Reclaimed rubber softening agent and preparation method thereof

A technology of softener and reclaimed rubber, which is applied in the field of reclaimed rubber and can solve problems such as secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

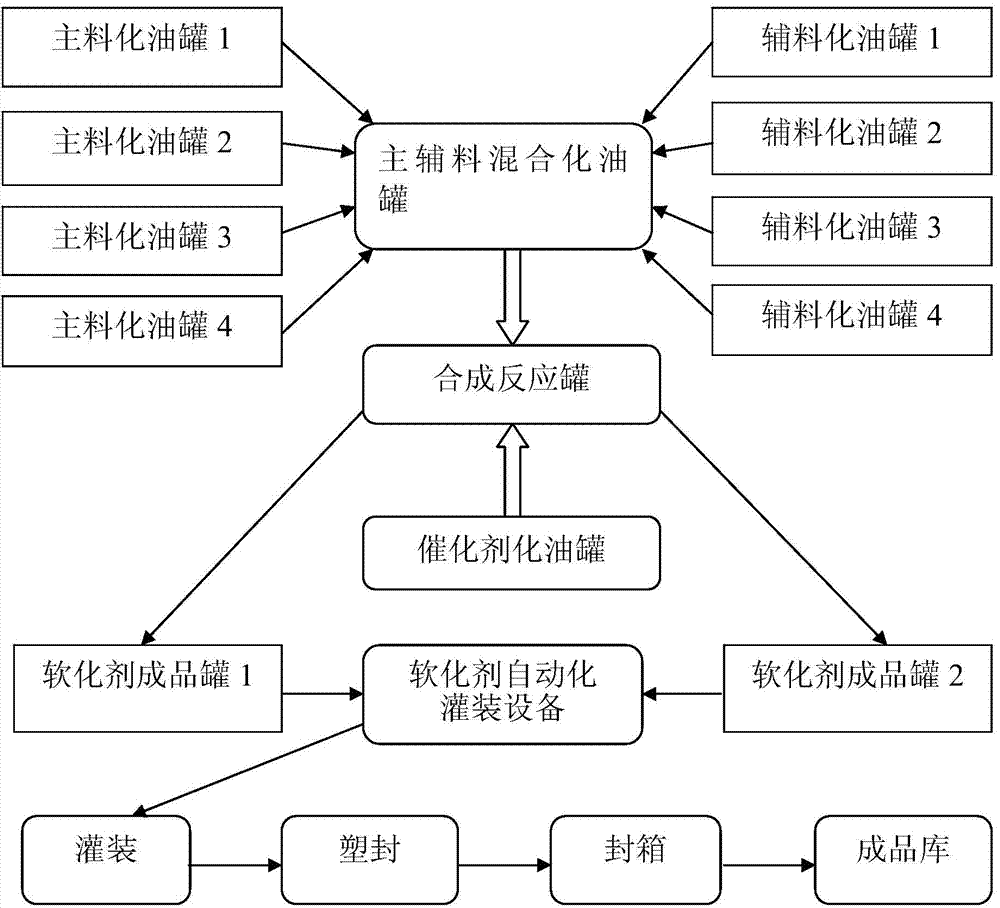

[0094] according to figure 1 The process is to use 50 parts by weight of natural vegetable oil (10 parts by weight of camellia oil, 15 parts by weight of cottonseed oil, 15 parts by weight of linseed oil, and 10 parts by weight of palm oil) of the main ingredient, biochemical oil (comprising 12.5 parts of straw biochemical oil and shell biochemical oil (10 parts by weight of coconut shell, 10 parts by weight of pine nut shell, 5 parts by weight of peanut shell>) 50 parts by weight, after mixing and stirring evenly, add o-phthalic 11.42 parts by weight of the diformate catalyst were used to catalyze the synthesis of a softener; the softener index is shown in Table 1 below. When in use, the whole (outer) tire rubber powder is recovered for every 1000 parts by weight. The fineness of the rubber powder is 20 meshes. 20 parts by weight, heated and stirred evenly; using high-temperature dynamic desulfurization (temperature 200 degrees Celsius, pressure 2.2Mpa, desulfurization time 8...

Embodiment 2

[0096] The main ingredient is 70 parts by weight of natural vegetable oil (10 parts by weight of tea oil, 30 parts by weight of cottonseed oil, and 30 parts by weight of sesame oil), and the auxiliary material biochemical oil (including straw and shell biochemical oil ) 35 parts by weight, after mixing and stirring, add 12 parts by weight of phthalate catalyst to catalyze Synthetic softener; the softener index is as shown in Table 1 below. When in use, recover the whole (outer) tire rubber powder per 1000 parts by weight. The fineness of the rubber powder is 30 meshes. 25 parts by weight, heated and stirred evenly; high-temperature dynamic desulfurization (temperature 200 degrees Celsius, pressure 2.2Mpa, desulfurization time 70 minutes) process, the technical indicators of the reclaimed rubber thus obtained are: moisture10Mpa, elongation at break>390%, Mooney viscosity<70ML. Exceeding the national tire reclaimed rubber premium product level.

Embodiment 3

[0098] The main ingredient is 70 parts by weight of natural vegetable oil (40 parts by weight of cottonseed oil, 30 parts by weight of palm oil), and the biochemical oil of auxiliary materials (including straw and shell biochemical oil ) 25 parts by weight, mixed and stirred evenly, and 10.85 parts by weight of a phthalate catalyst were added to catalyze the synthesis of a softener; the softener index is shown in Table 1. When in use, the whole (outer) tire rubber powder is recovered for every 1000 parts by weight. The fineness of the rubber powder is 30 meshes. 30 parts by weight, heated and stirred evenly; adopt high-temperature dynamic desulfurization (temperature 210 degrees Celsius, pressure 2.5Mpa, desulfurization time 75 minutes) process, the technical indicators of the reclaimed rubber thus obtained are: moisture content 10.5Mpa, elongation at break>400%, Mooney viscosity<68ML. Exceeding the national tire reclaimed rubber premium product level.

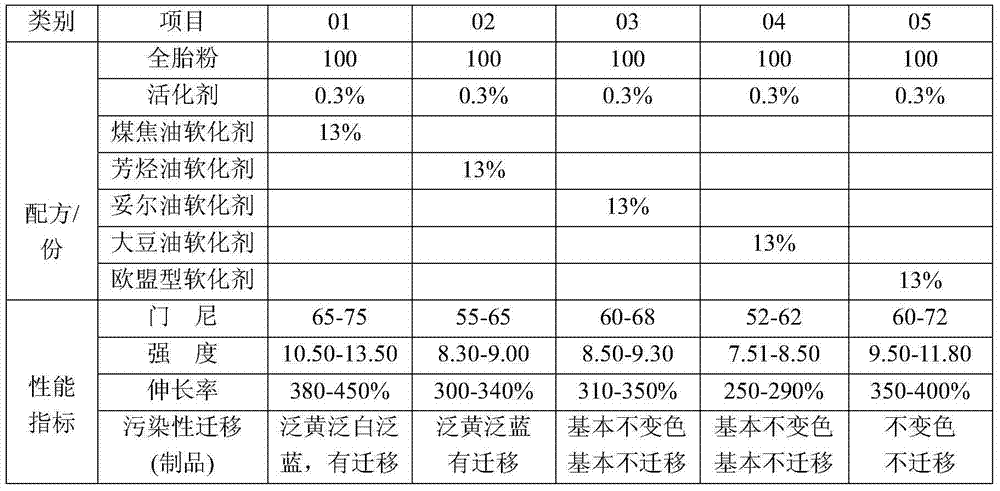

[0099] Table 1

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Mooney viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com