Polyolefin box sealing glue and preparation method thereof

A polyolefin sealing and polyolefin technology, applied in the direction of adhesives, mineral oil hydrocarbon copolymer adhesives, adhesive types, etc., can solve problems such as poor thermal stability, achieve short curing time, avoid aging, Effect of good polymer compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

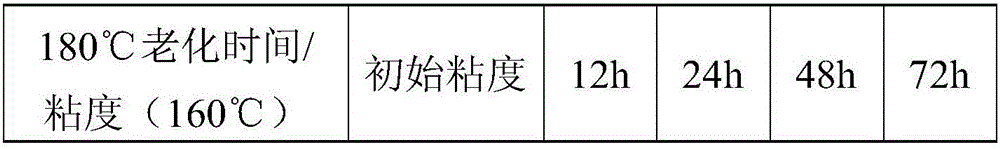

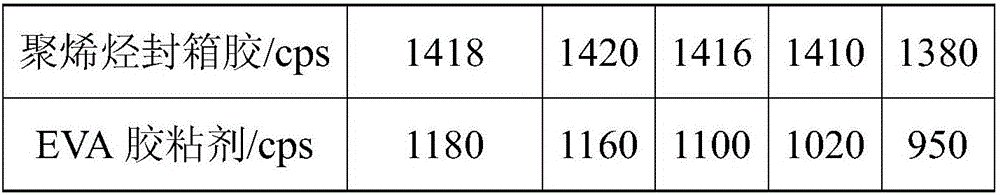

[0023] The following examples further illustrate the technical solutions of the present invention.

[0024] The invention provides a polyolefin box sealing glue and a preparation method thereof. The polyolefin box sealing glue contains the following raw materials in weight percentage: 30-50% of polyolefin plastic body, 15-25% of wax, 10-25% of petroleum resin 20%, tackifying resin 20-30%, and antioxidant 0-1.0%.

[0025] Among them, the glass transition temperature of the polyolefin plastic body is -60°C, the wax is polyethylene wax, the petroleum resin is a hydrogenated C5 petroleum resin with a softening point of 100°C, and the tackifying resin is a hydrogenated C5 petroleum resin with a softening point of 115°C. The antioxidant is a composite antioxidant containing hindered phenol and phosphite.

[0026] Among them, Bareco SX 100 is used for wax, Eastotal C 100W is used for petroleum resin, Eastotal C 115W is used for tackifying resin, and Irganox B 225 is used for antioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com