Bamboo single-plate softening method

A bamboo and veneer technology, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of reducing the quality of bamboo veneer and destroying the component structure of bamboo veneer, so as to reduce the elastic modulus, increase the softening speed, Effect of increased moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

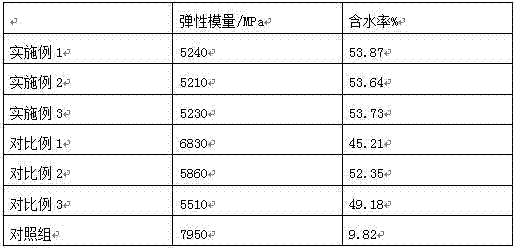

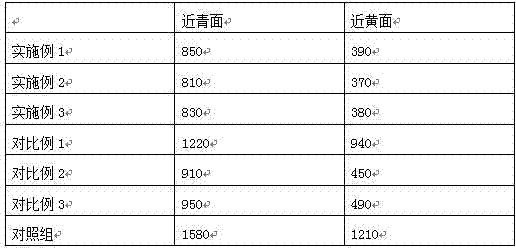

Examples

Embodiment 1

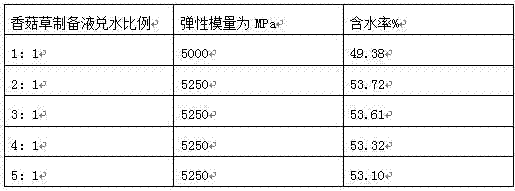

[0018] The invention discloses a method for softening bamboo veneers. The method for softening bamboo veneers is to preheat the bamboo veneers, then use the preparation liquid of shiitake mushrooms mixed with water for cooking, and carry out auxiliary treatment with ultrasonic waves.

[0019] The preparation method of the Lentinus edodes preparation liquid is as follows: After mixing the leaves and stems of the Lentinus edodes, crush them to 100 mesh, add 10 times the mass of water to decoct for 32 minutes, then stir at 2000r / min for 10 minutes, then cool to 30°C, Obtain a decoction, then add a compound enzyme of 0.8% of the decoction mass to the decoction, enzymatically hydrolyze for 4 hours, then perform an enzyme inactivation treatment, then cool naturally to room temperature, and then carry out solid-liquid decoction under high-speed centrifugation. Separation to obtain a mixed solution, which is the preparation solution of Lentinus edodes.

[0020] The mixed mass ratio of...

Embodiment 2

[0028] The invention discloses a method for softening bamboo veneers. The method for softening bamboo veneers is to preheat the bamboo veneers, then use the preparation liquid of shiitake mushrooms mixed with water for cooking, and carry out auxiliary treatment with ultrasonic waves.

[0029] The preparation method of the Lentinus edodes preparation liquid is as follows: After mixing the leaves and stems of the Lentinus edodes, crush them to 100 mesh, add 10 times the mass of water to decoct for 35 minutes, then stir at 2000r / min for 10 minutes, then cool to 32°C, Obtain a decoction, then add a compound enzyme of 0.8% of the decoction mass to the decoction, enzymatically hydrolyze for 4 hours, then perform an enzyme inactivation treatment, then cool naturally to room temperature, and then carry out solid-liquid decoction under high-speed centrifugation. Separation to obtain a mixed solution, which is the preparation solution of Lentinus edodes.

[0030] The mixed mass ratio of...

Embodiment 3

[0038] The invention discloses a method for softening bamboo veneers. The method for softening bamboo veneers is to preheat the bamboo veneers, then use the preparation liquid of shiitake mushrooms mixed with water for cooking, and carry out auxiliary treatment with ultrasonic waves.

[0039] The preparation method of the Lentinus edodes preparation liquid is as follows: After mixing the leaves and stems of the Lentinus edodes, crush them to 100 mesh, add 10 times the mass of water to decoct for 33 minutes, then stir at 2000r / min for 10 minutes, then cool to 31°C, Obtain a decoction, then add a compound enzyme of 0.8% of the decoction mass to the decoction, enzymatically hydrolyze for 4 hours, then perform an enzyme inactivation treatment, then cool naturally to room temperature, and then carry out solid-liquid decoction under high-speed centrifugation. Separation to obtain a mixed solution, which is the preparation solution of Lentinus edodes.

[0040] The mixed mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com