Ultrasonic vibration assisted foil plate precision micro-blanking forming device and method

A technology of ultrasonic vibration and micro-blanking, which is applied in the field of mechanical processing, can solve the problems that the section quality and shape and position tolerance cannot meet the requirements, the vibration system is difficult to realize, and the forming quality is not high enough, so as to suppress the initiation and expansion of cracks and the size of tools. Small, the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

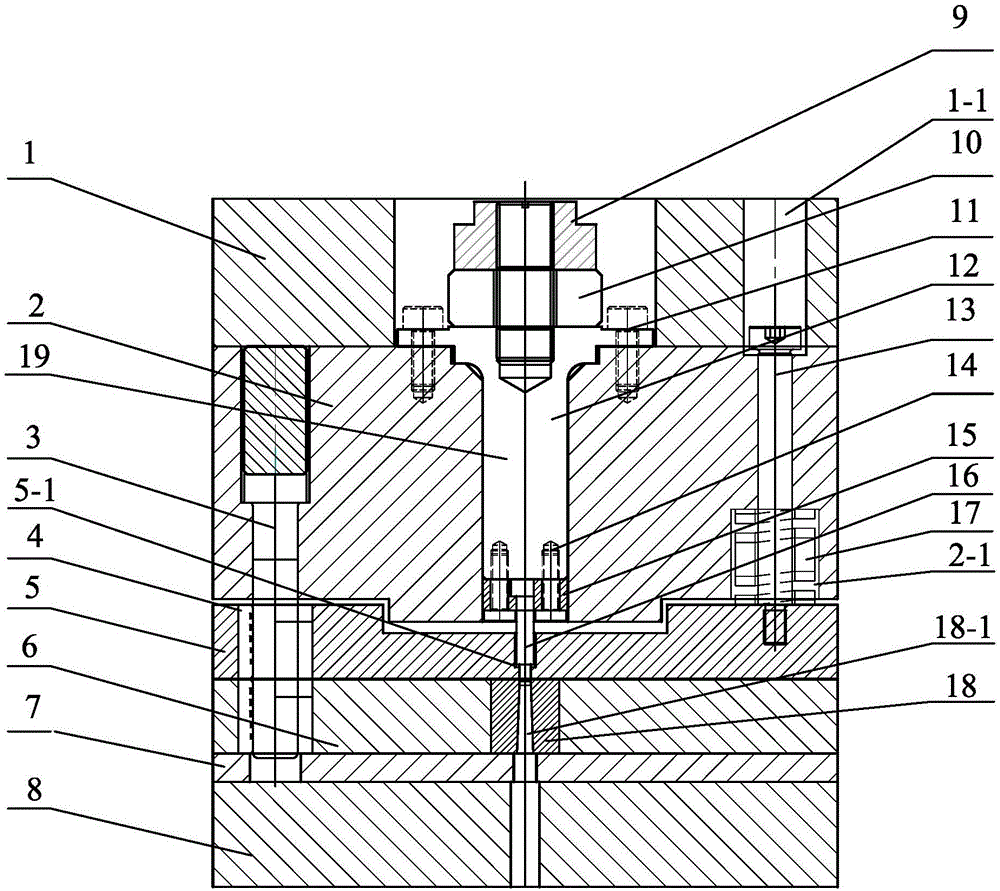

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment, the ultrasonic vibration assisted foil plate precision micro-blanking forming device described in this embodiment includes an upper template 1, an upper backing plate 2, a guide post 3, a discharge plate 5, a die fixing plate 6, and a lower backing plate 7 , lower template 8, piezoelectric ceramics 10, vibrator 12, punch fixing block 15, punch 16 and die 18, upper template 1, upper backing plate 2, unloading plate 5, die fixing plate 6, lower backing plate 7. The lower formwork 8 is superimposed from top to bottom, and the guide column 3 passes through the upper backing plate 2, the discharge plate 5, and the die fixing plate 6 from top to bottom, and the through hole in the middle of the upper formwork 1 and the upper backing plate 2 The through hole in the middle part forms the upper cavity 19, the piezoelectric ceramic 10, the vibrator 12, the punch fixing block 15, and the punch 16 are inse...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the ultrasonic vibration assisted foil plate precision micro-blanking forming device in this embodiment also includes a blanking spring guide post 13 and a blanking spring 17, and a reset through hole 1-1 is opened on the upper surface of the upper template 1, The upper end of the clamping spring guide post 13 is inserted in the reset through hole 1-1, and the lower end of the clamping spring guide post 13 passes through the spring mounting hole 2-1 on the lower surface of the upper backing plate 2 and is inserted into the discharge plate 5, the clamping spring 17 is set on the clamping spring guide post 13, and the clamping spring 17 is located in the spring mounting hole 2-1, and the upper end of the clamping spring 17 is engaged with the clip on the top of the spring mounting hole 2-1. platform contact, the lower end of the blank holder spring 17 is in contact with the upper surface...

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 This embodiment will be described. The piezoelectric ceramic 10 of the ultrasonic vibration assisted foil plate precision micro-blanking forming device described in this embodiment is fixedly installed on the upper end surface of the vibrator 12 through a fastening nut 9 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com