Structure for packaging organic electroluminescence device

An encapsulation structure and electro-luminescence technology, which are applied to electroluminescence light sources, electric light sources, lighting devices, etc., can solve the problems affecting the quality of the OLED device 10, the failure of the OLED element 13, and the increase in manufacturing, so as to improve the production quality. efficiency and manufacturing efficiency, improve product quality, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

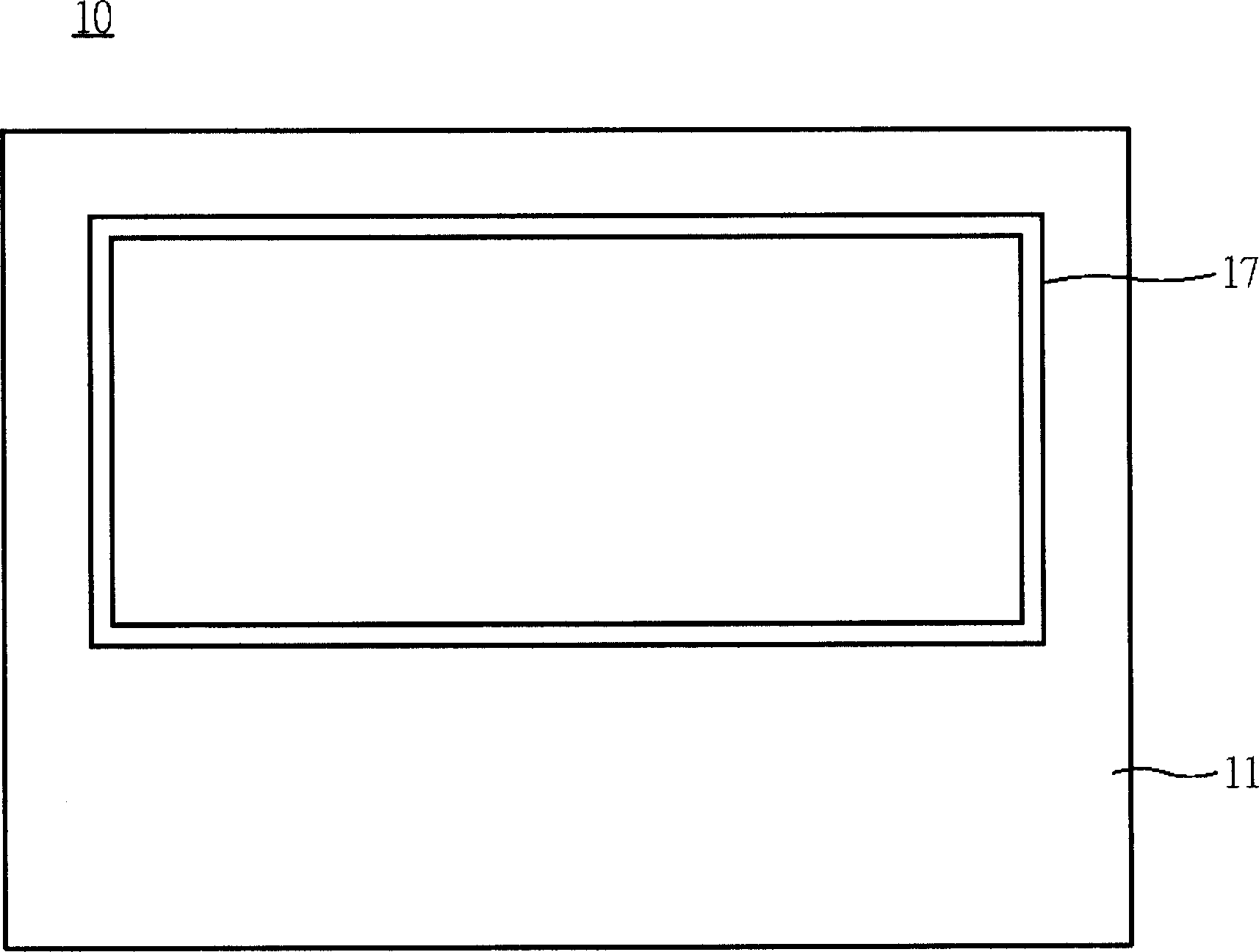

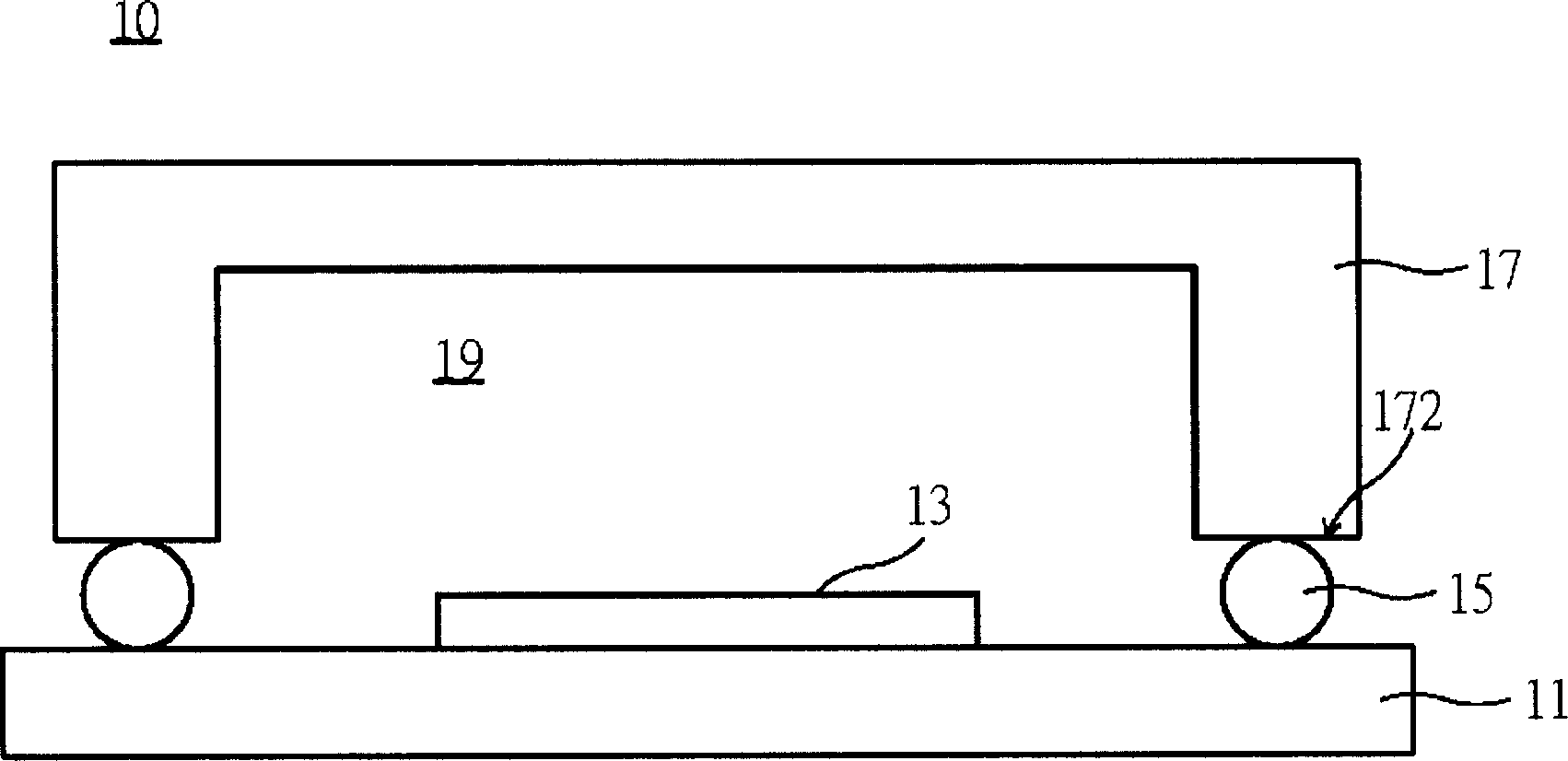

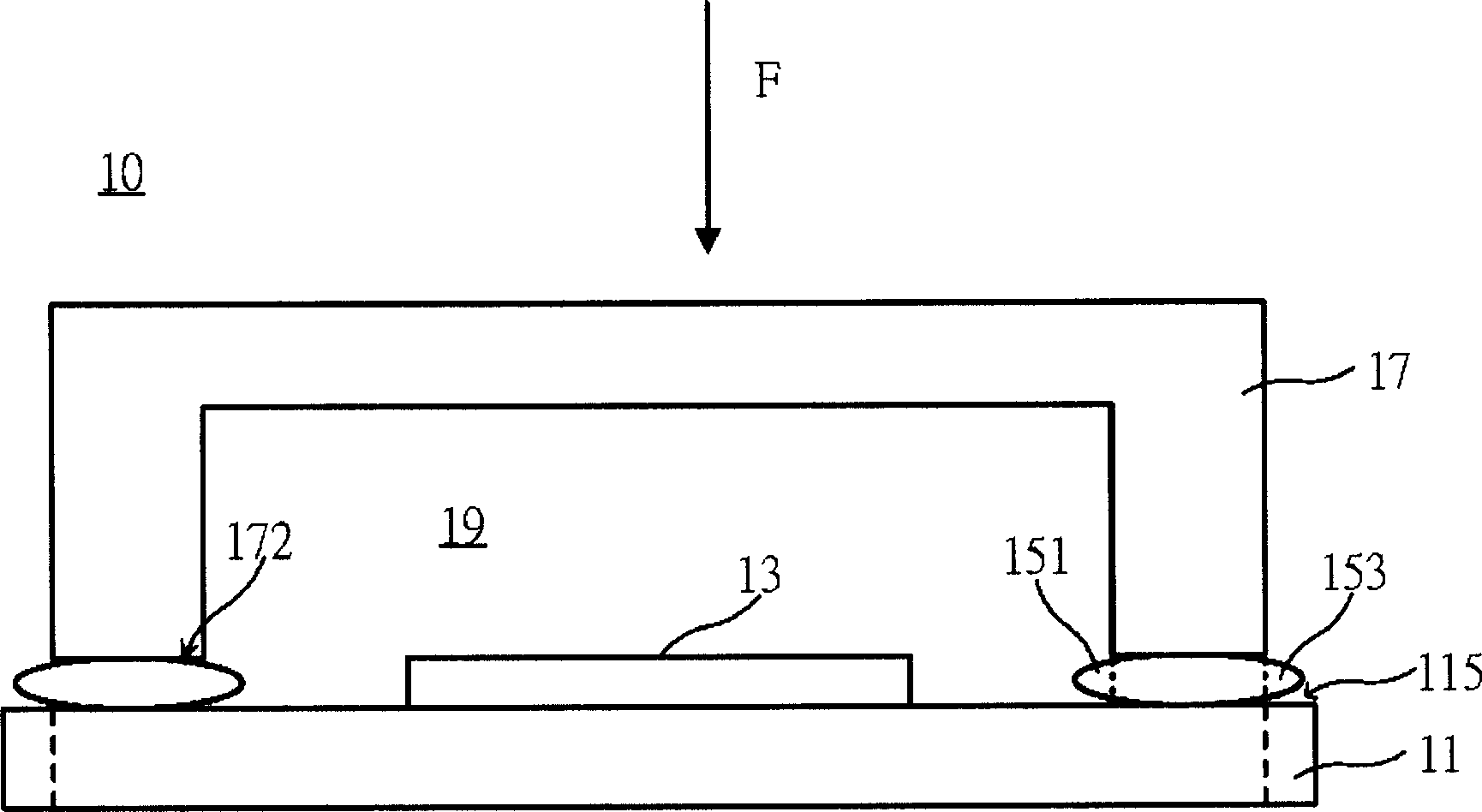

[0071] First, see Figure 2A , 2B and 2C are respectively a top view, a schematic cross-sectional view and a partially enlarged schematic view of a preferred embodiment of the present invention; There is at least one organic electroluminescence (OLED) element 23, and an encapsulation cover plate 27 is provided above the substrate 21, and the encapsulation cover plate 27 is used to cover the OLED element 23 to form a protective encapsulation structure. Moreover, at least one partition wall is provided on the glue coating area 272 of the packaging cover plate 27, such as the inner partition wall 271 and the outer partition wall 273 shown in this embodiment, and the inner partition wall 271, the outer partition wall 273 and the packaging cover plate 27. A sealing area 275 can be naturally formed between the glue-coating areas 272. The sealing area 275 can be defined and used to place an adhesive 25. Through the setting of the adhesive 25, the substrate can be 21 and the package...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com