Patents

Literature

30results about How to "Prevent glue overflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

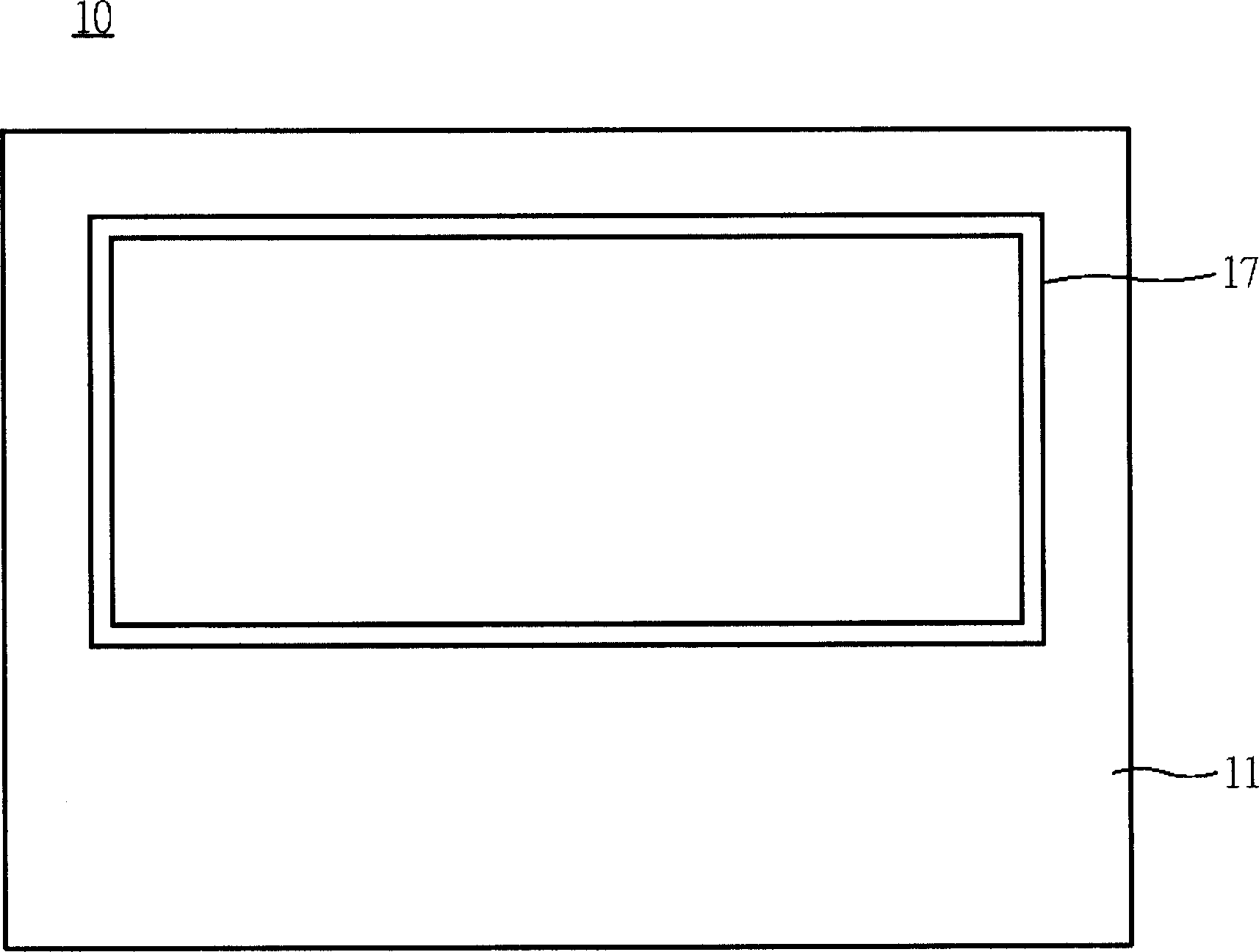

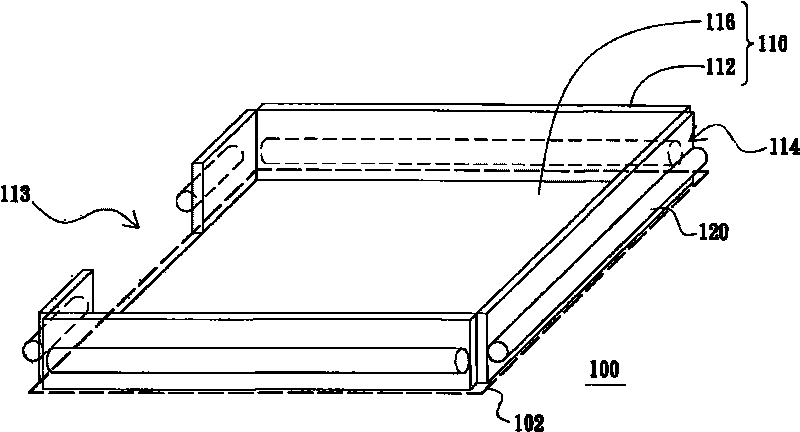

Display panel

Owner:AU OPTRONICS CORP

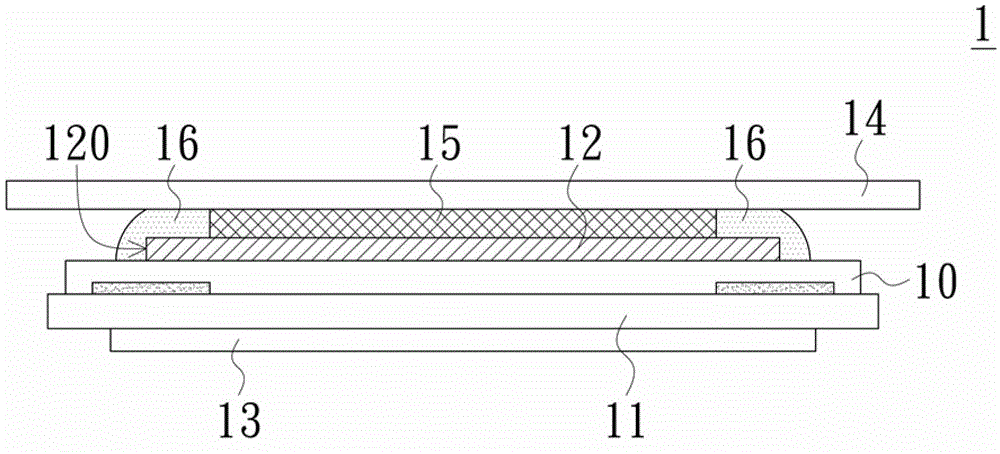

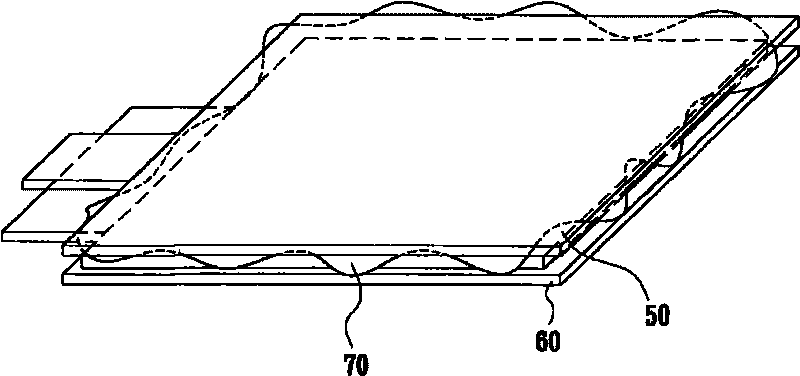

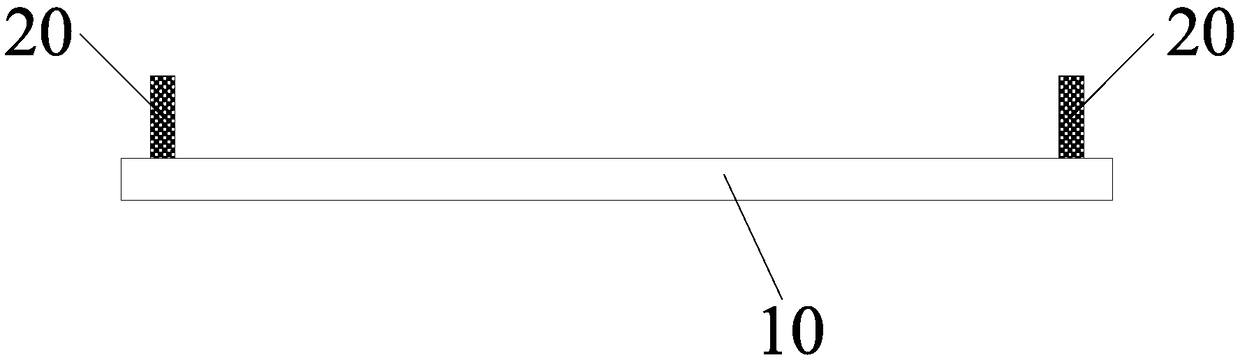

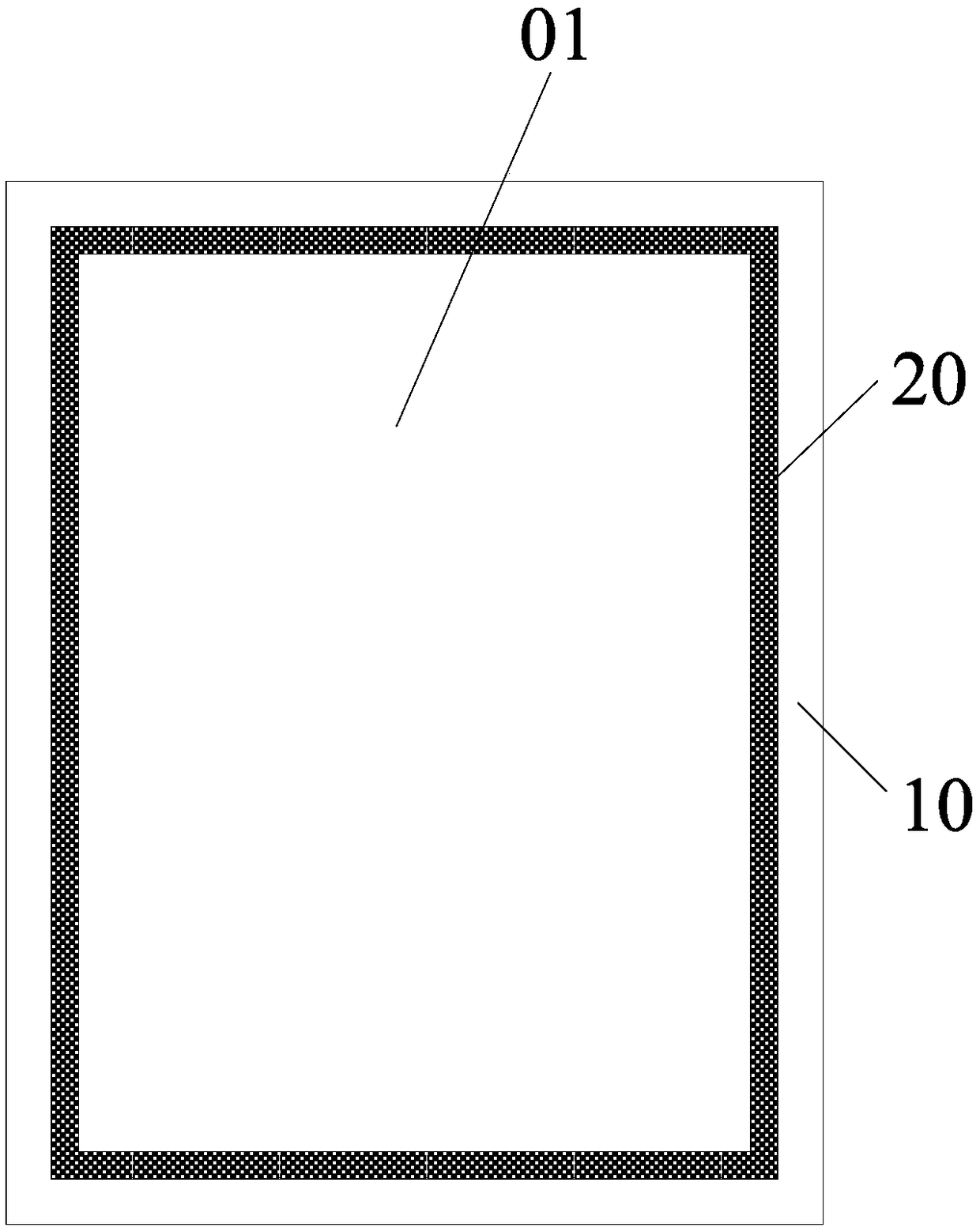

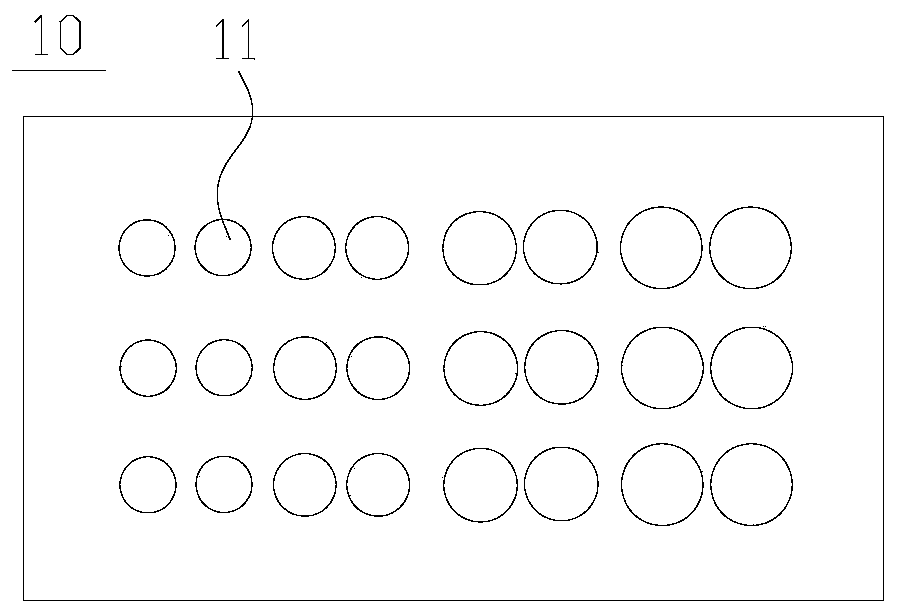

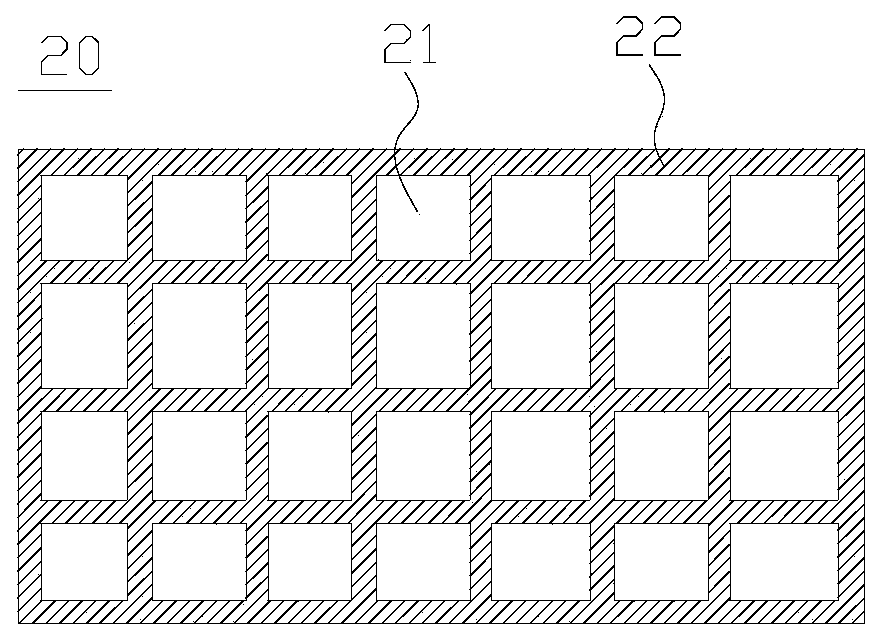

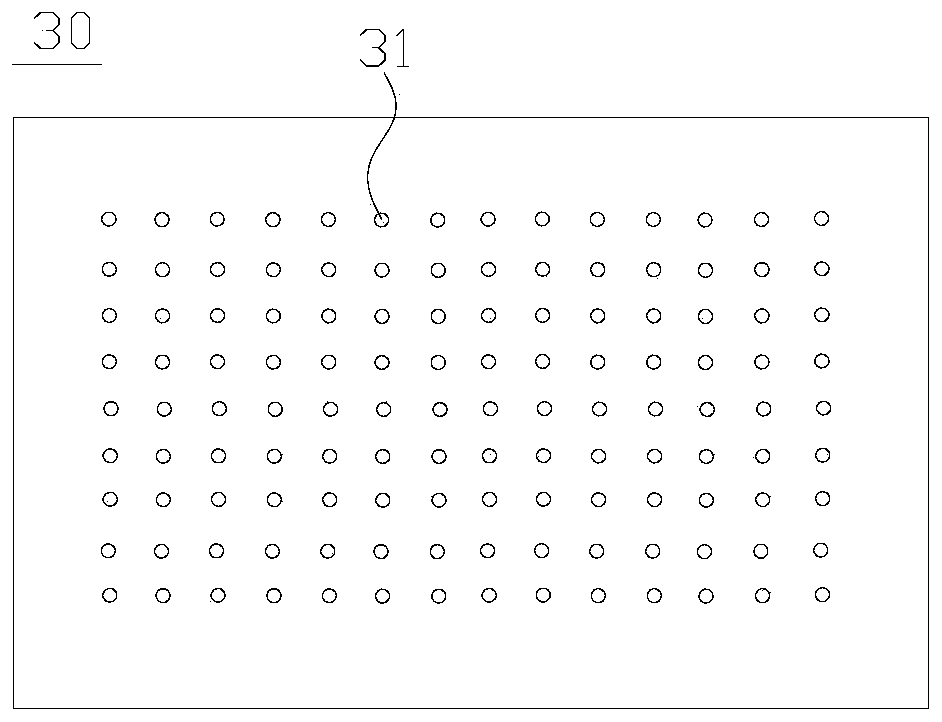

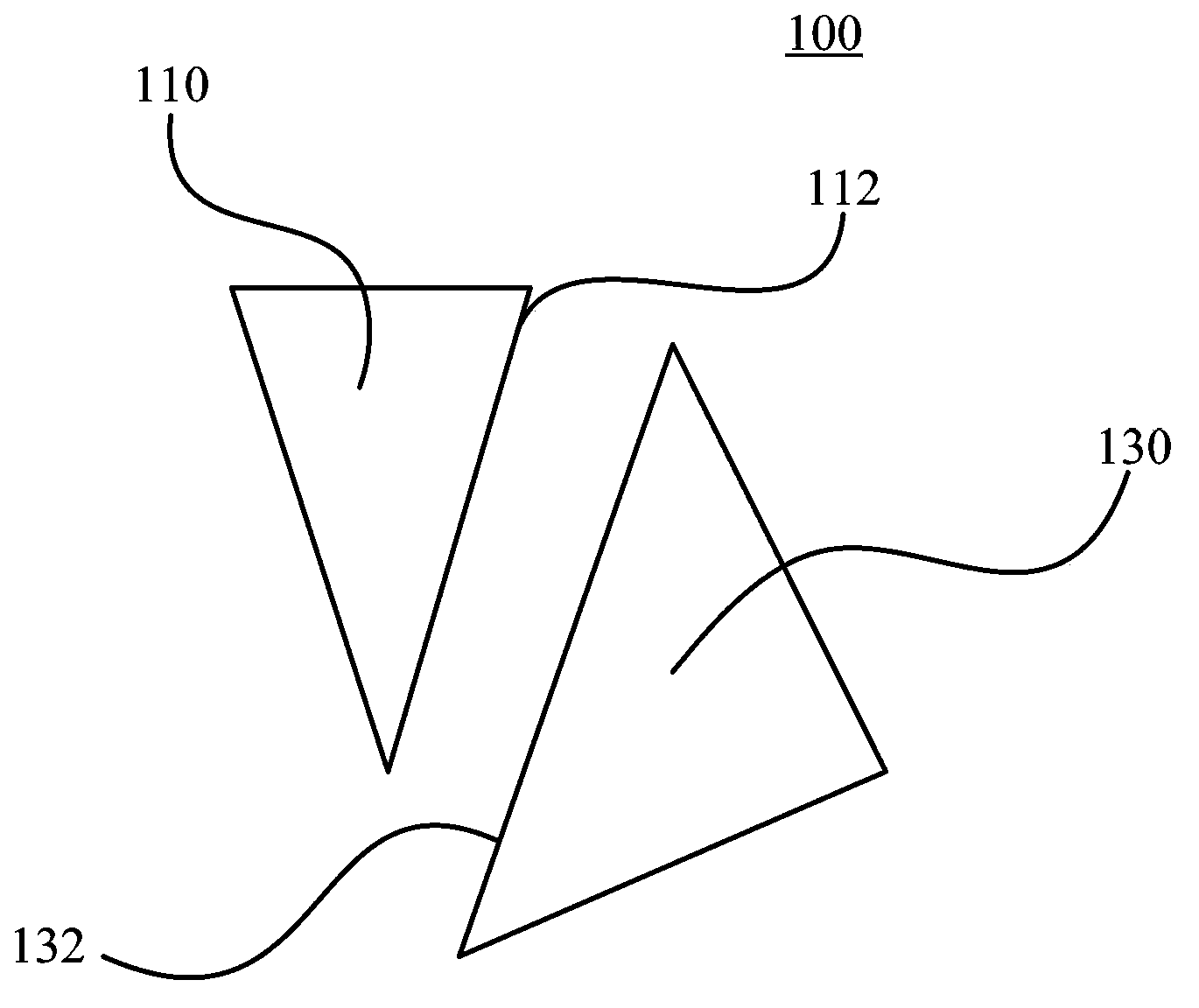

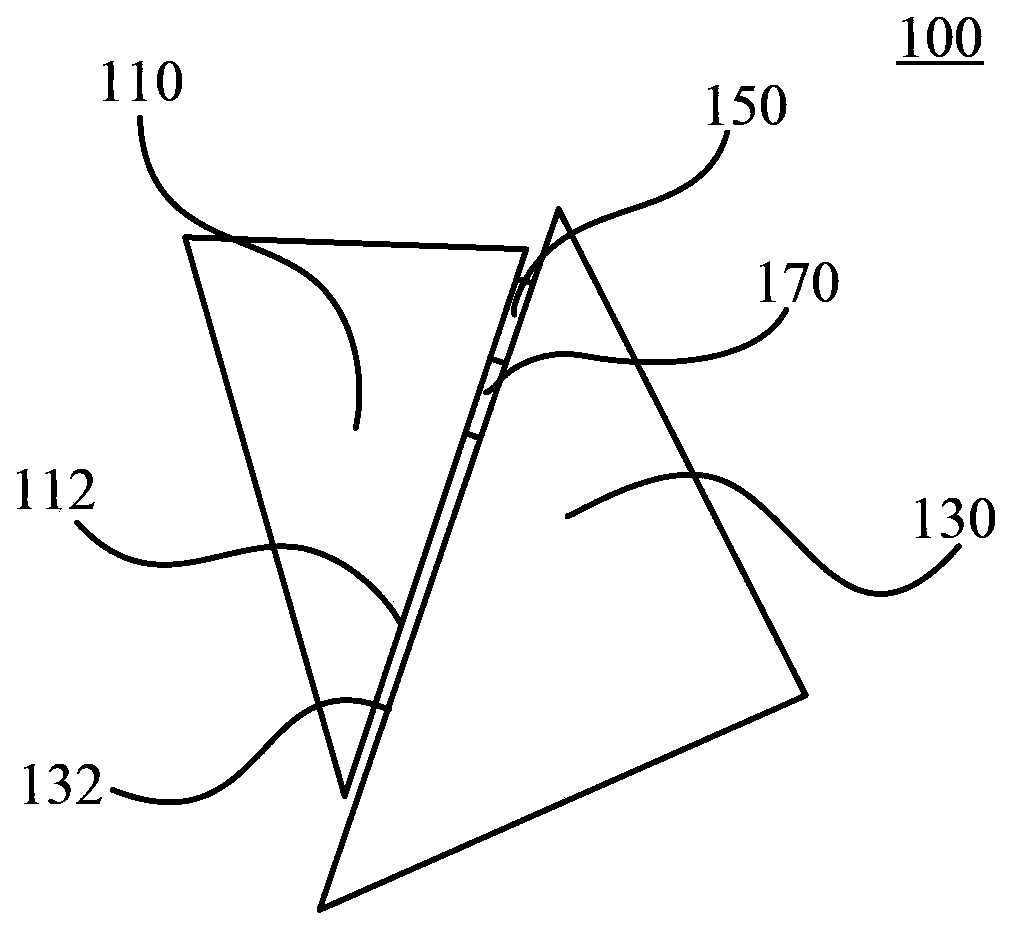

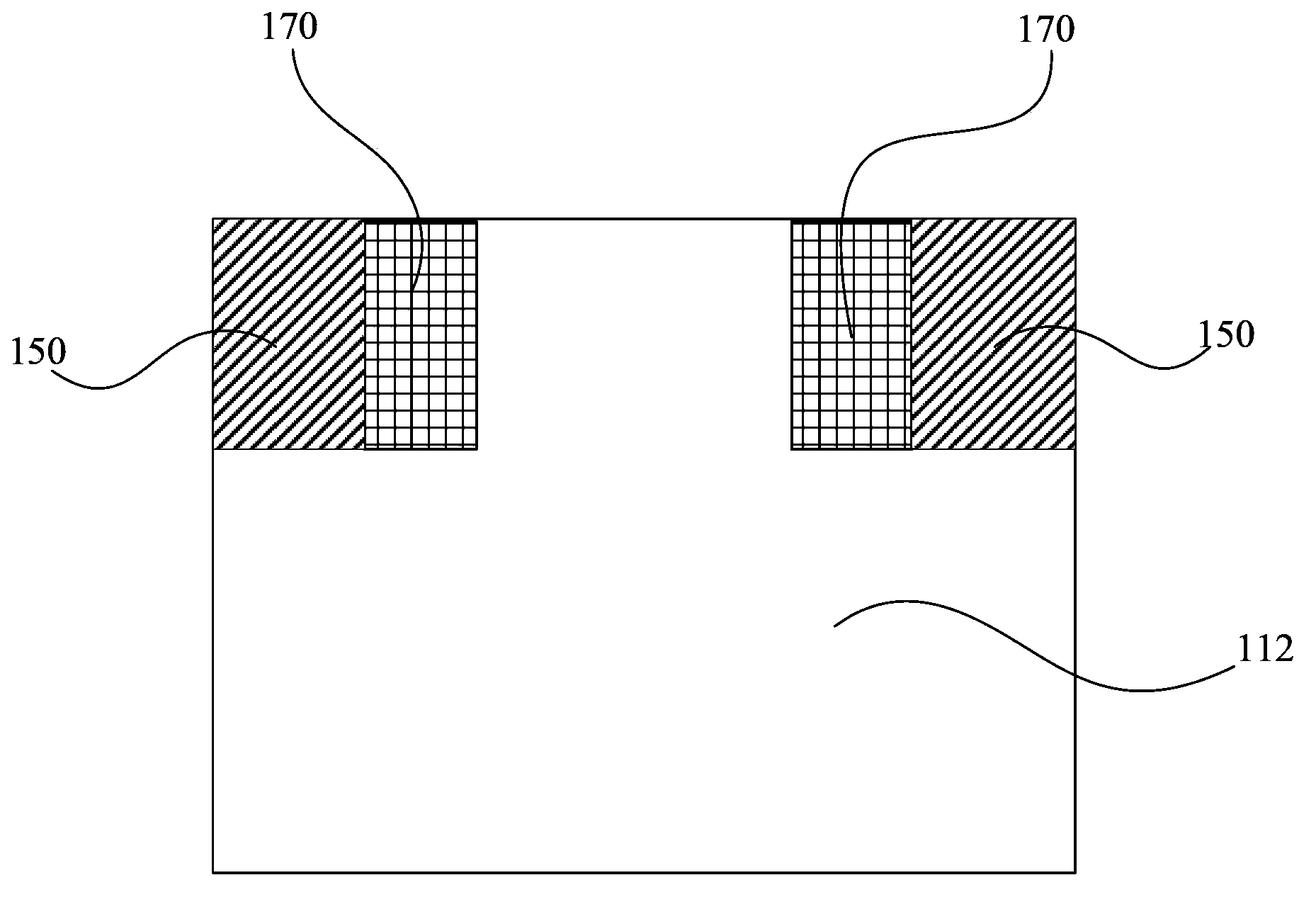

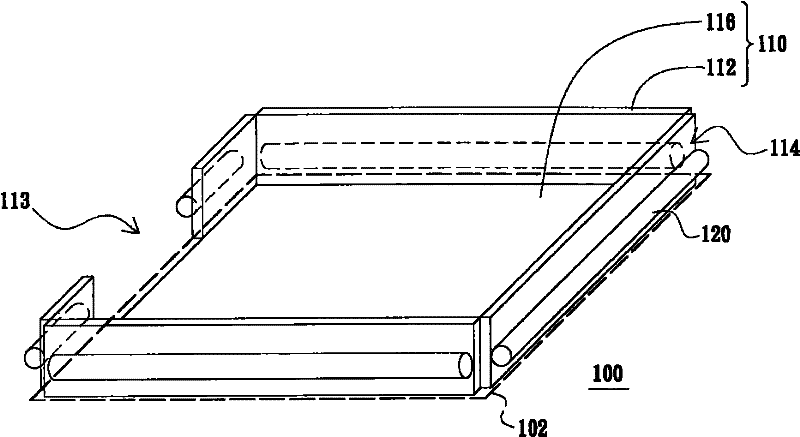

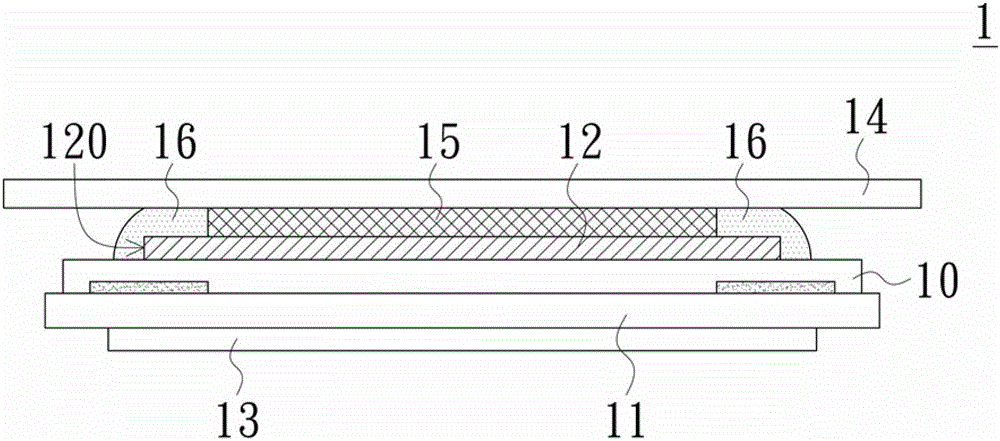

Structure for packaging organic electroluminescence device

InactiveCN1652647AImprove production yieldImprove production efficiencyElectroluminescent light sourcesSolid-state devicesEngineeringAgglutination

Encapsulation structure for organic electroluminescence device (OELD) includes following parts and structures: base plate and OELD on the base plate; encapsulation cover plate above the base plate in use for covering the OELD; multiple partition walls are setup at glue spreading region; A sealing glue regions are formed between two adjacent partition walls naturally. Agglutination glue is accommodated inside sealing glue regions. Thus, encapsulation cover plate through agglutination glue is agglutinated on the base plate. The invention raises superior rate and manufacturing efficiency and quality of product, as well as reduces glue flooding so as to be in favor of mass manufacture of the product.

Owner:UNIVISION TECHNOLOGY

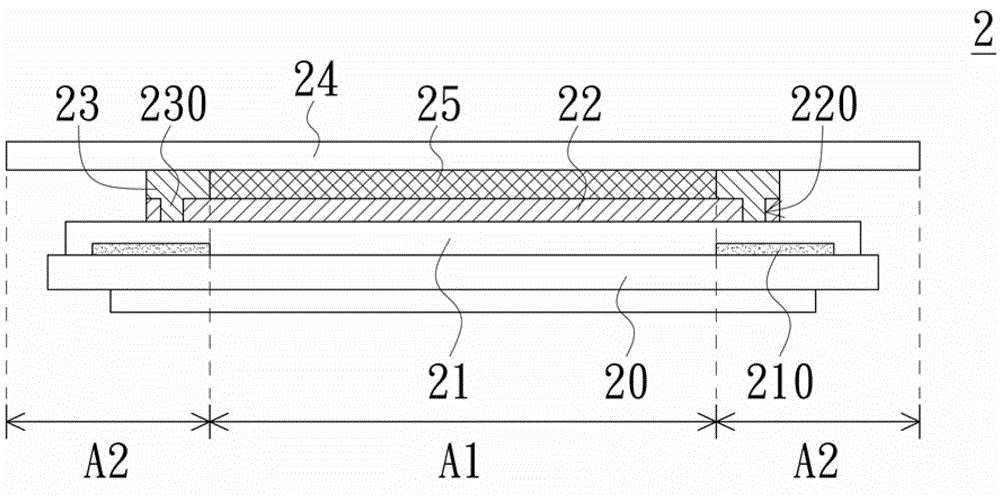

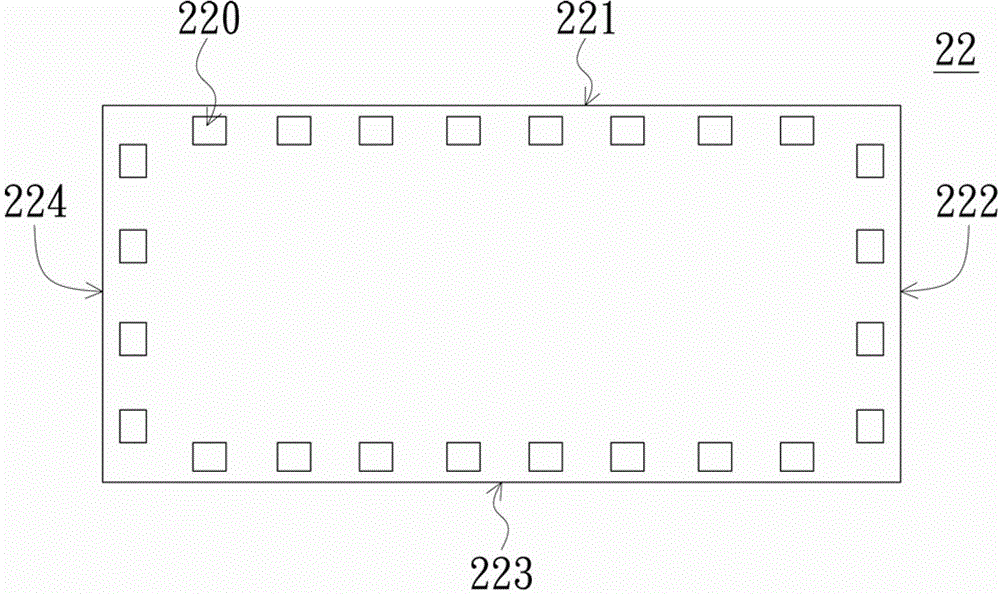

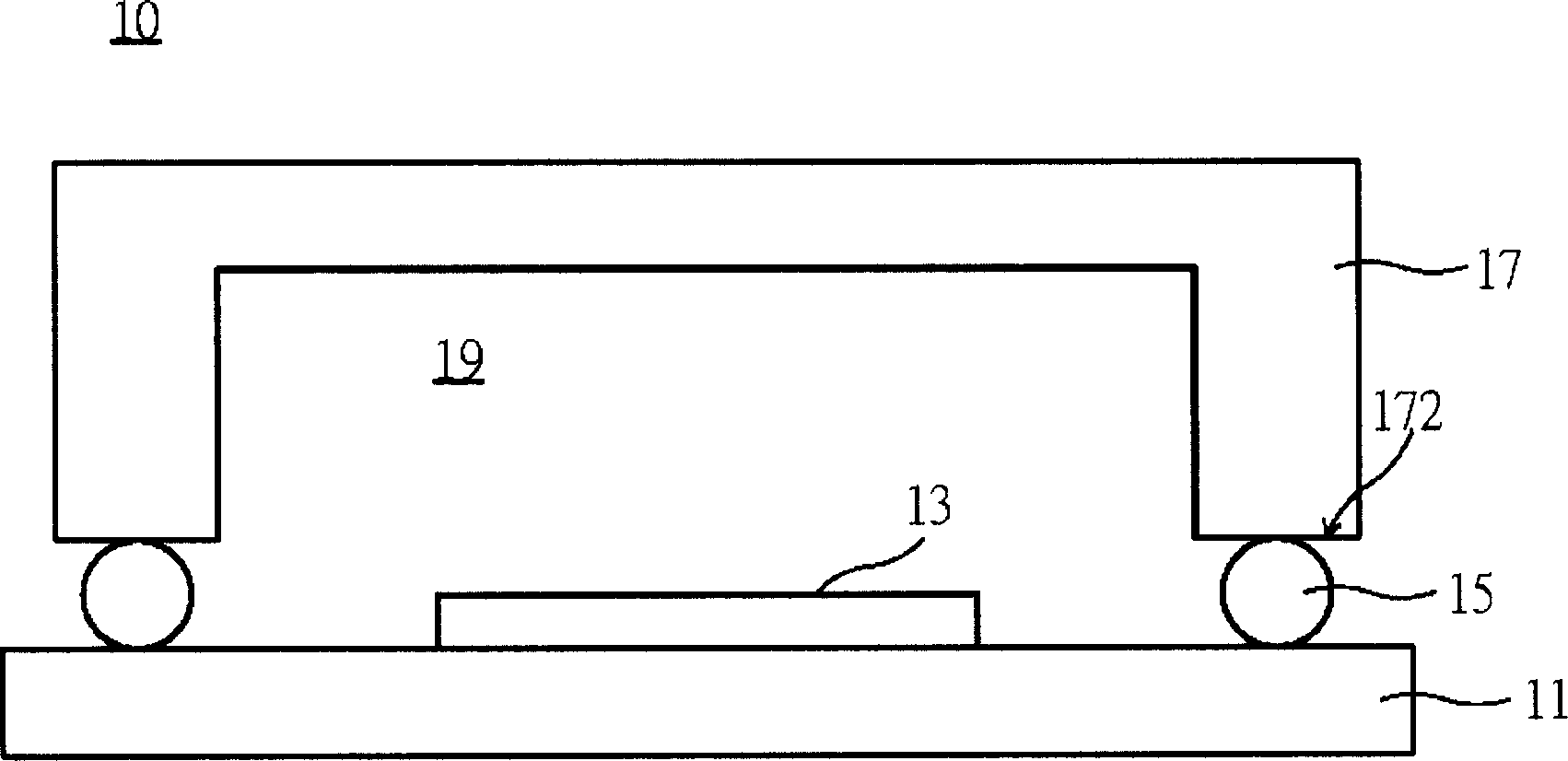

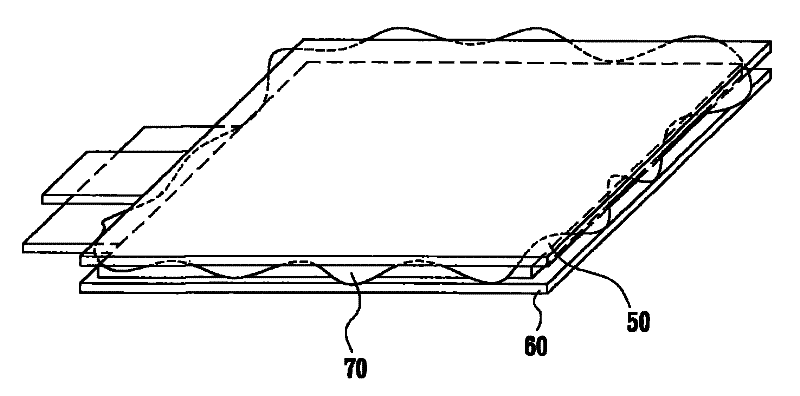

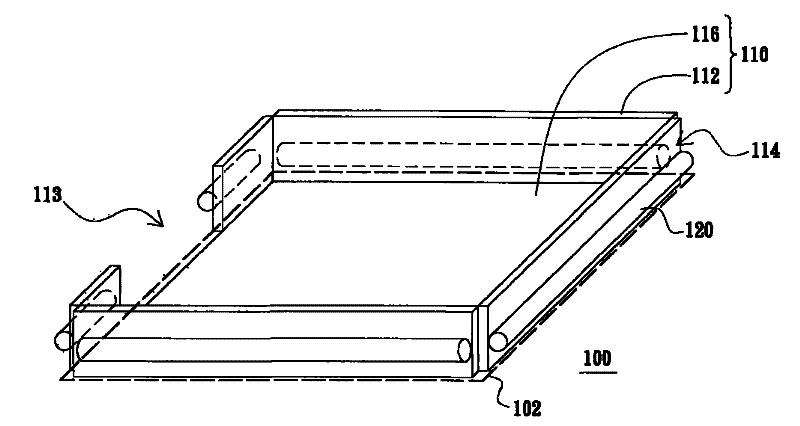

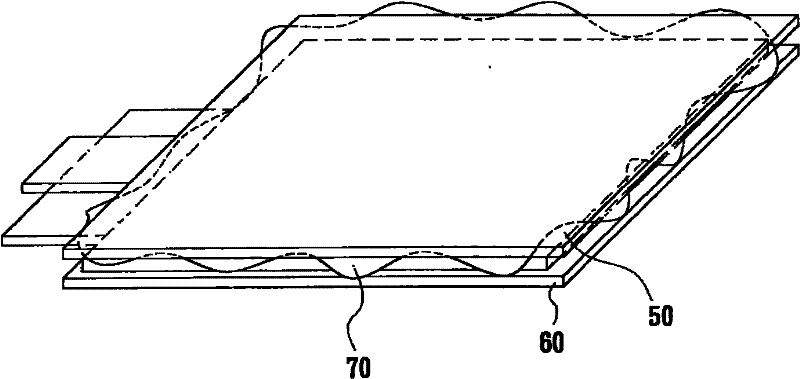

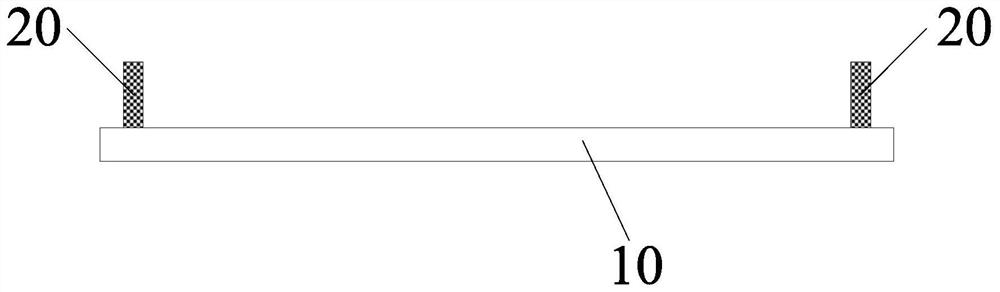

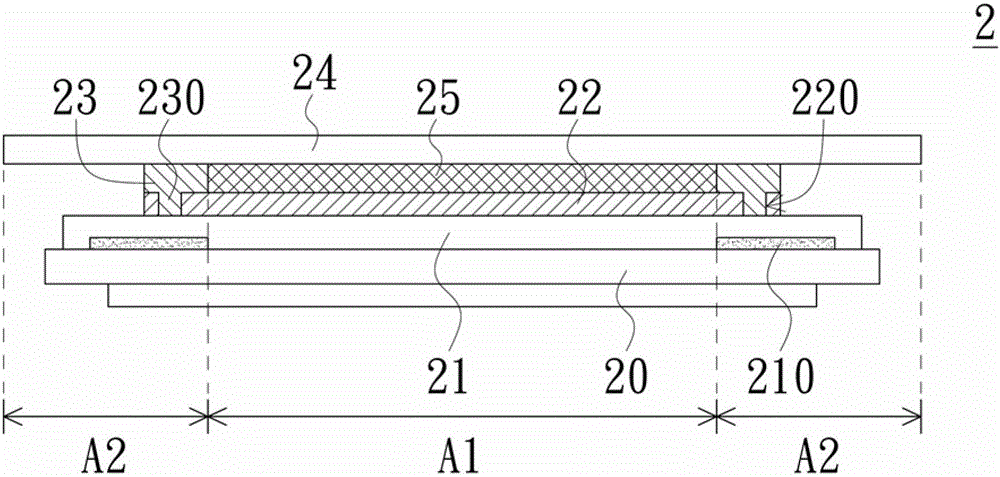

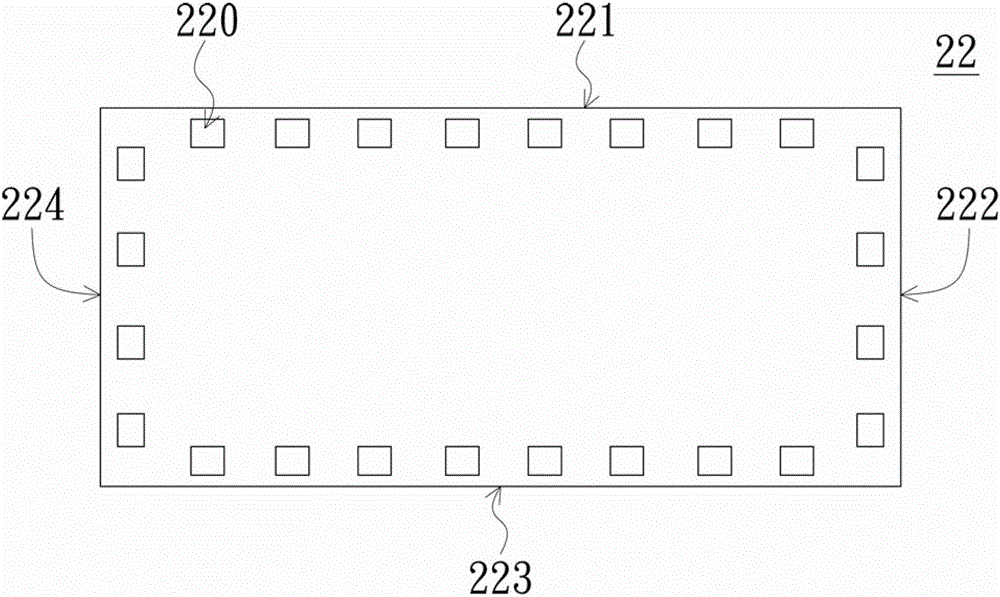

Glue overflow-preventing device and baseplate-laminating method using same

ActiveCN101702402AImprove glue overflowPrevent glue overflowSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:AU OPTRONICS CORP

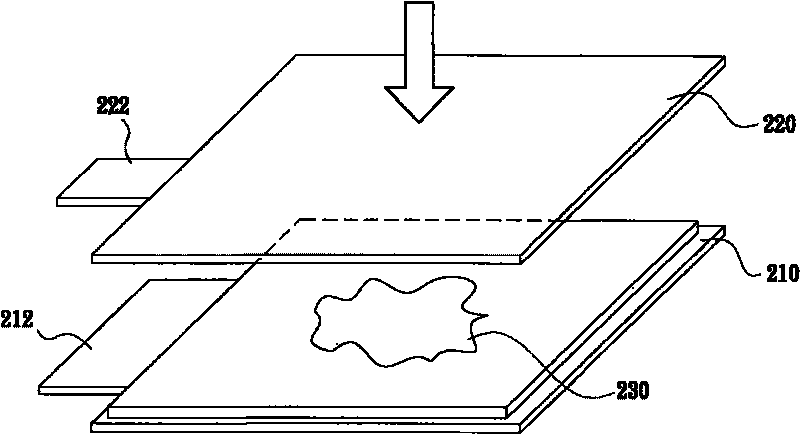

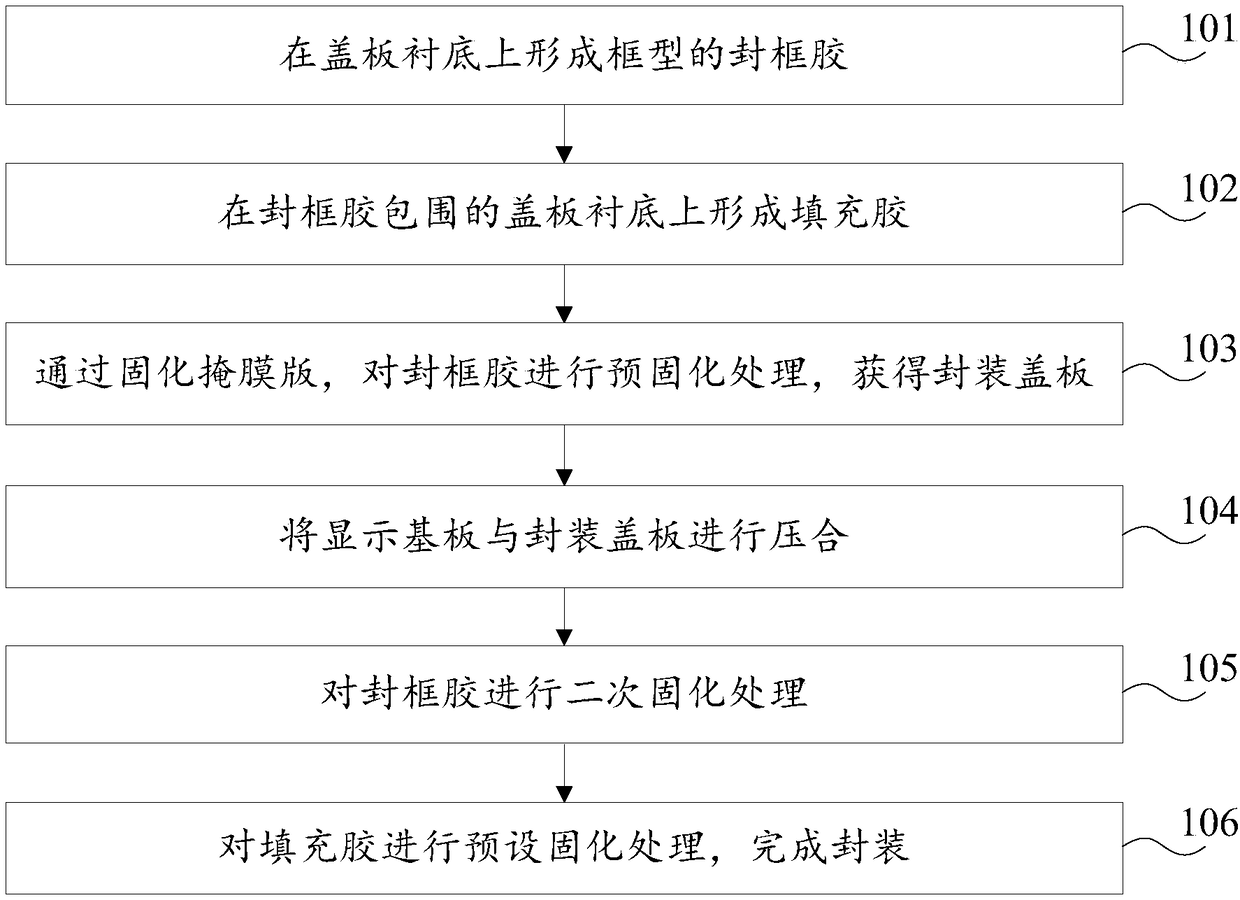

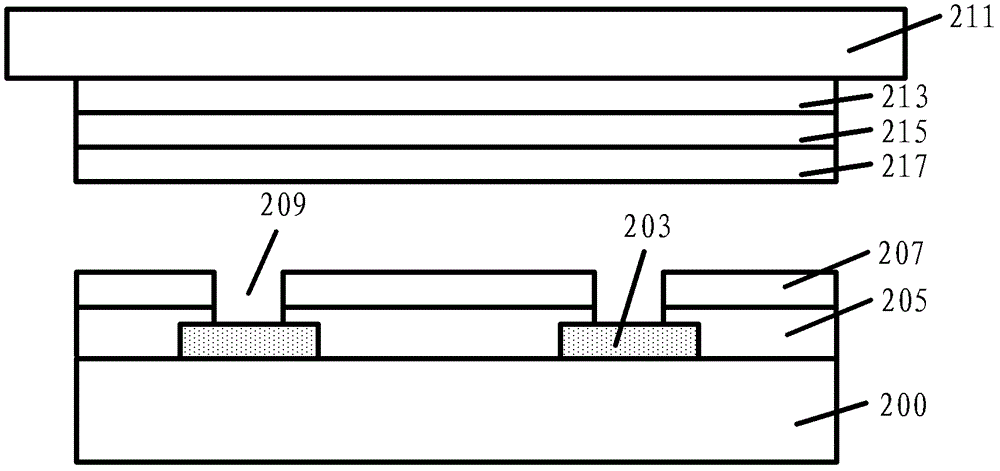

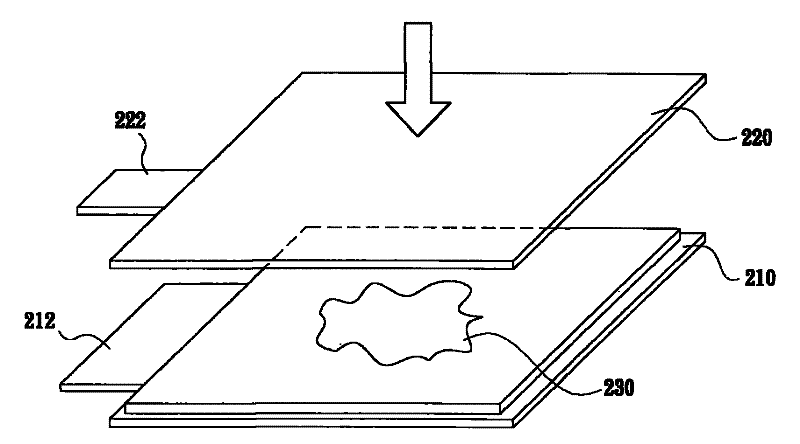

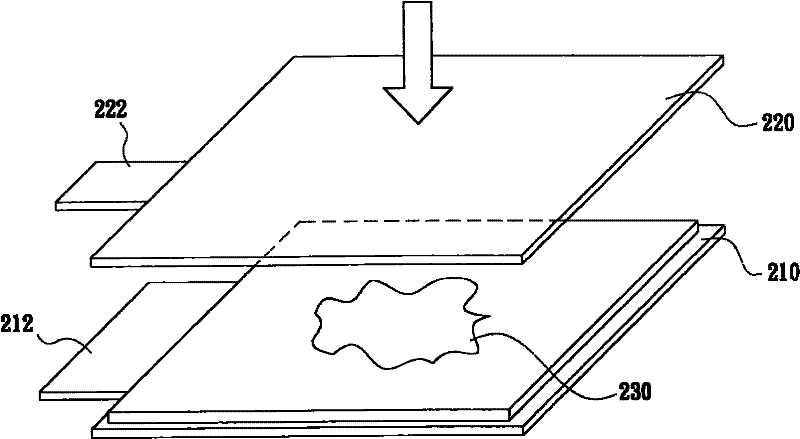

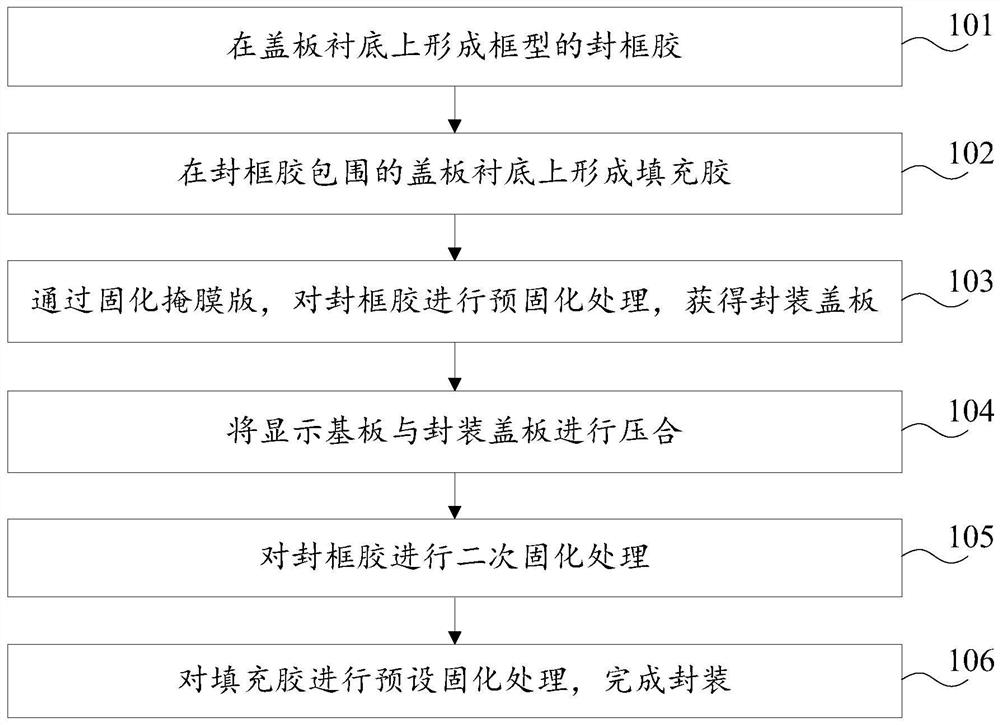

Display panel and package method thereof

ActiveCN109309174AHigh degree of curingImprove liquiditySolid-state devicesSemiconductor/solid-state device manufacturingSurface plate

The present invention provides a display panel and a package method thereof, and relates to the technical field of package. The method comprises the steps of: forming a frame-type box sealing glue ona cover plate substrate; forming filling glue on the cover plate substrate encircled by the box sealing glue; performing solidification of a mask to perform pre-solidification processing of the box sealing glue and obtain a package cover plate; laminating the display substrate and the package cover plate; performing secondary solidification processing of the box sealing glue; and performing presetsolidification processing for the filling glue to complete package. In the embodiment of the invention, the mask is solidified to separately perform pre-solidification processing for the box sealingglue, and at the same time, the filling glue cannot be subjected to pre-solidification processing to separately increase the solidification degree of the box sealing glue and improve the liquidity ofthe filling glue in the follow-up craft process so as to avoid the phenomenon that the box sealing glue can be collapsed by the filling glue and the filling glue is filled when the panel is laminated.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

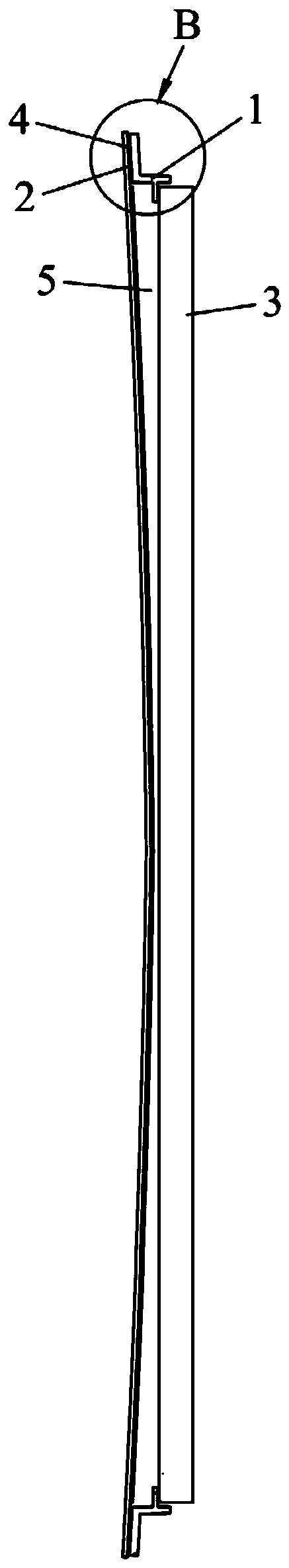

Strippable blue glue plug hole jig and method for stripping blue glue plug hole

ActiveCN110225661APrevent glue overflowPrinted circuit aspectsPrinted circuit manufacturePrinted circuit boardEngineering

The invention relates to the technical field of printed circuit boards, in particular to a strippable blue glue plug hole jig and a method for stripping blue glue plug hole. A compressed air box and an air guide plate are arranged, and compressed air is input into the compressed air box, so that air with certain pressure is output from the compressed air box and is led into a through hole of a PCBproduction board through an air guide through hole of the air guide plate; and when the strippable blue glue is subjected to silk-screen printing, the strippable blue glue flowing to a hole in the bottom of the through hole is subjected to upward resistance by compressed air, and the strippable blue glue can be prevented from flowing out of the through hole through balance of gravity and resistance. Meanwhile, an air guide mesh base plate stacked between the air guide plate and the compressed air box is arranged, the air flow which enters the air guide plate can be balanced and stabilized through the air guide mesh base plate, so that the air flow which finally enters each through hole of the PCB production plate is stable, and the surface of the strippable blue glue which is plugged at the hole opening of the through hole is flat.

Owner:DALIAN CHONGDA CIRCUIT

Camera module

PendingCN108267826AReasonable structureStructural stabilityTelevision system detailsColor television detailsCamera moduleEngineering

The invention relates to a camera module, which comprises an optical lens, a lens stand and a base, wherein the lens stand is used for bearing the optical lens; and the base is used for fixedly bearing the lens stand, the base has a length of 8 mm, a width of 8 mm and a height of 1 mm; and an annular boss is arranged on the base. The camera module has a reasonable structure, glue overflow can be prevented, the bonding strength is high, and the structure is stable and firm.

Owner:NINGBO SUNNY OPOTECH CO LTD

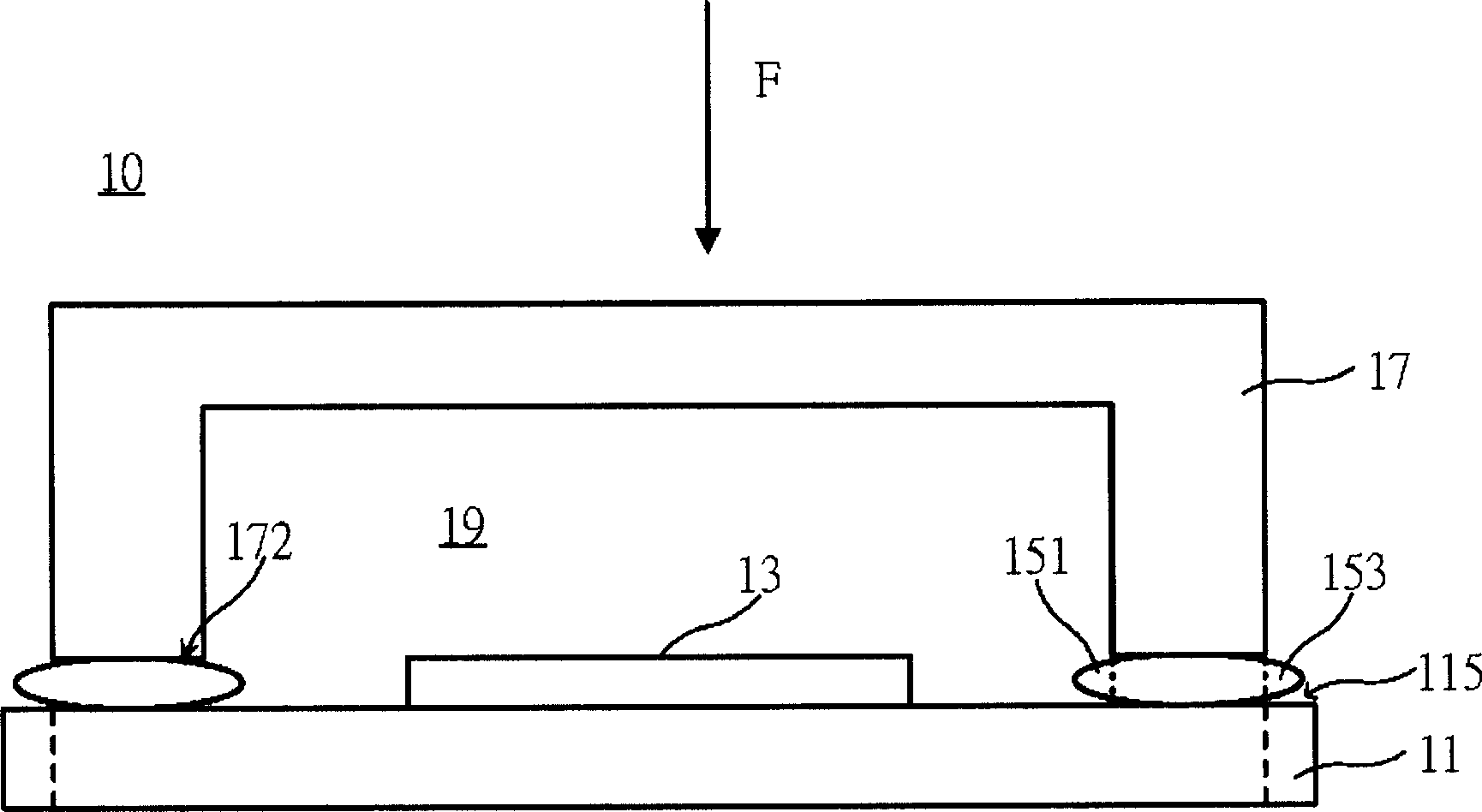

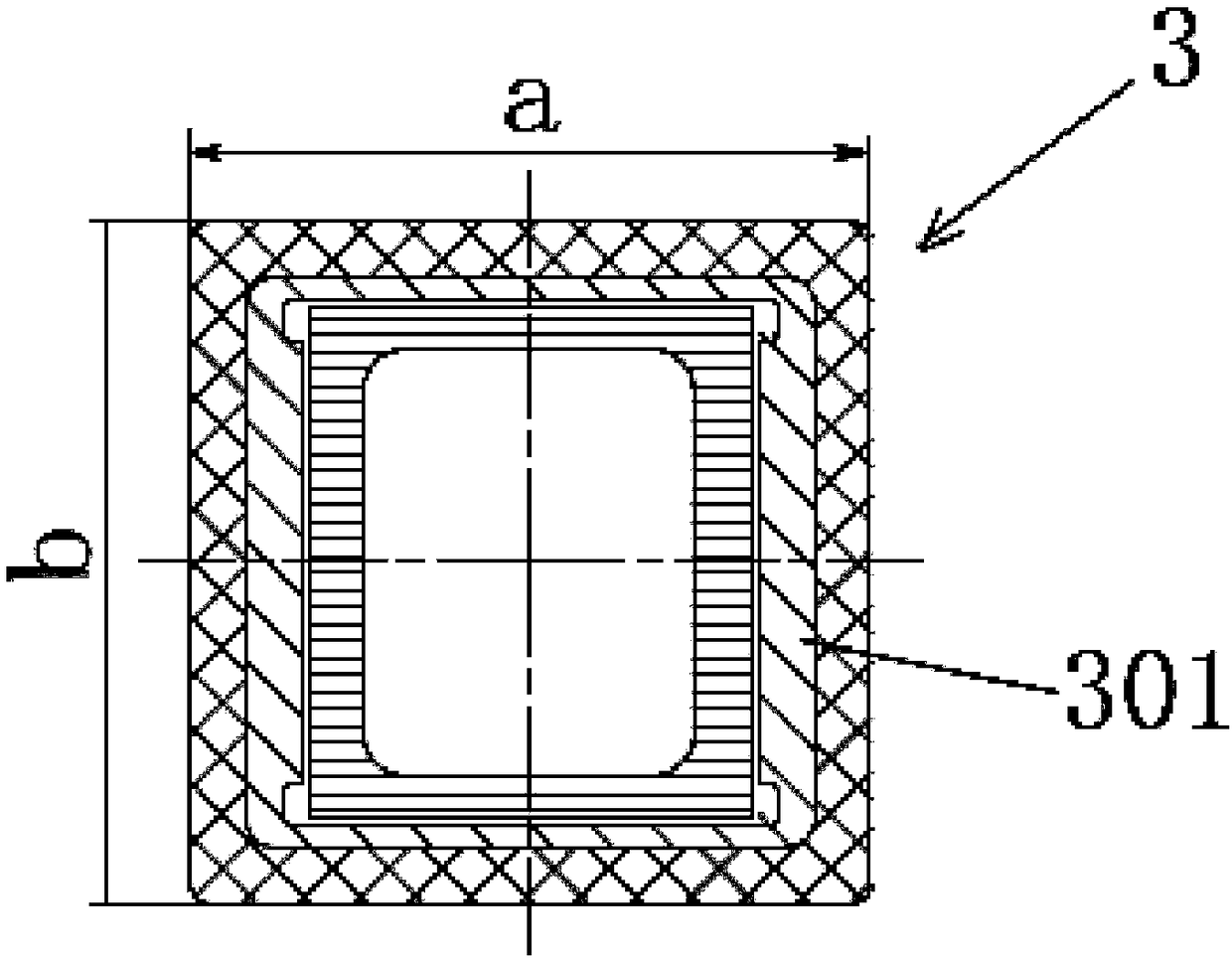

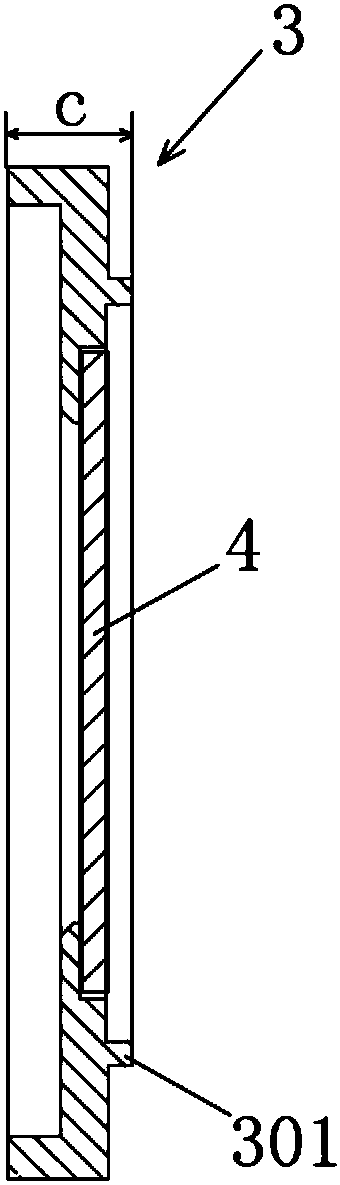

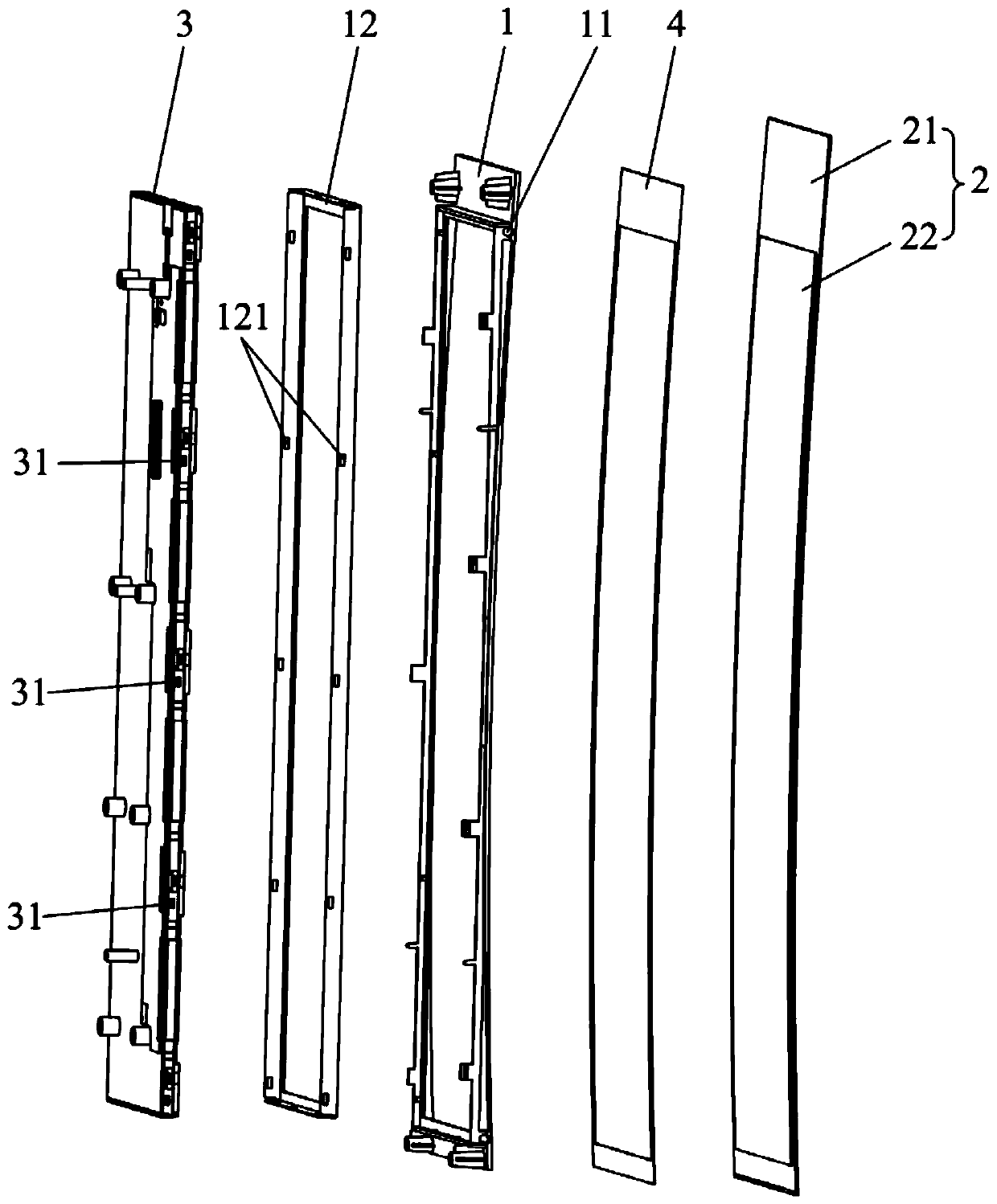

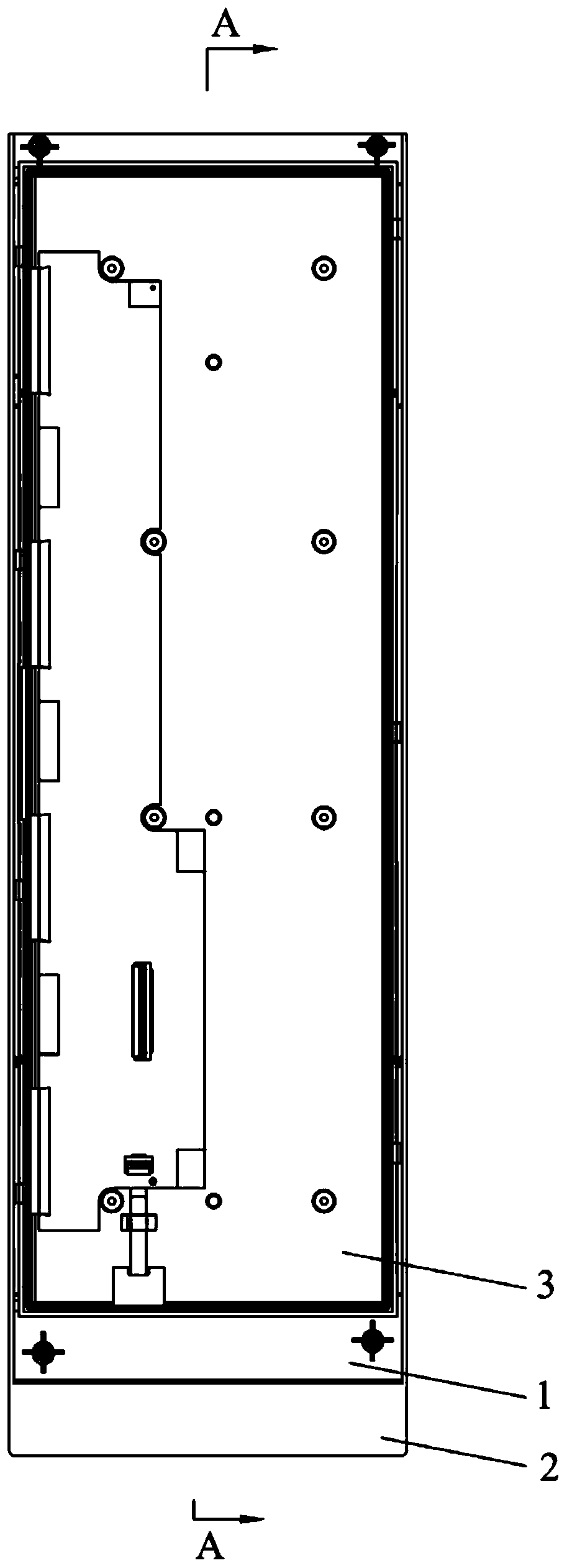

Full fitting tool and full fitting method of curved surface screen and planar liquid crystal module

The invention discloses a full fitting tool and a full fitting method of a curved surface screen and a planar liquid crystal module, and belongs to the technical field of full fitting of display screens. The full fitting tool of the curved surface screen and the planar liquid crystal module comprises a positioning glue injection frame component, a first side of the positioning glue injection framecomponent is configured to be fitted with the curved surface screen, a second side of the positioning glue injection frame component is configured to fix the planar liquid crystal module, a glue injection space is formed between the curved surface screen and the planar liquid crystal module in the positioning glue injection frame component, at least one glue injection opening is further disposedon the positioning glue injection frame component, and the glue injection opening communicates with the glue injection space. In the full fitting method of the curved surface screen and the planar liquid crystal module, the above full fitting tool of the curved surface screen and the planar liquid crystal module is adopted. Prior to a glue injection procedure, the planar liquid crystal module is fixed at first, that is, a flow space of liquid optical glue is limited before the glue injection to prevent the overflow or lack of glue.

Owner:CHINA FIRST AUTOMOBILE

Lithium battery processing device and processing method thereof

InactiveCN114464898AImprove capping efficiencyLow manufacturing costLiquid surface applicatorsFinal product manufactureManufacturing engineeringMechanical engineering

The invention relates to a lithium battery processing device and a processing method thereof.The lithium battery processing device comprises a conveying mechanism which is at least used for conveying a battery shell; the first driving part is connected with a swing arm, the swing arm is used for driving a gluing mechanism and a pressing mechanism, the gluing mechanism at least can glue the inner wall of the battery shell, a conveying mechanism is arranged between the conveying mechanism and the first driving part, and the conveying mechanism is at least used for conveying a cover body. When the cover body is located in the pressing working area of the pressing mechanism, the pressing mechanism presses the cover body to enable the cover body to be matched with the battery shell; in addition, the first driving piece drives the conveying mechanism, the gluing mechanism and the pressing mechanism at the same time, linkage of the conveying mechanism, the gluing mechanism and the pressing mechanism is achieved, multiple driving devices do not need to be used for respective driving, and the manufacturing cost of the equipment is further reduced.

Owner:赵绿梅

Manufacturing method of injection molded part and injection molded part

Owner:HONG FU TAI PRECISION ELECTRONICS (YANTAI) CO LTD +1

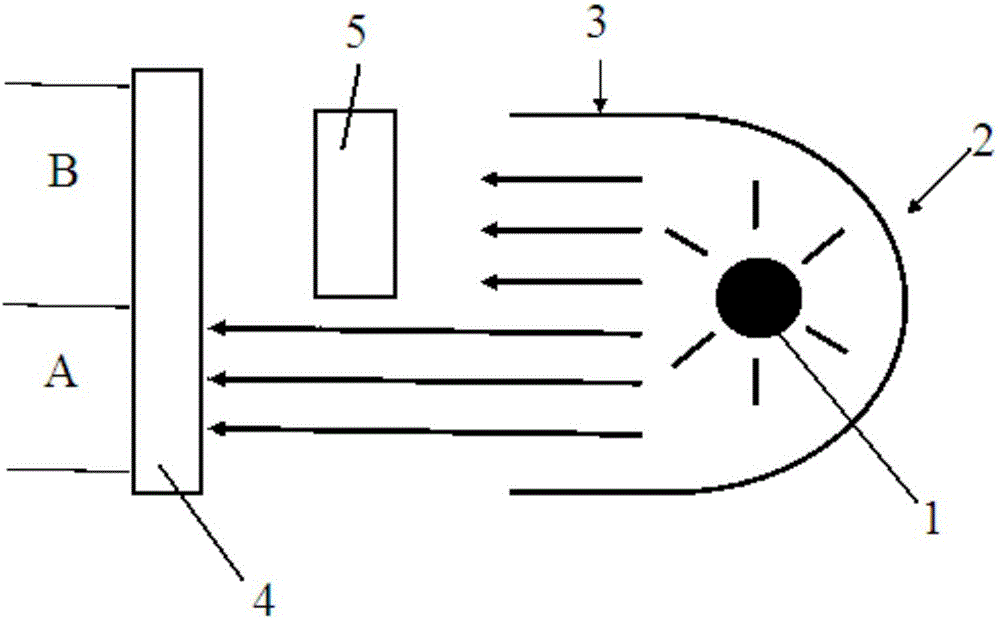

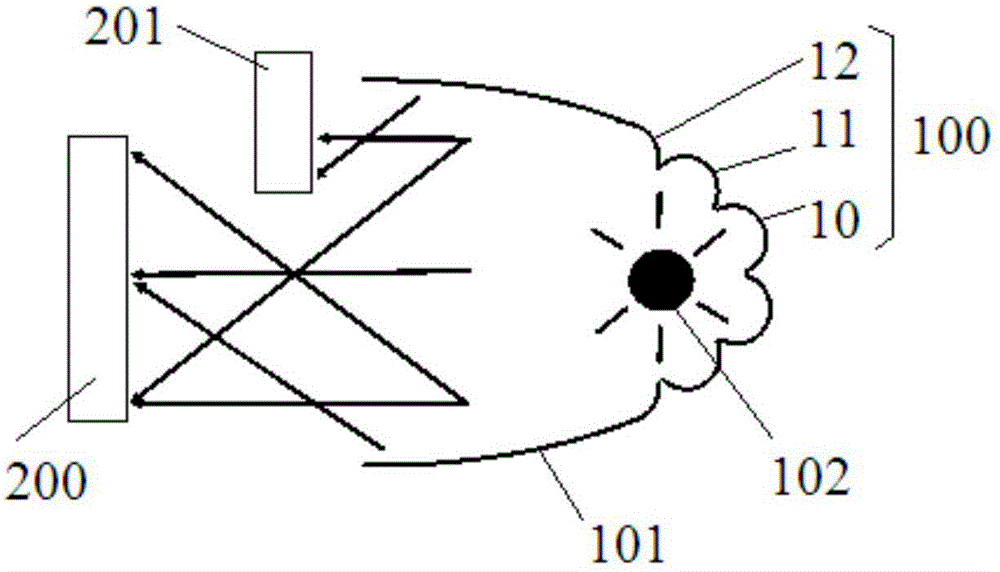

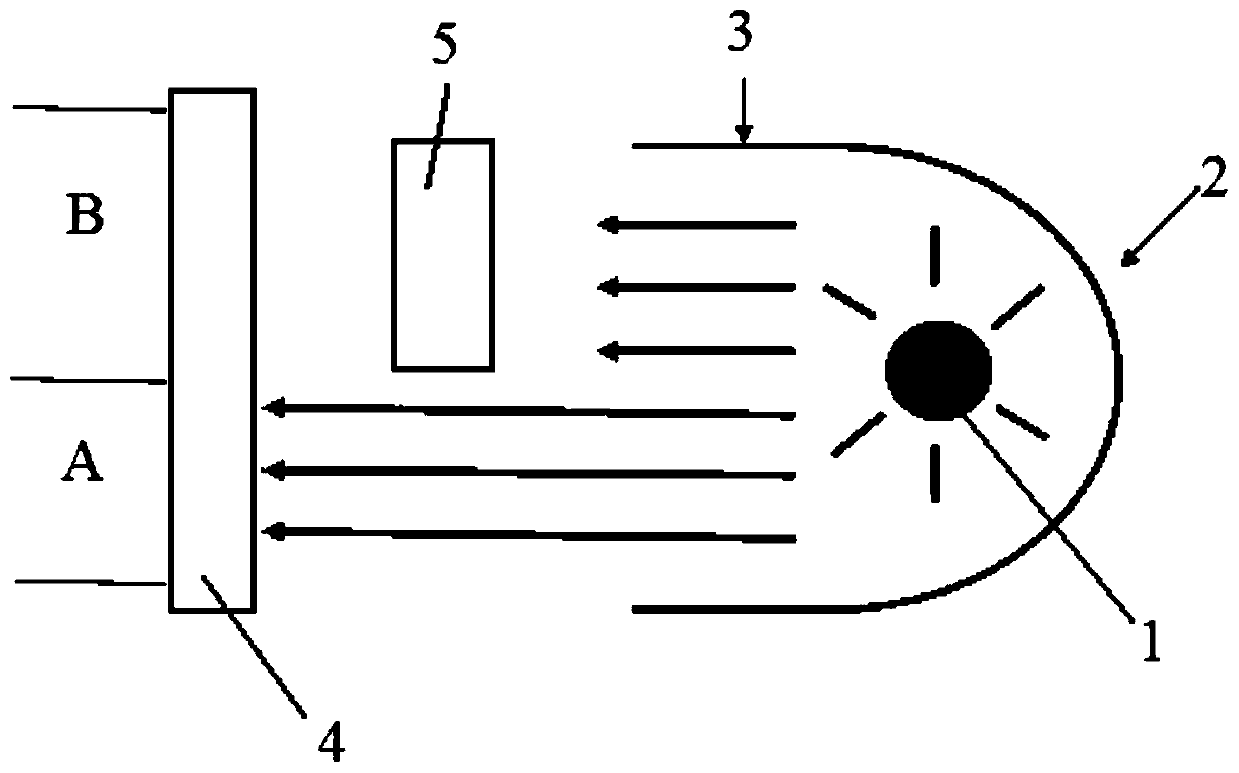

Curing lamp

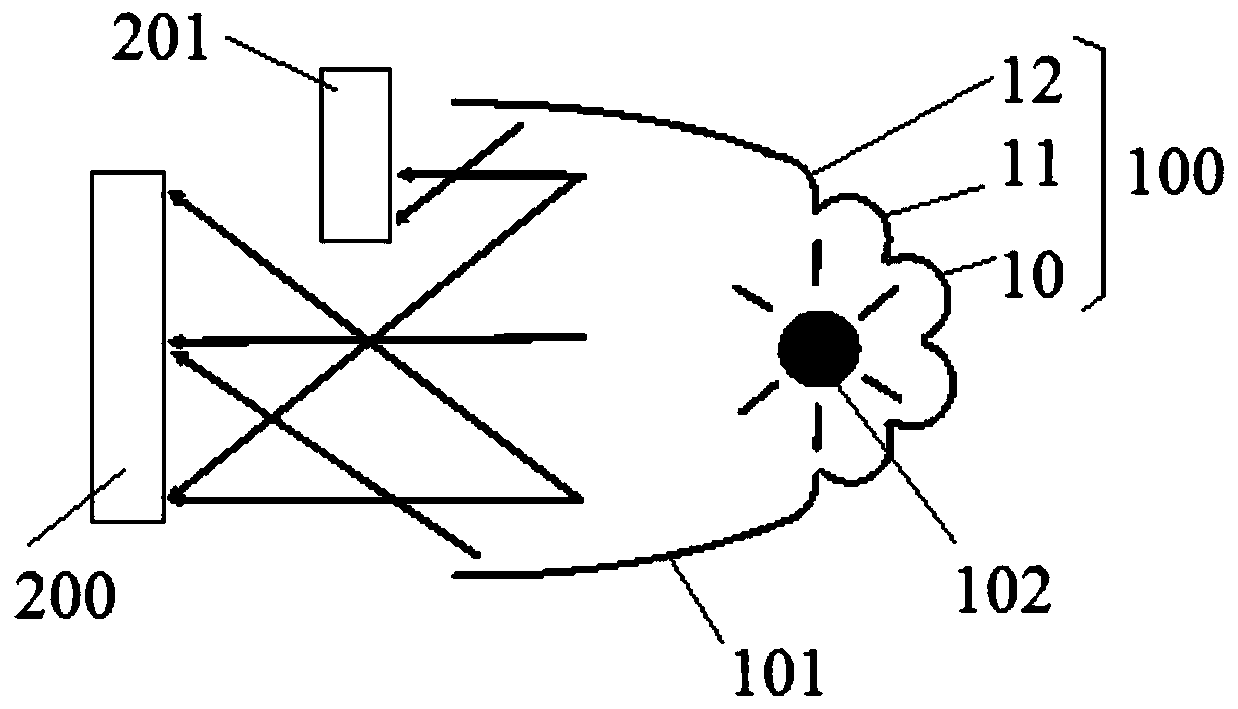

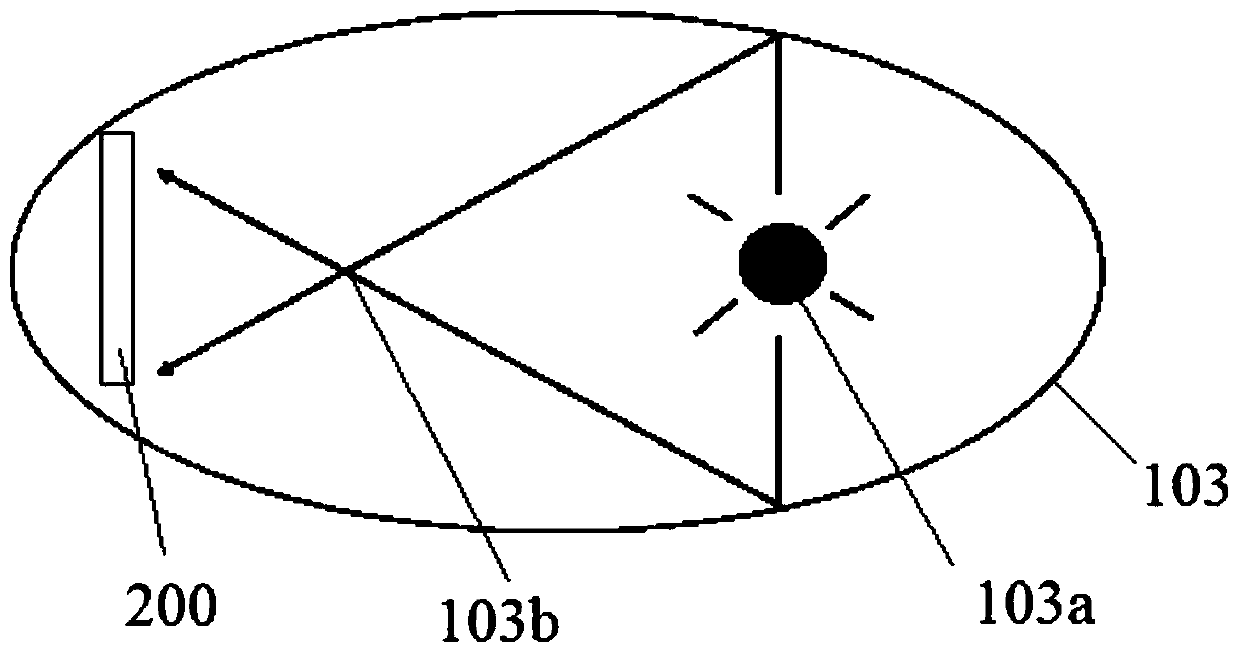

ActiveCN106111493AHigh strengthLarge scattering anglePretreated surfacesCoatingsDisplay deviceOptoelectronics

The invention provides a curing lamp which comprises a light source and a lampshade, wherein the lampshade is composed of a bottom reflecting surface and edge reflecting surfaces; the bottom reflecting surface is arranged on one side, away from an illuminated object, of the light source and is a hemispherical curved surface; and the edge reflecting surfaces are arranged surrounding the periphery of one side, facing the illuminated object, of the light source and are connected with the bottom reflecting surface. According to the curing lamp provided by the invention, lights can bypass an obstacle formed by slight deformation of a display device so as to prevent glue from overflowing, the strength of the lights can also be improved, the scattering angle of the lights can be increased, and the uniformity of lights emitted from different angles can be improved, thus the curing effect can be improved.

Owner:BOE TECH GRP CO LTD +1

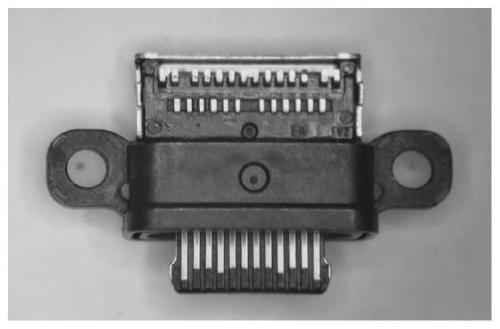

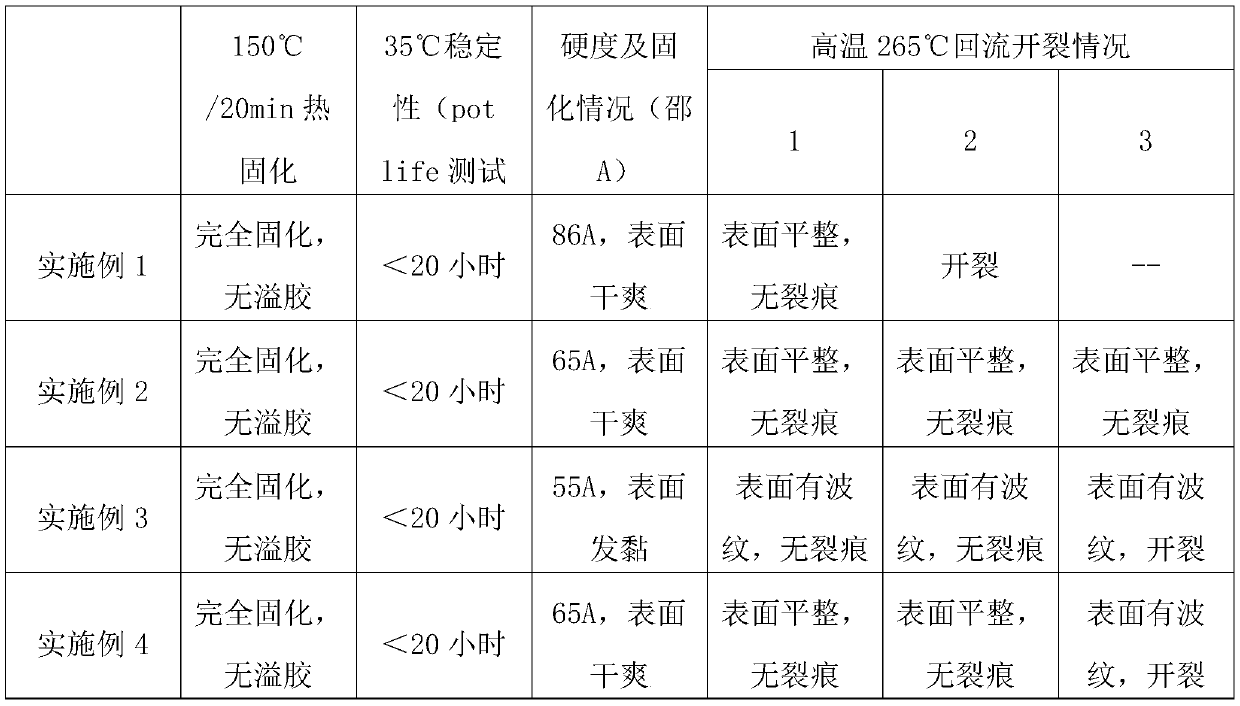

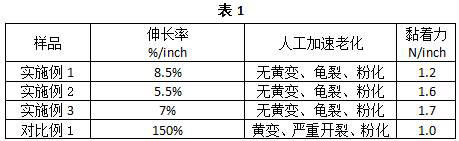

High-temperature-resistant flexible single-component epoxy sealing adhesive and preparation method thereof

ActiveCN111117542AGood flexibilityGel fastNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to the field of adhesives, in particular to a high-temperature-resistant flexible single-component epoxy sealing adhesive and a preparation method thereof. The high-temperature-resistant flexible single-component epoxy sealing adhesive is prepared from the following raw materials in parts by weight: 10-40 parts of epoxy resin, 10-30 parts of a mixed softening resin, 5-20 parts of an active diluent, 5-20 parts of a mixed curing agent, 0.01-1 part of a polymerization inhibitor, 0.1-5 parts of fumed silica, 0.01-1 part of an infiltration flow promoter and 5-30 parts of spherical silica powder, the mixed curing agent is a mixture of a modified amine latent heat curing agent and a modified imidazole latent heat curing agent, and the mixed softening resin is prepared from at least two of F100, F300, Capa3050, H2004, HEF750, HEF751, EP-4000L and EP-4000S. The adhesive disclosed by the invention can be widely applied to sealing processes of USB ports and high-temperature-resistant reflow soldering processes, has good bonding performance on PA46, stainless steel, PC and the like, and ensures excellent waterproof sealing performance and plugging resistance of the USB ports of electronic products.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

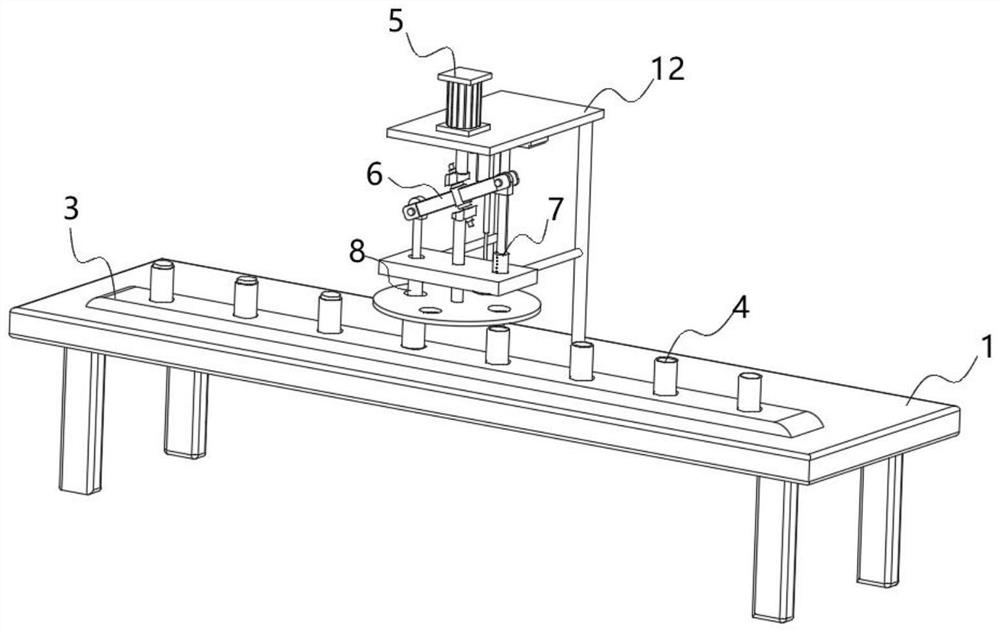

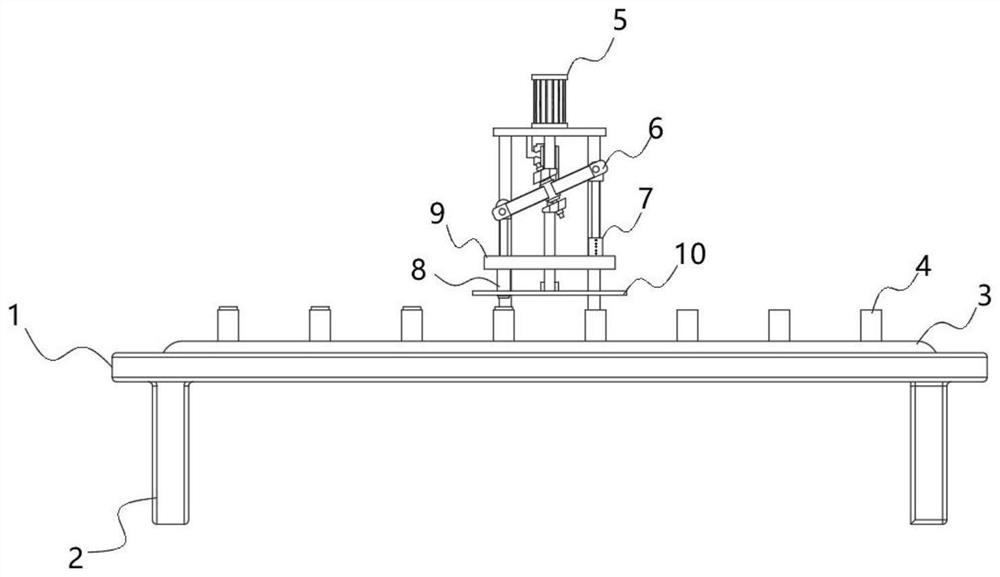

Suturing equipment for medical anaesthetic mask machining

InactiveCN114801216AAvoid glue overflowQuality assuranceDomestic articlesElectric machineryDrive motor

The invention discloses a medical anaesthetic mask processing sewing device which comprises a supporting frame, a workbench is arranged on the supporting frame, a placing table is arranged on the workbench, a side plate is further arranged on the workbench, a mechanical arm is arranged on the side plate, a driving motor is arranged at the bottom of the workbench, and the mechanical arm is arranged on the driving motor. A driving motor is arranged on the workbench, a driving shaft is arranged at the output end of the driving motor and rotationally penetrates through the workbench, a connecting block is arranged at the end of the driving shaft, connecting rods are arranged on any two adjacent sides of the connecting block, a flattening assembly and a gluing assembly are arranged on the two connecting rods correspondingly, and an air curtain assembly is arranged on the outer side of the containing table. According to the sewing equipment for medical anaesthetic mask machining, it is guaranteed that an air cushion is horizontally placed through the placing table and the flattening assembly, then air is blown towards the upper surface of the air cushion from the inner side and the outer side through the air curtain assembly when the air cushion and the air cushion are attached, uv glue is prevented from overflowing, and the connecting quality of the air cushion and the air cushion is guaranteed.

Owner:驻马店市中心医院

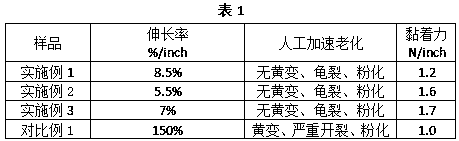

Manufacturing method of high-weather-resistance fragile label material

ActiveCN110903775APrevent glue overflowCompliant with fragile label requirementsStampsFilm/foil adhesive primer layersComposite filmWeather resistance

The invention discloses a manufacturing method of a high-weather-resistance fragile label material, and the method comprises the following steps: Q1, a PET base material which is not subjected to corona treatment and is 36-100 microns thick is selected, the surface of the PET base material is coated with a weather-resistant layer coating, and a composite film A is prepared and wound; Q2, the surface of the weather-resistant layer of the composite film A is coated with a color layer coating, and a composite film B is prepared and wound; Q3, a covering layer is formed on the surface of the colorlayer of the composite film B, and a composite film C is prepared and wound; Q4, a pressure-sensitive adhesive layer is applied to latticed release paper or a release film to prepare a composite filmD; and Q5, the covering layer of the composite film C and the pressure-sensitive adhesive layer of the composite film D are compounded to obtain the high-weather-resistance fragile label material. Through the steps, the high-weather-resistance fragile label material can be finally prepared, has excellent chemical stability and physical characteristics, reaches higher weather resistance level andfragile requirements, and has wide market prospect.

Owner:浙江龙游道明光学有限公司

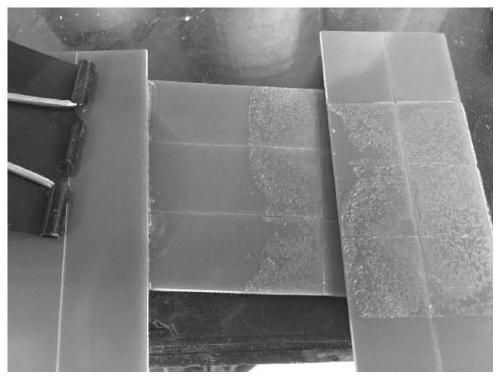

Total internal reflection prism and manufacturing method thereof

InactiveCN103809266AControl spacingPrevent glue overflowMountingsTotal internal reflectionBonding process

The invention discloses a total internal reflection prism comprising a first prism, a second prism, optical cement layers and optical oil layers. The first prism comprises a first bonding layer. The second prism comprises a second bonding layer. The first bonding layer is bonded with the second bonding layer through the optical cement layers to make the first prism and the second prism formed into an integral body. The optical oil layers are arranged in parallel on edges of the optical cement layers and bonded with the first bonding layer and the second bonding layer. In the total internal reflection prism, a layer of optical oil layer can be printed on the first bonding layer and / or the second bonding layer at first, then optical cement is applied onto the first bonding layer and / or the second bonding layer, and finally, the first bonding layer is bonded with the second bonding layer. The optical oil layers have a certain thickness and arranged between the first bonding layer and the second bonding layer, so the space between the first bonding layer and the second bonding layer can be controlled accurately to prevent the occurrence of the excessive cement condition in the bonding process. Meanwhile, a total internal reflection prism manufacturing method is further provided.

Owner:SHENZHEN O FILM TECH

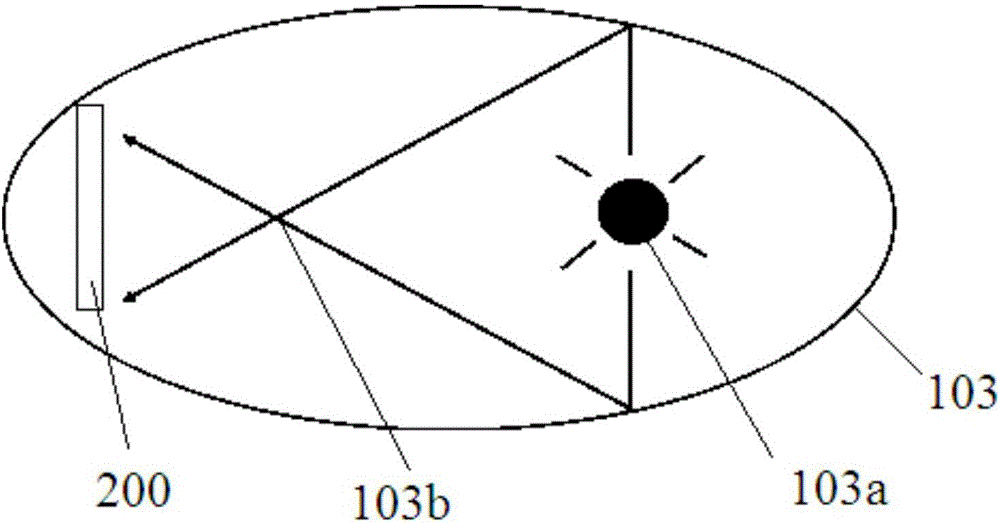

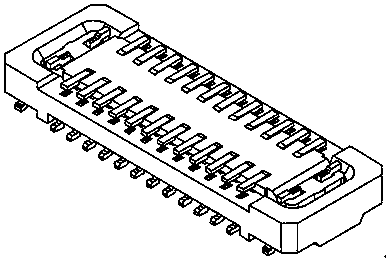

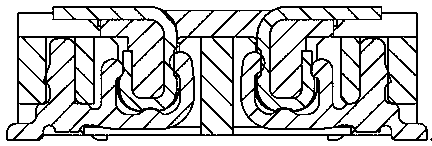

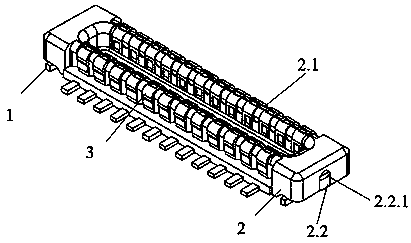

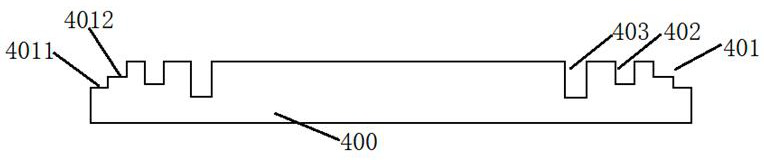

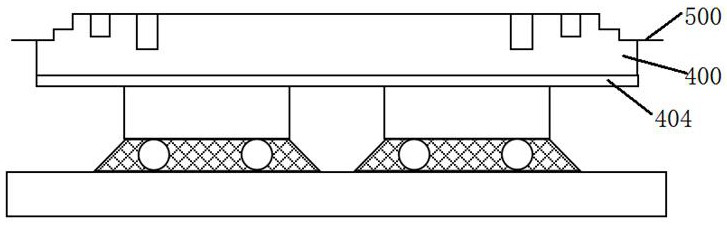

Plate-to-plate male connector in strong lock structure

The invention discloses a plate-to-plate male connector in a strong lock structure. The male connector comprises fixing pins, a plastic body and a conductive terminal, and the fixing pins, the plasticbody and the conductive terminal are assembled together. The conductive terminal is in an inverted N-shaped structure, and the surface of the conductive terminal is provided with a plurality of concave structures in equilateral triangle distribution. The concave structures in the surface of the conductive terminal contact with female connector conducive terminal contact points which are enabled to fall into male conductive terminal grooves, and each contact of the conductive terminal is fixed, so that problems of separating and turning after insertion of male and female connectors are avoided. A glue sink structure surrounds the plastic body and the conductive terminal to prevent glue overflowing caused by an injection molding process. Left and right sides of the plastic body are providedwith projections respectively, one end is provided with a smooth arc surface for smooth transition joint with the lateral side, a guide effect is achieved in butt joint of the male and female connectors, and easiness in pulling is achieved in separation of the male and female connectors. The projections are small in female connector body inner groove contact area, a large space is reserved by twosides of each projection and a female connector body, and a fulcrum effect in pulling up is achieved.

Owner:江苏益鑫通精密电子有限公司

curing light

ActiveCN106111493BHigh strengthLarge scattering anglePretreated surfacesCoatingsDisplay deviceOptoelectronics

The invention provides a curing lamp which comprises a light source and a lampshade, wherein the lampshade is composed of a bottom reflecting surface and edge reflecting surfaces; the bottom reflecting surface is arranged on one side, away from an illuminated object, of the light source and is a hemispherical curved surface; and the edge reflecting surfaces are arranged surrounding the periphery of one side, facing the illuminated object, of the light source and are connected with the bottom reflecting surface. According to the curing lamp provided by the invention, lights can bypass an obstacle formed by slight deformation of a display device so as to prevent glue from overflowing, the strength of the lights can also be improved, the scattering angle of the lights can be increased, and the uniformity of lights emitted from different angles can be improved, thus the curing effect can be improved.

Owner:BOE TECH GRP CO LTD +1

A peelable blue rubber plug hole fixture and peelable blue rubber plug hole method

ActiveCN110225661BPrevent glue overflowPrinted circuit aspectsPrinted circuit manufactureEngineeringPrinted circuit board

Owner:DALIAN CHONGDA CIRCUIT

Method for laminating cover film in flexible board

ActiveCN103108502BImprove signal transmission performancePrevent glue overflowMultilayer circuit manufactureEngineeringHigh pressure

The invention provides a method for laminating a cover film in a soft board. The method includes a first step of providing a soft copper clad substrate and the cover film, a welding disc is formed on the soft copper clad substrate, and a window is arranged on the cover film, a second step of enabling the cover film to be covered on the surface of the soft copper clad substrate, and enabling the welding disc to be exposed out of the window, a third step of forming a glue blocking layer corresponding to the window after the cover film is covered on the surface of the soft copper clad substrate, and a fourth step of laminating the soft copper clad substrate and the cover film after the glue blocking layer is formed. The glue blocking layer has good elastic deformation capacity under a high temperature and high pressure environment, can fully fill the window in the laminating process, and avoids glue leakage, so the method improves signal transmission capacity of a follow-up formed printed circuit board (PCB) soft board.

Owner:JIANGNAN INST OF COMPUTING TECH

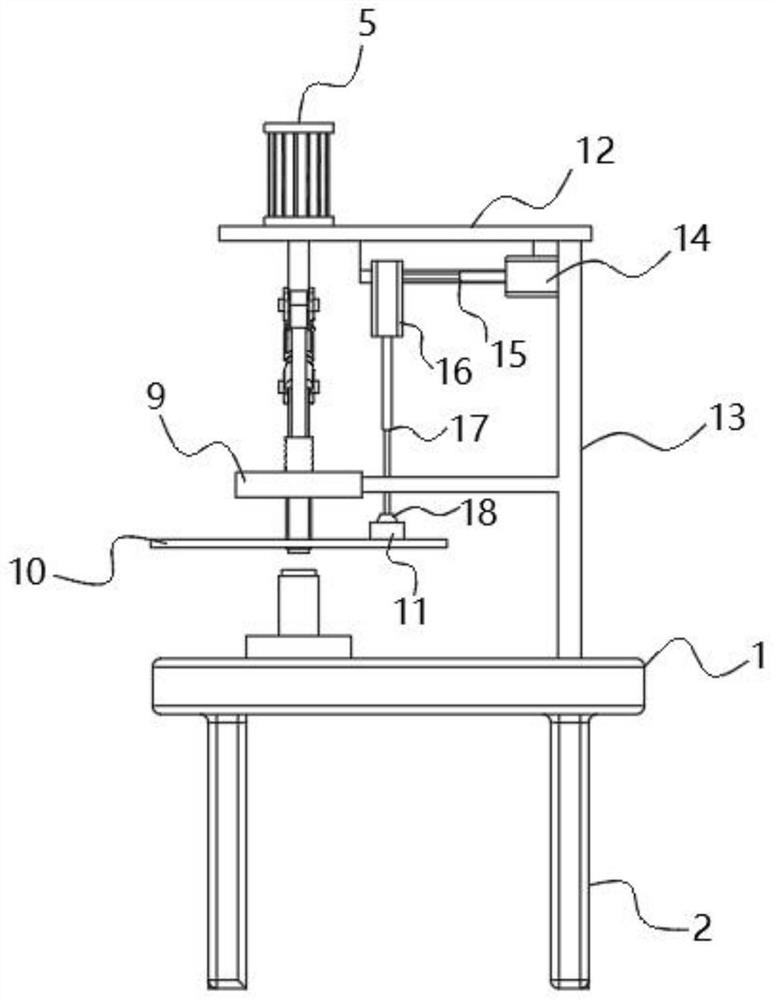

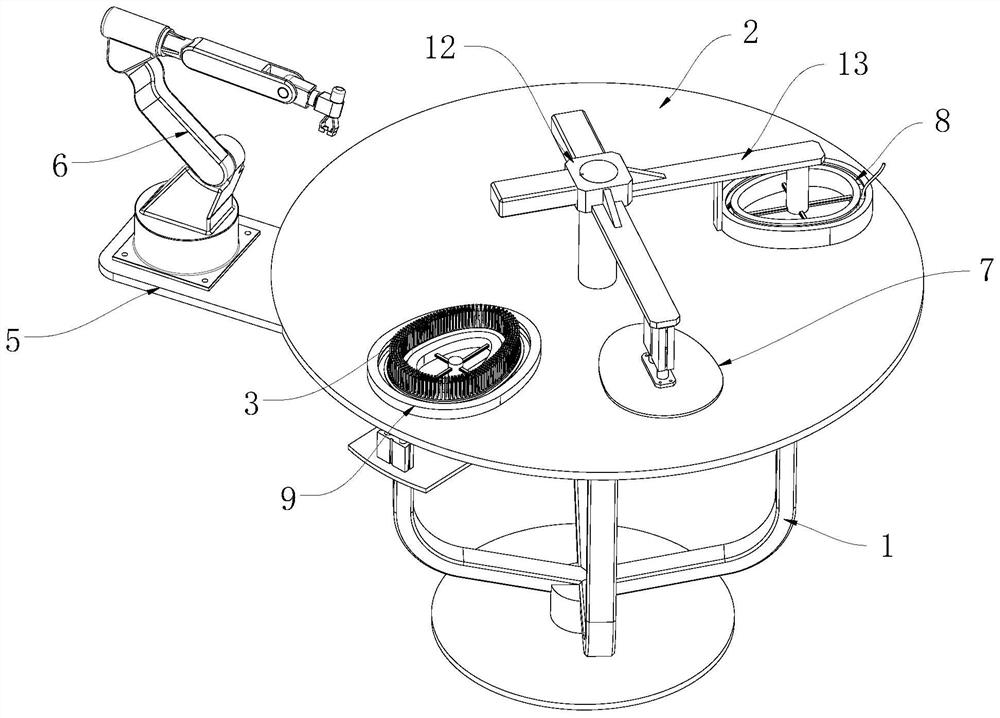

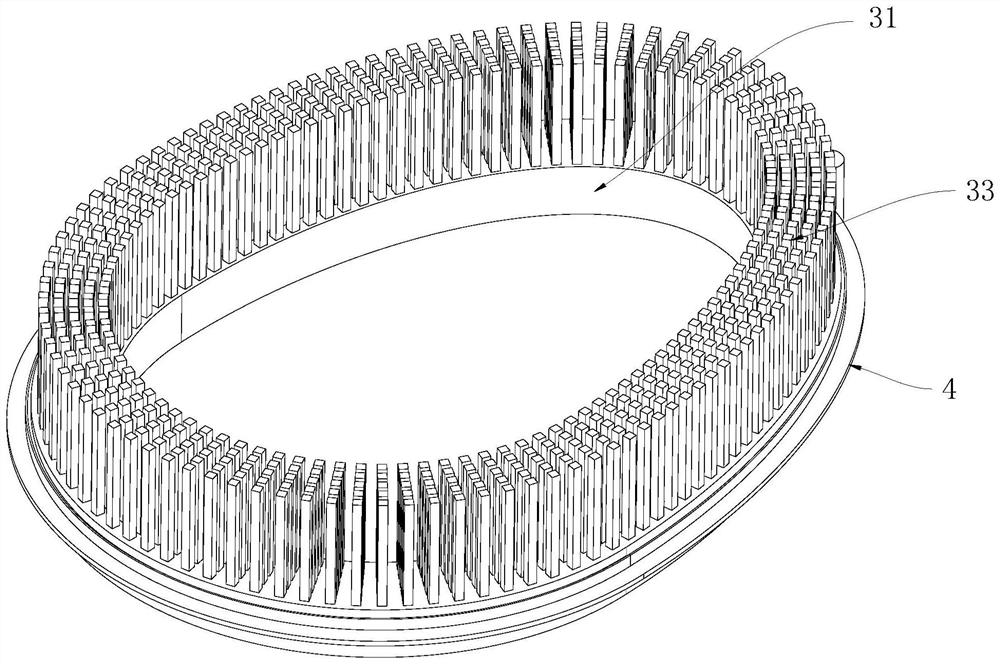

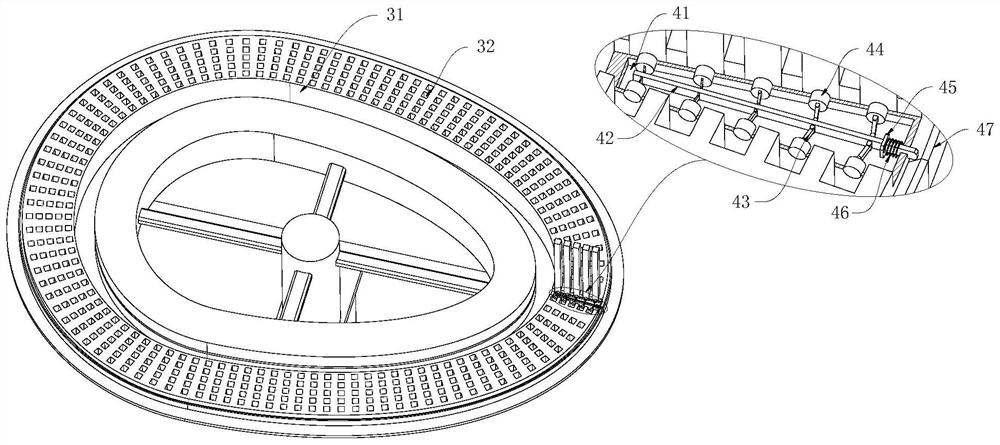

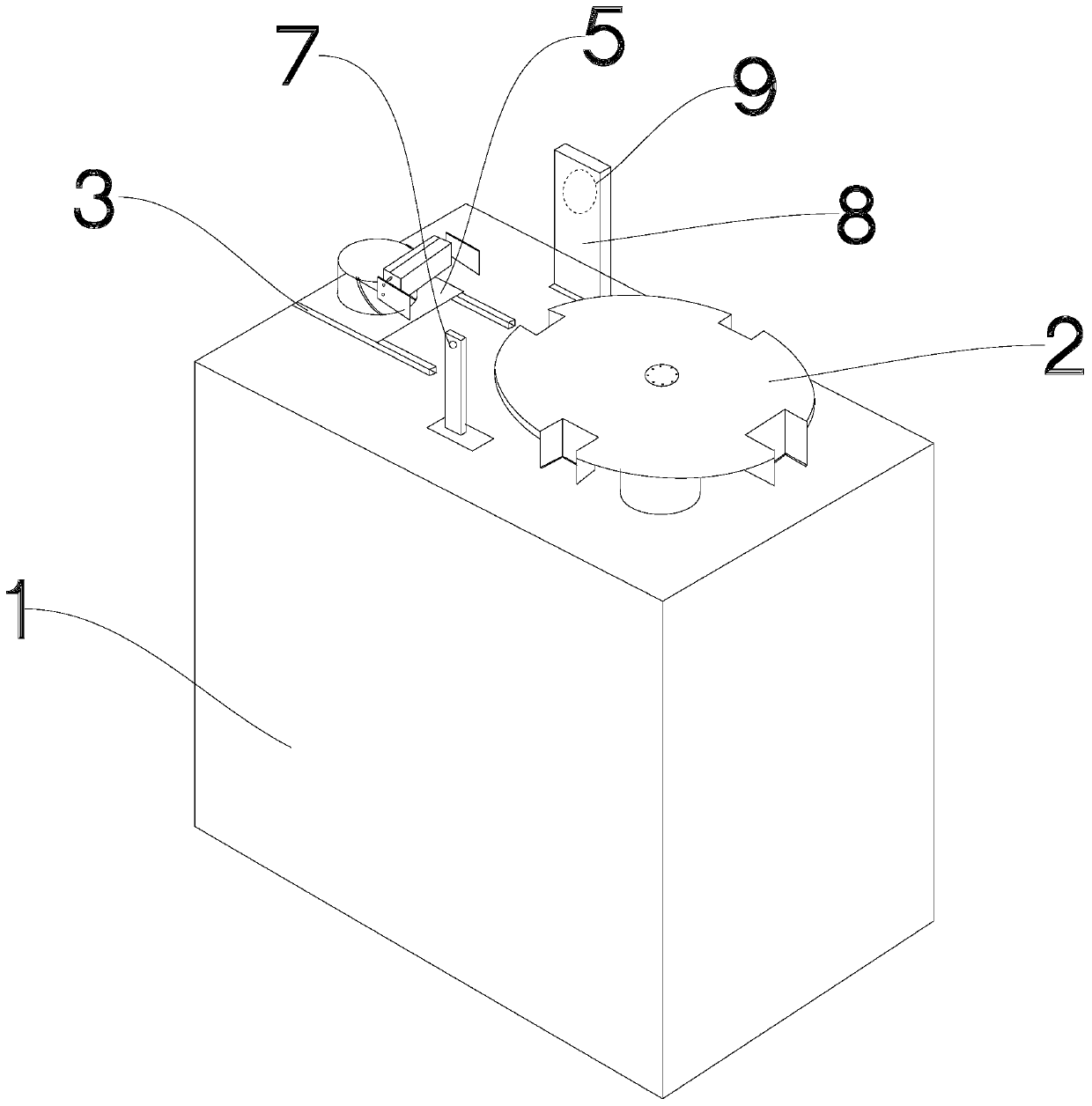

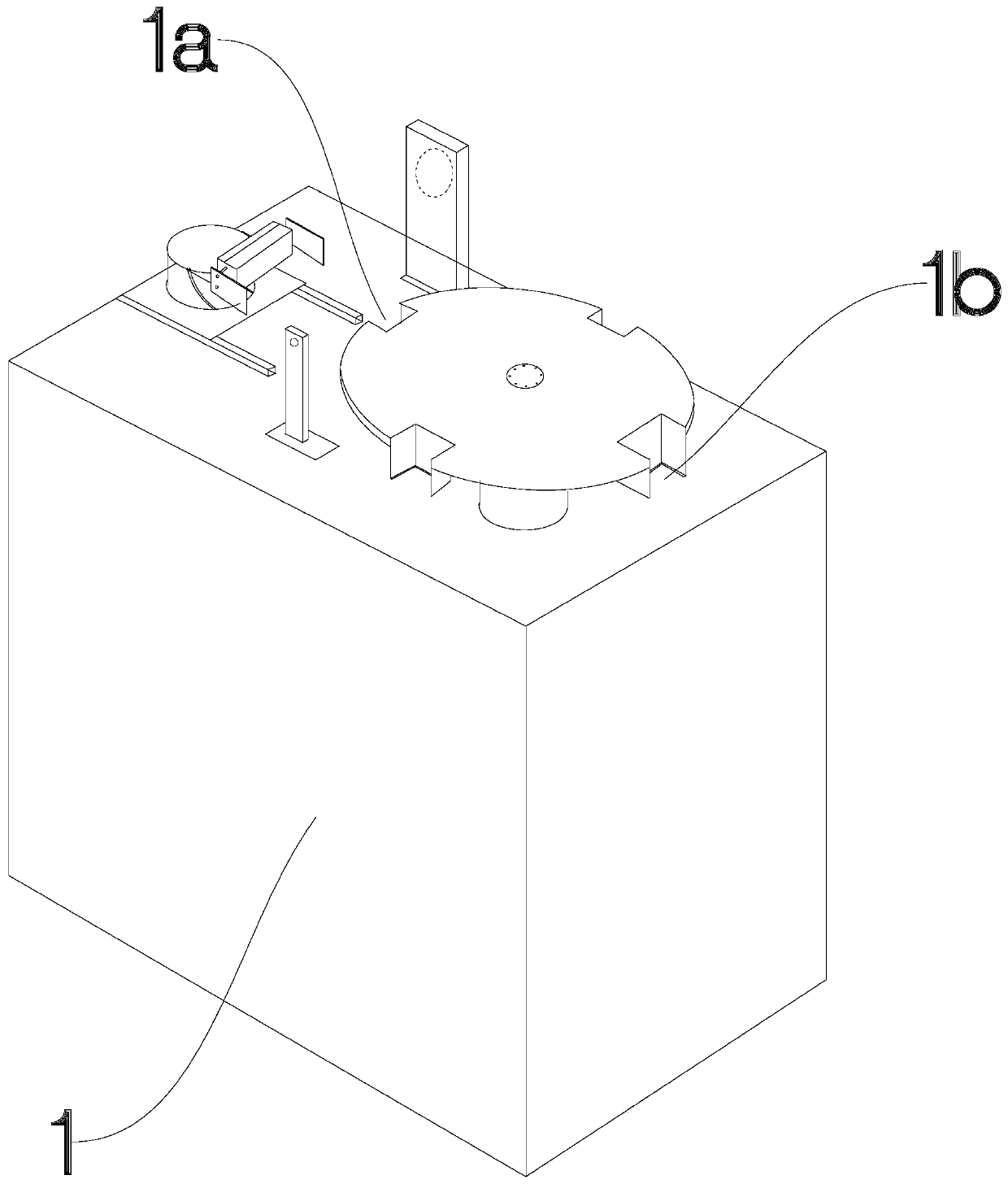

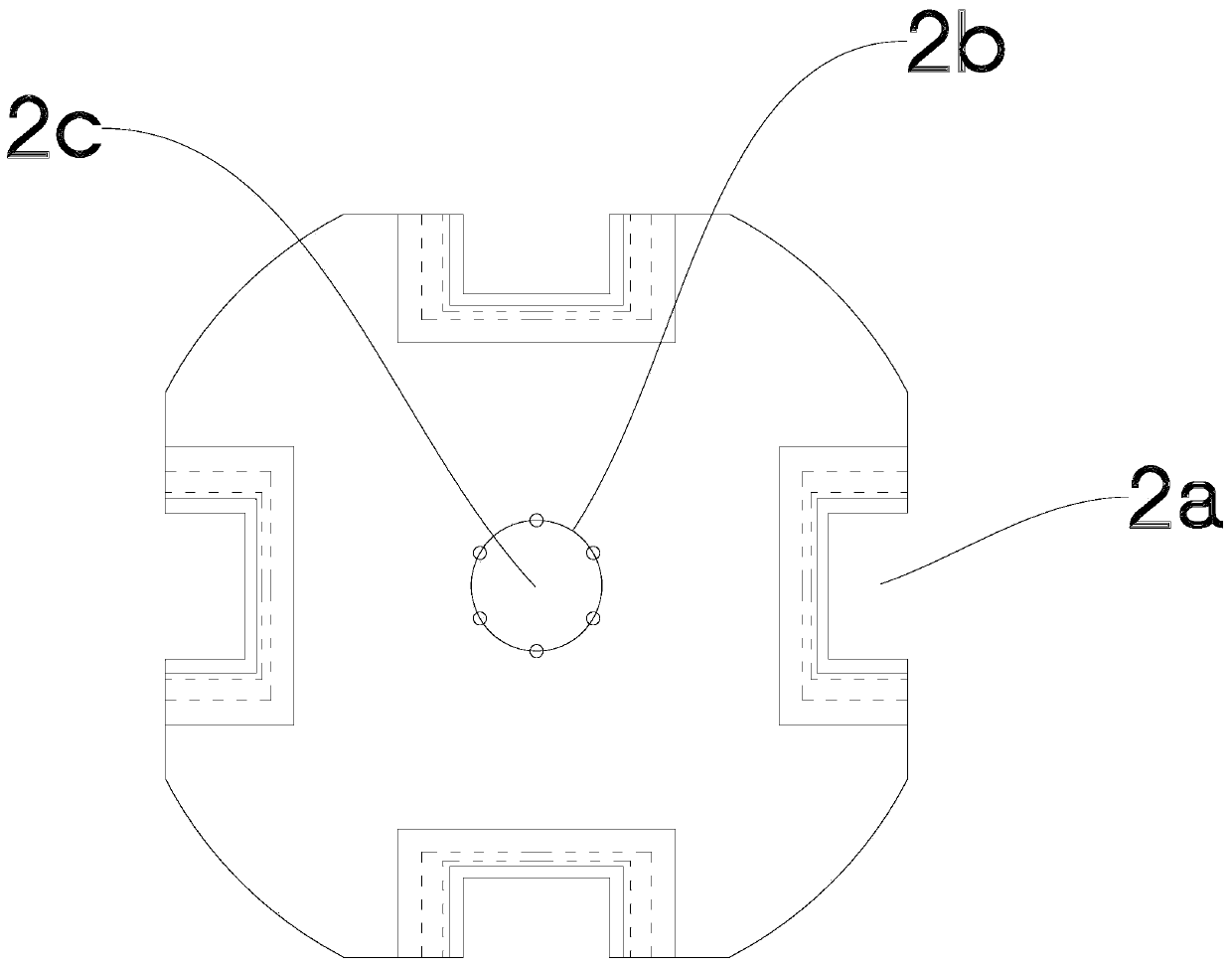

Automatic component glue filling device of LED driver

ActiveCN110732458AAccelerate the sinking rate of the flowAvoid the phenomenon of less glueLiquid surface applicatorsCoatingsEngineeringWorkbench

The invention discloses an automatic component glue filling device of an LED driver, and aims to solve the technical problem that in the prior art, a finished product of the LED driver is prone to generate excessive glue, excessive glue or insufficient glue. The automatic component glue filling device comprises a workbench, wherein an indexing rotary disc is arranged on the workbench; a glue filling station, a feeding station and a discharging station on the workbench are symmetrically arranged in the radial direction of the indexing rotary disc; a linear moving module is arranged on one side,close to the glue filling station, of the workbench; the linear moving module can move close to or away from the glue filling station under the driving of a power module; a vibration module and a clamping module are arranged on the linear moving module; when the indexing rotary disc drives the LED driver to rotate from the feeding station and the discharging station to the glue filling station under the driving of the power module, the clamping module is driven by the linear moving module to be close to the LED driver, and a liquid level detector arranged on the side face of the glue fillingstation monitors the liquid level of a glue filling opening of the LED driver while the glue filling module arranged above the workbench is used for filling glue to the LED driver.

Owner:ZHEJIANG KAIYAO LIGHTING

Heat dissipation type packaging structure and forming method thereof

ActiveCN114823573AImprove stabilityAvoid damageSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsHemt circuits

The invention relates to a heat dissipation type packaging structure and a forming method thereof, and relates to the field of semiconductor packaging, and the method comprises the steps: installing a plurality of semiconductor tube cores on a circuit substrate in an inverted manner, and forming a step part, a first annular groove and a second annular groove in a first surface of a heat dissipation plate, the first annular groove is located between the step part and the second annular groove, the heat dissipation plate is bonded on a plurality of semiconductor tube cores through a heat conduction bonding layer, a separation film is arranged on the first surface of the heat dissipation plate in a pressing mode, and the separation film is directly attached to the bottom faces and the side faces of the continuous steps. The separation film covers the top end of the first annular groove and the top end of the second annular groove, a molding compound is injected between the separation film and the circuit substrate, and the molding compound supports the separation film, so that the molding compound fills the step part. The heat dissipation performance of the chip can be improved.

Owner:WEIHAI HONGLIN ELECTRIC POWER TECH CO LTD

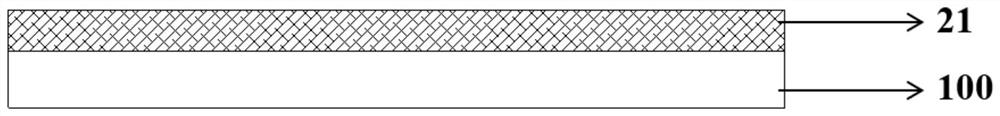

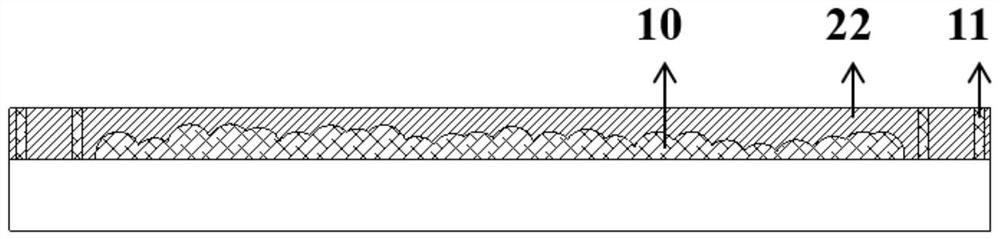

Preparation method of light diffusion sheet

ActiveCN110346855BPrevent glue overflowOptical performance impactDiffusing elementsPhotomechanical exposure apparatusPhysical chemistryEngineering

The invention provides a preparation method of a light diffusion sheet. The preparation method includes the following steps: forming a photoresist layer on the surface of the substrate, defining the photoresist layer to have a central area and a peripheral area, the peripheral area includes n first peripheral areas and n+1 second peripheral areas, the first A peripheral region and a second peripheral region are alternately arranged around the central region, n is a natural number ≥ 1; the photoresist layer is sequentially exposed and developed to form a microstructure layer in the central region, and the first peripheral region and the second peripheral area to form an anti-overflow glue structure with grooves, the anti-overflow glue structure surrounds the microstructure layer, wherein the exposure intensity to the central area is less than the exposure intensity to the first peripheral area, and the exposure intensity to the second peripheral area The intensity is less than the exposure intensity for the first peripheral region. Utilizing the above-mentioned anti-overflow structure effectively prevents possible glue overflow when the light diffusion sheet is fixed in the lens, and avoids the influence of the overflow on the optical performance of the device.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

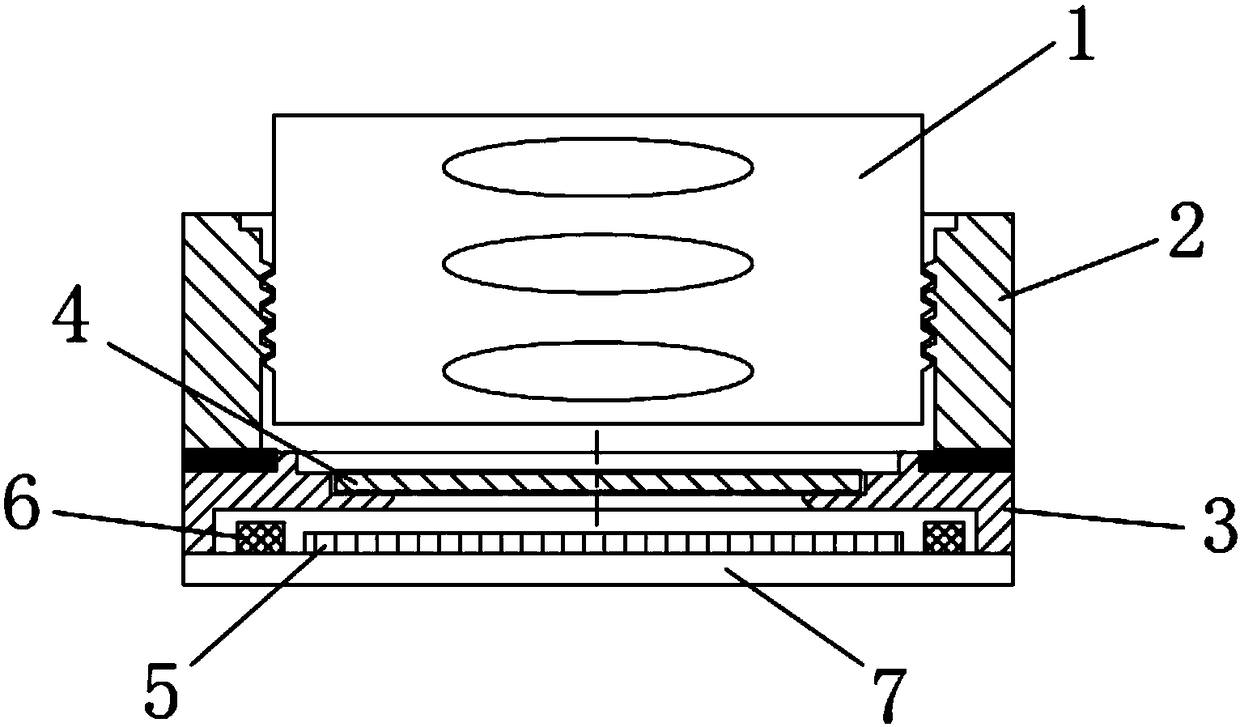

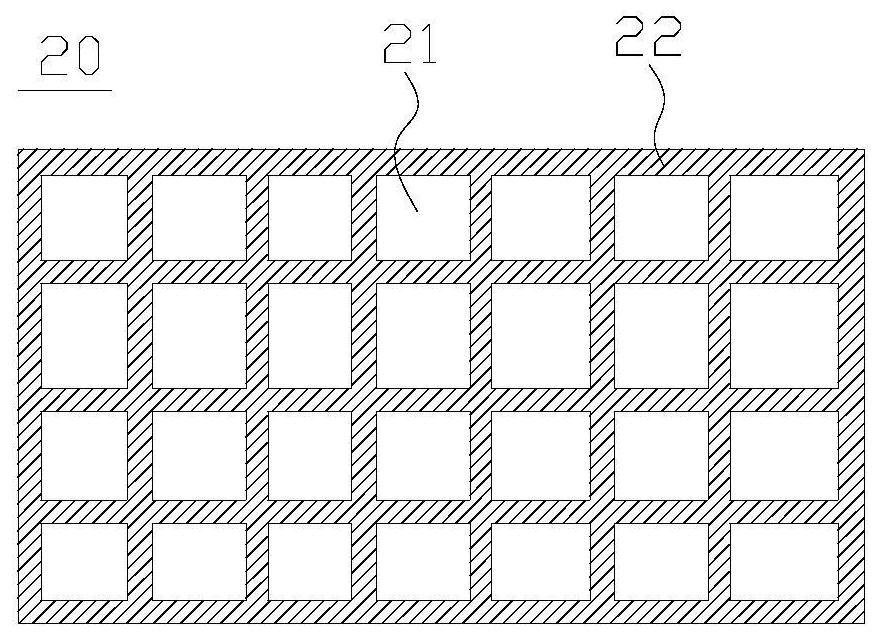

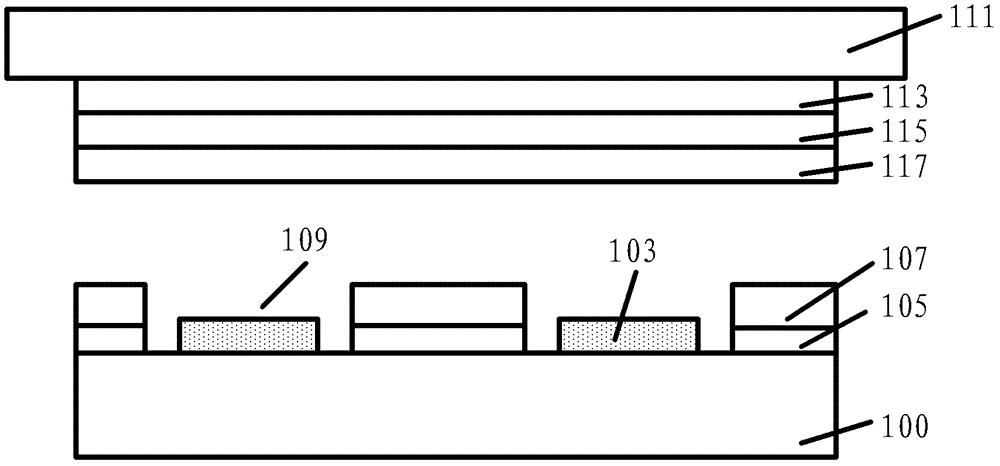

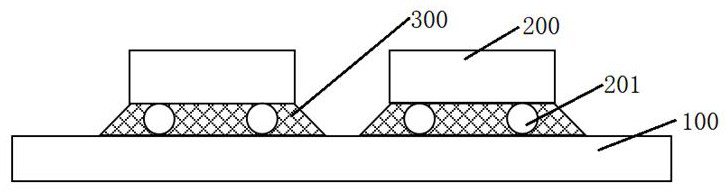

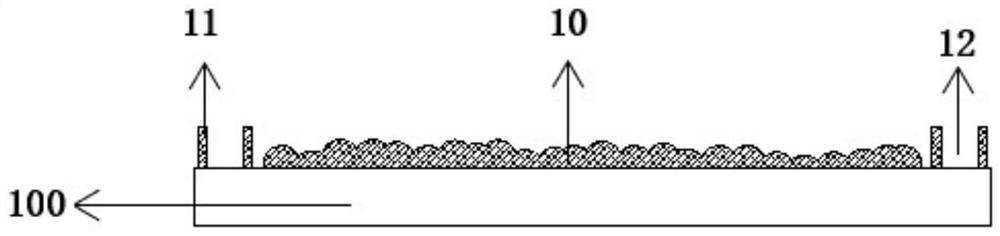

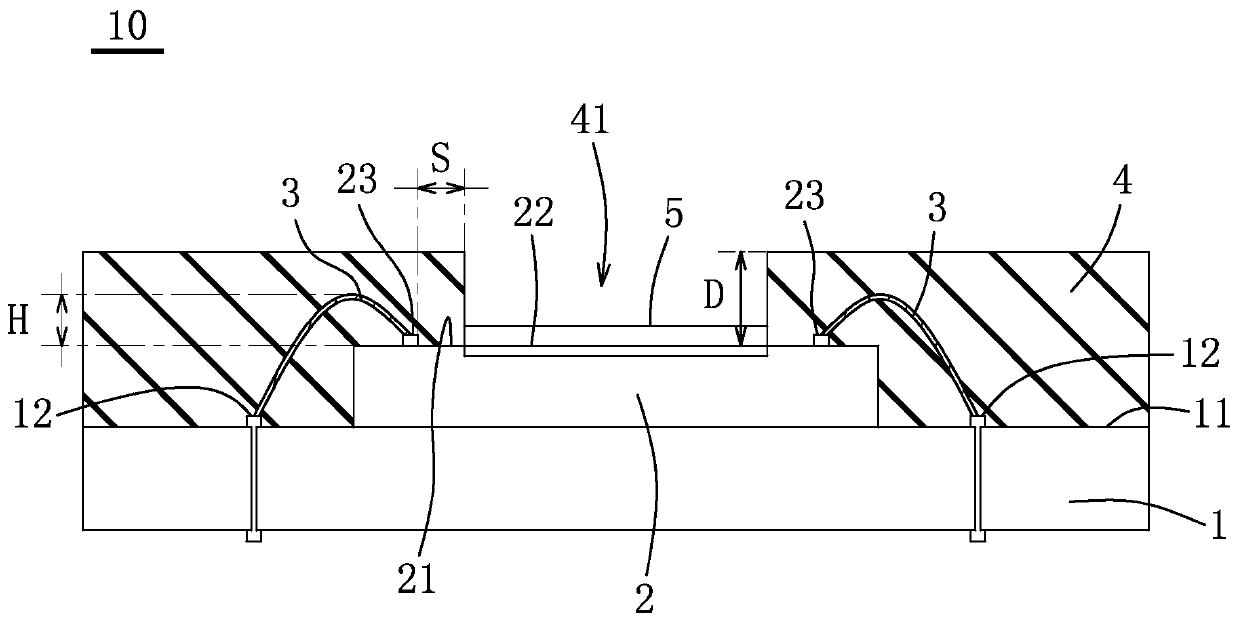

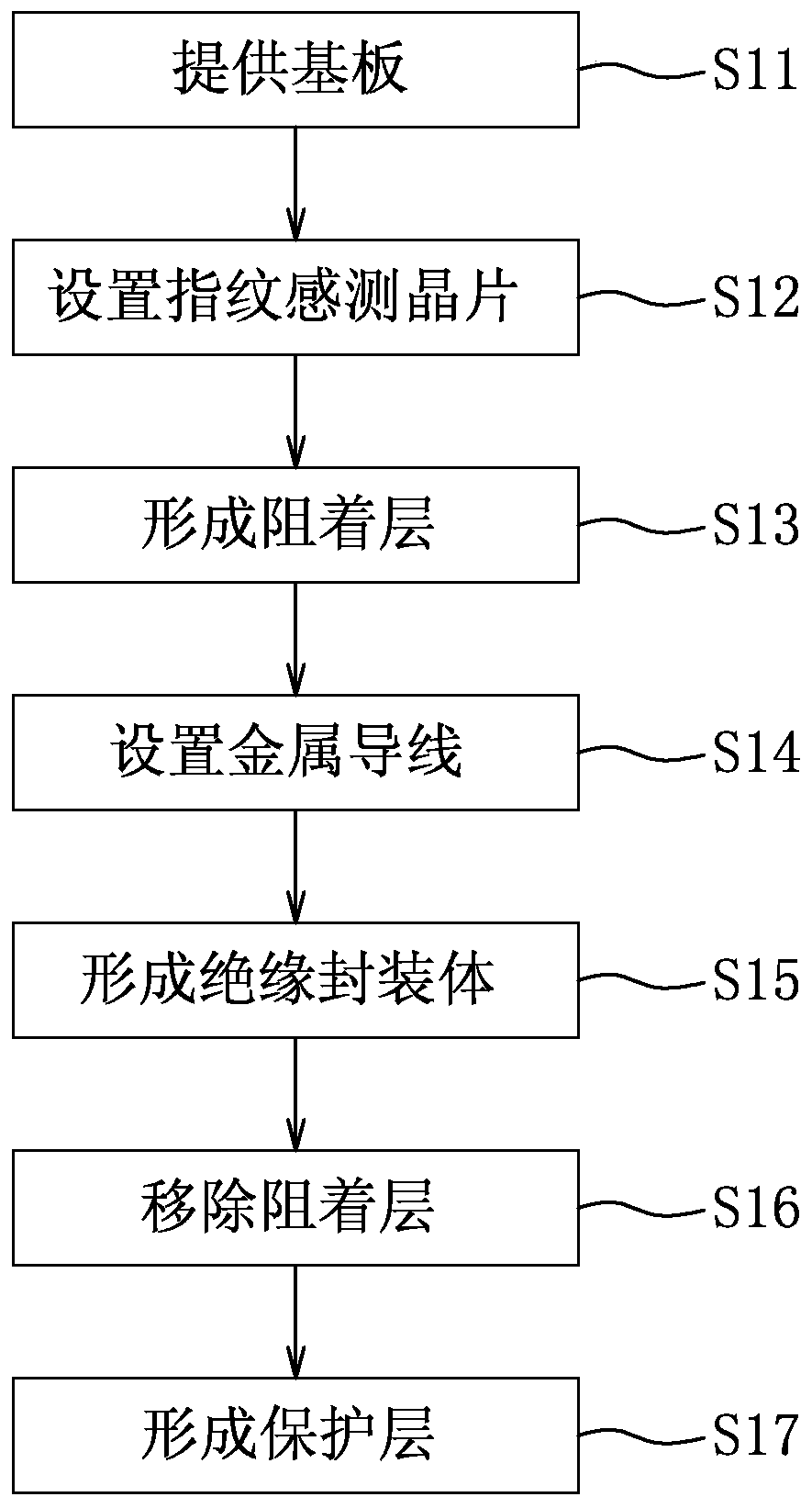

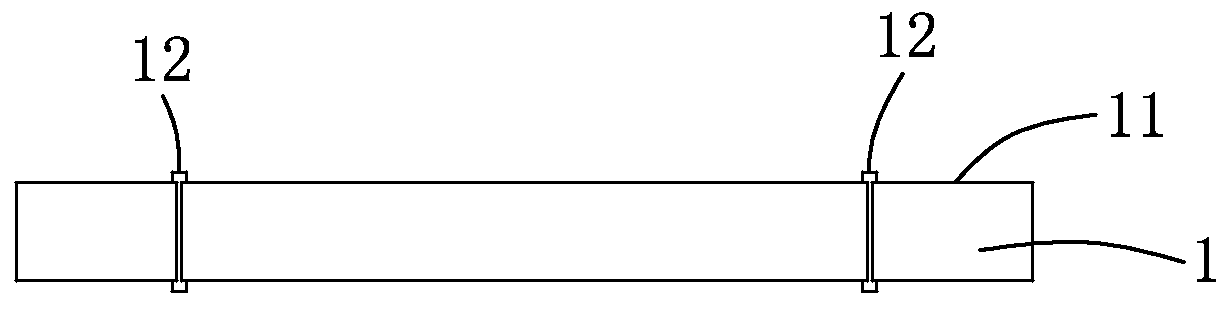

Fingerprint sensor package module made and process for making fingerprint sensor package module

PendingCN110659554APrevents Sensitivity DropsAccurate coverageSolid-state devicesAcquiring/reconising fingerprints/palmprintsWaferingEngineering

The invention discloses a fingerprint sensor package module made and a process for making the fingerprint sensor package module. The fingerprint sensor package module includes a substrate, a fingerprint sensing chip, a plurality of metal wires, and an insulating package. The substrate comprises a mounting surface and a plurality of circuit contacts arranged on the mounting surface. Wherein the fingerprint sensing chip is arranged on the mounting surface of the substrate, the fingerprint sensing chip is provided with a first surface back to the mounting surface, a sensing area located on the first surface and a plurality of electrical contacts arranged on the first surface and adjacent to the periphery of the sensing area, and the distance between the electrical contacts and the sensing area is smaller than 300 microns. The metal wire is bridged between the circuit contact and the electrical contact. The insulating package covers the mounting surface of the substrate, the fingerprint sensing chip and the metal wire, and an open groove for exposing the sensing area is formed in the insulating package. Therefore, the size of the fingerprint sensing chip is not too large, and the sizeof the f fingerprint sensor package module is reduced.

Owner:TONG HSING ELECTRONICS IND LTD

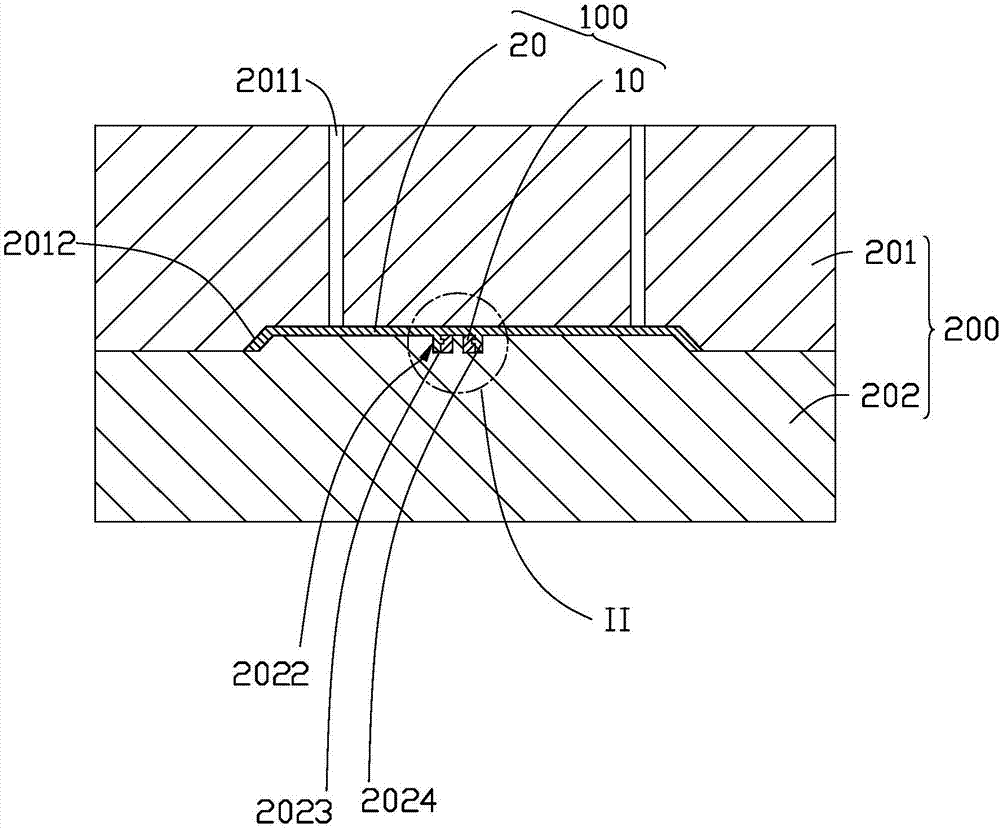

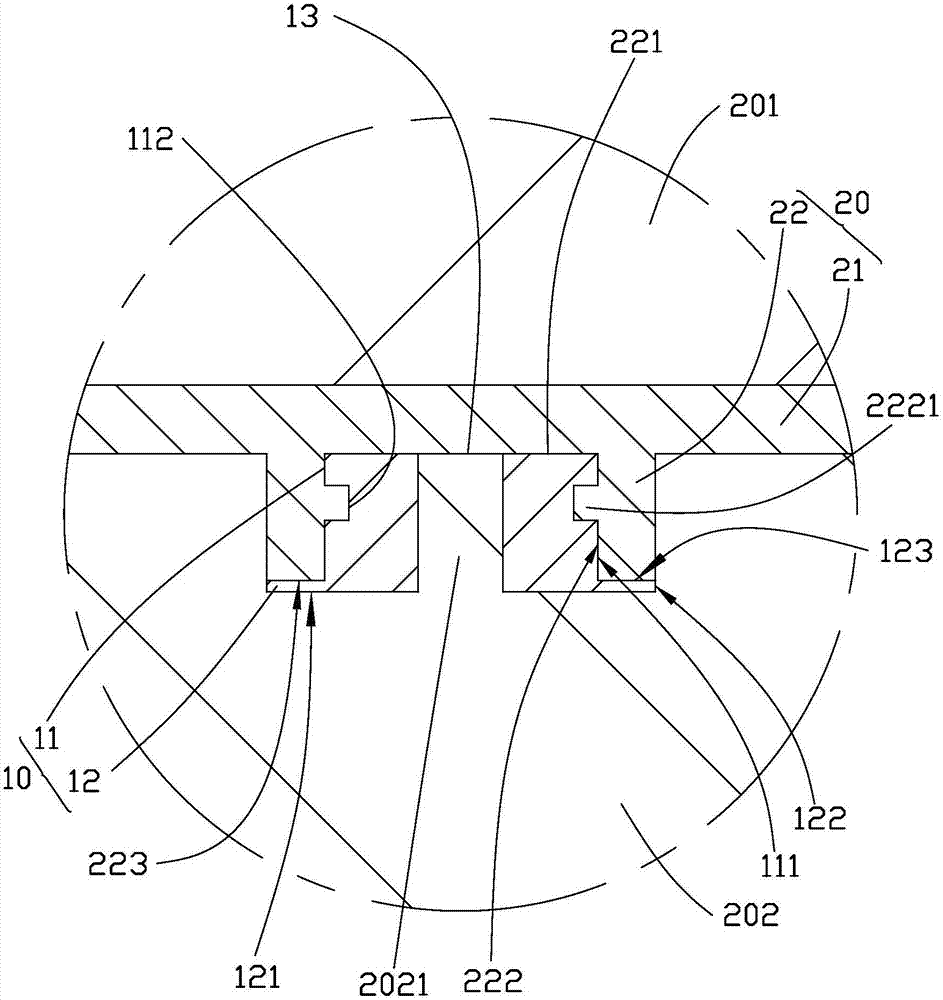

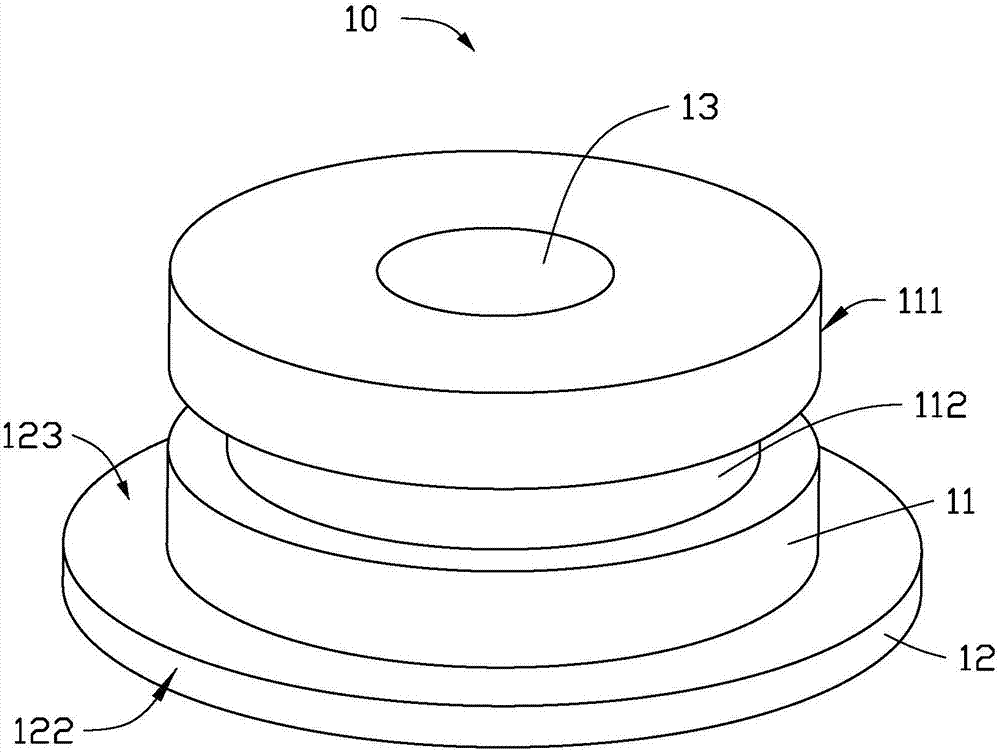

Glue overflow-preventing device and baseplate-laminating method using same

ActiveCN101702402BPrevent glue overflowImprove the situation of overflowing glueSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:AU OPTRONICS CORP

Substrate adhesion method

ActiveCN102148170BPrevent glue overflowImprove the situation of overflowing glueSemiconductor/solid-state device manufacturingEngineeringColloid

The invention discloses a substrate adhesion method, which is applied to adhesion of two substrates. The substrate adhesion method comprises the following steps of: providing an adhesive-overflowing resistant device, wherein the adhesive-overflowing resistant device comprises a frame body and at least one colloid solidification piece, the frame body is provided with a sidewall which is arranged along a closed track, the sidewall is provided with at least one notch, and the colloid solidification piece is arranged on an outer surface of the sidewall; placing the substrates in the frame body and coating a colloid between the substrates; pressing the substrates; and solidifying the colloid by the at least one colloid solidification piece. In the adhesive-overflowing resistant device, the colloid can be overflowed only from the notch on the sidewall of the frame body, so that the situation of adhesive overflowing can be improved. Moreover, the colloid solidification piece which is arranged on the outer surface of the sidewall can solidify the colloid on edges of the substrates after the substrates are pressed, so that the situation of adhesive overflowing after the substrates are taken out can be prevented. Furthermore, the adhesive-overflowing resistant device is used in the substrate adhesion method, so that the situation of the adhesive overflowing can be improved.

Owner:AU OPTRONICS CORP

A display panel and packaging method thereof

ActiveCN109309174BHigh degree of curingImprove liquiditySolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceSealant

The invention provides a display panel and a packaging method thereof, and relates to the technical field of packaging. Wherein, the method includes: forming a frame-shaped sealant on a cover substrate; forming a filler on the cover substrate surrounded by the sealant; Perform pre-curing treatment to obtain a package cover plate; press the display substrate and the package cover plate; perform secondary curing treatment on the frame sealing glue; perform a preset curing treatment on the filling glue to complete the packaging. In the embodiment of the present invention, the frame sealant can be pre-cured separately by curing the mask, while the filler glue is not pre-cured at the same time. Therefore, the curing degree of the frame sealant can be individually enhanced, and the The fluidity of the filling glue in the subsequent process can prevent the sealant from being washed away by the filling glue and the phenomenon of the filling glue overflowing when the panels are pressed together.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

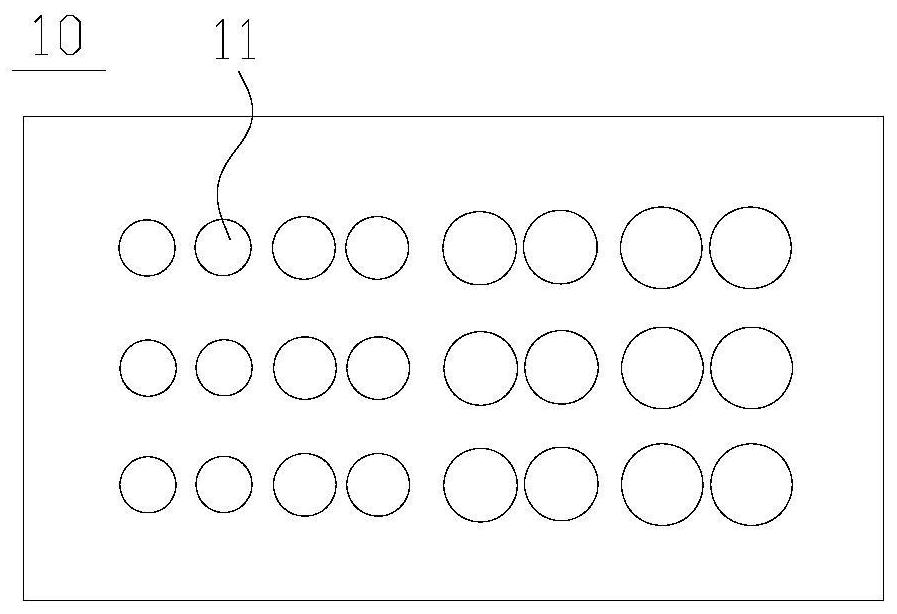

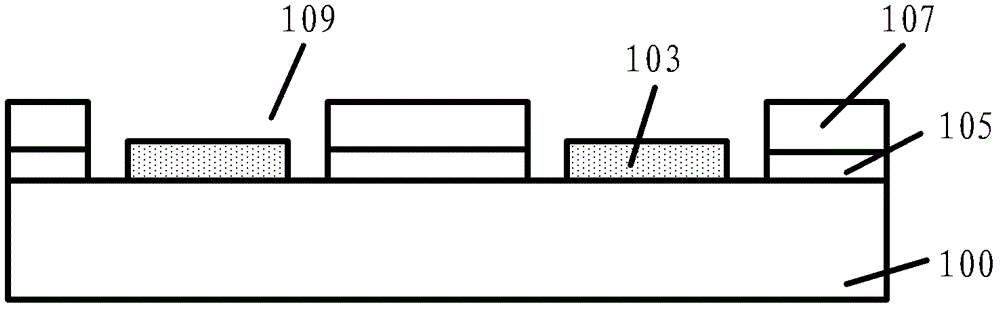

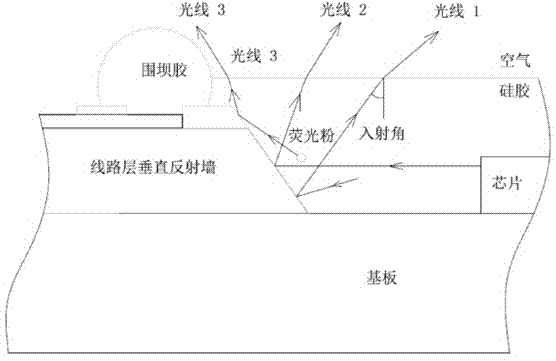

Structure for raising highly reflective material LED light source luminous flux output

InactiveCN104851958APrevent glue overflowReduce tensionSemiconductor devicesInsulation layerEngineering

The present invention discloses a structure for raising a highly reflective material LED light source luminous flux output, relating to a structure for raising an LED light source luminous flux output. The invention aims to provide the structure for raising the highly reflective material LED light source luminous flux output, and a glue overflow phenomenon in the molding process can be prevented. The technical scheme is that the structure comprises a substrate, a circuit layer, a GaN LED chip array, and a phosphor layer silica gel layer. The phosphor layer silica gel layer and the line layer are adjacent to dam glue. The line layer comprises a front line layer, a back line layer and a connection line layer. A plug member is arranged between the connection line layers of the inner walls of a conductive through hole, and a slope reflection wall 9 is formed at an insulation layer surface facing the GaN LED chip array. The structure is applicable to raise the highly reflective material LED light source luminous flux output.

Owner:CHENGDU SIKETAI TECH

A method for making a highly weather-resistant and fragile label material

ActiveCN110903775BPrevent glue overflowCompliant with fragile label requirementsStampsFilm/foil adhesive primer layersComposite filmPet substrate

The invention discloses a method for making a highly weather-resistant and fragile label material, which includes the following steps: Q1: Select a non-corona-treated PET substrate with a thickness of 36 μm to 100 μm, and apply a weather-resistant coating on the surface of the PET substrate to obtain Composite film A and winding; Q2: Coating the color layer paint on the weather-resistant layer surface of composite film A to prepare composite film B and winding; Q3: Forming a covering layer on the surface of the color layer of composite film B to obtain a composite film C and rewinding; Q4: Coating the pressure-sensitive adhesive layer coating on the grid-shaped release paper or release film to obtain the composite film D; The sensitive adhesive layer is compounded to produce a highly weather-resistant and fragile label material. Through the above steps, the present invention can finally produce a highly weather-resistant and fragile label material, which has excellent chemical stability and physical properties, and meets high weather-resistant grade and fragile requirements, and has broad market prospects.

Owner:浙江龙游道明光学有限公司

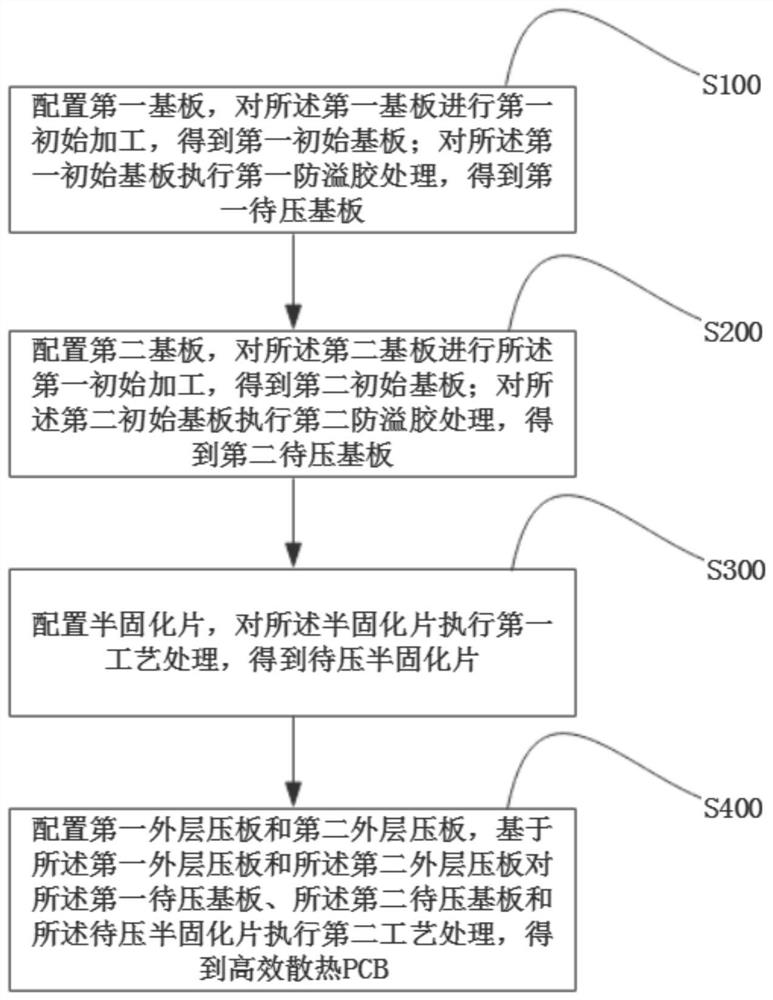

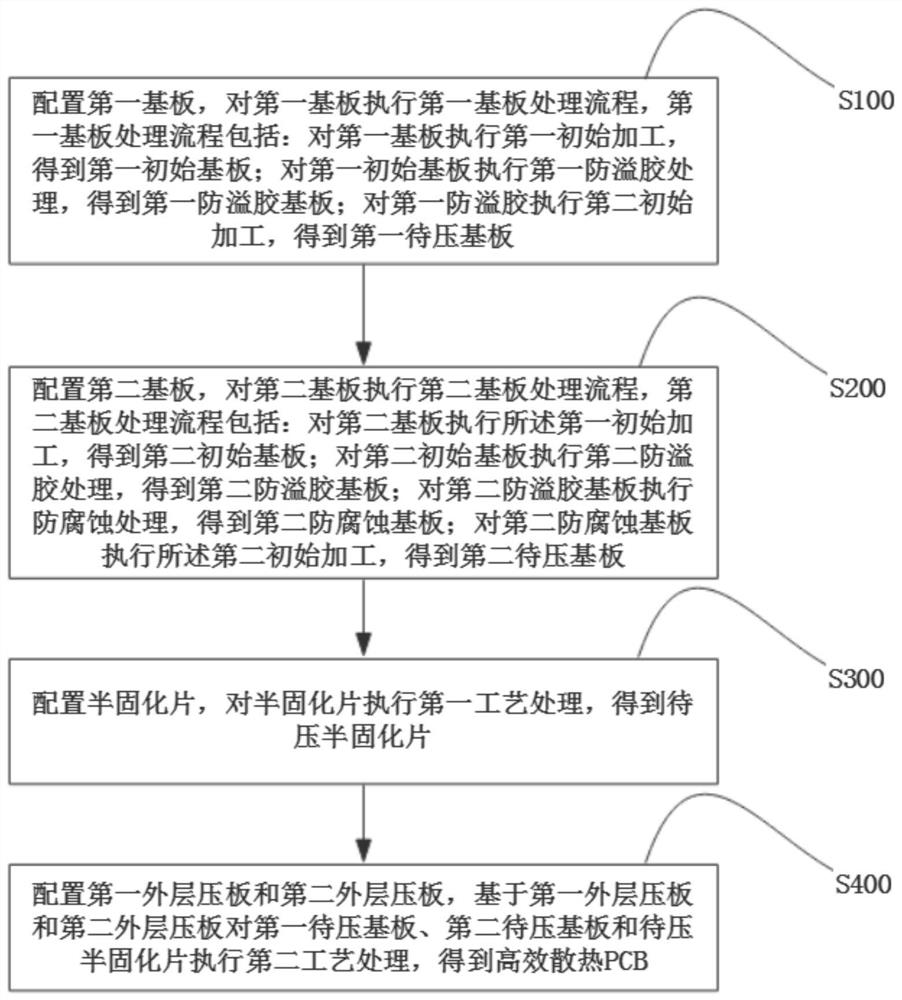

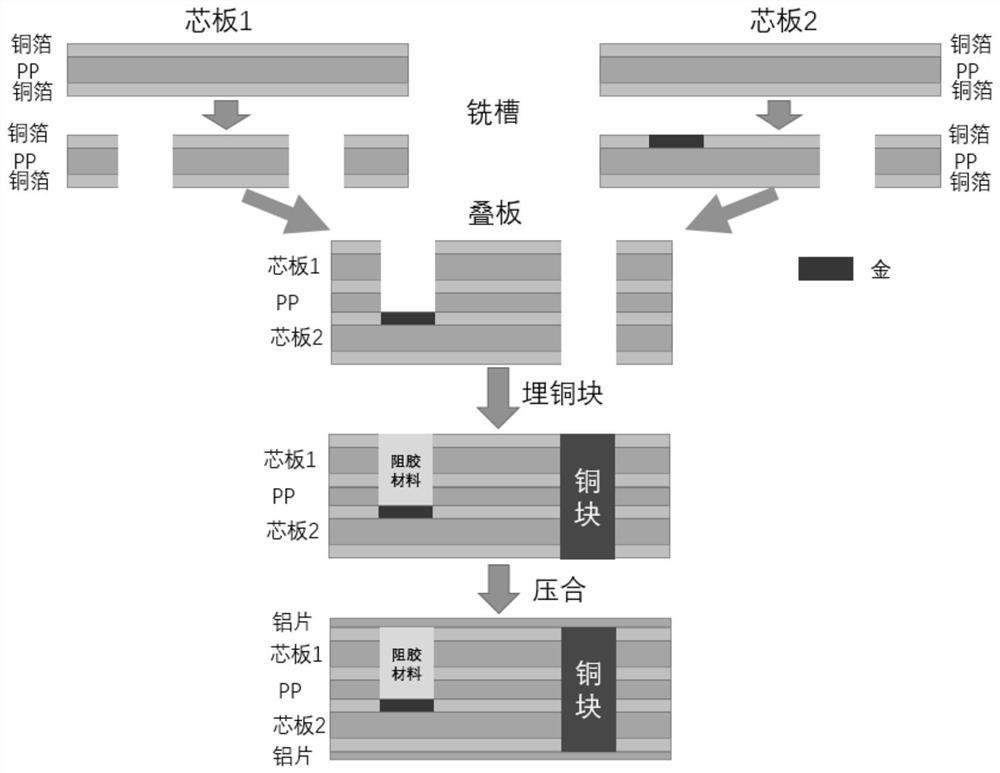

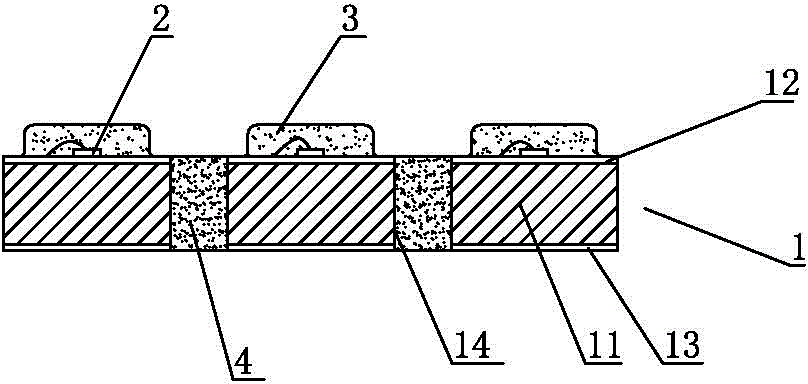

Manufacturing method and system of efficient heat dissipation PCB and PCB

InactiveCN113194638AWith cooling functionImprove flatnessMultilayer circuit manufactureCircuit thermal arrangementsProcess engineeringIndustrial engineering

The invention discloses a manufacturing method of an efficient heat dissipation PCB. The method comprises the following steps of: configuring a first substrate, and carrying out first initial machining on the first substrate, and obtaining a first initial substrate; performing first glue overflow prevention treatment on the first initial substrate to obtain a first substrate to be pressed; configuring a second substrate, and performing first initial machining on the second substrate to obtain a second initial substrate; and performing second glue overflow prevention treatment on the second initial substrate to obtain a second substrate to be pressed. configuring a prepreg, and performing first process treatment on the prepreg to obtain a prepreg to be pressed; and configuring a first outer laminated board and a second outer laminated board, and performing second process treatment on the first substrate to be pressed, the second substrate to be pressed and the prepreg to be pressed based on the first outer laminated board and the second outer laminated board to obtain the efficient heat dissipation PCB, According to the manufacturing method, the PCB with a heat dissipation function can be manufactured, and it can be ensured that the manufactured PCB has good smoothness, andmeets the high-efficiency heat dissipation requirement.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

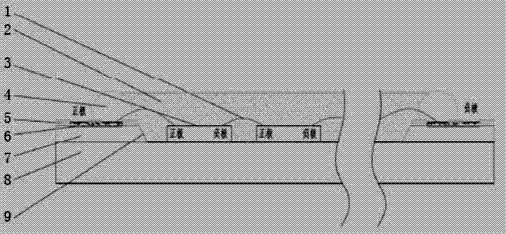

Chip LED and manufacturing method thereof

ActiveCN103022321BPrevent glue overflowClean thoroughlySolid-state devicesSemiconductor devicesCooking & bakingCompression molding

Owner:HONGLI ZHIHUI GRP CO LTD

display panel

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com