Oil composition and plastic oil product

An oil and fat composition and technology for the composition, which are applied in the fields of edible oil/fat, production/processing of edible oil/fat, food science, etc., can solve the problems of scarcity of resources, etc., and achieve a wide plastic range, fast crystallization rate, and plasticity temperature. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The second aspect of the present invention provides a method for preparing an oil composition, said method including the step of mixing oil and fat raw materials.

[0059] In a preferred example of the present invention, the oil and fat raw materials include oil A with an SSU content of more than 51 wt% and oil B with a UUS content of more than 70 wt%.

[0060] In the present invention, fats A and B may both be animal and vegetable fats, one of them may be obtained by compounding triglyceride monomers, and both may be obtained by compounding triglyceride monomers.

[0061] In another preferred example of the present invention, the fat A is one or more of lard, tallow, fish oil, and chicken and duck fat, and the fat B is palm oil, soybean oil, rapeseed oil, corn oil, sesame oil , cottonseed oil, coconut oil in one or more.

[0062] In another preferred example of the present invention, the oil raw material is compounded from triglyceride monomers; preferably, the trigly...

Embodiment 1

[0122] Embodiment 1: take natural oil as raw material to prepare oil products

[0123] 15wt% 1,2-stearic acid-3-arachidic acid glyceride, 50wt% 1-palmitic acid-2-stearic acid-3-oleic acid glyceride, 35wt% 1-stearic acid-2-oleic acid -3-Glyceryl linolenate is sent into the mixing tank to obtain oil A1; %1,2-palmitoleic acid-3-palmitin glyceric acid ester is sent into the mixing tank to obtain oil B1.

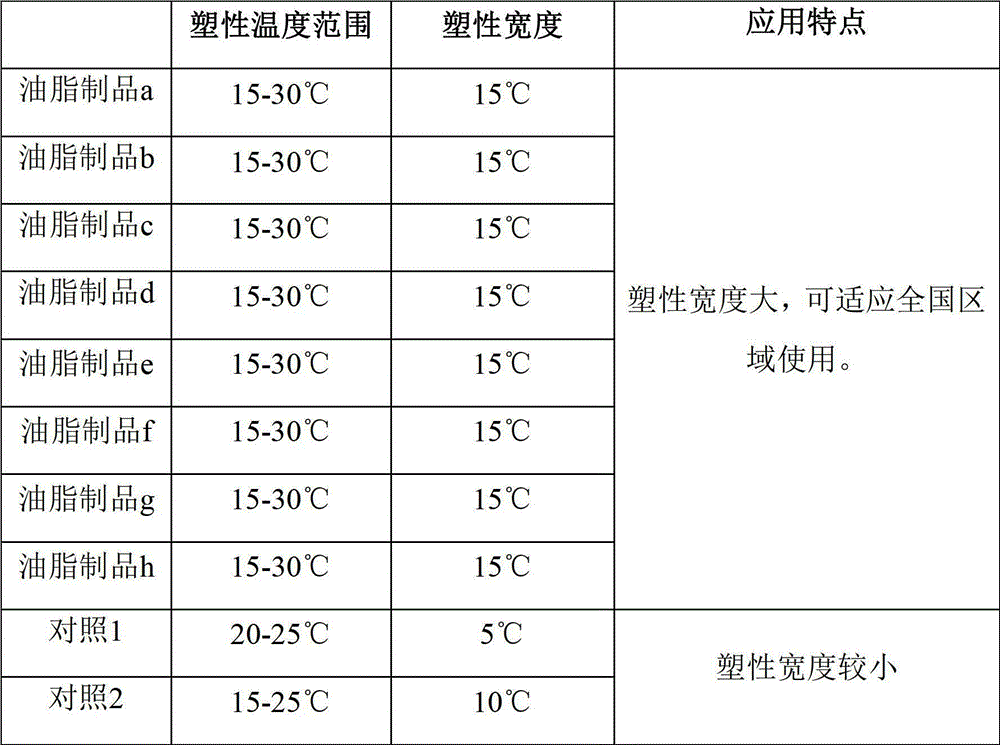

[0124] After the raw materials shown in Table 2 are sent into the mixing tank, they are stirred and mixed (stirred at 140-180rpm for 30 minutes), then sent to the quencher for conventional quenching treatment (cooling at a rate of 7°C / min for 3 minutes), and then sent to the kneader Perform conventional kneading treatment (kneading treatment at a rotational speed of 100-120 rpm for 3 minutes), and finally conventional aging treatment (aging at a temperature of 20° C. for 3 days) to prepare plastic oil products a~d.

[0125] Table 2 Example 1 Raw Materials

[0126] ser...

Embodiment 2

[0128] Embodiment 2: Preparation of oil products with compound oil as raw material

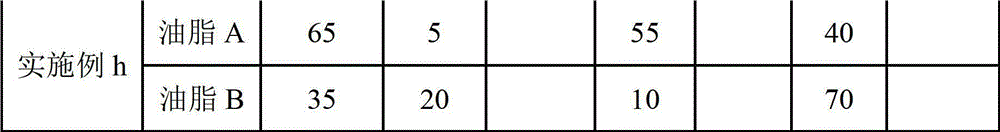

[0129] Send the mixing tank according to the raw materials shown in Table 3 and mix to obtain the required grease A and grease B, for example, 5wt% PPP (tripalmitin), 55wt% SSO (1,2-stearic acid-3- Glyceryl oleate), 40wt% SOO (1,2-oleic acid-3-stearic acid glyceride) are sent into the mixing tank and mixed to obtain the grease A in embodiment g. The oil and fat raw materials in other embodiments are compounded according to this method.

[0130] After the fats A and B of compounding gained are sent into the blending tank according to the consumption shown in Table 2, they are stirred and mixed (stirring at 140-180rpm for 25-35min), and then sent into the quenching machine for conventional quenching treatment (with 5-10 ℃ / min rate of cooling for 3-7 minutes), then sent to the kneader for conventional kneading treatment (3-5 minutes of kneading treatment at a speed of 100-120 rpm), and finally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com