Fingerprint sensor package module made and process for making fingerprint sensor package module

A technology for encapsulating modules and fingerprints, which is used in the acquisition/organization of fingerprints/palmprints, character and pattern recognition, instruments, etc., and can solve the problems of the sensitivity of fingerprint sensing chips and the impact of process yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

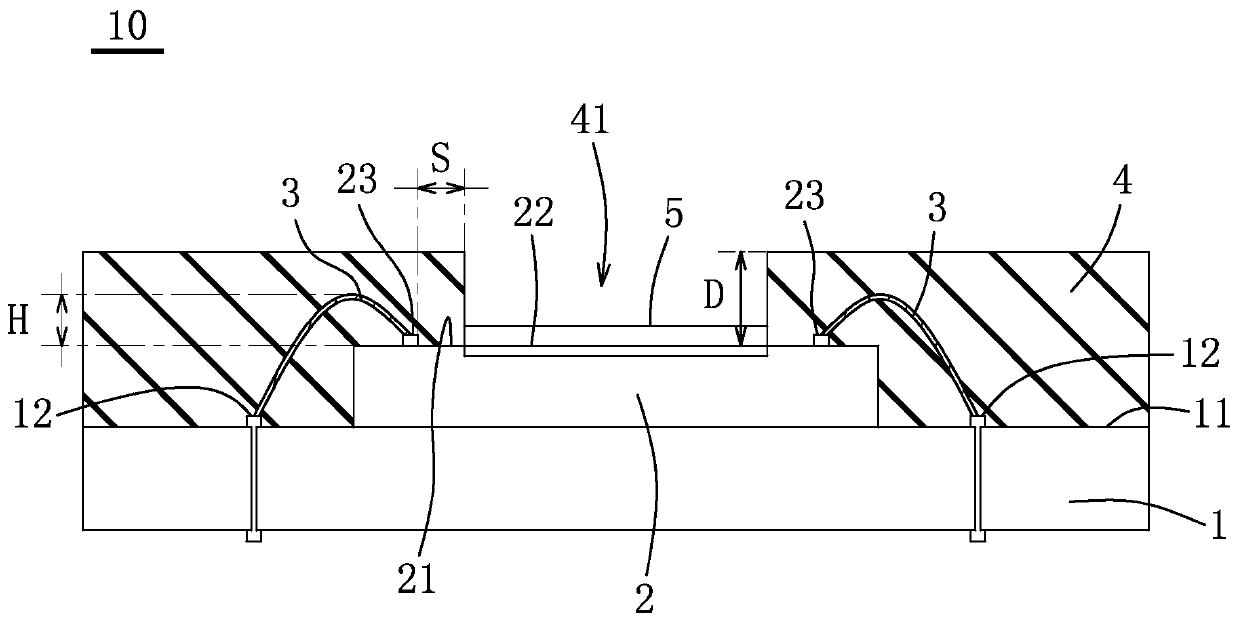

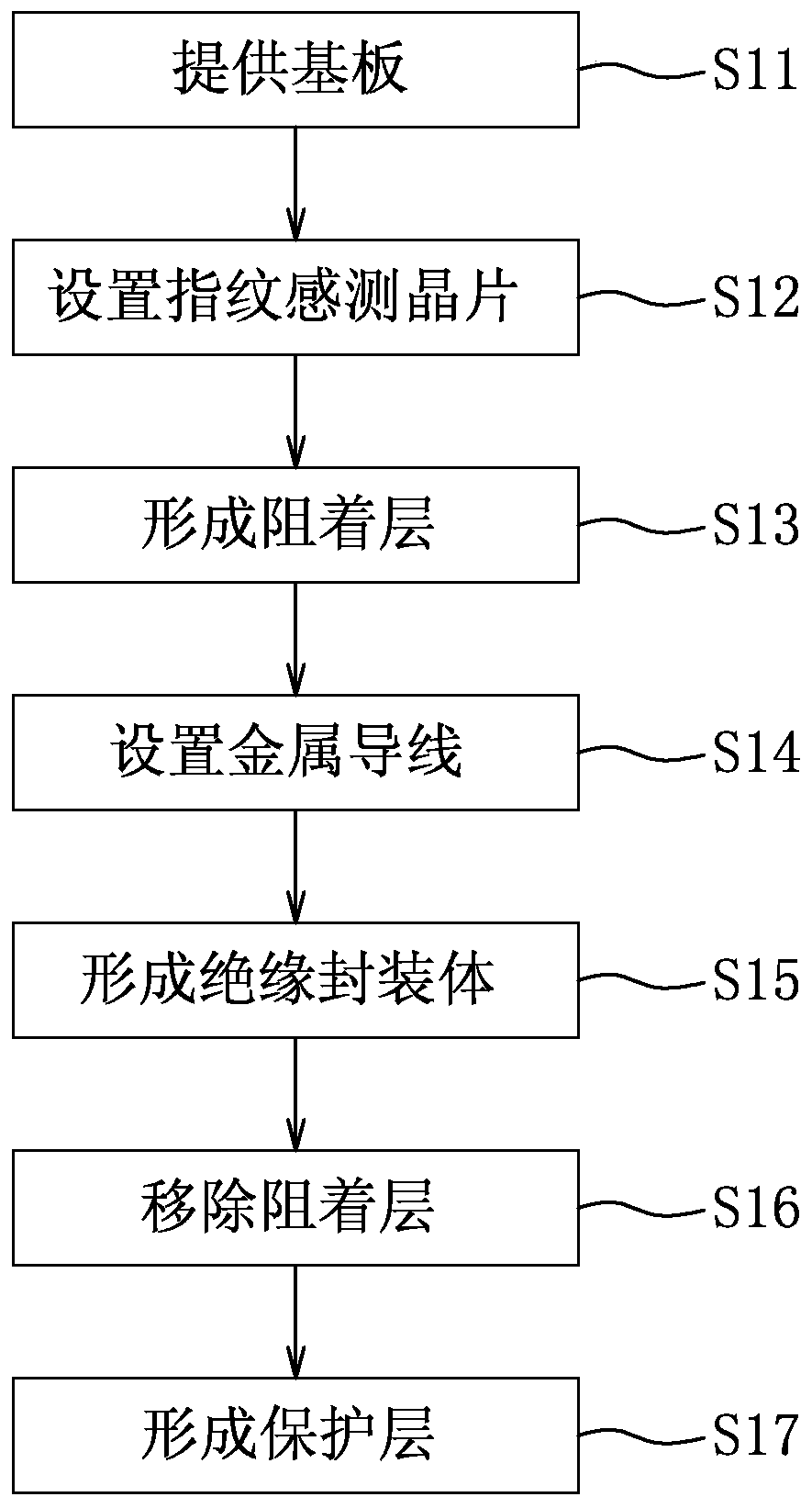

[0034] refer to figure 1 and figure 2 , is a first embodiment of the fingerprint sensing package module 10 and its manufacturing method of the present invention, the fingerprint sensing package module 10 includes a substrate 1, a fingerprint sensing chip 2, a plurality of metal wires 3, an insulating package Body 4, and a light-transmitting protective layer 5.

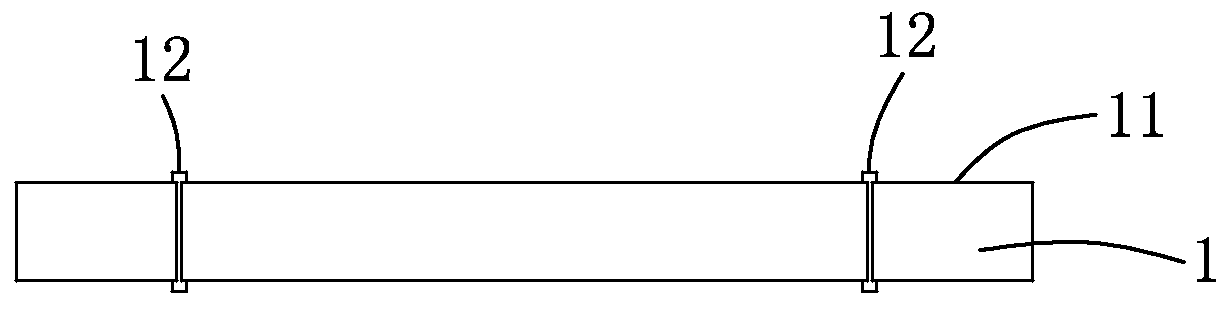

[0035] The substrate 1 is, for example, various types of circuit boards such as ceramic circuit boards, and includes a mounting surface 11 and a plurality of circuit contacts 12 disposed on the mounting surface 11 .

[0036] The fingerprint sensing chip 2 is arranged on the installation surface 11 of the substrate 1, and has a first surface 21 facing away from the installation surface 11, a chip located on the first surface 21 and suitable for fingerprint sensing. The sensing area 22, and a plurality of electrical contacts 23 arranged on the first surface 21 and adjacent to the periphery of the sensing area 22, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com