is prepared from the following raw materials in parts by weight: 400-450 parts of fresh milk, 16-18 parts of tremella, 7-8 parts of Rhizoma sagittariae sagittifoliae pulp, 2-3 parts of small shrimps, 2-3 parts of fresh leaf of Moringa, 3-4 parts of kale borecole, 1-2 parts of Rhizoma Gastrodiae, 4-5 parts of Herba Dendrobii, 1-2 parts of Folium Vaccinii Bracteati, 1-2 parts of Fructus Amomi, 0.8-0.9 part of gelatin, 16-18 parts of sucrose, 0.16-0.18 part of pectase, a proper amount of lemon juice, a proper amount of a leavening agent, and a proper amount of water. The fresh milk and the tremella are used as main materials, meanwhile, Chinese herbal medicine ingredients such as Herba Dendrobii are added, and therefore, effects of reinforcing the stomach and promoting salivation, and nourishing Yin and clearing away heat are achieved. In addition, adopted auxiliary materials such as Rhizoma sagittariae sagittifoliae pulp have functions of lowering blood fat and blood pressure, and relieving fatigue.

Owner:HEFEI KANGLING HEALTH TECH

Method for preparing substitute tea for preventing phlegm from forming and stopping coughing by utilizing reddish orange

InactiveCN106889269ADisadvantages of Avoiding LossesFast softening speedTea substituesAdditive ingredientTime-Consuming

A method for preparing substitute tea for preventing phlegm from forming and stopping coughing by utilizing reddish orange comprises the steps of screening, purification through purification air of 20-35 DEG C, flash evaporation and softening, core moistening, shaping, forming, tablet forming, far infrared drying and package. The method has the advantages that the effective ingredient loss of reddish orange is small, the time consumed for production is short, a preparation process is reasonable and environment-friendly, and the prepared substitute tea is high in effective ingredient content and convenient to brew and has the obvious effects of preventing phlegm from forming and stopping coughing.

Owner:南宁市天然润宝农林投资有限责任公司

Efficient full-automatic taro cleaning machine

The invention discloses a high-efficiency fully automatic taro cleaning machine, which comprises a shell, a feeding device, a first stirring device, a separation pipe, a second stirring device, a high-pressure spray device, a second retaining net, a first retaining net and a ten thousand to the wheel; the first stirring device is arranged on the upper part of the shell; the device of the present invention is provided with the first stirring device, which has the effect of softening the soil on the surface of the taro, and simultaneously utilizes the stirring device to speed up the softening speed, and utilizes the belt The setting of the bristle stirring rod has the function of cleaning the softened taro; through the setting of the separation pipe and the first screen, it has the function of separating the taro and sewage; through the rotating disk with burrs in the second stirring device and arc The setting of stirring and cleaning blades can molt the place where the taro is in contact with the device; through the setting of the high-pressure nozzle in the high-pressure spraying device, the function of using high-pressure water to clean the taro at the end and remove the sundries attached to the surface of the taro .

Owner:HUIAN HUACHEN TRADE CO LTD

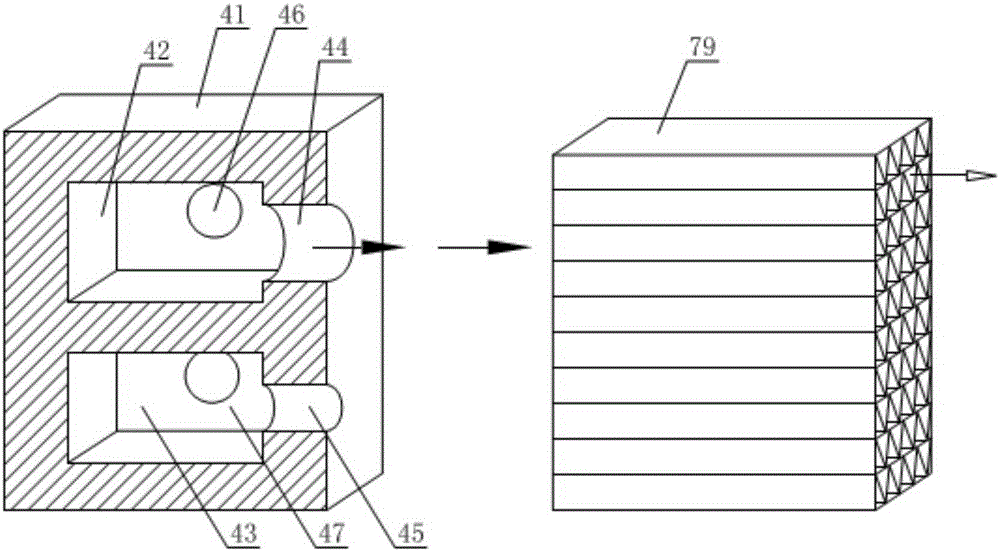

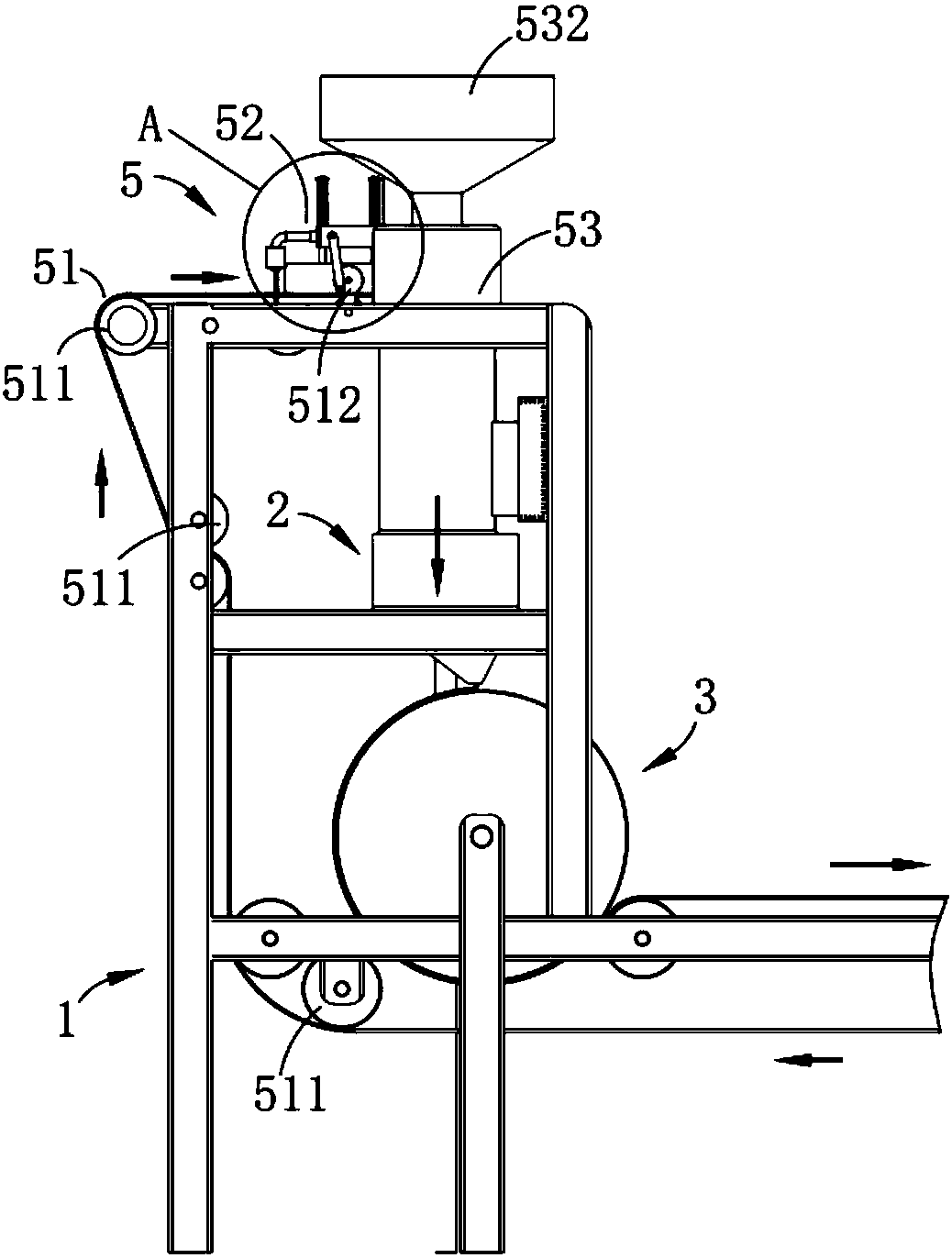

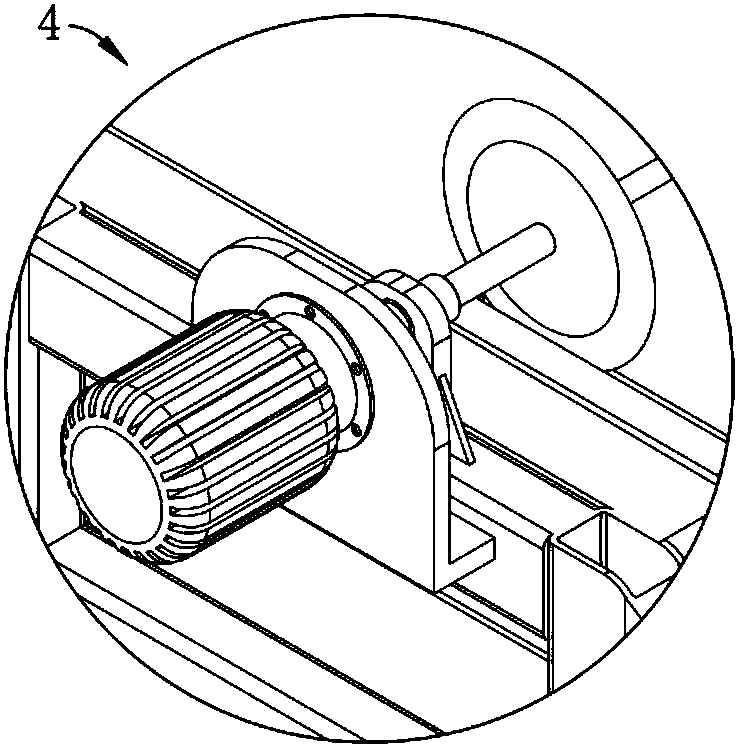

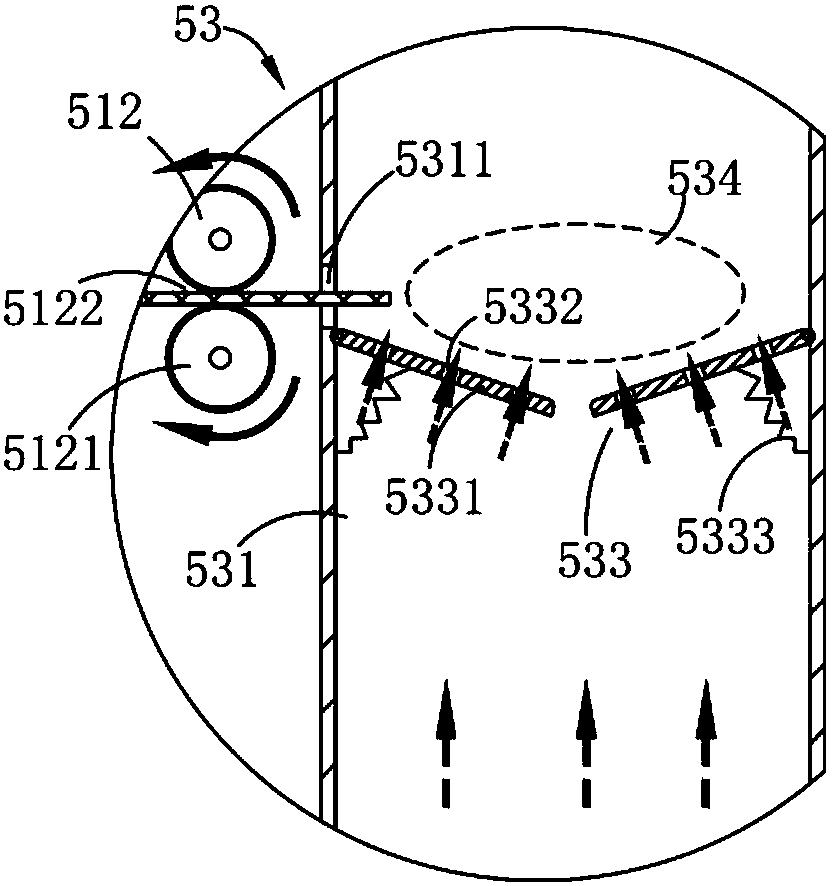

ABA cast film manufacturing equipment and manufacturing method

InactiveCN108453978ANot easy to scatterSolve technical problems prone to stratificationFlat articlesCoatingsFixed ratioEngineering

The invention relates to the technical field of cast film production, in particular to ABA cast film manufacturing equipment. The equipment comprises a machine frame, a fusing mechanism, a tape casting mechanism, a cutting mechanism and an edge material reuse mechanism, wherein the edge material reuse mechanism comprises a transmission part, a section cutting part and a mixing part; the transmission part comprises a plurality of guide rollers and a lead-in assembly; the mixing part comprises a mixing cabin, a storage part and a mixing assembly; the storage part is used for new material discontinuous quantitative lead-in; the mixing assembly is used for fixed ratio mixing of edge material sections and the new materials; the edge materials and the new materials are in contact mixing in the mixing region and are then transferred; meanwhile, the new materials are covered inside the edge materials to form a mixing unit by the edge material sections; then, the materials enter the fusing mechanism for liquification treatment; through the lead-in assembly, the edge materials are subjected to quantitative transmission; the section cutting part is controlled to perform equal distance sectioncutting treatment; then, the bonding proportioning of the mixing assembly and the edge material section in a way of coating the new materials by the edge material sections by using the mixing assembly is realized; the technical problem of easy delamination in the fusing process of the edge materials and the new materials in the prior art can be solved.

Owner:ZHEJIANG SHANLIAN NEW MATERIAL TECH CO LTD

Synthetic chamois, and manufacture process thereof

The invention discloses a synthetic chamois, and a manufacture process thereof. The synthetic chamois provided by the invention is manufactured from the following raw materials in parts by weight: 22-32 parts of poly(vinyl alcohol), 8-14 parts of starch, 14-18 parts of poly(methyl methacrylate), 500-700 parts of water, 20-30 parts of sulfuric acid (2-5% diluted sulfuric acid) and 23-27 parts of formaldehyde. The manufacture process provided by the invention comprises the following steps of: adding poly(vinyl alcohol), starch and poly(methyl methacrylate) to water at normal temperature and normal pressure, heating and stirring for dissolving, cooling to normal temperature, adding formaldehyde, then adding sulfuric acid, stirring, injecting to a mold, molding at the temperature of 75-85 DEG C, cooling, demolding, centrifuge-drying, cleaning, carrying out mildewproof treatment, packaging and checking to obtain a product. The obtained product has the characteristics of proper wiping friction force, high water-encountering softening speed after being dry and hard, good elasticity and texture, good cleaning effect, easy use and low cost increase (increased by only 5%) and has an appearance similar to true leather, in short, the synthetic chamois provided by the invention has good texture and low cost.

Owner:昆勤清洁用品(昆山)有限公司

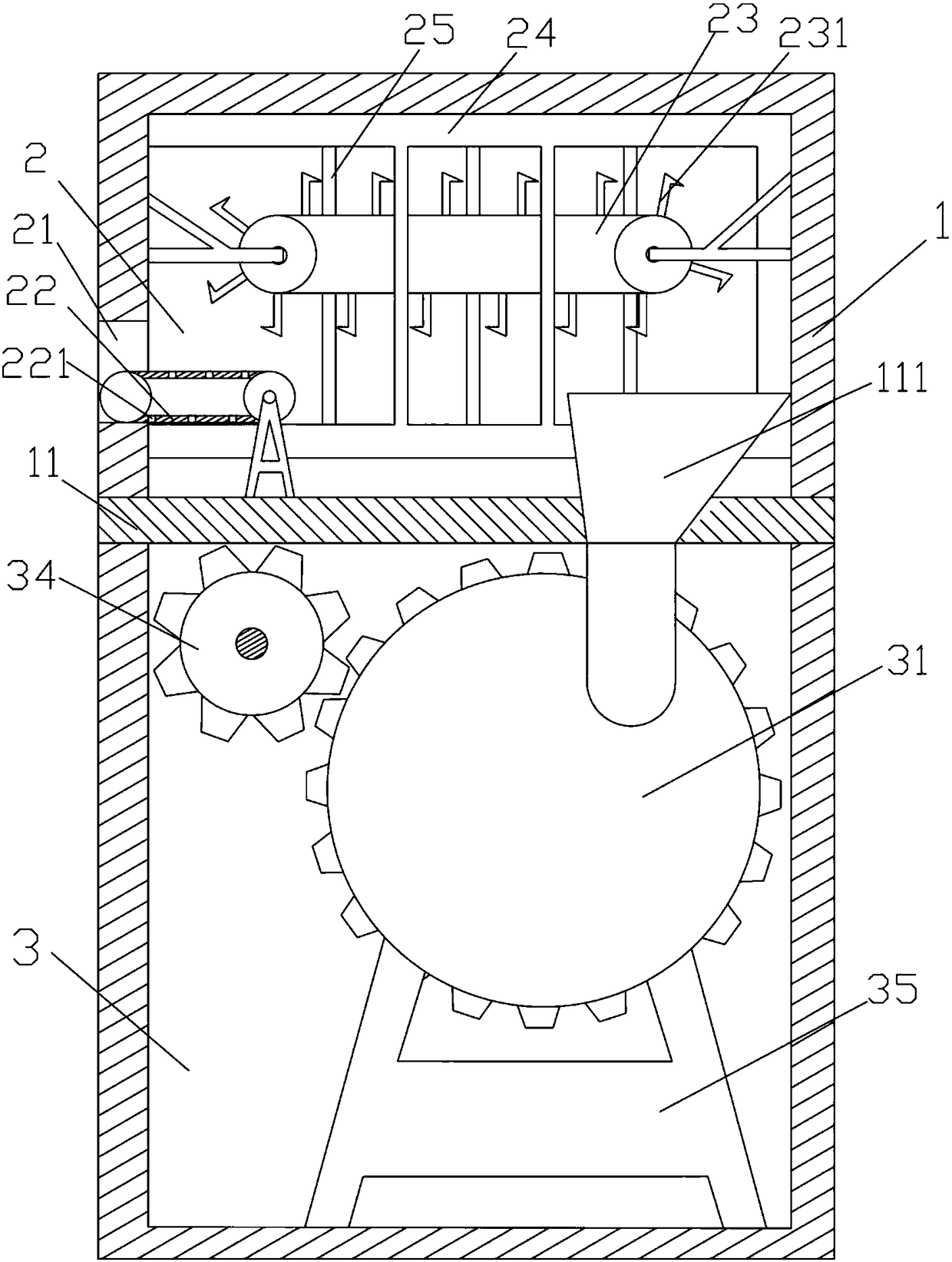

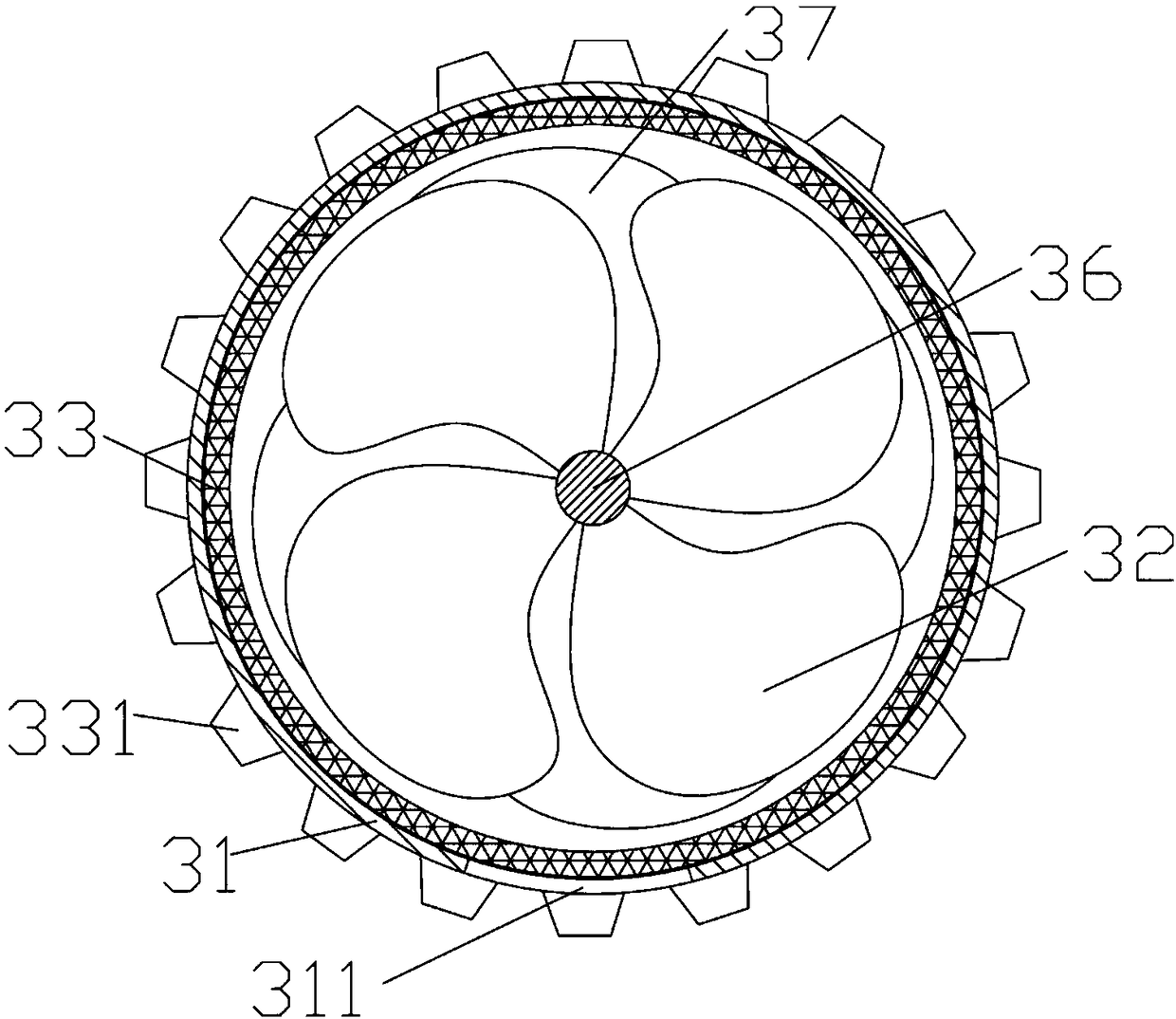

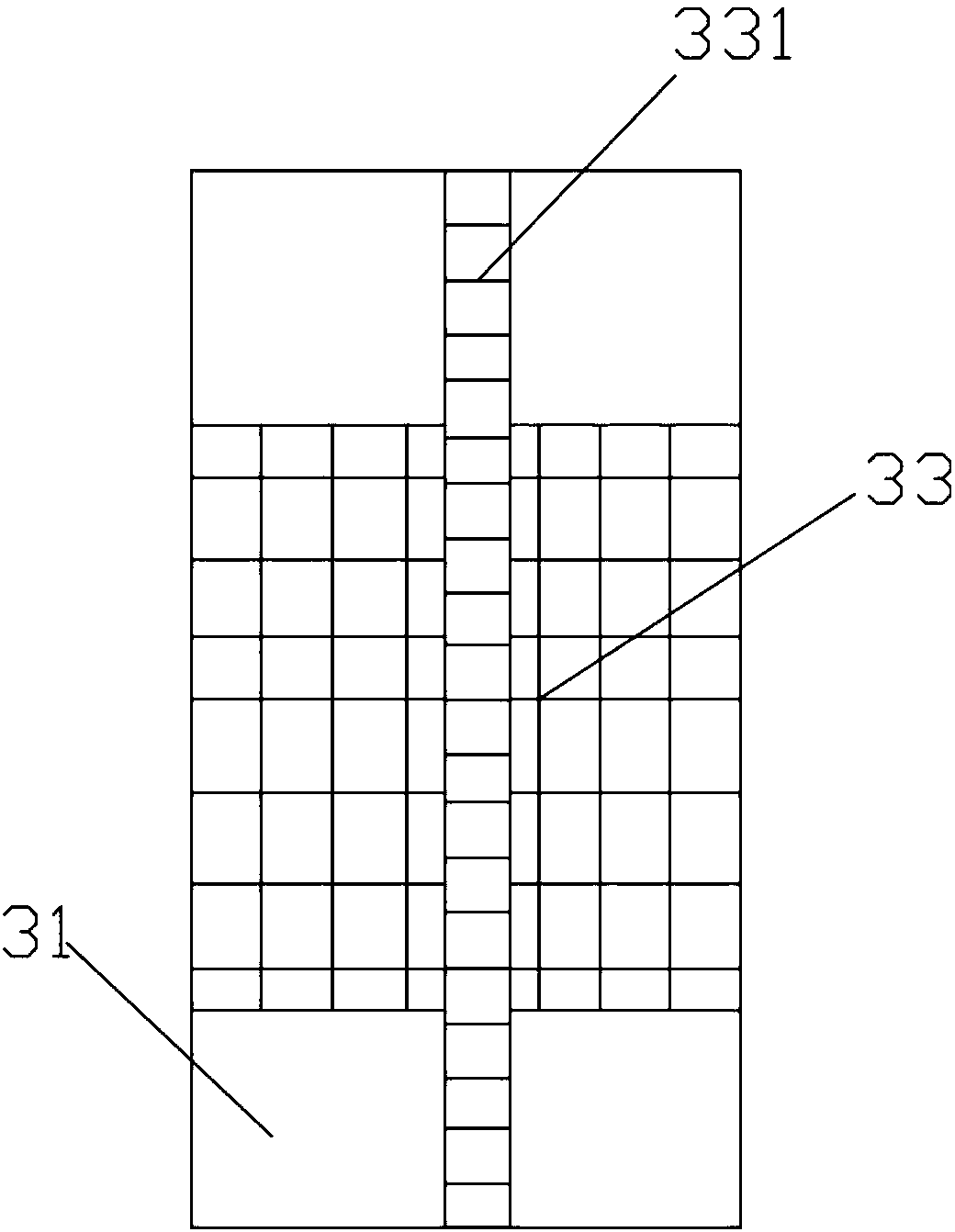

Waste tire crusher

ActiveCN108481624AFast softening speedShorten heating timePlastic recyclingMechanical material recoveryWaste tiresEngineering

The invention discloses a waste tire crusher. The comprises a box body, wherein a partition plate, a heating cavity arranged above the partition plate and a crushing cavity arranged below the partition plate are arranged in the box body, the heating cavity is internally provided with a heating mechanism, and the crushing cavity is internally provided with a crushing mechanism. According to the waste tire crusher, the partition plate is arranged, the box body is divided into the upper cavity and the lower cavity which are independent, and the two cavities can work independently and can also cooperate with each other for running, so that the working efficiency is improved; the heating mechanism is used for heating waste tires to a softening degree without melting, and the crushing mechanismis used for crushing and cutting the waste tires, so that the follow-up utilization of the waste tires is facilitated; and due to the adoption of the structure, the softened waste tires can enter thecrushing mechanism to be crushed in a mode of being more labor-saving and efficient, and the crushing efficiency of the waste tires is greatly improved.

Owner:常州绿境环保科技有限公司

A kind of reclaimed rubber softener and preparation method thereof

Owner:湖南中海顺达新材料股份有限公司

Softening process of east-sea cucumaria japonica

InactiveCN105029516AImprove food tasteGreat tasteFood preservationFood preparationHydrolysatePhosphate

The invention relates to a softening process of east-sea cucumaria japonica, wherein the softening process includes the steps of (1) performing pre-treatment; (2) performing primary enzymolysis with a primary enzymatic hydrolysate prepared by compounding pepsin and papain with addition of water; (3) puncturing the surface of the cucumaria japonica to form pores which are uniformly staggered, preparing a secondary enzymatic hydrolysate by compounding papain, bromelain, alcalase protease, a composite phosphate and calcium chloride with addition of water, and performing secondary enzymolysis; (4) performing vacuum tumbling; and (5) performing moulding. The softening process can effectively hydrolyze the collagen in the skin, can change the tissue structure of the skin, can reduce hardness of the skin and can improve the mouthfeel of the cucumaria japonica. By means of combination of biological enzymolysis and physical methods, the softening process is greatly increased in softening speed, is reduced in processing cost and can further improve the mouthfeel of the cucumaria japonica.

Owner:ZHEJIANG OCEAN UNIV

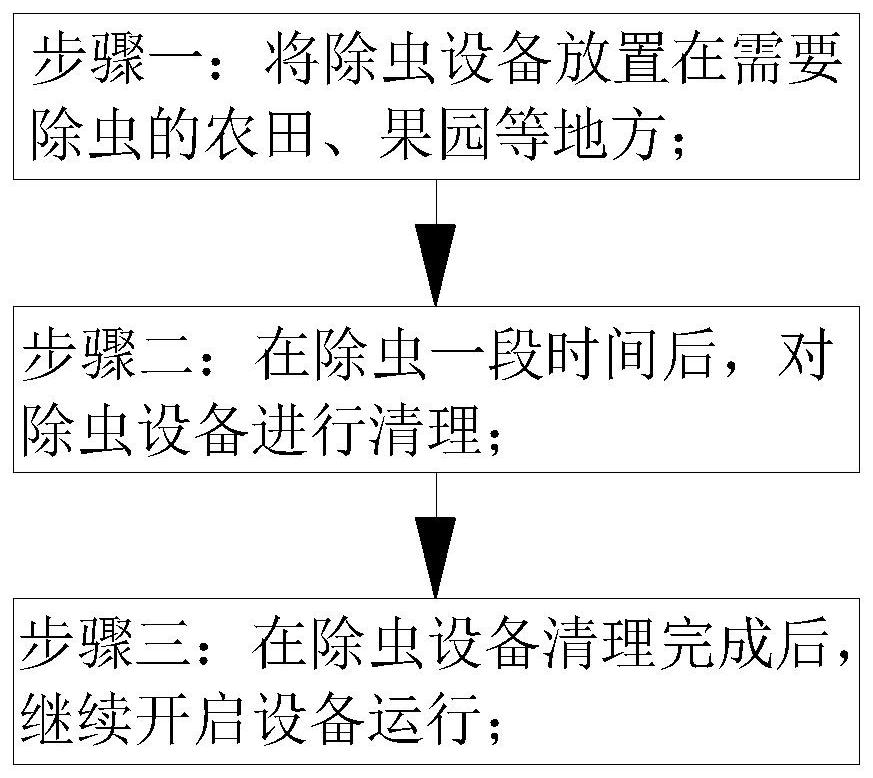

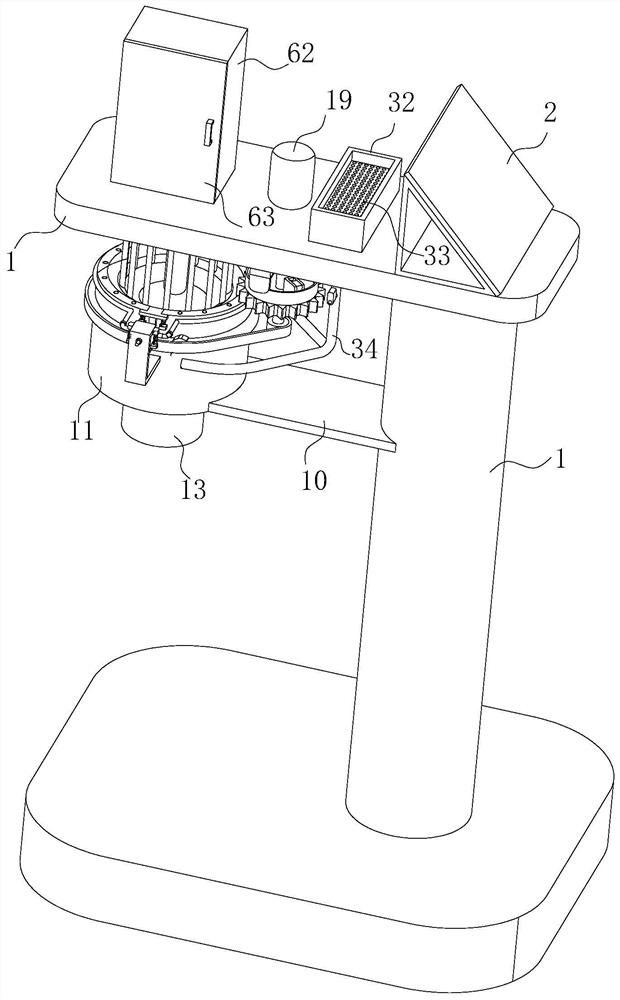

Agricultural environment-friendly deinsectization method

InactiveCN112655441AStay attractiveAutomatically achieve the purpose of cleaningRenewable energy machinesCleaning using toolsAgricultural scienceEnvironmental engineering

The invention discloses an agricultural environment-friendly deinsectization method, and belongs to the technical field of agricultural environment-friendly deinsectization. The environment-friendly deinsectization method comprises the following steps: step 1, deinsectization equipment is placed in a farmland, an orchard and other places needing deinsectization. By arranging a transmission gear, a water injection mechanism and other structures, when a cleaning disc slides downwards under the action of the gravity of the cleaning disc, large mosquitoes on the surface of an electric insect rod are pushed away from the surface of the electric insect rod to completely fall into the top of a cleaning barrel, and meanwhile, the surface of the electric insect rod is heated through the mutual friction effect between the surface of the electric insect rod and a cleaning brush, small sundries difficult to clean on the surface of the electric insect rod are heated and softened, meanwhile, by means of a water outlet pipe, rainwater stored in a water receiving box enters a cleaning tank through the water outlet pipe, on one hand, the water entering the cleaning tank cools the electric insect rod, and on the other hand, the softened sundries on the surface of the electric insect rod are washed away.

Owner:亳州市谯城区蓝鲸信息科技有限公司

Nontoxic environment-friendly bamboo weaving burr softening and removing agent and preparation method thereof

InactiveCN106189230AGood removal effectFast softening speedWood treatment detailsChemistryWood panel

The invention discloses a nontoxic environment-friendly bamboo weaving burr softening and removing agent and a preparation method thereof. A stirring tank and a reaction kettle work separately to prepare base materials, and the base materials are mixed to react to prepare the softening and removing agent. According to the burr removing agent prepared through the method, fluid can automatically flow and completely cover a wood board surface, a removing effect is good, solidification is rapid, the softening speed is high, the softened burr can be solidified and clamped to the solidified softening agent and can be easily torn away after being solidified, no residue or smell is left, the effect is better, and application and popularization are convenient.

Owner:阜南县铭钰柳木工艺品有限公司

Softening and removing agent for burrs on surface of irregular wood block and preparation method of softening and removing agent

InactiveCN106078993AGood removal effectFast softening speedWood treatment detailsWood impregnation detailsChemistryOdor

The invention discloses a softening and removing agent for burrs on the surface of an irregular wood block and a preparation method of the softening and removing agent. A stirring tank and a reaction still work independently, and a base material is prepared; and then a hybrid reaction is conducted on the base material to obtain the softening and removing agent. According to the burr removing agent prepared through the preparation method, liquid can automatically flow and completely cover the surface of a wood plate, the removing effect is good, solidification is fast, and the softening speed is high; after softening, the burrs can be solidified and clamped in the solidified softening agent, and the softening agent can be torn off easily after solidification; and residues and undesirable odor are avoided, the effect is better, and the softening and removing agent is convenient to apply and popularize.

Owner:阜南县铭钰柳木工艺品有限公司

Yoghurt with brown sugar, wax apple and white fungus and production method thereof

InactiveCN105981811AFast softening speedAvoid damageMilk preparationOther dairy technologyBiotechnologyPectinase

The invention discloses black sugar lotus mist tremella yoghurt, which is prepared from the following raw materials in parts by weight: 400-450 fresh milk, 16-18 tremella, 4-6 kale, 4-5 champagne, 4-5 brown sugar, lotus mist 5-8, oxtail ginseng 1-2, licorice root 3-4, lotus seed core 3-4, coltsfoot flower 1-2, gelatin 0.8-0.9, sucrose 16-18, pectinase 0.16-0.18, lemon juice, fermentation Appropriate amount of medicine and water. The present invention uses fresh milk and white fungus as the main ingredients, and adds lotus seed core and other Chinese herbal medicine ingredients at the same time, which has the effects of clearing away heat, lowering blood pressure, strengthening the heart and calming the nerves; in addition, the auxiliary materials such as lotus mist used in the present invention have the functions of clearing away heat, diuresis and calming the nerves.

Owner:HEFEI KANGLING HEALTH TECH

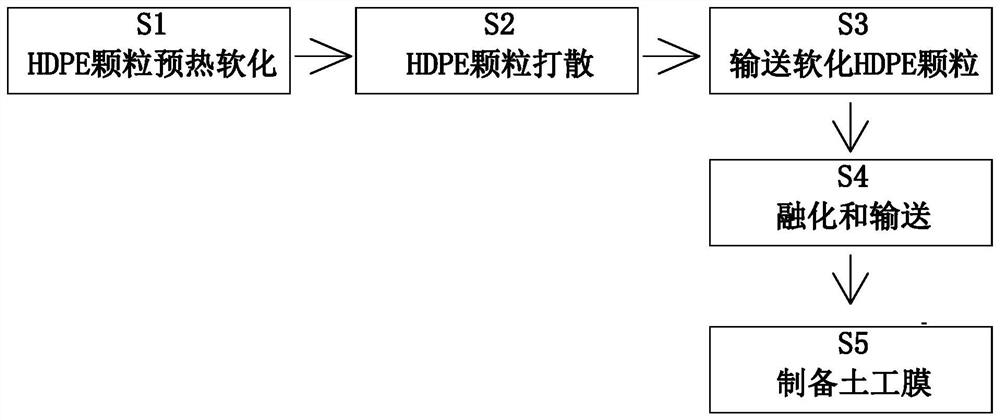

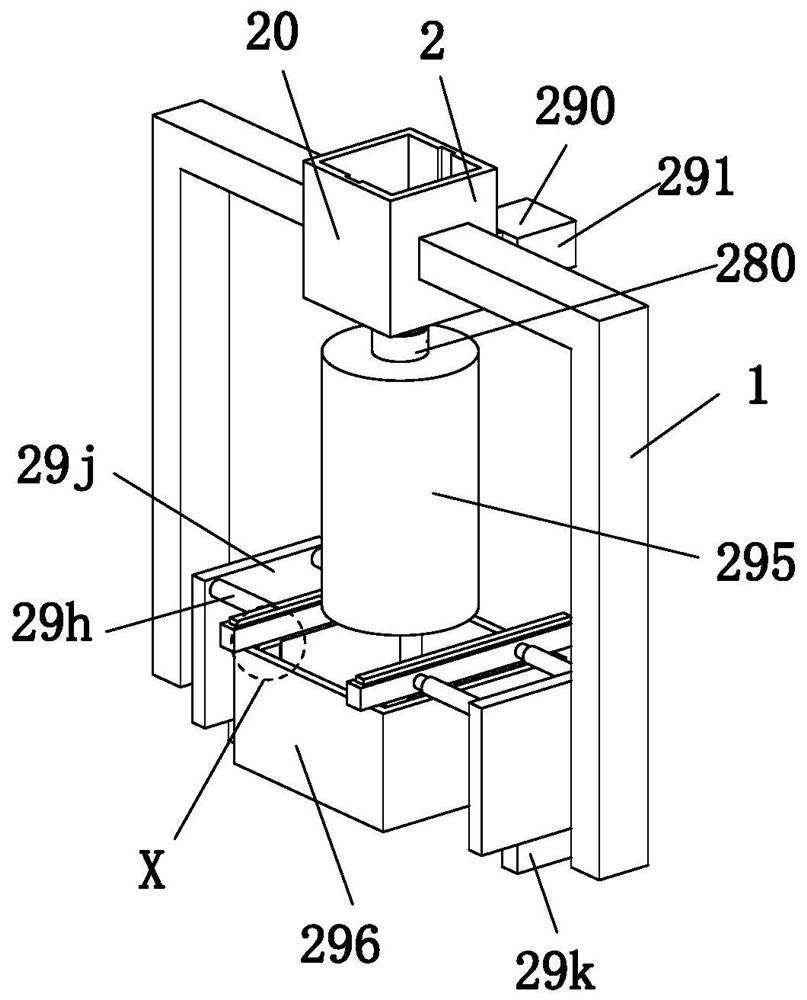

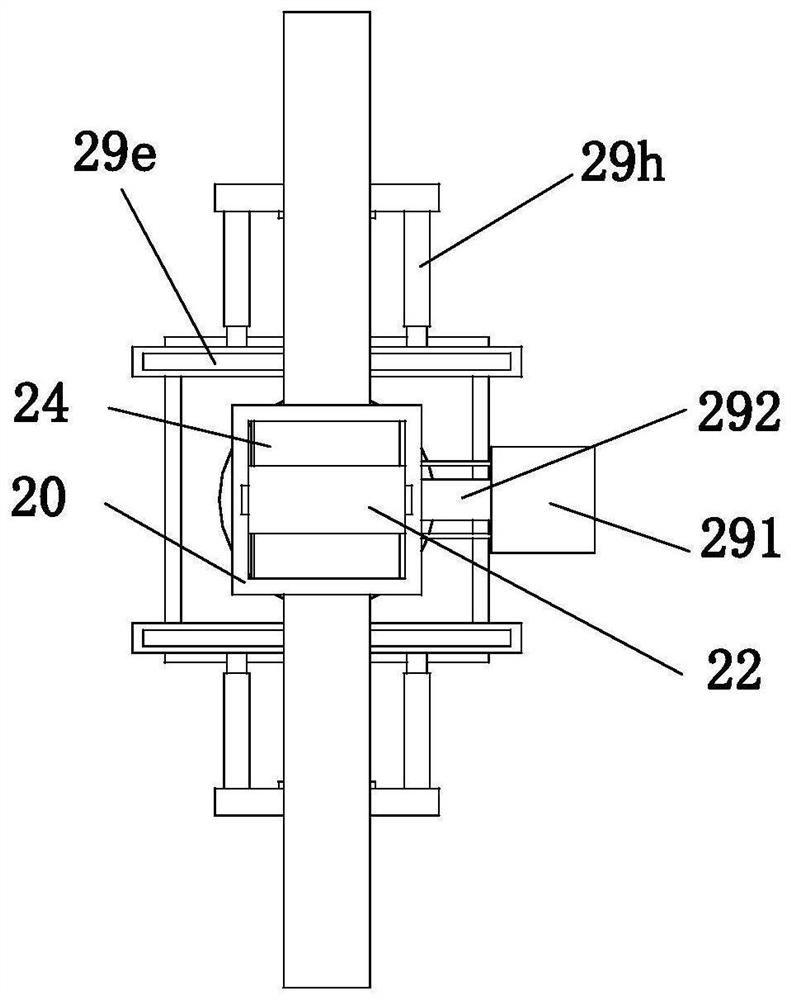

Preparation and molding technology of HDPE geomembrane

InactiveCN112721256AIncrease meltingAvoid the phenomenon of sticking togetherHollow article cleaningFlat articlesGeomembraneMolding machine

The invention relates to a geomembrane preparation and molding technology. According to the technology, a geomembrane preparation and molding device is used and comprises vertical frames and a molding mechanism, the vertical frames are arranged on the existing working ground in a bilateral symmetry manner, the vertical frames are of inverted L-shaped structures, and the molding mechanism is arranged between the vertical frames. The HDPE geomembrane is prepared and molded by the aid of a design concept of combining multi-mode heating structures, the melting degree of HDPE particles is increased through a preheating and reheating melting mode, and the preheated HDPE particles can be in a scattering motion state from top to bottom through the arranged molding mechanism; according to the state, the phenomenon that the HDPE particles are stacked and bonded into clusters can be avoided, meanwhile, the preheating and softening uniformity of the HDPE particles can be improved, and the softening speed can be increased; the arranged reheating and melting structure is of a spiral type, so that the retention time of the HDPE particles in the structure can be prolonged, and then the melting effect of the HDPE particles is improved.

Owner:尤晨曦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com