Polylactide-type polyurethane-modified polylactic acid alloy and preparation method thereof

A polyurethane modification and polylactide technology, applied in the field of polymer materials, can solve problems such as toughness decline, and achieve the effects of easy control, excellent heat resistance and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

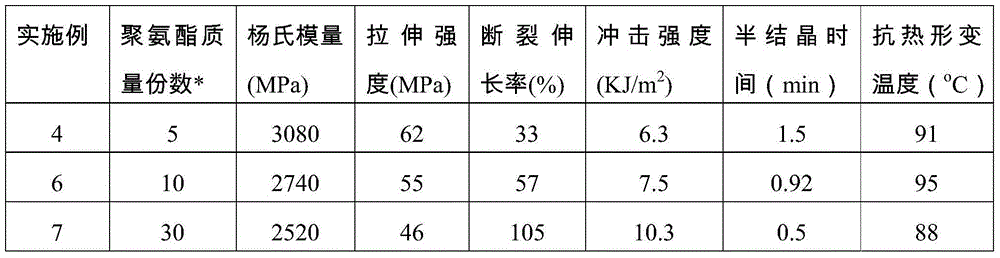

Examples

preparation example Construction

[0024] The present invention provides a preparation method of polylactide polyurethane modified polylactic acid alloy, which comprises the following steps:

[0025] a Dissolve D-polylactide polyol, diisocyanate and catalyst in a solvent and react at 50℃~100℃ under the protection of protective gas to obtain prepolymer. Among them, D-polylactide polyol , The molar ratio of diisocyanate to catalyst is 1:3~5:0.001~0.01;

[0026] b. Add a chain extender to the prepolymer to carry out a chain extension reaction to obtain a D-polylactide polyol polyurethane elastomer, wherein the molar ratio of the chain extender to the D-polylactide polyol is 2 to 4 :1;

[0027] c 60 parts by mass to 99.5 parts by mass of polylactic acid and 0.5 parts by mass to 40 parts by mass of D-polylactide polyol polyurethane elastomer are pre-mixed, and then melted and extruded at 175°C to 190°C through a twin screw to obtain polypropylene Lactide polyurethane modified polylactic acid alloy.

[0028] In step a, the...

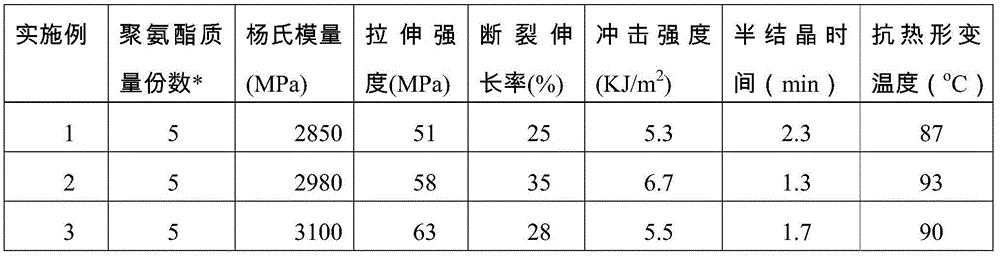

Embodiment 1

[0043] After mixing D type-polylactide polyol (number average molecular weight 500, hydroxyl value 238mg KOH / g), isophorone diisocyanate (IPDI), dibutyl tin dilaurate at a molar ratio of 1:3:2:0.005 , Added to the reactor, reacted at 75° C. for 3 hours, adding anhydrous acetone (50% of the total mass of the material) was added to adjust the viscosity to obtain a prepolymer.

[0044] 1,4-Butanediol (DBO) was added to the prepolymer to carry out the chain extension reaction. After the reaction, the acetone was removed by vacuum drying to obtain D-polylactide polyol polyurethane, which was obtained by gel chromatography (GPC) The number average molecular weight was measured to be 305,000, and the molecular weight distribution index was 1.6.

[0045] Take the prepared D-polylactide polyol polyurethane (5 parts by mass) and polylactic acid (the number average molecular weight of polylactic acid is 150,000, and its parts by mass is 95) and mix them uniformly, then melt them in a twin-scr...

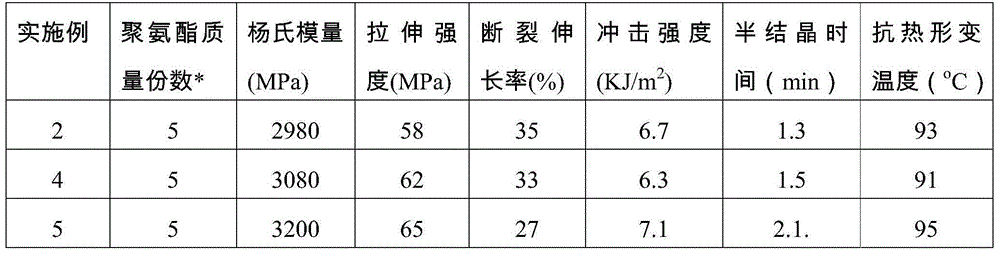

Embodiment 2

[0048] Massage D type-polylactide polyol (number average molecular weight 1000, hydroxyl value 118mg KOH / g), isophorone diisocyanate (IPDI), 1,4-butanediol (DBO), dibutyl tin dilaurate After mixing with a molar ratio of 1:3:2:0.005, it is added to the reactor and reacted at 75° C. for 3 hours. Anhydrous acetone (the added amount is 50% of the total mass of the material) is added to adjust the viscosity to obtain a prepolymer.

[0049] 1,4-Butanediol (DBO) was added to the prepolymer to carry out the chain extension reaction. After the reaction, the acetone was removed by vacuum drying to obtain D-polylactide polyol polyurethane, which was obtained by gel chromatography (GPC) The number average molecular weight was measured to be 501,000, and the molecular weight distribution index was 1.7.

[0050] Take the prepared D-polylactide polyol polyurethane (5 parts by mass) and polylactic acid (the number average molecular weight of polylactic acid is 150,000, and its parts by mass is 95)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com