Oil composition and method for preparing same

An oil and fat composition and oil technology, which can be used in the production/processing of edible oil/fat, edible oil/fat phase, edible oil/fat, etc., and can solve the problems of narrow plastic temperature range and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1: the preparation of lard

[0076] The subcutaneous fat of live pigs is selected after being cleaned and placed in an environment of 150-190°C for boiling, the oil is squeezed out, and after conventional impurity removal and refining treatments, the iodine value is 60-62gI / 100g and the melting point is 40- lard 1 at 42°C; and lard 2 with an iodine value of 68-70gI / 100g and a melting point of 30-32°C.

Embodiment 2

[0077] Embodiment 2: the preparation of palm oil

[0078]Choose commercially available palm oil (iodine value 50-52gI / 100g, melting point 32-34 ℃) as raw material, adopt conventional dry fractionation method to carry out two fractionation, obtain iodine value 33-35gI / 100g of palm stearin with a melting point of 50-55°C; then use the palm stearin for the second fractionation to obtain the fractionated stearin. Control the crystal growth temperature, time and filter pressure of the second sub-extraction to obtain iodine value of 8-10gI / 100g, melting point of 58-60°C palm oil 1, iodine value of 33-35gI / 100g, melting point of 50-52°C palm oil 2, iodine value 22-23gI / 100g, palm oil 3 with a melting point of 56-58°C.

Embodiment 3

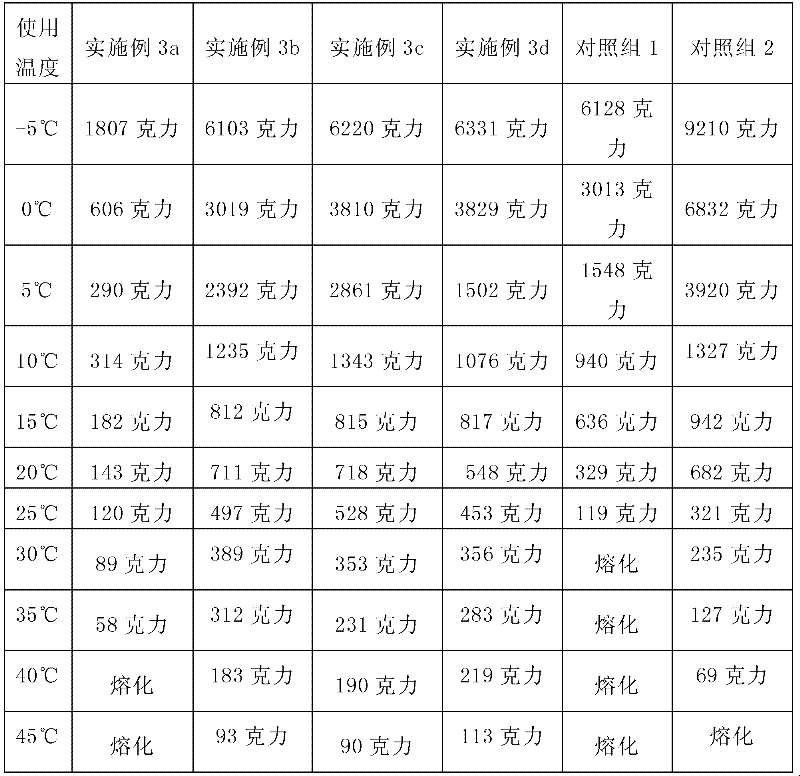

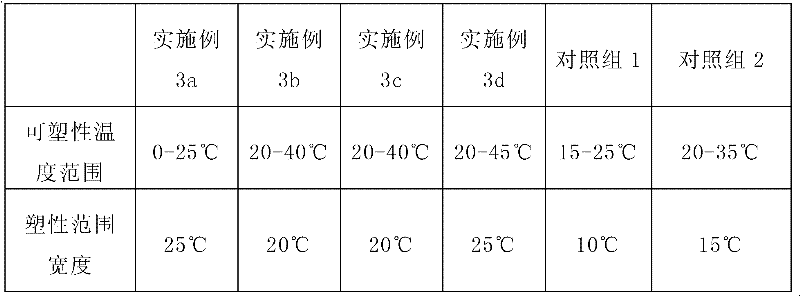

[0079] Embodiment 3: the preparation of plastic oil composition (anhydrous type margarine)

[0080] Control group 1 (Sunshine brand anhydrous ghee produced by Kerry Special Oils (Shanghai) Co., Ltd., sold in winter, spring and autumn, and belongs to water-free margarine)

[0081] The oil raw material of control group 1 is mainly palm kernel oil and palm oil, obtains corresponding oil mixture after oil modification, this oil mixture is sent into mixing tank and stirred and mixed, then add auxiliary materials (essence, Pigment, antioxidant, emulsifier) are stirred and mixed, then sent to a quencher for conventional quenching treatment, then sent to a kneader for conventional kneading treatment, and finally conventional aging treatment (aging at 15-40°C for more than 2 days).

[0082] Control group 2 (Sunshine brand anhydrous ghee produced by Kerry Special Oils (Shanghai) Co., Ltd., sold in Xia Chunqiu, belongs to water-free margarine)

[0083] The production method of control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com