Preparation method of cerium dioxide nano hollow sphere

A technology of ceria and hollow spheres, which is applied in the preparation of microspheres, chemical instruments and methods, rare earth metal oxides/hydroxides, etc., can solve the problems of long precursor time, etc., and achieve simple methods and fast crystallization speeds , Heating effect evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Dissolve 0.1 mmol of cerium nitrate and 0.3 mmol of pyridine-2,5-dicarboxylic acid in a mixed solvent of 10 ml of absolute ethanol and 10 ml of dimethylformamide;

[0030] Step 2: Put the above mixed solution in a polytetrafluoroethylene-lined microwave tank, react at 180°C for 20 minutes, centrifuge and wash after the reaction, and dry at 60°C to obtain cerium coordination polymer ultramicrosphere powder;

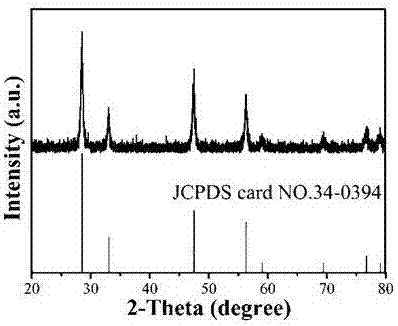

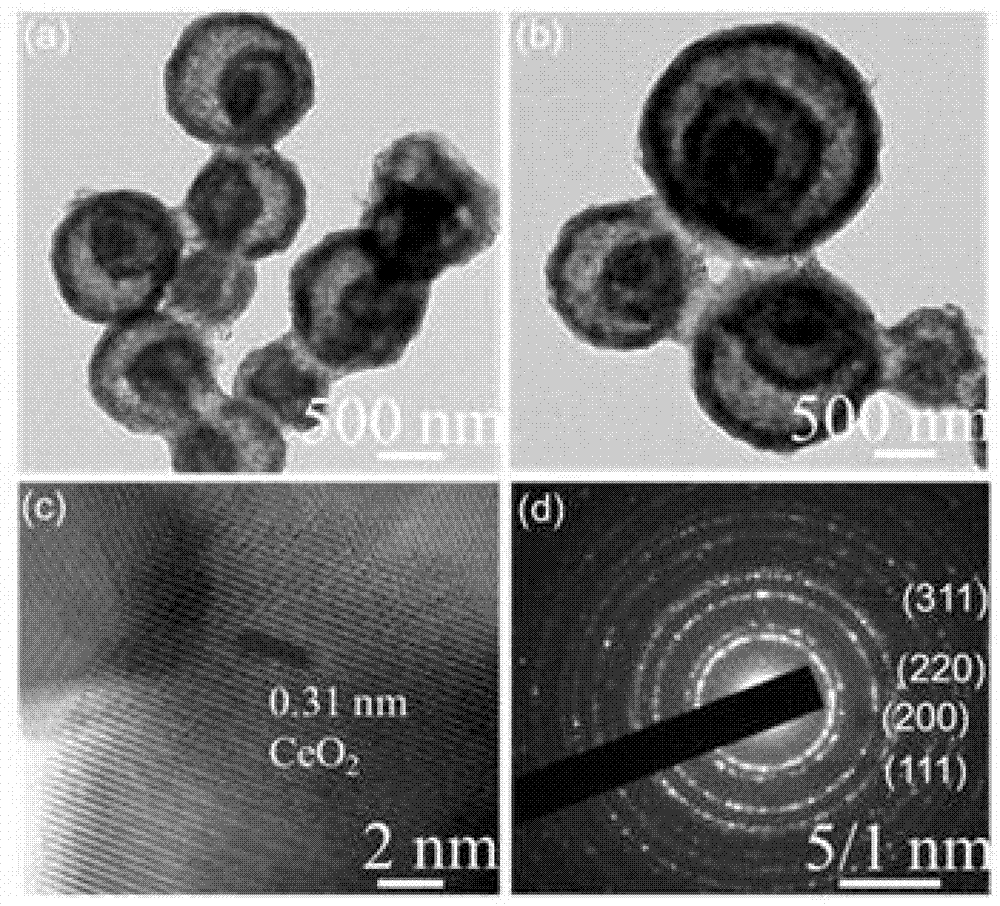

[0031] Step 3: Place the dried sample obtained above in a muffle furnace, calcinate at 600 °C for 4 h, and cool to room temperature to obtain a multilayer core-shell structure CeO 2 hollow ball.

Embodiment 2

[0033] Step 1: Add 0.1 mmol Ce(NO 3 ) 3 ·6H 2 O cerium nitrate and 0.3 mmol pyridine-2,5-dicarboxylic acid were dissolved in a mixed solvent of 10 ml absolute ethanol and 10 ml dimethylformamide;

[0034] Step 2: Put the above mixed solution in a microwave reaction tank, react at 160 °C for 10 min, centrifuge and wash after reaction, and dry at 60 °C to obtain cerium coordination polymer ultramicrosphere powder;

[0035] Step 3: Place the dried sample obtained above in a muffle furnace for calcination at 600 °C for 4 h, and cool to room temperature to obtain a multilayer core-shell structure CeO 2 hollow ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com