A kind of preparation method of modified multi-walled carbon nanotube material

A multi-walled carbon nanotube and modification technology, which is applied in chemical analysis by titration method, can solve the problems of complex grafting methods and cumbersome process procedures, and achieve reduced van der Waals force, good hydrophilicity, and good polymerization The effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation of a modified multi-walled carbon nanotube material, comprising the following steps:

[0035] 1) Using N,N-methylenebisacrylamide (MBA) and diethylenetriamine (DETA) as raw materials, a golden yellow viscous liquid amino-terminated hyperbranched polymer (NH 2 -HBP);

[0036] 2) Weigh 5 g of amino-terminated hyperbranched polymers (NH 2 -HBP), put in a three-necked flask, add 50g of ultrapure water and stir until completely dissolved;

[0037] 3) Use a microanalytical balance to weigh 0.5g of carboxyl-terminated carbon nanotubes, add them into a three-necked flask in a water bath at 45°C, react at a stirring speed of 20r / min for 3h, and then obtain modified multi-walled carbon nanotubes by suction filtration The tubes were repeatedly washed with ultrapure water three to four times, and dried in an oven at 60° C. to obtain multi-walled carbon nanotubes grafted with amino-terminated hyperbranched polymers.

Embodiment 2

[0039] A preparation of a modified multi-walled carbon nanotube material, comprising the following steps:

[0040] 1) Using N,N-methylenebisacrylamide (MBA) and diethylenetriamine (DETA) as raw materials, a golden yellow viscous liquid amino-terminated hyperbranched polymer (NH 2 -HBP);

[0041] 2) Weigh 8 g of amino-terminated hyperbranched polymers (NH 2 -HBP), put in a three-necked flask, add 80g of ultrapure water and stir until completely dissolved;

[0042] 3) Then weigh 0.8g of carboxyl-terminated carbon nanotubes with a microanalytical balance, add them into a three-necked flask in a water bath at 50°C, react at a stirring speed of 25r / min for 3.5h, and then obtain the modified multi-walled carbon by suction filtration The nanotubes are repeatedly washed with ultrapure water for three to four times, and dried in an oven at 70° C. to obtain multi-walled carbon nanotubes grafted and modified by amino-terminated hyperbranched polymers.

Embodiment 3

[0044]A preparation of a modified multi-walled carbon nanotube material, comprising the following steps:

[0045] 1) Using N,N-methylenebisacrylamide (MBA) and diethylenetriamine (DETA) as raw materials, a golden yellow viscous liquid amino-terminated hyperbranched polymer (NH 2 -HBP);

[0046] 2) Weigh 10 g of amino-terminated hyperbranched polymers (NH 2 -HBP), put in a three-necked flask, add 50g of ultrapure water and stir until completely dissolved;

[0047] 3) Weigh 1g of carboxyl-terminated carbon nanotubes with a microanalytical balance, add them to a three-necked flask in a water bath at 55°C, react at a stirring speed of 30r / min for 4h, and then obtain modified multi-walled carbon nanotubes by suction filtration , repeatedly washed with ultrapure water for three to four times, and dried in an oven at 80° C. to obtain multi-walled carbon nanotubes grafted with amino-terminated hyperbranched polymers.

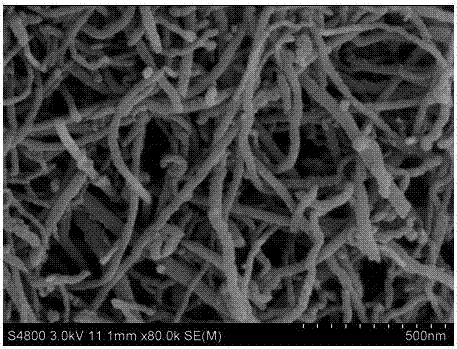

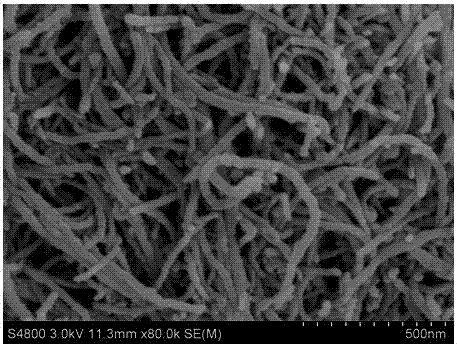

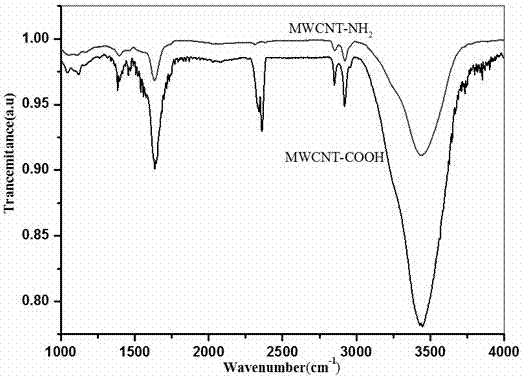

[0048] The diameter of the modified multi-walled carbon nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com