Low-temperature resistant irradiation fluorosilicone rubber

A technology of fluorosilicone rubber and low temperature resistance, applied in the field of polymer materials, can solve the problems of decreased elasticity of fluorosilicone rubber sealing materials, affecting the safety of automobiles and machinery, and brittle damage, etc., to improve low temperature resistance and avoid cross-linking. It is not easy to control and improves the effect of high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

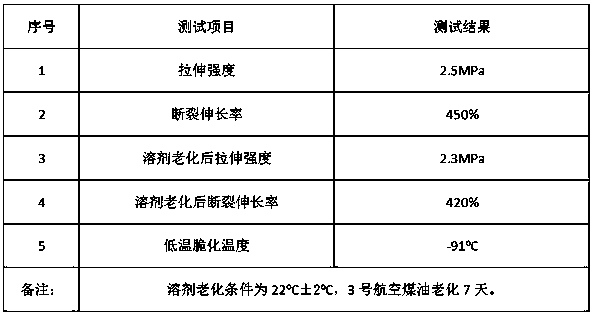

Examples

Embodiment 1

[0041] A kind of radiation-type low-temperature-resistant fluorosilicone rubber proposed by the present invention, its raw materials include: methyl vinyl phenyl silicone rubber (Shenyang Aviation Rubber and Plastic Products Factory, brand name: Hangxing HX9011-110-PVMQ, Molecular weight 500,000, phenyl content 5mol%) 100 parts; Vinyl-terminated liquid fluorosilicone rubber (produced by Changchun Xilante New Material Co., Ltd., brand name FS-1602, viscosity 15000mm 2 / s) 50 parts; methyl phenyl silicone oil (manufactured by Changchun Xilante New Material Co., Ltd., brand name XLT-1005, viscosity 1000mm 2 / s) 10 parts; silicon-aluminum polymer (manufactured by Changchun Silent New Material Co., Ltd., trade name AS-1509) 6 parts; fumed silica (German Wacker, trade name H18, specific surface area 100m 2 / g) 10 parts; hard clay 20 parts; diatomaceous earth 15 parts; rosin glyceride 1.5 parts.

[0042] The implementation steps of this embodiment are as follows.

[0043] In the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com