Patents

Literature

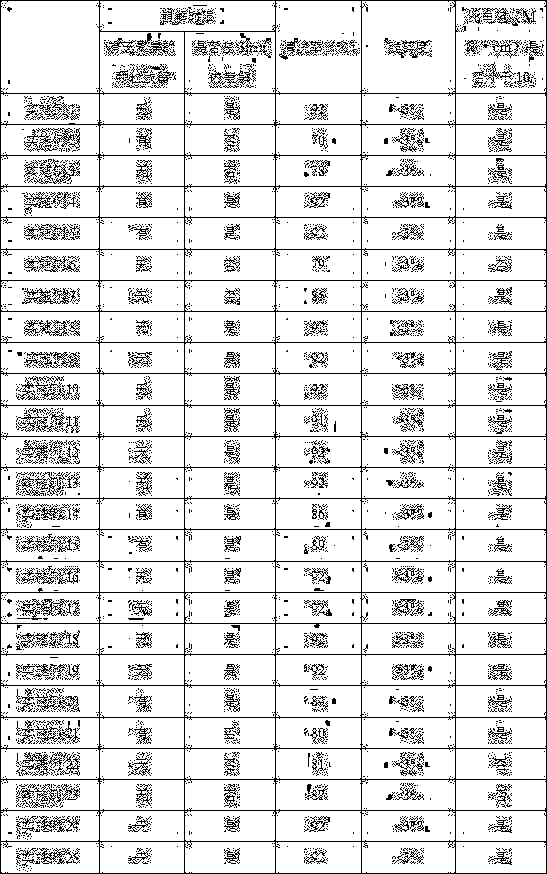

32results about How to "Has a softening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sterilization processing method of rattan plaited article materials

InactiveCN104476639ASimple processing methodInsect-resistantBiocideWood treatment detailsMildewSoftening

The invention provides a sterilization processing method of rattan plaited article materials, and belongs to the technical field of rattan plaited article production. The sterilization processing method comprises following steps: rattan is harvested, and each 10 to 20 strips are bonded with a consistent direction so as to obtain one bouquet of rattan; the bonded rattan bouquets are immersed in a processing solution with the end tip of rattan upward, and are exposed to sunlight for 3 to 6 h; leaves of the rattan bouquets are removed, the rattan bouquets are dried with hot air, wherein at a first stage, the rattan bouquets are dried to medium dry, and are subjected to moisture retention for 30 to 50 min for a first time with softening steam, at a second stage, the rattan bouquets are dried to be sixty percent dry, and are subjected to moisture retention for 1 to 3 h for a second time with softening steam, and at a third stage, the rattan bouquets are dried to be eighty percent dry; and the processed rattan bouquets are stored at shade places for natural air drying. According to the sterilization processing method, the fresh rattan is processed firstly; the sterilization processing method is simple, is capable of realizing sterilization, insect prevention, moth prevention, and mildew and rot prevention, and prolonging service life of rattan plaited articles; the obtained steam used for softening is capable of realizing rattan softening, and volatile substances contained by the steam is capable of realizing sterilization and fragrance improvement of rattan.

Owner:ANHUI HONGFU CRAFTS

Weaving method of willow rattan product

InactiveCN104400854AExtended use timeHas a softening effectWood treatment detailsCane mechanical workingToxic materialEngineering

The invention provides a weaving method of a willow rattan product, and relates to the technical field of production of the willow rattan product. The method comprises the following steps: trimming willow rattans, immersing the trimmed willow rattans in a mildew and moth resistant treatment liquid for 18-48h, taking out the willow rattans, and draining to remove water; placing the mildew and moth resistant treated willow rattans in a drying oven, and drying; and weaving the dried willow rattans. The weaving method is simple and feasible, and prolongs the service life of the willow rattan product and avoids infestation or mildew through the mildew and moth resistant treatment of the willow rattans. The mildew and moth resistant treatment liquid does not release toxic substances in the use process, has good mildew and moth resistance, greatly prolongs the service life of the willow rattan product, makes the mildew and moth resistance time reach above 5 years, makes the willow rattan product have a delicate taste, has no side effects to human bodies, also has a softening effect on the willow rattans, and is in favor of weaving.

Owner:GP TOPARTS MFR ANHUI

Sterilizing processing liquid for processing rattans

InactiveCN104397071ASimple processing methodInsect-resistantBiocidePest repellentsBiotechnologyOyster

The invention provides a sterilizing processing liquid for processing rattans, and relates to the technical field of rattan-weaved product production. The processing liquid is composed of the following raw materials in parts by weight: 3 to 7 parts of andrographis paniculata, 2 to 4 parts of cordate houttuynia, 1 to 3 parts of basil, 2 to 4 parts of wild chrysanthemum, 3 to 7 parts of tribulus terrestris, 2 to 4 parts of prunella vulgaris, 3 to 6 parts of santal, 4 to 8 parts of honeysuckle flower, 3 to 7 parts of purslane, 2 to 4 parts of perilla leaf, 2 to 5 parts of Chinese magnoliavine, 2 to 5 parts of hairyvein agrimony, 1 to 3 parts of tabasheer, 2 to 4 parts of fructus forsythiae, 2 to 4 parts of yellow gentian, 2 to 4 parts of rhizoma atractylodis, 2 to 4 parts of eupatorium, 1 to 3 parts of cyrtomium rhizome, 1 to 3 parts of common cnidium fruit, 1 to 3 parts of rheum officinale, 1 to 3 parts of stemona, 2 to 4 parts of smoke stalk, 1 to 3 parts of oyster, and 3 to 7 parts of tree peony bark. In the processing method, live rattans are processed by the provided liquid. The processing method is simple. The processed rattans are sterilized and have the functions of insect resistance, mothproof property, and mold resistance. The service life of rattan-weaved products can be prolonged. The prepared softening steam can soften the rattans, and the volatile substances in the steam can sterilize the rattans and increase the aroma of the rattans.

Owner:ANHUI HONGFU CRAFTS

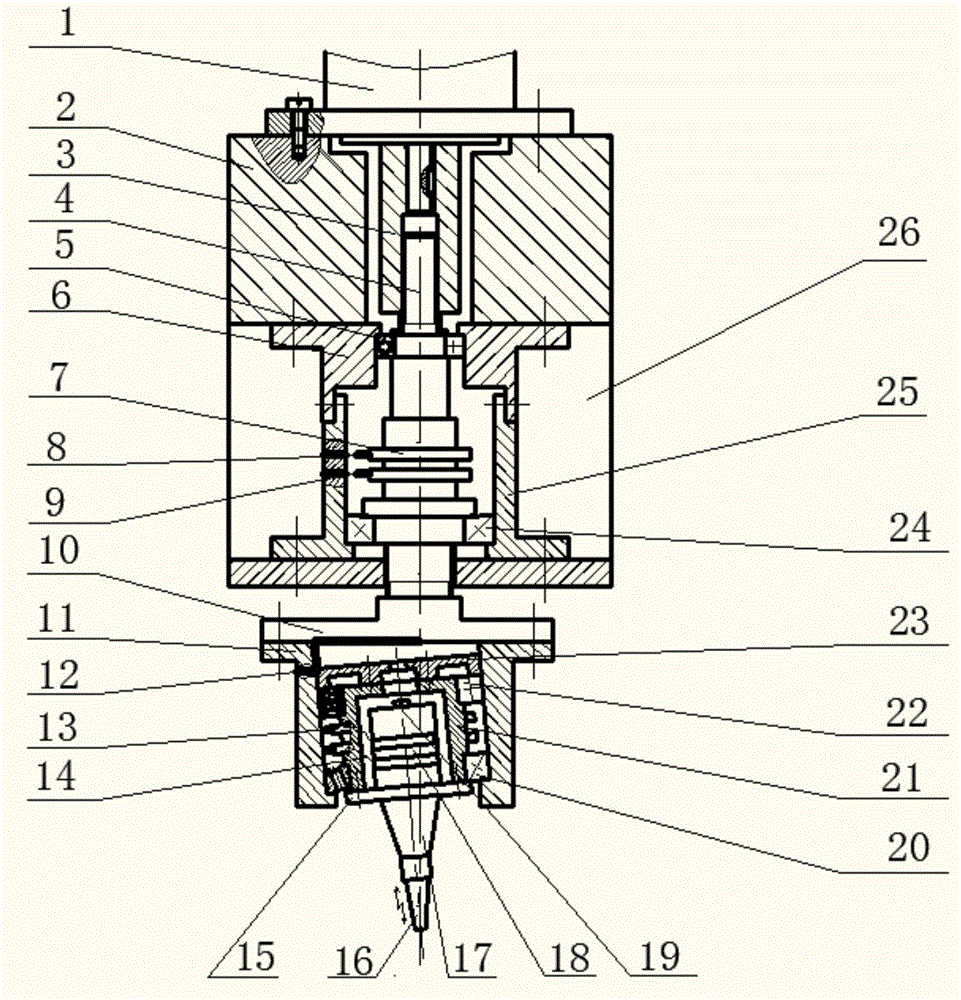

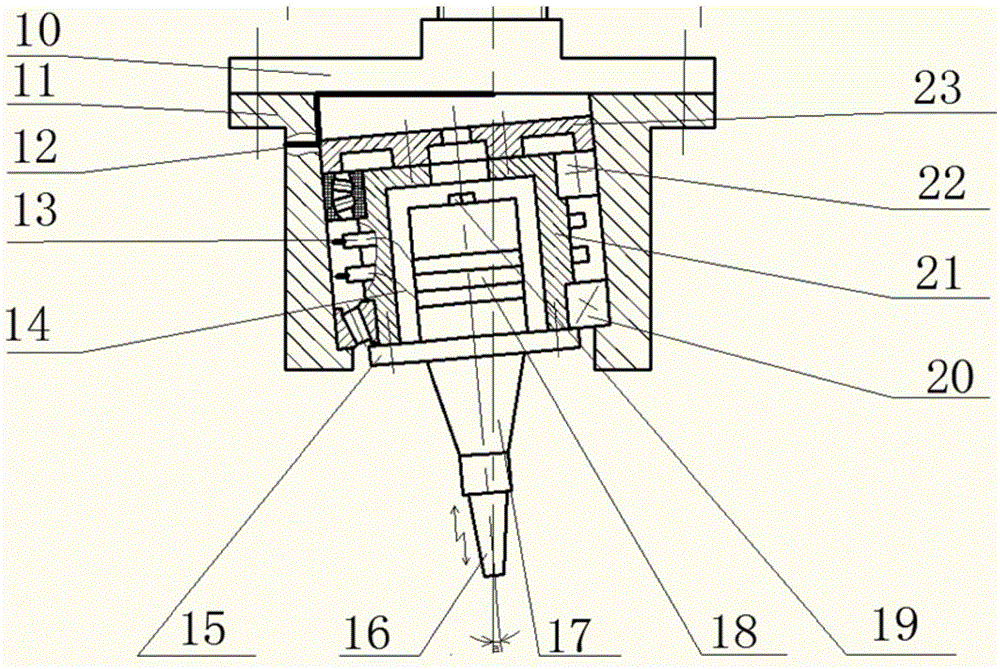

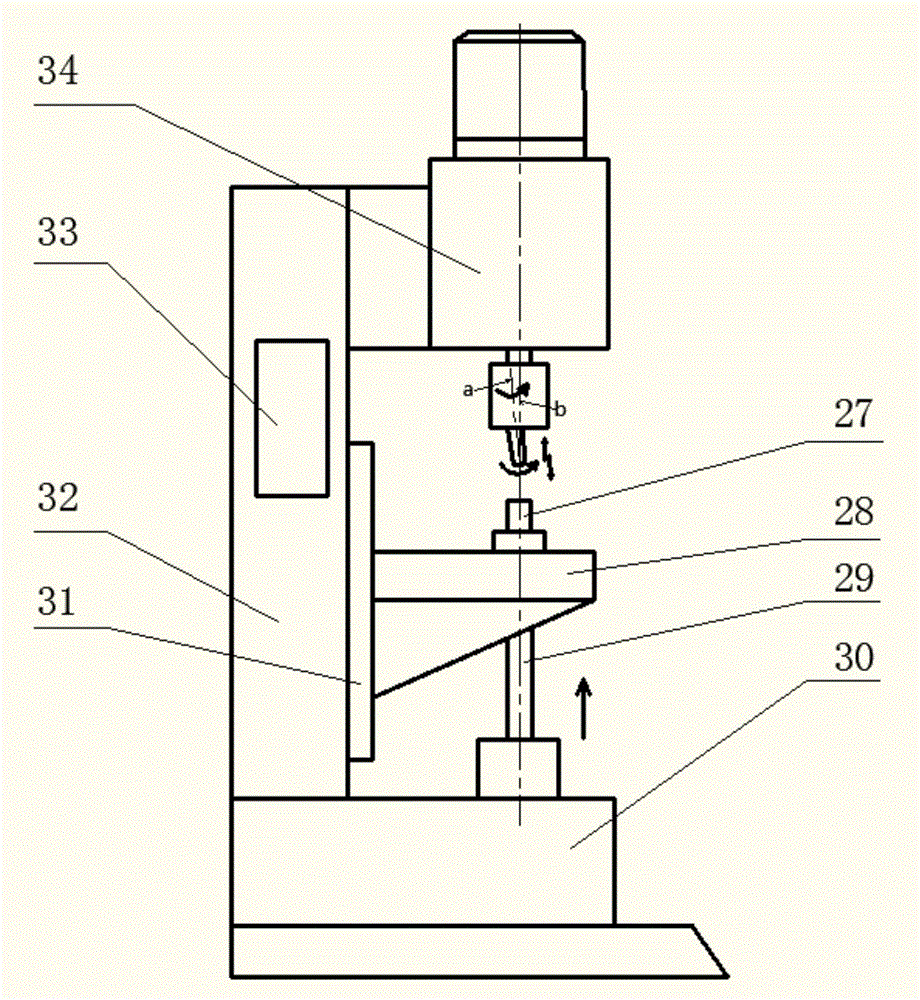

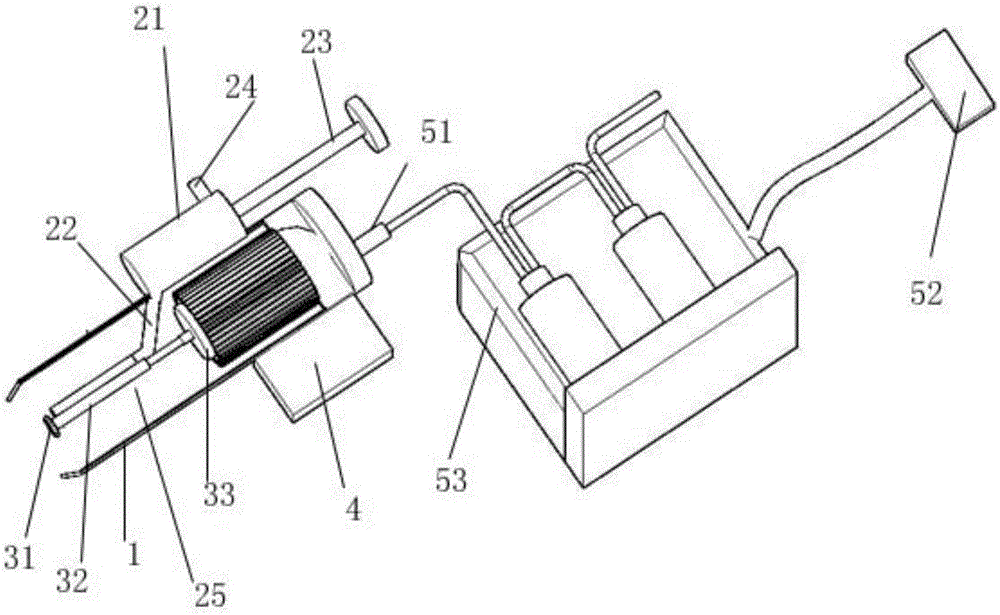

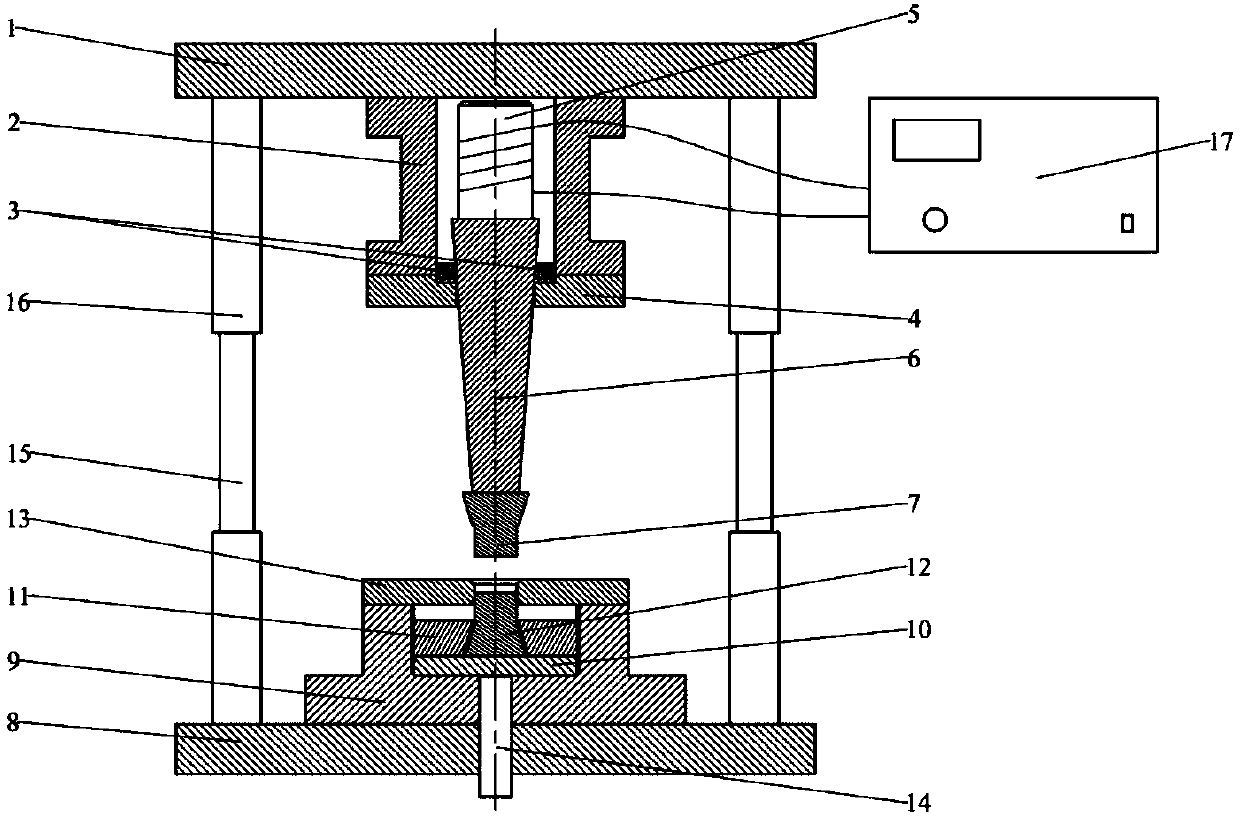

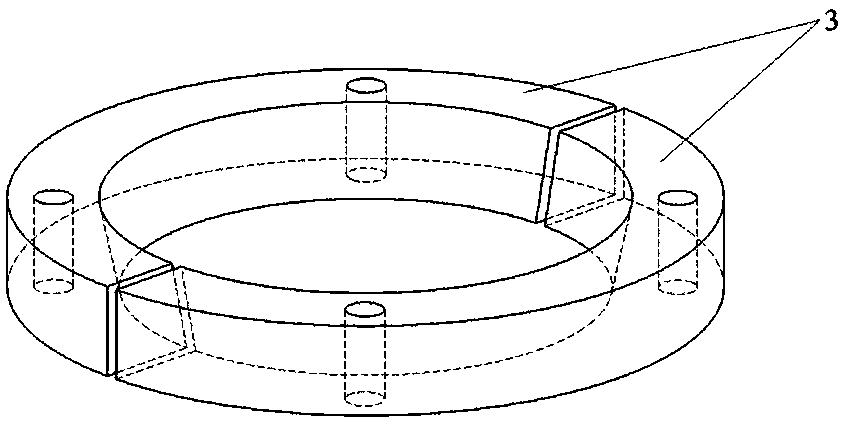

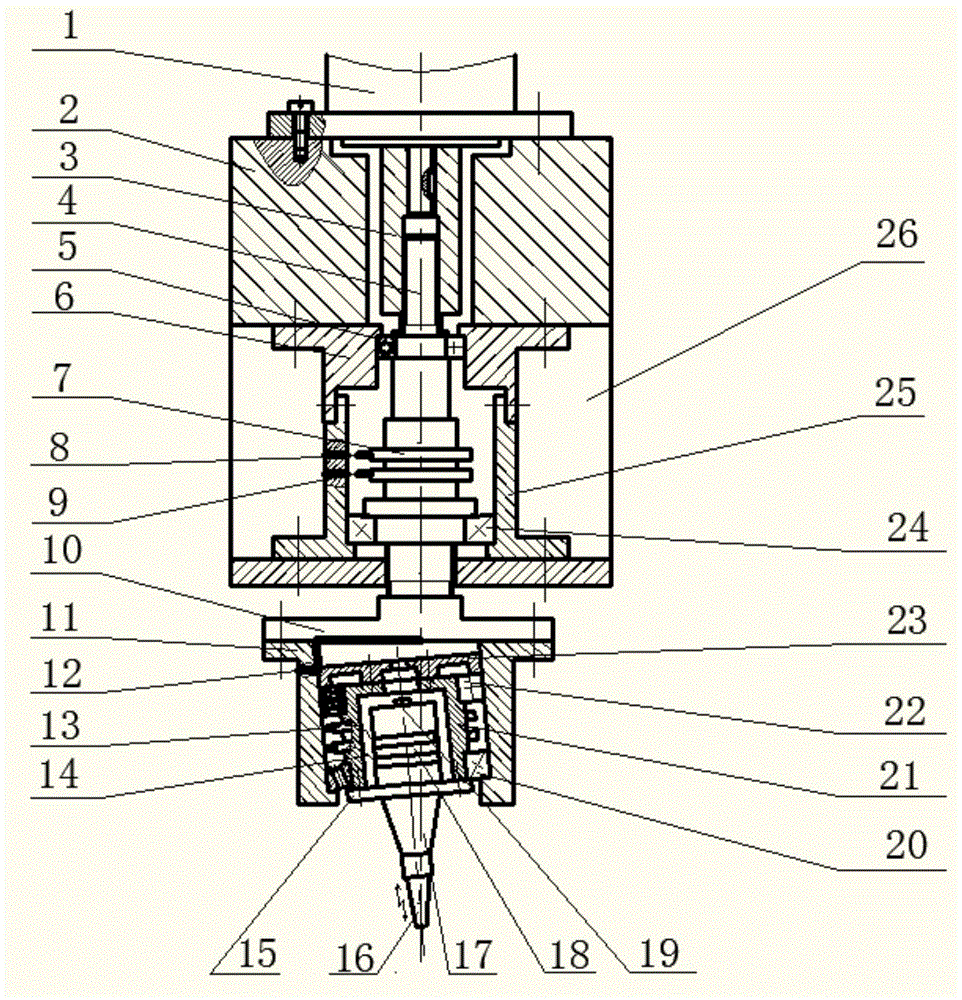

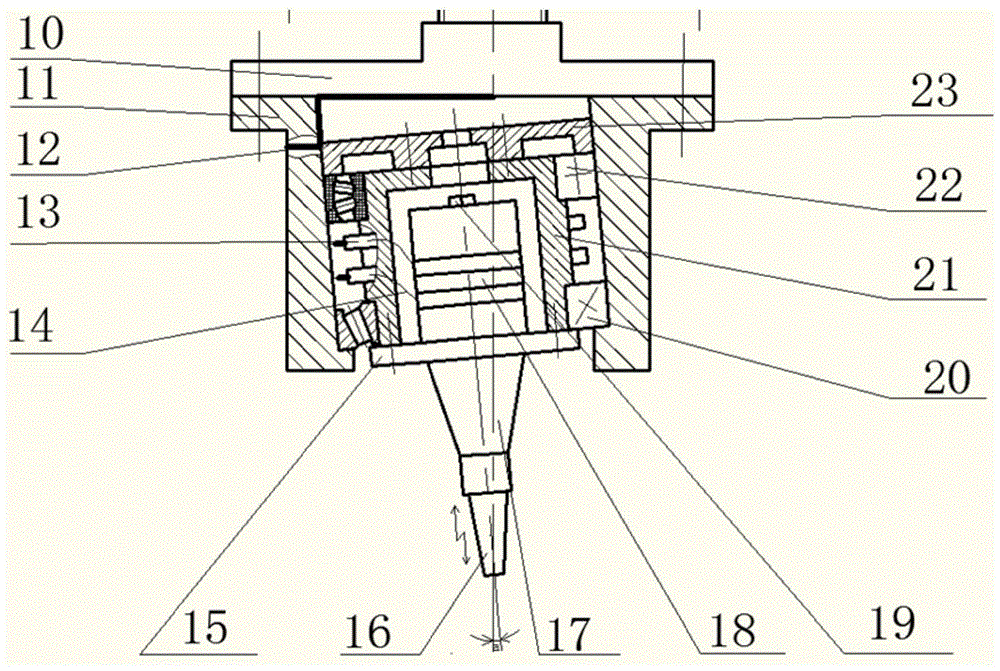

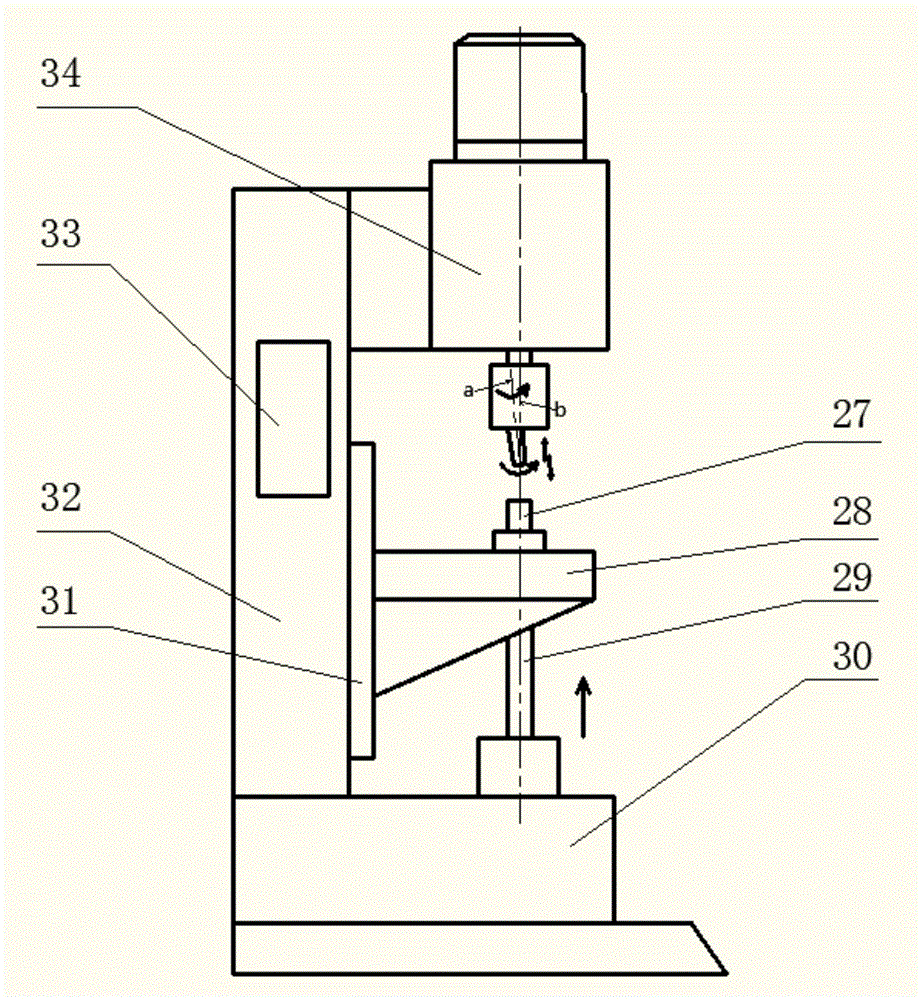

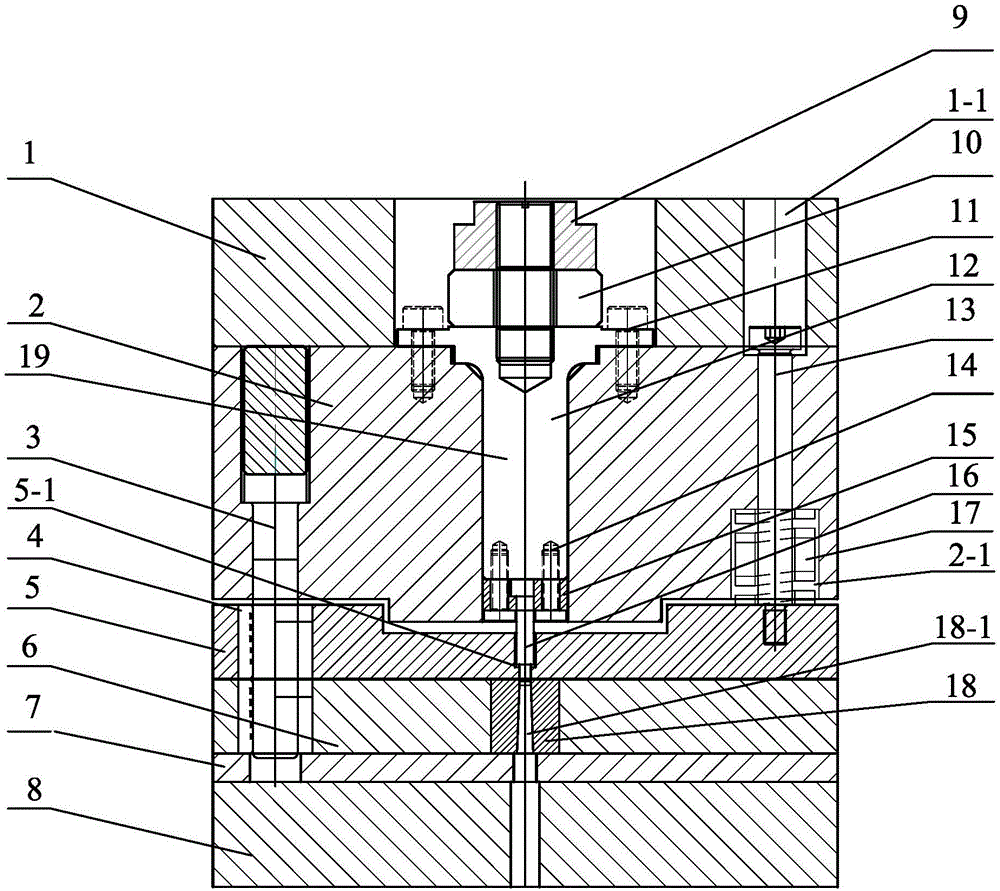

Supersonic vibration spin riveting machine

The invention discloses a supersonic vibration spin riveting machine. The supersonic vibration spin riveting machine comprises an upper riveting head (16) which is connected with an amplitude transformer (17). The supersonic vibration spin riveting machine is characterized in that the amplitude transformer (17) is connected with a high frequency transducer (18), and the high frequency transducer (18) is installed in an inner sleeve (21); the inner sleeve (21) is installed in a cylindrical lower bearing pedestal (11) and connected with a connecting end base (10), the connecting end base (10) is connected with the lower end of a main shaft (4), and the upper end of the main shaft (4) is connected with a motor (1); a first electricity collecting ring (7) is installed in the middle of the main shaft (4) and connected with a first wire (9) and an outer guide line through a carbon brush (8) and transmits high frequency electrical signals obtained from an ultrasonic generator; and a second electricity collecting ring (13) transmits the high frequency electrical signals of the first electricity collecting ring (7) to the transducer (18) through a second wire (12), so that the transducer (18) generates high frequency mechanical vibration to drive the amplitude transformer (17) to do high-frequency vibration. By means of the supersonic vibration spin riveting machine, the riveting force can be reduced, and the riveting efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

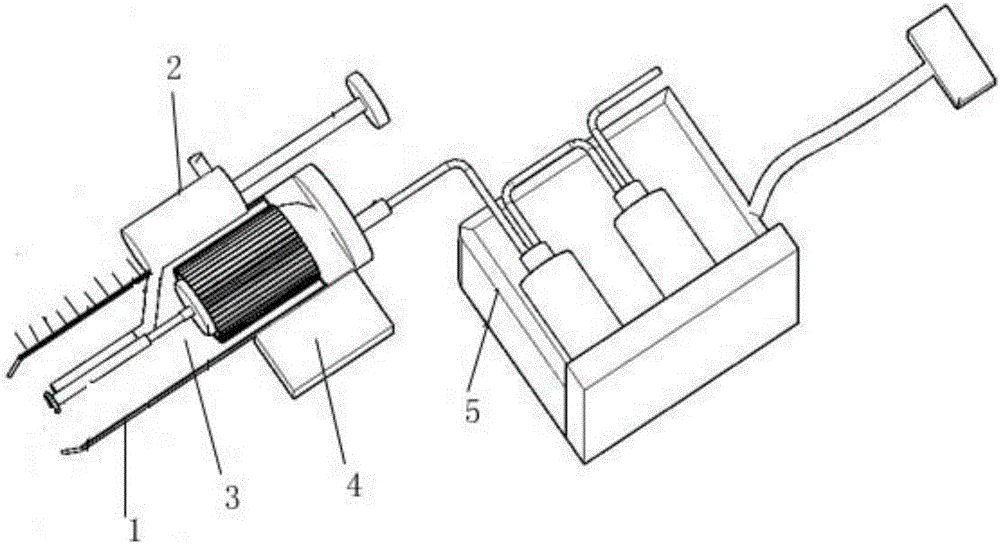

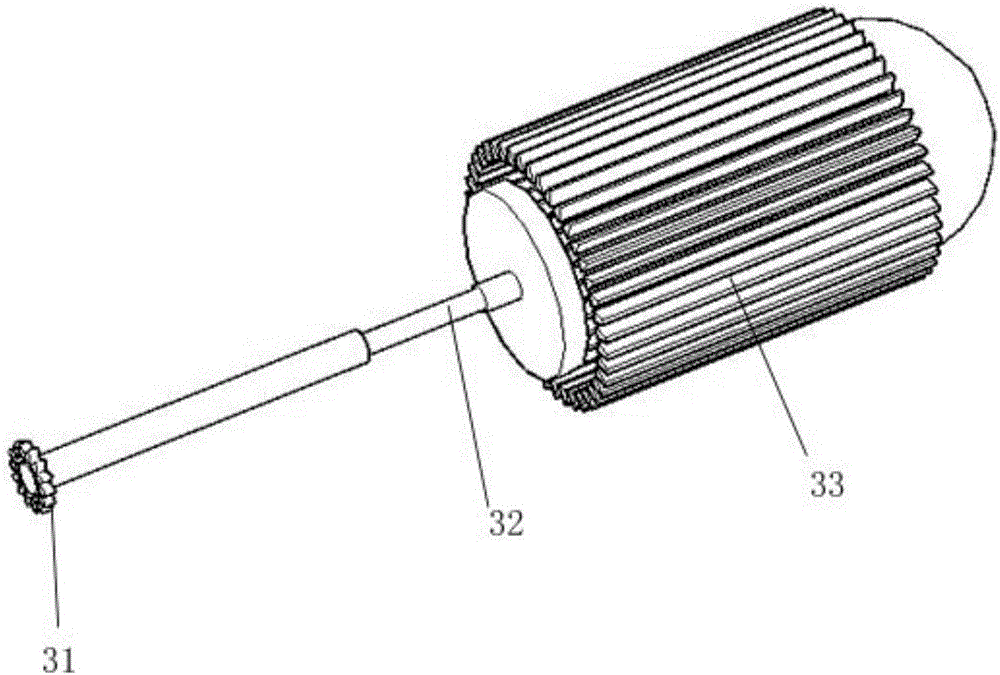

Excrement absorber

The invention relates to an excrement absorber. The excrement absorber comprises a cannula body, an injection device, a crushing device, a storage device and a negative pressure device, wherein the other end of the cannula body is connected with the injection device, and the injection device comprises a casing, a delivery pipe and a push rod; the delivery pipe is connected to one end of the casing, and the storage device is located on the lower edge of one end of the cannula body; the crushing device comprises a crushing head, a rotating shaft and a motor; the rotating shaft penetrates through an auxiliary passage of the delivery pipe; one end of the rotating shaft is connected with the crushing head and the other end of the rotating shaft is connected with the motor; the negative pressure device comprises a connecting pipe, a filter net and a vacuum extractor. The excrement absorber has the advantages as follows: excrement can be softened, the insertion position is controllable, the excrement can be crushed, softened and tiny excrement pieces can be sucked out, so that the smooth excrement dredging effect can be realized, the excrement absorber is simple and convenient to operate, can relieve pain of a patient, becomes a special medical apparatus product for constipation and has wide application prospects in clinical popularization and use.

Owner:太仓市中医医院

Mildew-proof and mothproof treating fluid for treating willow rattans

ActiveCN104354202AExtended use timeHas a softening effectWood treatment detailsReed/straw treatmentSodium bicarbonateToxic material

The invention provides mildew-proof and mothproof treating fluid for treating willow rattans, and relates to the technical field of production of wicker products. The treating fluid is prepared from the following components in parts by weight: 5 to 9 parts of table vinegar, 3 to 7 parts of alcohol, 3 to 7 parts of potassium alum, 1 to 5 parts of lysimachia foenum-graecum hance, 4 to 8 parts of babysbreath, 1 to 5 parts of fineleaf schizonepeta herb, 1 to 3 parts of Chinese parsnip root, 1 to 5 parts of sodium bicarbonate, 2 to 6 parts of sodium silicate, 3 to 7 parts of radix isatidis, 4 to 8 parts of honeysuckles, 1 to 5 parts of tabasheer, 1 to 3 parts of borax, 1 to 13 parts of cassia twig, 2 to 6 parts of sandalwood, 3 to 7 parts of as arum sieboldii, 6 to 12 parts of Chinese honeylocust fruits, 2 to 4 parts of wild peppers, 3 to 7 parts of kadsura root-bark, 5 to 11 parts of semen perillae acutae, 2 to 6 parts of aconitum carmichaelii, 5 to 11 parts of pepperweed seeds, 1 to 3 parts of radix euphorbiae lantu, 2 to 8 parts of radix stemonae, 5 to 9 parts of evodia rutaecarpa, 5 to 11 parts of pyrethrum and 2 to 4 parts of rehmannia glutinosa. According to the mildew-proof and mothproof treating fluid, the release of toxic substances is avoided in a using process, good mildew-proof and mothproof effects are achieved, the service life of a wicker product is greatly prolonged, mildew and moth can be prevented for more than 5 years, and the wicker product can also be kept fragrant, and has side effects on a human body; the mildew-proof and mothproof treating fluid also has a softening effect on willow rattans, and is favorable for weaving.

Owner:GP TOPARTS MFR ANHUI

Softening steam for treating wicker

InactiveCN104441157ASimple processing methodImprove effective utilizationBiocidePest repellentsAdditive ingredientHouttuynia

The invention provides softening steam for treating wicker and relates to the technical field of production of wicker-woven products. The softening steam is prepared through cooking the following raw material ingredients in parts by weight with water: 2-4 parts of alcohol, 3-7 parts of toilet water, 4-8 parts of boric acid, 1-3 parts of datura flower, 2-4 parts of lavandula angustifolia, 2-4 parts of cassia twig, 1-3 parts of dahurian rhododendron leaf, 3-5 parts of cordate houttuynia, 2-4 parts of jasmine flower, 4-8 parts of gardenia flower and 5-8 parts of Chinese honeylocust fruit. According to a treatment method, living wicker is treated firstly, the method is simple, insect proofing, moth proofing and mildew and rot proofing effects on the wicker are achieved, and the service lives of the wicker-woven products can be prolonged; the prepared softening steam plays a role in softening the wicker, and volatile substances contained in the steam can also be used for sterilizing and flavoring the wicker.

Owner:ANHUI HONGFU CRAFTS

Full fly ash building brick and its manufacturing method and special additive

A flyash brick for building is prepared from the flyash (90-96 wt.%) and the composite additive (4-10 wt%) containing water glass, alkaline oxide or the alkaline compounds, bentone, and iron oxide. Its advantages are high strength and low cost.

Owner:山西民兴实业有限公司

Walnut seedling culture method

InactiveCN105165355AImprove the environmentHigh organic contentSeed and root treatmentCultivating equipmentsDiseaseSoil treatment

The invention discloses a walnut seedling culture method which comprises the following steps: (1) seed collection, (2) seed storage, (3) soil treatment, (4) seed treatment, (5) sowing and (6) seedling management. Seedlings cultivated through the method not only are high in survival rate, but also are high in stress resistance, the pest and disease incidence is obviously lowered, the seedlings grow well, the root system is robust, branches and leaves are luxuriant, and the seedlings have high market competitiveness.

Owner:全椒县大地种植专业合作社

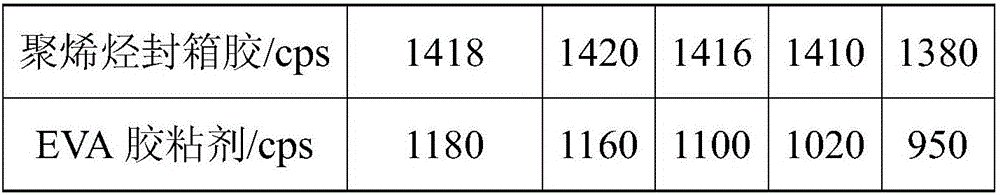

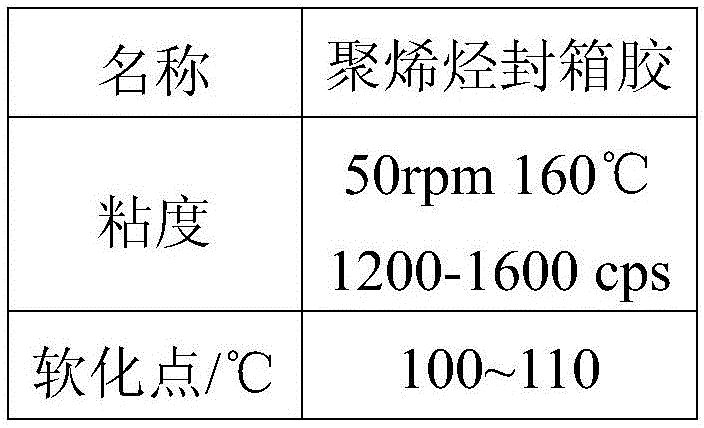

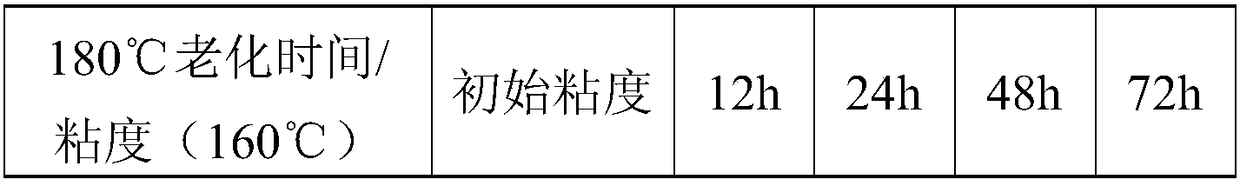

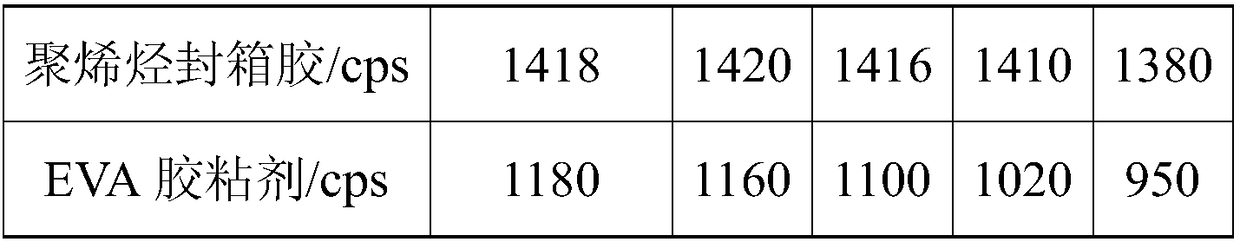

Polyolefin box sealing glue and preparation method thereof

ActiveCN106244049AGood polymer compatibilityPrevent agingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWaxPolyolefin

The invention discloses polyolefin box sealing glue and a preparation method thereof. The polyolefin box sealing glue is prepared from the following raw materials in percentage by weight: 30 to 50 percent of polyolefin plastic bodies, 15 to 25 percent of wax, 10 to 20 percent of petroleum resin, 20 to 30 percent of tackifying resin and 0 to 1.0 percent of antioxidants. The preparation method of the polyolefin box sealing glue concretely comprises the following steps that 1, a stirring container is heated; wax is fed into a stirring container; stirring is started; 2, the polyolefin plastic bodies, partial petroleum resin and partial tackifying resin are added into the stirring container to be stirred; 3, vacuum pumping is performed; 4, the rest petroleum resin and the rest tackifying resin are fed for heating; 5, the materials in the stirring container are subjected to temperature reduction and are discharged; 6, all basic indexes of the product are detected. The polyolefin box sealing glue and the preparation method of the polyolefin box sealing glue provided by the invention have the advantages that the polyolefin box sealing glue has good thermal stability effect and strong thermal viscous force; the curing time is extremely short; the requirements of a fast production line can be met.

Owner:VALENCE BONDING TECH SHANGHAI CO LTD

Treatment liquid for treating wicker

InactiveCN104441126AThe processing method is simpleExtended service lifeBiocidePest repellentsDandelionLigusticum chuanxiong

The invention provides treatment liquid for treating wicker and relates to the technical field of production of wicker-woven products. The treatment liquid is prepared from the following raw material ingredients in parts by weight: 3 parts of radix semiaquilegiae, 2 parts of herba violae, 1 part of basil, 2 parts of flos chrysanthemi indici, 3 parts of dandelion, 2 parts of selfheal spike, 3 parts of sandalwood, 4 parts of asarum, 3 parts of purslane, 2 parts of emblic leafflower fruit, 2 parts of chaenomeles lagenaria, 4 parts of seaweed, 5 parts of Chinese honeylocust fruit, 3 parts of alum, 2 parts of compound of glauber-salt and liquorice, 1 part of tabasheer, 2 parts of forsythia fruit, 3 parts of herba andrographitis, 3 parts of rabdosia rubescens, 5 parts of gardenia, 2 parts of radix clematidis, 1 part of radix stemonae, 2 parts of gentian, 1 part of Chuanxiong rhizome and 3 parts of tree peony bark. The treatment liquid is aqueous extract medicated liquid of traditional Chinese medicine compositions, wherein 10kg of aqueous extract medicated liquid is prepared from 1 kg of traditional Chinese medicine compositions. According to a treatment method, living wicker is treated firstly, the method is simple, insect proofing, moth proofing and mildew and rot proofing effects on the wicker are achieved, and the service lives of the wicker-woven products can be prolonged; prepared softening steam plays a role in softening the wicker, and volatile substances contained in the steam can also be used for sterilizing and flavoring the wicker.

Owner:ANHUI HONGFU CRAFTS

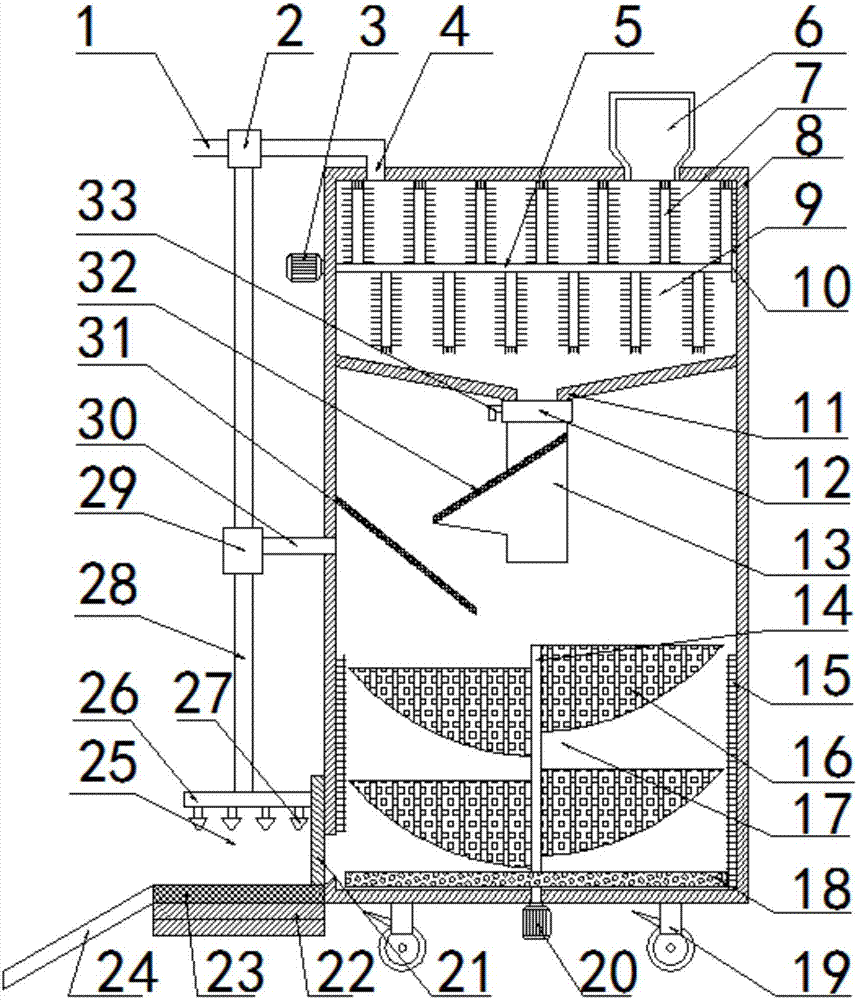

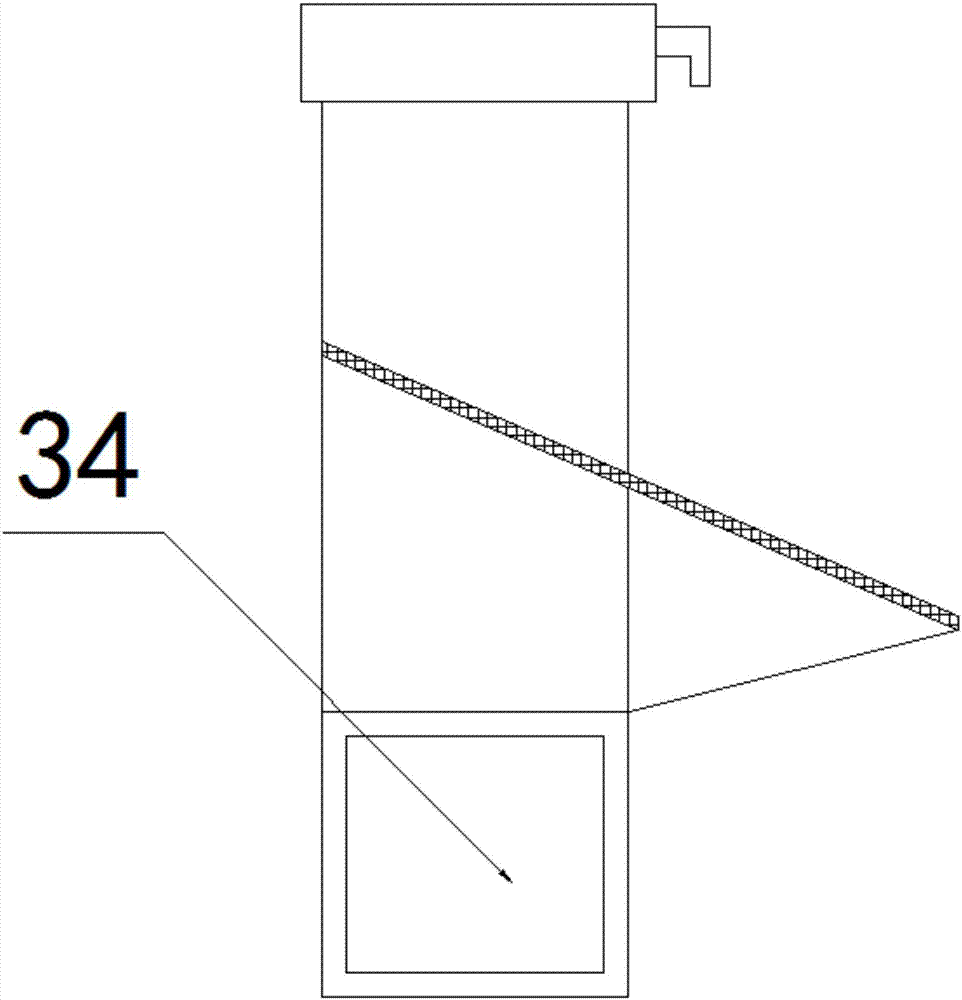

Efficient full-automatic taro cleaning machine

The invention discloses a high-efficiency fully automatic taro cleaning machine, which comprises a shell, a feeding device, a first stirring device, a separation pipe, a second stirring device, a high-pressure spray device, a second retaining net, a first retaining net and a ten thousand to the wheel; the first stirring device is arranged on the upper part of the shell; the device of the present invention is provided with the first stirring device, which has the effect of softening the soil on the surface of the taro, and simultaneously utilizes the stirring device to speed up the softening speed, and utilizes the belt The setting of the bristle stirring rod has the function of cleaning the softened taro; through the setting of the separation pipe and the first screen, it has the function of separating the taro and sewage; through the rotating disk with burrs in the second stirring device and arc The setting of stirring and cleaning blades can molt the place where the taro is in contact with the device; through the setting of the high-pressure nozzle in the high-pressure spraying device, the function of using high-pressure water to clean the taro at the end and remove the sundries attached to the surface of the taro .

Owner:HUIAN HUACHEN TRADE CO LTD

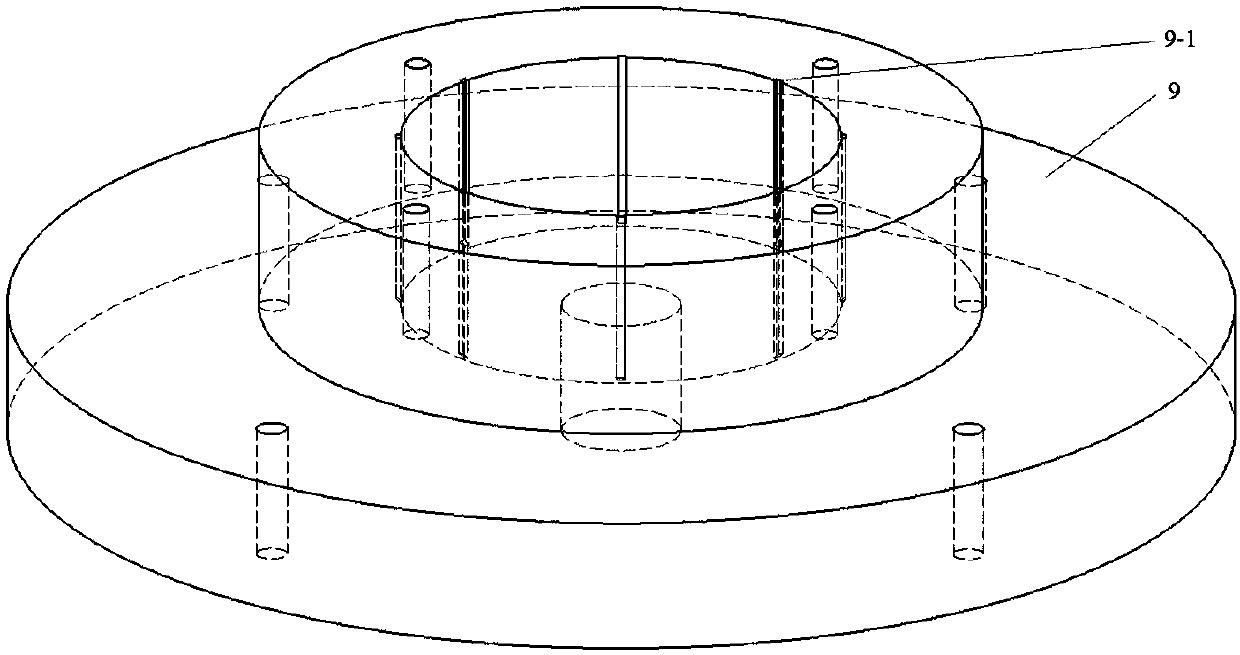

Supersonic vibration-assisted metal coin stamp embossing formation device and method

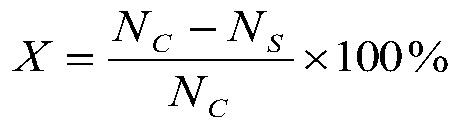

PendingCN107856427AHas a softening effectReduce deformation resistanceMechanical vibrations separationStampingManufacturing technologyTransformer

The invention belongs to the technical field of coin stamp manufacturing, and discloses a coin stamp embossing formation device and method. The device comprises a lower die, an upper die, a guide mechanism, an ultrasonic amplitude transformer, an ultrasonic transducer and an ultrasonic generator. The lower die comprises a lower die holder, a lower die plate, a backing plate, a lower coining die, amiddle ring and an ejector rod. The upper die comprises an upper die holder, a connecting sleeve, an upper die fixing plate and an upper coining die. The method includes the following steps that (1)a metal billet cake is put onto the lower coining die; (2) the ultrasonic transducer and the ultrasonic generator are connected through an electric wire, the vibrational frequency is set and the ultrasonic generator is started; (3) the upper coining die is driven by a coining forming machine to move downwards, and the billet cake is deformed; and (4) after the upper coining die moves downwards toa set position, coin stamp forming is completed; and then the upper coining die is driven by the coining forming machine to move upwards, and the ejector rod moves upwards to push out a coin stamp. The coin stamp fully filled can be obtained under the action of low embossing force, and meanwhile the service life of the coining dies is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

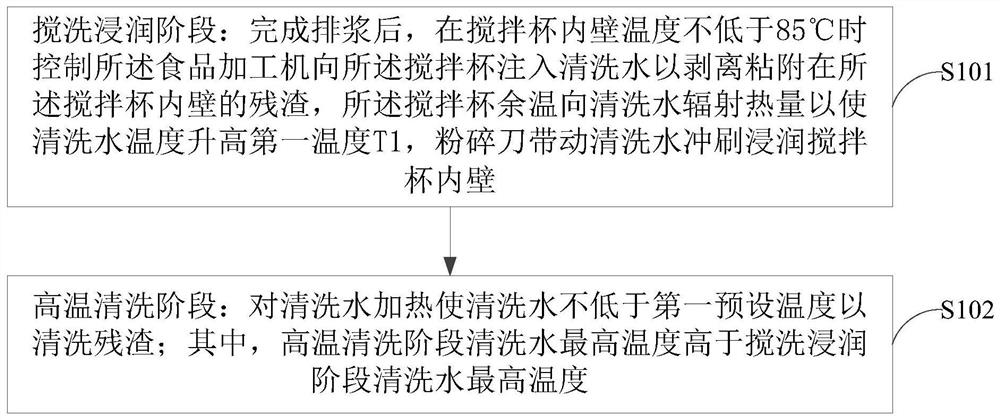

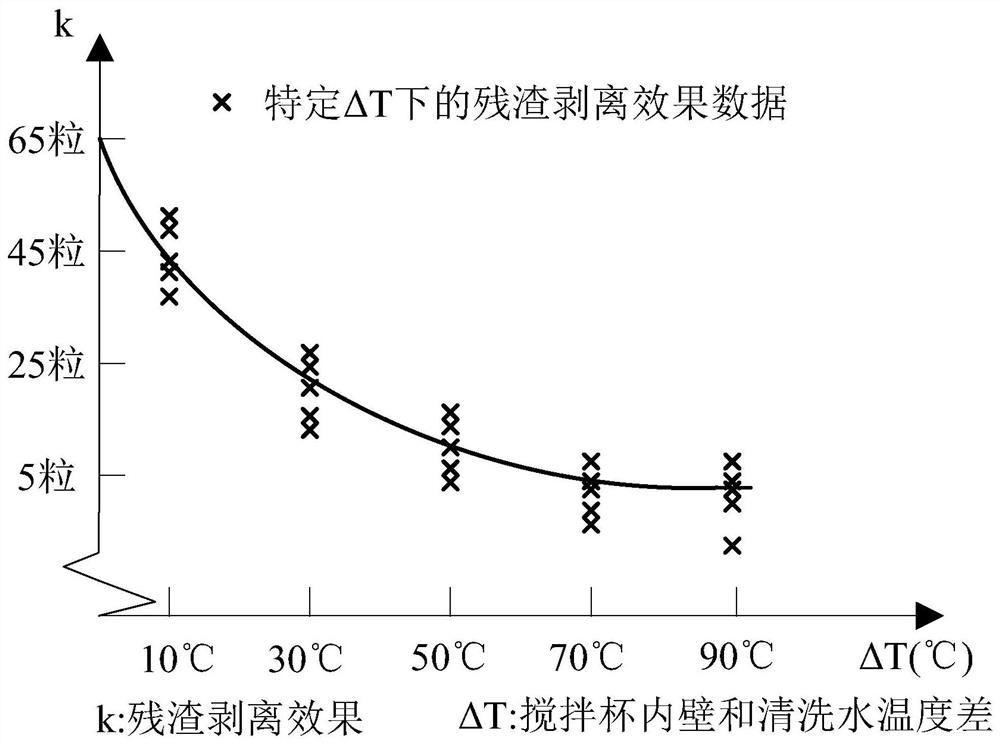

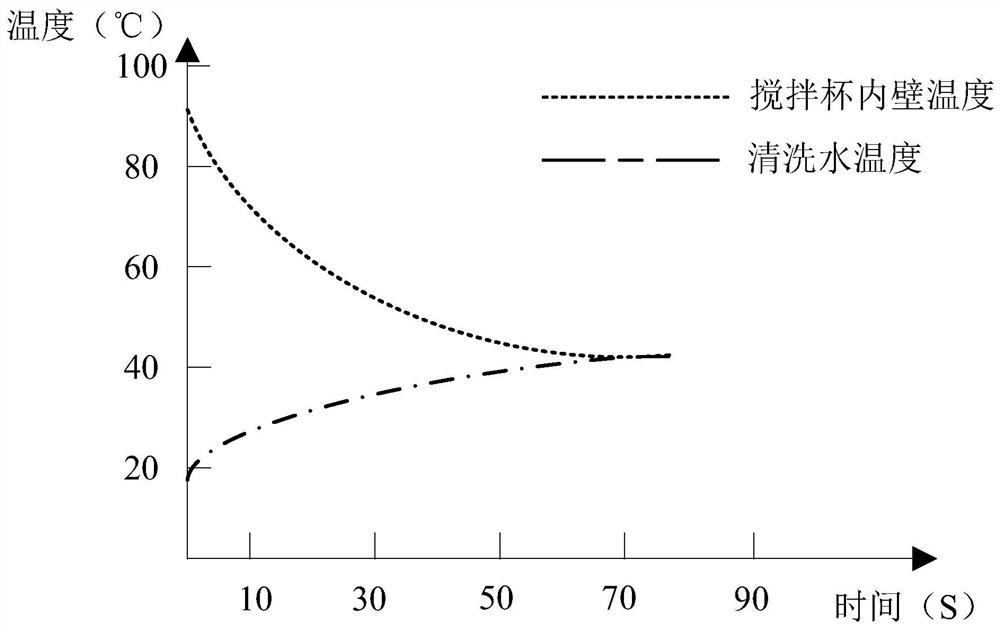

Self-cleaning method of food processor and food processor

PendingCN111802933AReduce impactPromote softeningKitchen equipmentElectric machineryProcess engineering

The invention provides a self-cleaning method of a food processor and the food processor. The food processor comprises a machine body, a stirring cup and a motor arranged on the machine body, the stirring cup comprises a cup body, a cup cover and a crushing knife driven by a motor, the self-cleaning method comprises the following steps: a stirring, washing and infiltrating stage: injecting cleaning water into a stirring cup to peel off residues adhered to the inner wall of the stirring cup when the temperature of the inner wall of the stirring cup is not lower than 85 DEG C after slurry discharge is completed, radiating heat to the cleaning water by the residual heat of the stirring cup to increase the temperature of the cleaning water by a first temperature, and driving the cleaning waterto wash and infiltrate the stirring cup, and a high-temperature cleaning stage: heating the cleaning water to enable the cleaning water to be not lower than a first preset temperature so as to cleanresidues. The highest temperature of cleaning water in the high-temperature cleaning stage is higher than that of cleaning water in the stirring-washing infiltration stage. According to the method, residues can be easily peeled off from the inner wall of the cup body or the inner wall of the cup cover, and therefore the good cleaning effect is achieved.

Owner:JOYOUNG CO LTD

Edible feed for eels and preparation method of edible feed

The invention discloses an edible feed for eels and a preparation method of the edible food, and belongs to the technical field of fish feeds. The edible feed consists of the following components in parts by weight: 5 to 20 parts of earthworm, 10 to 30 parts of conch meat, 1 to 10 parts of pig lung, 1 to 5 parts of edible salt, 1 to 5 parts of edible sodium bicarbonate, 1 to 5 parts of the vitamin C and 30 to 60 parts of compound feed; the edible feed for the eels is obtained by crushing and mixing the components. By adopting the technology and using the above formula, the raw materials of the formula of the edible feed are stable in source and low in cost; the production process of the edible feed is simple; through the reasonable combination of the components, various components supplement one another in effect and the effect of each component is played better, so that the nutritional value of the edible feed is increased; the edible feed has no toxic or side effects, adverse reaction or bad influences on the palatability of the feed; the eels fed by the feed are fine and tender in meat, high in nutritional value, and popular with consumers.

Owner:ZHEJIANG OCEAN UNIV

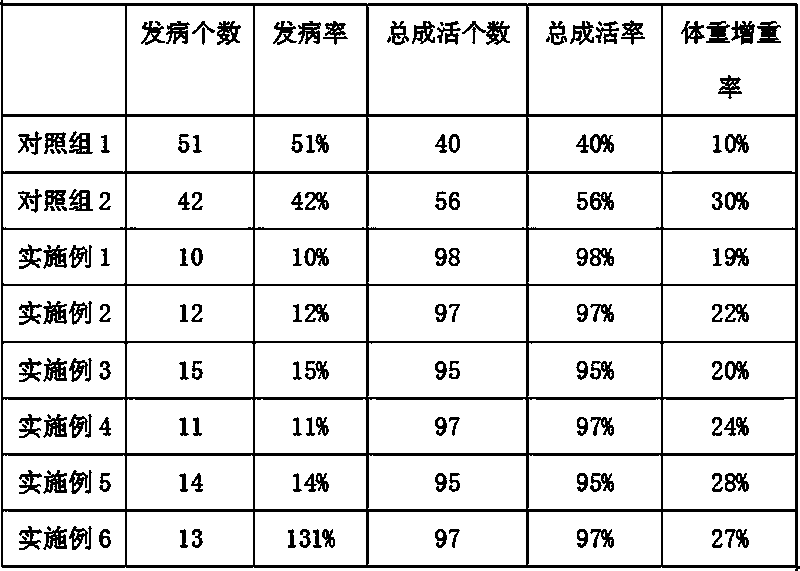

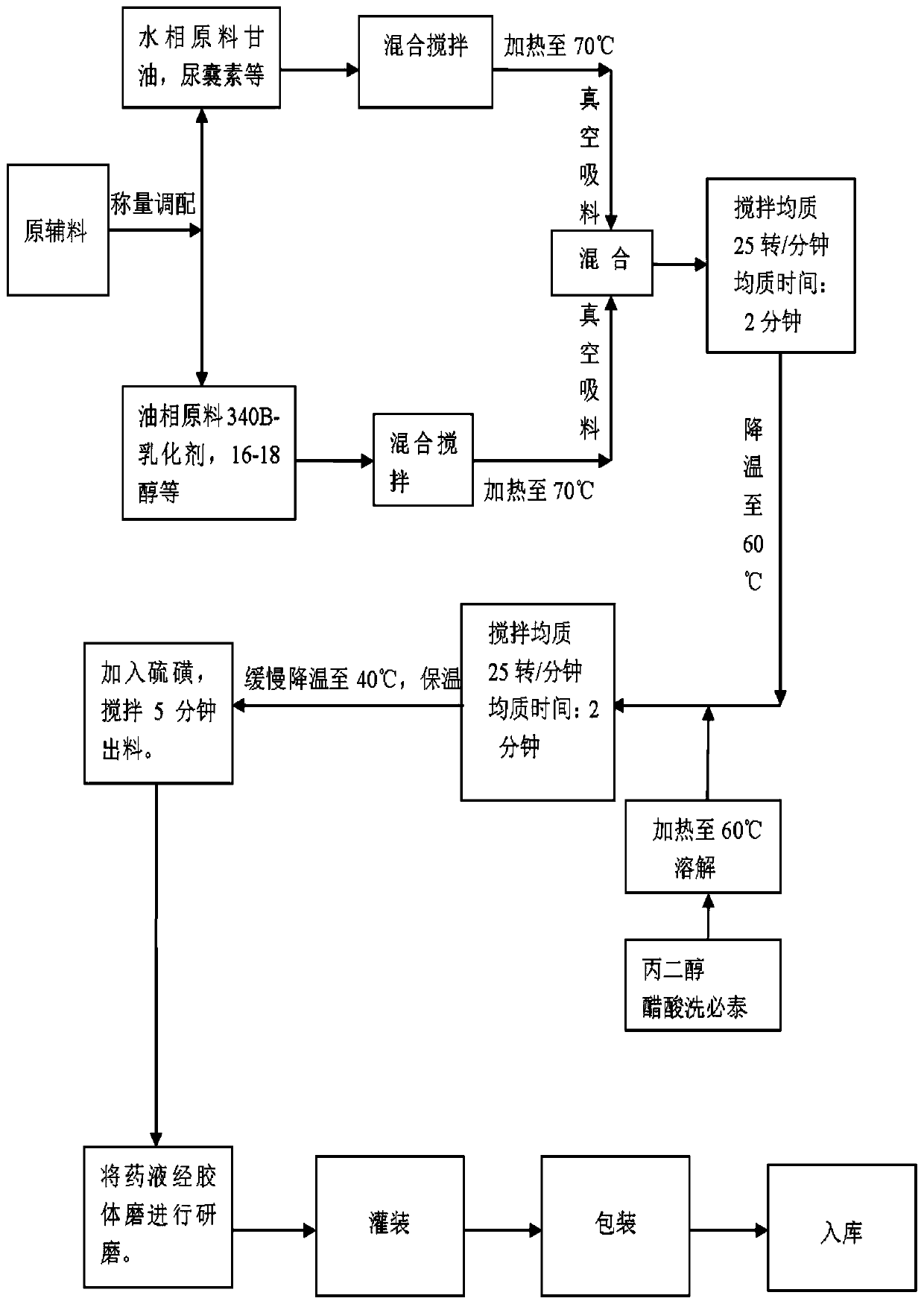

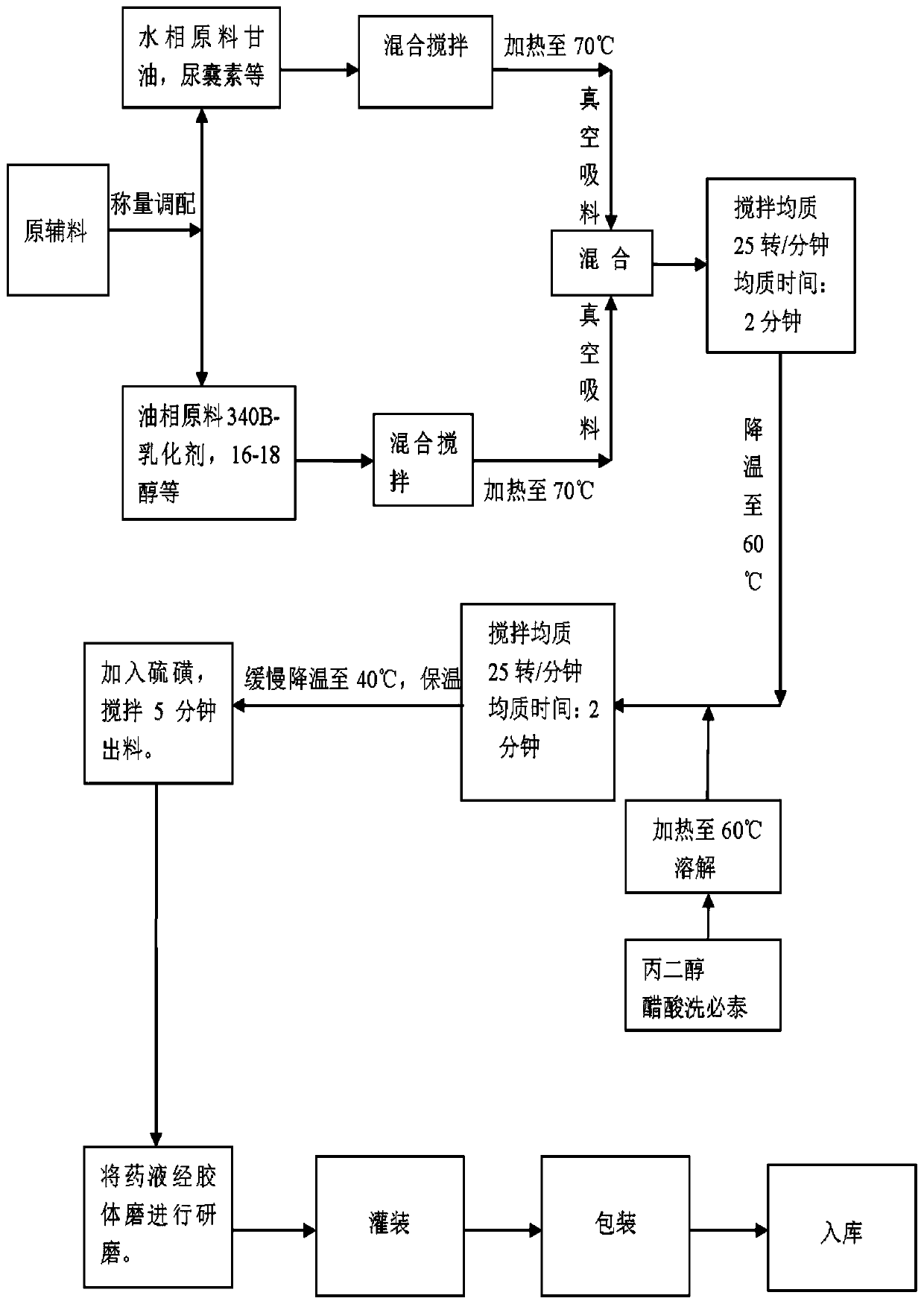

Efficient bacteriostatic drug composition and a preparation method and application thereof

ActiveCN109985063AMoisturizingHas a softening effectAntibacterial agentsOrganic active ingredientsEscherichia coliChlorhexidine Acetate

The invention provides an efficient bacteriostatic drug composition. Three components, namely chlorhexidine acetate, sulfur and allantoin, serve as the active ingredients of the composition, pathogenic bacteria parasitic on the skin can be effectively inhibited through the synergistic effects of the three components, and the composition especially has a significant inhibition effect on staphylococcus aureus, escherichia coli and candida albicans. At the same time, by strictly controlling the process temperature in the preparation process, the composition can effectively ensure the drug activity, give play to the synergistic effects of the components, and enhance the bacteriostatic effect.

Owner:YUAN INT GROUP

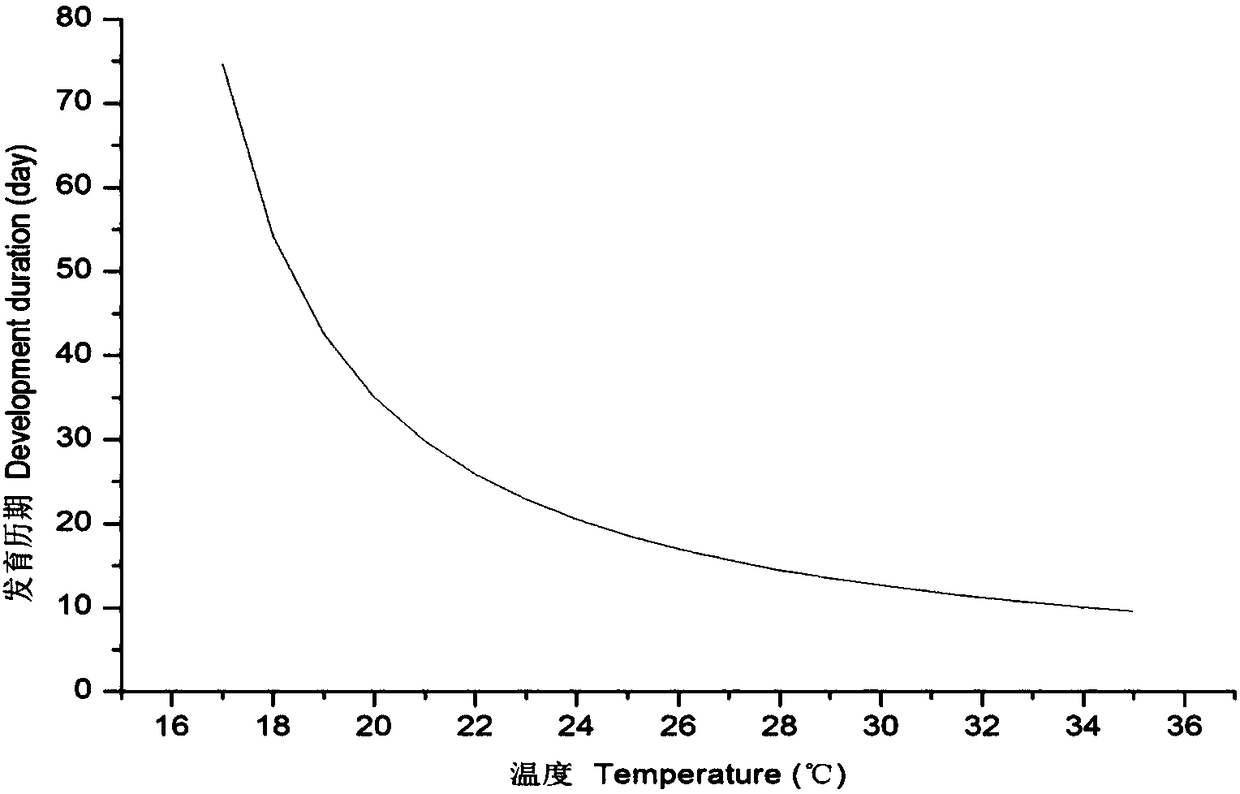

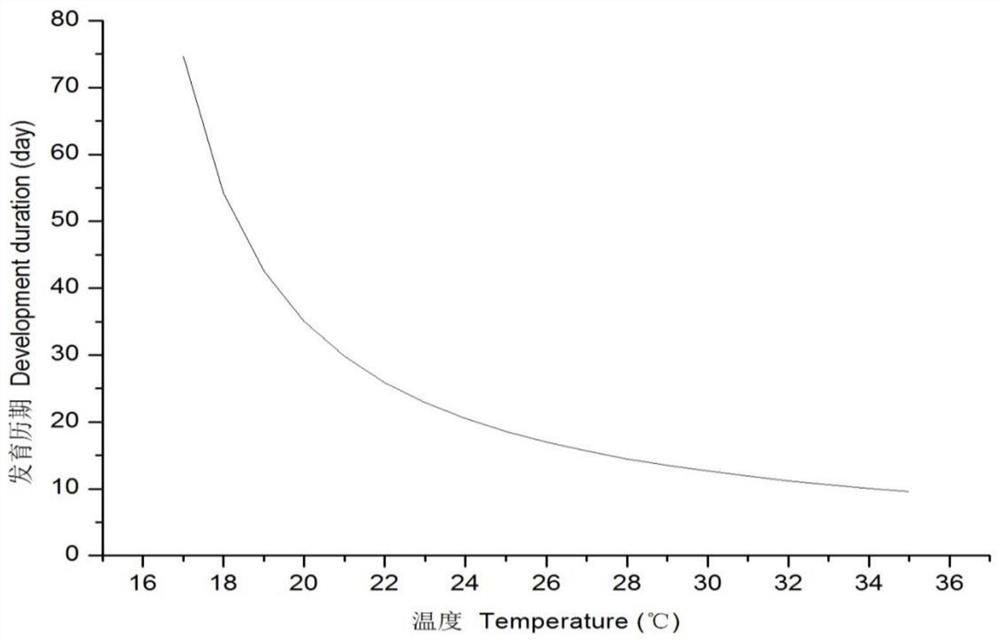

Large-scale propagation method for dioryctria rubellatetrastichus schoenobii ferriere

The invention discloses application of dioryctria rubellatetrastichus schoenobii ferriere cultivation in dioryctria pryeri control, provides a large-scale propagation method for dioryctria rubellatetrastichus schoenobii ferriere, and relates to the technical field of forestry protection. The method aims at applying effective biological control over dioryctria pryeri and other coniferous species seed and branch injurious insects. The propagation method has the steps of 1 bee species collecting and storing and 2 bee species propagation. Hosts are soaked with a hypochlorous acid water solution and are stored in a gradient cooling mode, so that the parasitic ability of the dioryctria rubellatetrastichus schoenobii ferriere is improved.

Owner:JILIN CITY ACADEMY OF FORESTRY +2

Wood leftover recycling method

InactiveCN103722598AHas a softening effectPrevent rotWood treatment detailsWood impregnation detailsRoot causePulp and paper industry

The invention discloses a wood leftover recycling method which makes wood leftovers into an integral wood by the following steps to recycle the leftovers: 1, washing the leftovers clean by clear water; 2, placing the leftovers into crystal soda solution to soak; 3, washing the leftovers clean with the clear water and continuously soaking the leftovers in the clear water; 4, placing the leftovers into the crystal soda solution to soak again; 5, air-drying the leftovers; 6, placing the leftovers into the crystal soda solution to soak for the third time, boiling the crystal soda solution and continuously soaking and boiling the leftovers in the boiling crystal soda solution; 7, placing the leftovers in glue to soak to enable the surfaces of the leftovers to sufficiently adsorb the glue; 8, pressing the leftovers together to form the utilizable integral wood. Compared with the prior art, the wood leftover recycling method can sufficiently utilize the wood leftovers, implements processing recycling of the wood leftovers, is beneficial to ecological protection of valuable or rare woods, meets the market requirements and eliminates the root cause of illegal logging of logs.

Owner:XIANYOU COUNTY JINZHONG MUSICAL INSTR CO LTD

High-pressure-resistant water permeable brick and making method thereof

The invention discloses a high-pressure-resistant water permeable brick and a making method thereof. The water permeable brick comprises the following components in parts by weight: 80-120 parts of construction wastes, 40-50 parts of scrap steel bars, 20-40 parts of waste mineral slag, 4-10 parts of reinforced fibers, 3-9 parts of iron oxide black, 4-12 parts of oyster shell powder and 8-12 partsof a water purification material. The reinforced fibers are added into the water permeable brick, and the reinforced fibers are prepared by mixing multiple fibers, so that growth of micro-cracks and formation of macro-cracks of a water permeable plate substrate under a pressure effect can be effectively hindered, the anti-deforming capability of the water permeable brick is enhanced, and the service life of the water permeable brick is prolonged. In addition, the water purification material added into the water permeable brick is environment-friendly and pollution-free and is capable of filtering, adsorbing and degerming water. The water permeable brick prepared in the invention is high in permeable rate and long in service life and has a water purification effect.

Owner:柳州柳晶环保科技有限公司

A kind of sterilization treatment method of rattan weaving raw material

InactiveCN104476639BSimple processing methodInsect-resistantBiocideWood treatment detailsMildewSoftening

Owner:ANHUI HONGFU CRAFTS

Cleaning tablet and preparation process thereof

InactiveCN111548870ADisintegrates quicklyEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsLaundry washing machineAdhesive

The invention relates to the technical field of detergents, and discloses a cleaning tablet. The cleaning tablet is prepared from the following raw materials in parts by weight: 20 to 50 parts of sodium percarbonate, 2 to 10 parts of tetra-acetyl ethylene diamine, 0 to 2 parts of sodium linear alkyl benzene sulfonate, 0 to 2 parts of fatty alcohol polyoxyethylene ether, 20 to 40 parts of sodium carbonate and 2 to 10 parts of an adhesive. The cleaning tablet can be quickly disintegrated after being in contact with water, small particles are formed, the contact area with the water is increased,and finally, the cleaning effect of the cleaning tablet on a washing machine tank is enhanced.

Owner:浙江美生日化用品有限公司

Ultrasonic vibration riveting machine

The invention discloses a supersonic vibration spin riveting machine. The supersonic vibration spin riveting machine comprises an upper riveting head (16) which is connected with an amplitude transformer (17). The supersonic vibration spin riveting machine is characterized in that the amplitude transformer (17) is connected with a high frequency transducer (18), and the high frequency transducer (18) is installed in an inner sleeve (21); the inner sleeve (21) is installed in a cylindrical lower bearing pedestal (11) and connected with a connecting end base (10), the connecting end base (10) is connected with the lower end of a main shaft (4), and the upper end of the main shaft (4) is connected with a motor (1); a first electricity collecting ring (7) is installed in the middle of the main shaft (4) and connected with a first wire (9) and an outer guide line through a carbon brush (8) and transmits high frequency electrical signals obtained from an ultrasonic generator; and a second electricity collecting ring (13) transmits the high frequency electrical signals of the first electricity collecting ring (7) to the transducer (18) through a second wire (12), so that the transducer (18) generates high frequency mechanical vibration to drive the amplitude transformer (17) to do high-frequency vibration. By means of the supersonic vibration spin riveting machine, the riveting force can be reduced, and the riveting efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of polyolefin sealing glue and preparation method thereof

ActiveCN106244049BHigh viscosityPrevent agingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesVacuum pumpingProduction line

The invention discloses polyolefin box sealing glue and a preparation method thereof. The polyolefin box sealing glue is prepared from the following raw materials in percentage by weight: 30 to 50 percent of polyolefin plastic bodies, 15 to 25 percent of wax, 10 to 20 percent of petroleum resin, 20 to 30 percent of tackifying resin and 0 to 1.0 percent of antioxidants. The preparation method of the polyolefin box sealing glue concretely comprises the following steps that 1, a stirring container is heated; wax is fed into a stirring container; stirring is started; 2, the polyolefin plastic bodies, partial petroleum resin and partial tackifying resin are added into the stirring container to be stirred; 3, vacuum pumping is performed; 4, the rest petroleum resin and the rest tackifying resin are fed for heating; 5, the materials in the stirring container are subjected to temperature reduction and are discharged; 6, all basic indexes of the product are detected. The polyolefin box sealing glue and the preparation method of the polyolefin box sealing glue provided by the invention have the advantages that the polyolefin box sealing glue has good thermal stability effect and strong thermal viscous force; the curing time is extremely short; the requirements of a fast production line can be met.

Owner:VALENCE BONDING TECH SHANGHAI CO LTD

A kind of large-scale propagation method of the red pine leaf spot borer biting wasp

The invention discloses an application of cultivating the red pine moth wasp in the prevention and treatment of the red pine moth, and provides a method for large-scale propagation of the red pine leaf red bee, which relates to the technical field of forestry protection; the purpose is To carry out effective biological control of fruit spot borer and other coniferous tree seeds and branch pests, the propagation method is as follows: step 1, collection and preservation of bee species; step 2, reproduction of bee species; soaking the host in hypochlorous acid aqueous solution , and gradient cooling preservation improved the parasitic ability of the red pine moth.

Owner:JILIN CITY ACADEMY OF FORESTRY +2

A mildew-proof and moth-proof treatment liquid for treating willow rattan

ActiveCN104354202BExtended use timeHas a softening effectWood treatment detailsReed/straw treatmentSodium bicarbonateSide effect

The invention provides mildew-proof and mothproof treating fluid for treating willow rattans, and relates to the technical field of production of wicker products. The treating fluid is prepared from the following components in parts by weight: 5 to 9 parts of table vinegar, 3 to 7 parts of alcohol, 3 to 7 parts of potassium alum, 1 to 5 parts of lysimachia foenum-graecum hance, 4 to 8 parts of babysbreath, 1 to 5 parts of fineleaf schizonepeta herb, 1 to 3 parts of Chinese parsnip root, 1 to 5 parts of sodium bicarbonate, 2 to 6 parts of sodium silicate, 3 to 7 parts of radix isatidis, 4 to 8 parts of honeysuckles, 1 to 5 parts of tabasheer, 1 to 3 parts of borax, 1 to 13 parts of cassia twig, 2 to 6 parts of sandalwood, 3 to 7 parts of as arum sieboldii, 6 to 12 parts of Chinese honeylocust fruits, 2 to 4 parts of wild peppers, 3 to 7 parts of kadsura root-bark, 5 to 11 parts of semen perillae acutae, 2 to 6 parts of aconitum carmichaelii, 5 to 11 parts of pepperweed seeds, 1 to 3 parts of radix euphorbiae lantu, 2 to 8 parts of radix stemonae, 5 to 9 parts of evodia rutaecarpa, 5 to 11 parts of pyrethrum and 2 to 4 parts of rehmannia glutinosa. According to the mildew-proof and mothproof treating fluid, the release of toxic substances is avoided in a using process, good mildew-proof and mothproof effects are achieved, the service life of a wicker product is greatly prolonged, mildew and moth can be prevented for more than 5 years, and the wicker product can also be kept fragrant, and has side effects on a human body; the mildew-proof and mothproof treating fluid also has a softening effect on willow rattans, and is favorable for weaving.

Owner:GP TOPARTS MFR ANHUI

A kind of wicker raw material processing method

InactiveCN104476638BSimple processing methodImprove effective utilizationWood treatment detailsWood impregnation detailsMildewSoftening

The invention provides a willow-artwork raw material processing method, and relates to the technical field of production of willow-artwork products. The method comprises the concrete steps: firstly picking wicker from willow, aligning heads and aligning tails, and binding 10-20 sticks of wicker to form a bunch; inserting the bound wicker bunch into a processing liquid, enabling wicker tips to be upward, and putting in the sun for 3-6 h; removing leaves of wicker, and using hot wind to baking, concretely, at a first stage, baking wicker to 50% of dryness and using softening steam to perform first moisture retention on wicker for 30-50 min, at a second stage, baking wicker to 60% of dryness and using softening steam to perform second moisture retention on wicker for 1-3 h, and at a third stage, baking wicker to 80% of dryness; and putting wicker in a shading place and naturally airing. Intravital wicker is firstly processed in the processing method, the method is simple, enables wicker to have effects of preventing insects and preventing moth and resisting mildew, and helps to prolong the service life of willow knit products, the prepared softening steam has the effect of softening willow, and volatile substances in the steam also are capable of performing sterilization and fragrance increase on wicker.

Owner:ANHUI HONGFU CRAFTS

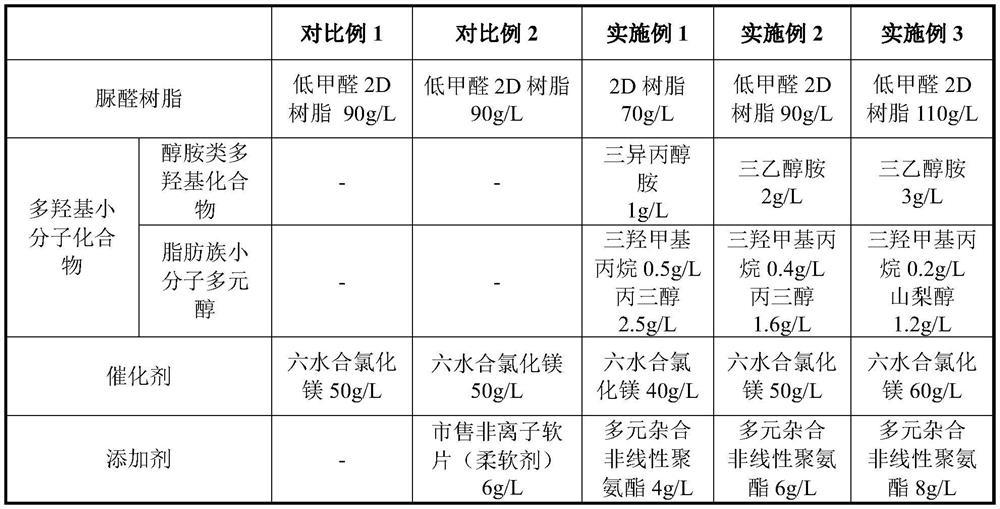

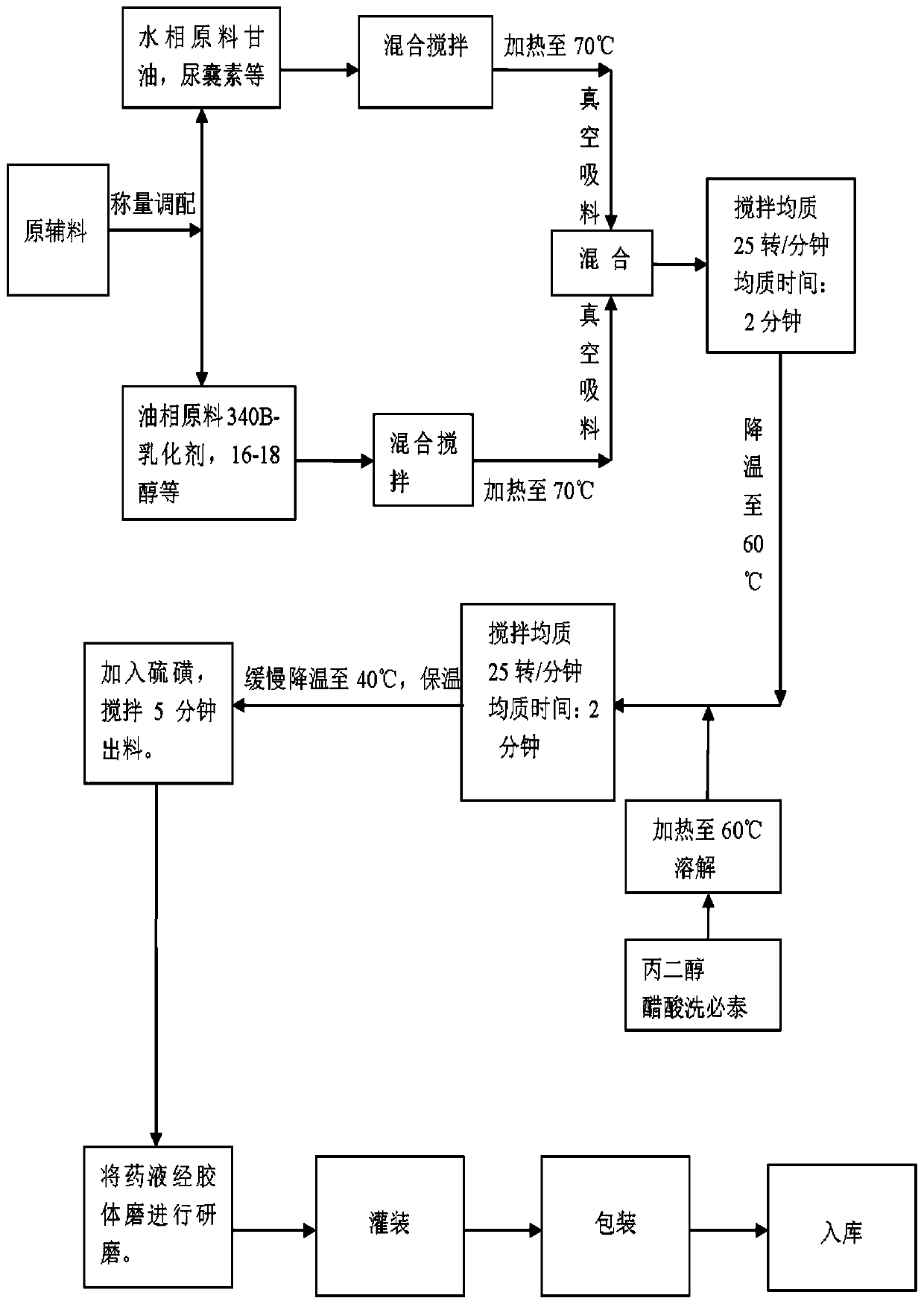

Urea-formaldehyde-resin-based crease-resistant finishing method for high-density and high-count cotton textile

PendingCN114687207AImprove wrinkle resistanceImprove swellingWrinkle resistant fibresGrip property fibresWoven fabricPolymer chemistry

The invention relates to the technical field of crease-resistant finishing of cotton textiles, and discloses a crease-resistant finishing method for high-density and high-count cotton textiles based on urea resin. The method comprises the following steps: (1) primary padding: performing padding treatment on the cotton fabric in an anti-wrinkle finishing bath; (2) pre-drying: carrying out heat treatment on the cotton fabric subjected to primary padding; (3) secondary padding: padding the cotton fabric in a multi-element hybrid nonlinear polyurethane solution; and (4) baking and cropping: carrying out heat treatment on the cotton fabric subjected to secondary padding. According to the crease-resistant urea-formaldehyde resin finishing liquid disclosed by the invention, the polyhydroxy small molecular compound is blended in the crease-resistant urea-formaldehyde resin finishing liquid, and can form a multi-branched net-shaped cross-linked substance with the urea-formaldehyde resin, so that large-size accumulation of the crease-resistant resin in a fiber amorphous region is facilitated, and the crease-resistant capability of a crease-resistant textile is improved.

Owner:WUHAN TEXTILE UNIV +1

A kind of high-efficiency antibacterial pharmaceutical composition and its preparation method and application

ActiveCN109985063BMoisturizingHas a softening effectAntibacterial agentsOrganic active ingredientsBiotechnologyChlorhexidine Acetate

The invention provides an efficient bacteriostatic drug composition. Three components, namely chlorhexidine acetate, sulfur and allantoin, serve as the active ingredients of the composition, pathogenic bacteria parasitic on the skin can be effectively inhibited through the synergistic effects of the three components, and the composition especially has a significant inhibition effect on staphylococcus aureus, escherichia coli and candida albicans. At the same time, by strictly controlling the process temperature in the preparation process, the composition can effectively ensure the drug activity, give play to the synergistic effects of the components, and enhance the bacteriostatic effect.

Owner:YUAN INT GROUP

Ultrasonic vibration assisted foil plate precision micro-blanking forming device and method

ActiveCN104162595BHas a softening effectReduce plastic deformation resistanceEjection devicesEngineeringUltrasonic vibration

The invention relates to a micro blanking forming device and method, in particular to a supersonic vibration auxiliary foil plate precision micro blanking forming device and method. The problems that existing precision foil plate common blanking forming quality is not high enough, the section quality and the form and location tolerance cannot meet needs, a mould is abraded seriously, and the service life is short are solved, and meanwhile the problems that in the large component vibration auxiliary forming process, energy is hard to transmit, and a vibration system is hard to achieve are solved. An upper mould plate, an upper cushion plate, a stripper plate, a female mould fixing plate, a lower cushion plate and a lower mould plate are sequentially overlapped from top to bottom, an upper cavity is formed by a through hole in the middle of the upper mould plate and a through hole in the middle of the upper cushion plate, piezoelectric ceramics, an oscillator, a male mould fixing block and a puncher pin are sequentially inserted into the upper cavity from top to bottom, a female mould is embedded in the middle of the upper surface of the lower cushion plate, and the lower portion of the puncher pin is inserted into a discharging hole in the middle of the upper surface of the stripper plate. The micro blanking forming device and method are used for the field of machining.

Owner:HARBIN INST OF TECH

A kind of preparation method of willow rattan anti-mildew anti-moth treatment liquid

ActiveCN104441163BExtended use timeHas a softening effectWood treatment detailsReed/straw treatmentSodium bicarbonatePavetta

Owner:GP TOPARTS MFR ANHUI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com