High-temperature-resistant high-thermal-conductivity glue-rich epoxy glass silk powder mica tape and manufacturing method thereof

A kind of glue epoxy glass, high temperature resistance technology, applied in mica, electrical components, insulators and other directions, can solve the problems of low electrical performance, poor packaging process, etc., to reduce internal stress, good thermal stability, good packaging process performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

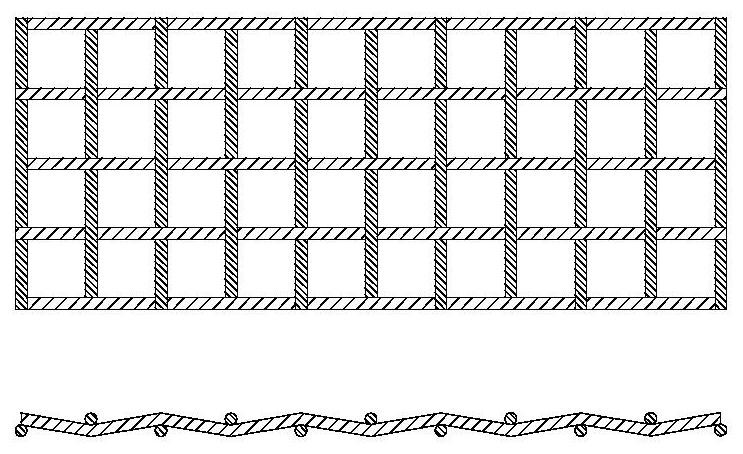

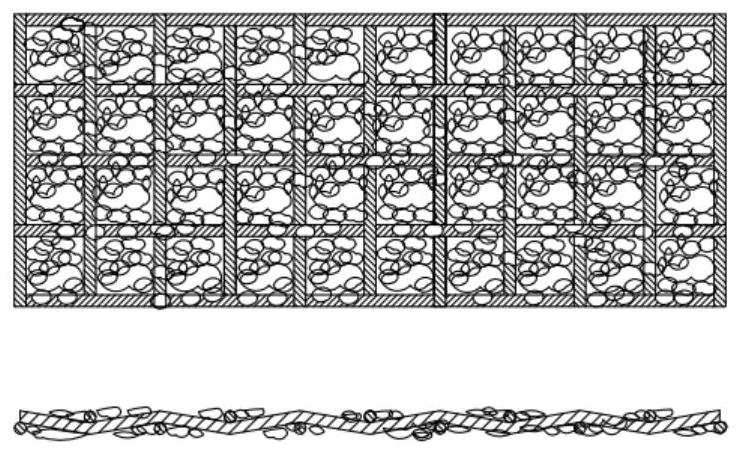

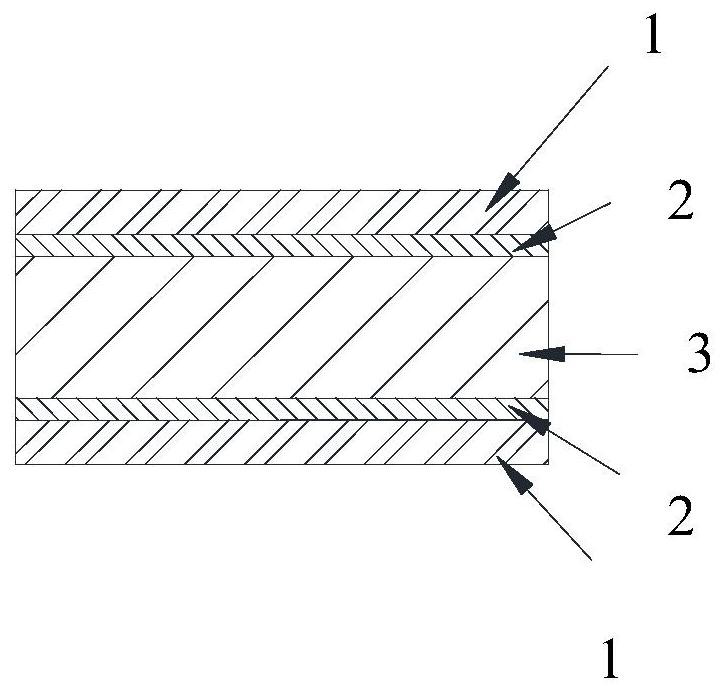

[0024] The high-temperature-resistant and high-thermal-conductivity multi-glue epoxy glass powder mica tape prepared in this embodiment is composed of a high-temperature-resistant high-thermal-conduction glass cloth layer 1, a high-temperature-resistant adhesive layer 2 and a powder mica paper layer 3, such as image 3 and Figure 4 As shown: the glass cloth in the high temperature resistant and high thermal conductivity glass cloth layer 1 is electrical alkali-free glass cloth; the material of the powder mica paper layer 3 is calcined high-voltage muscovite paper, and the mica weight is 100g / m 2 ~200g / m 2 Between; the bonding material of the high temperature resistant adhesive layer 2 is polyhedral oligomeric silsesquioxane POSS / epoxy hybrid material.

[0025] Surface activation treatment of high thermal conductivity filler: the mass percentage of high thermal conductivity filler, surfactant and solvent is 100%: 0.5% ~ 1.0%: 100%. Surfactant and solvent are prepared into a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com