Paper explosion-preventing softening device for line pressing and molding and softening method for pressed-line crease positions of paperboards

A technology of softening device and explosion-proof paper, which is applied in the direction of mechanical processing/deformation, can solve the problems of reduced bursting strength, low bursting value of cardboard, and reduced toughness of cardboard, and achieve the effect of fast softening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

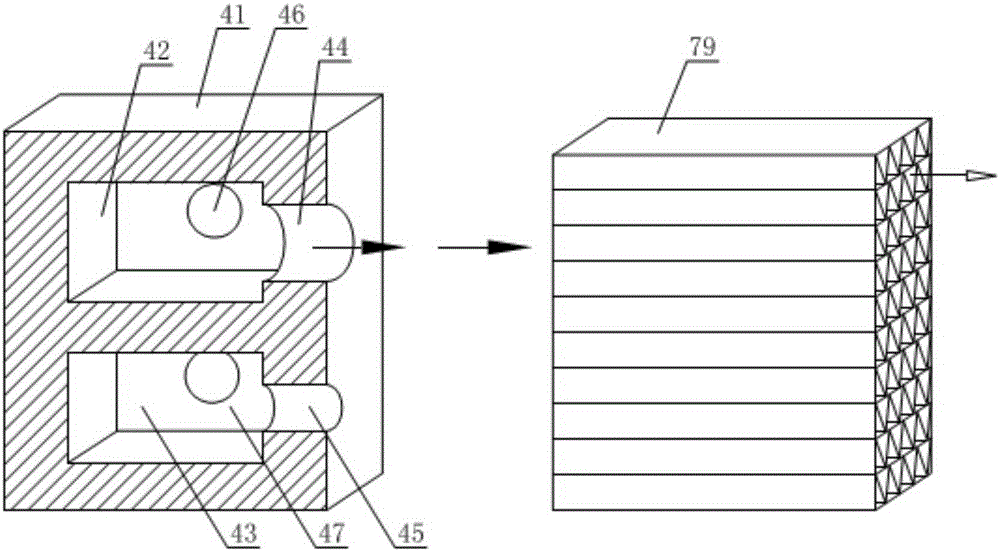

[0024] image 3 The solid arrows in the figure indicate the spraying direction of the nozzle 4, and the hollow arrows indicate the corrugated corrugated direction.

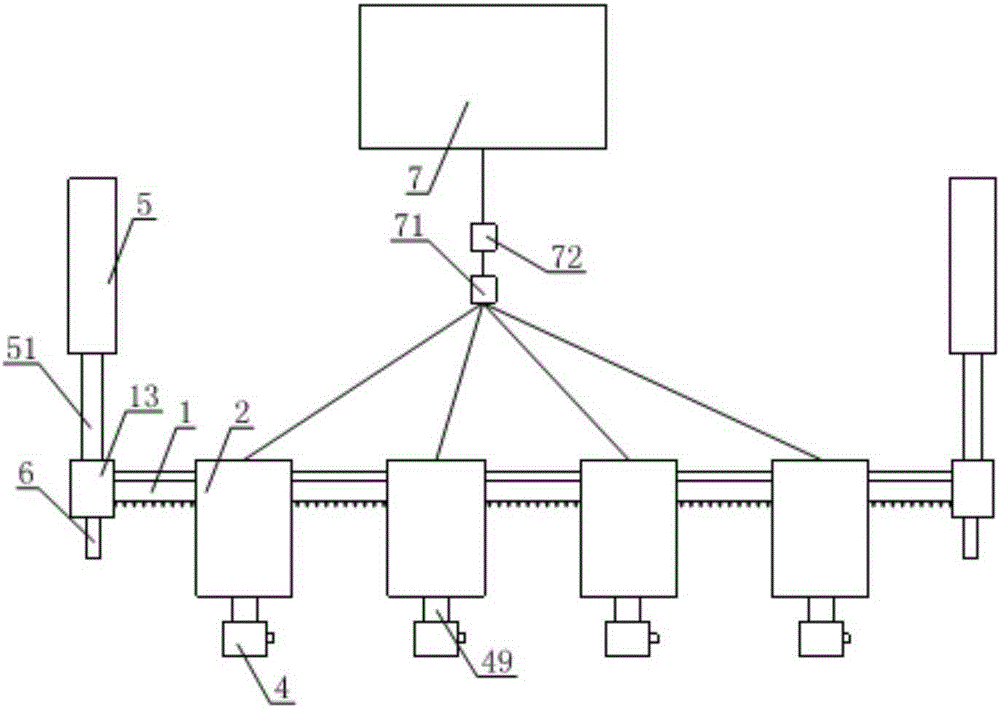

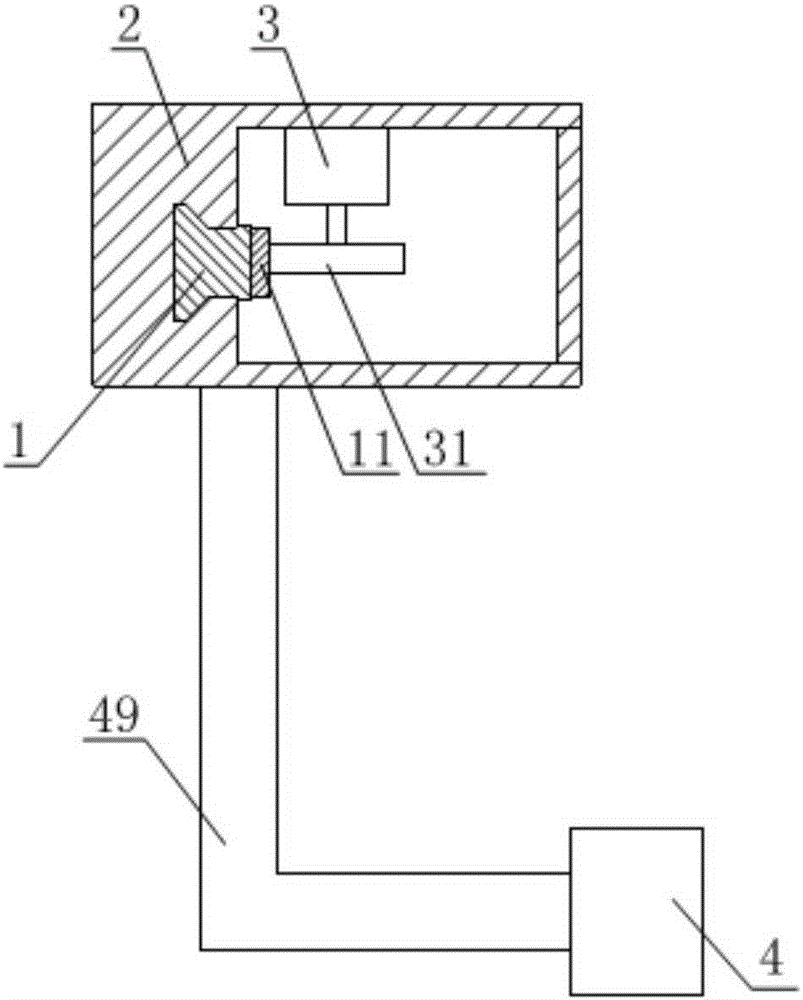

[0025] Such as figure 1 , figure 2 with Figure 5 As shown, the preferred embodiment of the pressure-line forming explosion-proof paper softening device of the present invention includes four nozzles 4, one transverse guide rail 1, four transverse moving seats 2, four drivers, and one longitudinal guide for adjusting the longitudinal position of the transverse guide rail 1. Mobile device, steam supply device 7 and control box 99. The driver is a motor 3, and the four laterally moving seats 2 are slidably arranged on the transverse guide rail 1, and each nozzle 4 is fixed to a transversely moving seat 2, and the motor 3 is used to drive the laterally moving seat 2 on the transverse guide rail 1. The upward movement makes the nozzle 4 move to the working position, the transverse guide rail 1 is fixed on the lon...

Embodiment 2

[0033] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that there are four horizontal guide rails and the horizontal guide rails are lead screws 81, and there are four longitudinal moving devices, and the lead screw 81, the motor 3, and the The seat 2 corresponds to the longitudinal moving device one by one, and the remaining parts are the same as in Embodiment 1.

[0034] The motor 3 is fixed on the transverse rail seat 13 , the output shaft of the motor 3 is connected to the lead screw 81 , and the transverse movement seat 2 is screwed on the lead screw 81 .

Embodiment 3

[0036] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 2 is that the driver is a cylinder 91, the transverse guide rail is a piston rod 92 of the cylinder 91, and the rest are the same as Embodiment 2. In other embodiments, the gas 91 is also replaced by a hydraulic cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com