Patents

Literature

188results about How to "Accurate coverage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

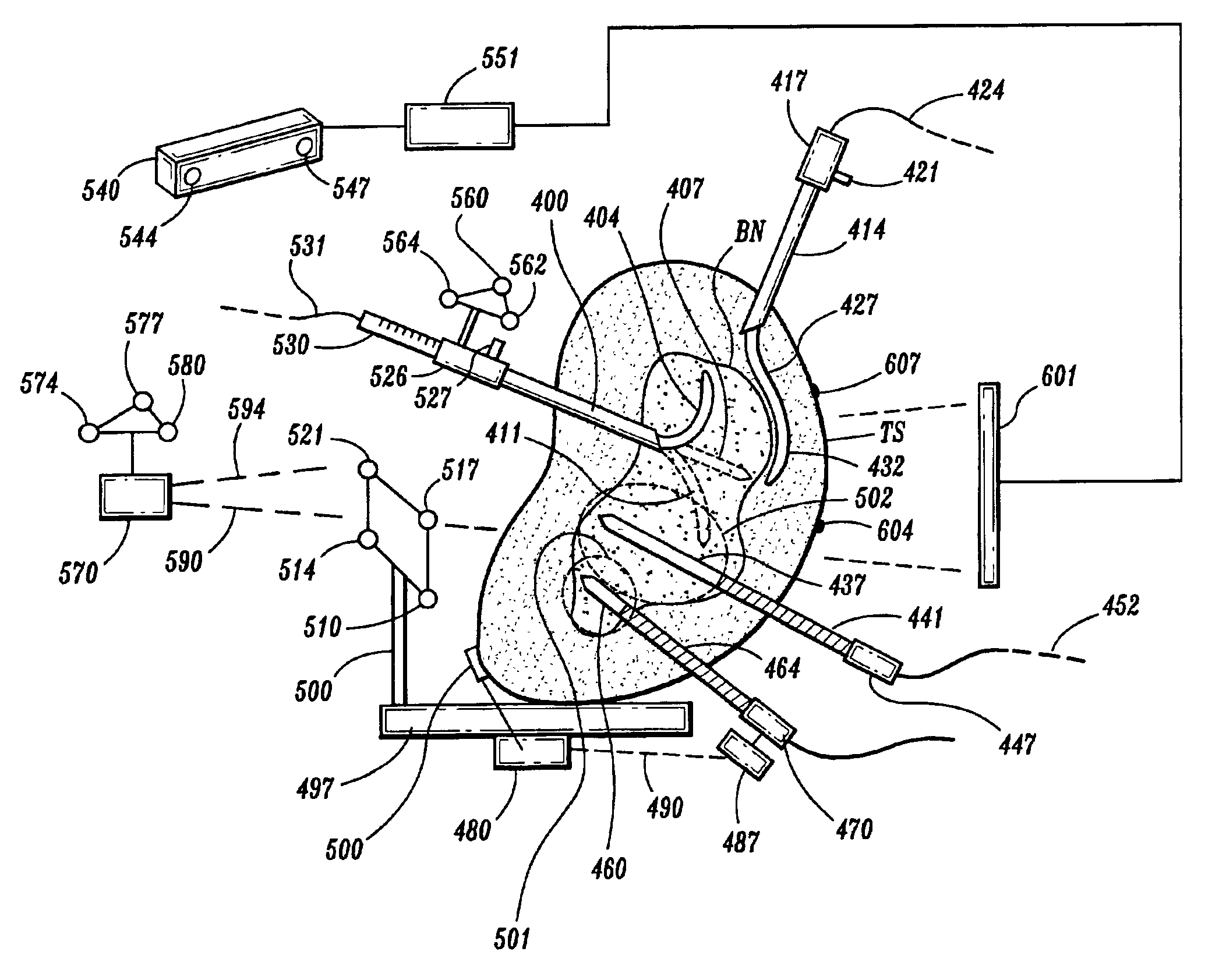

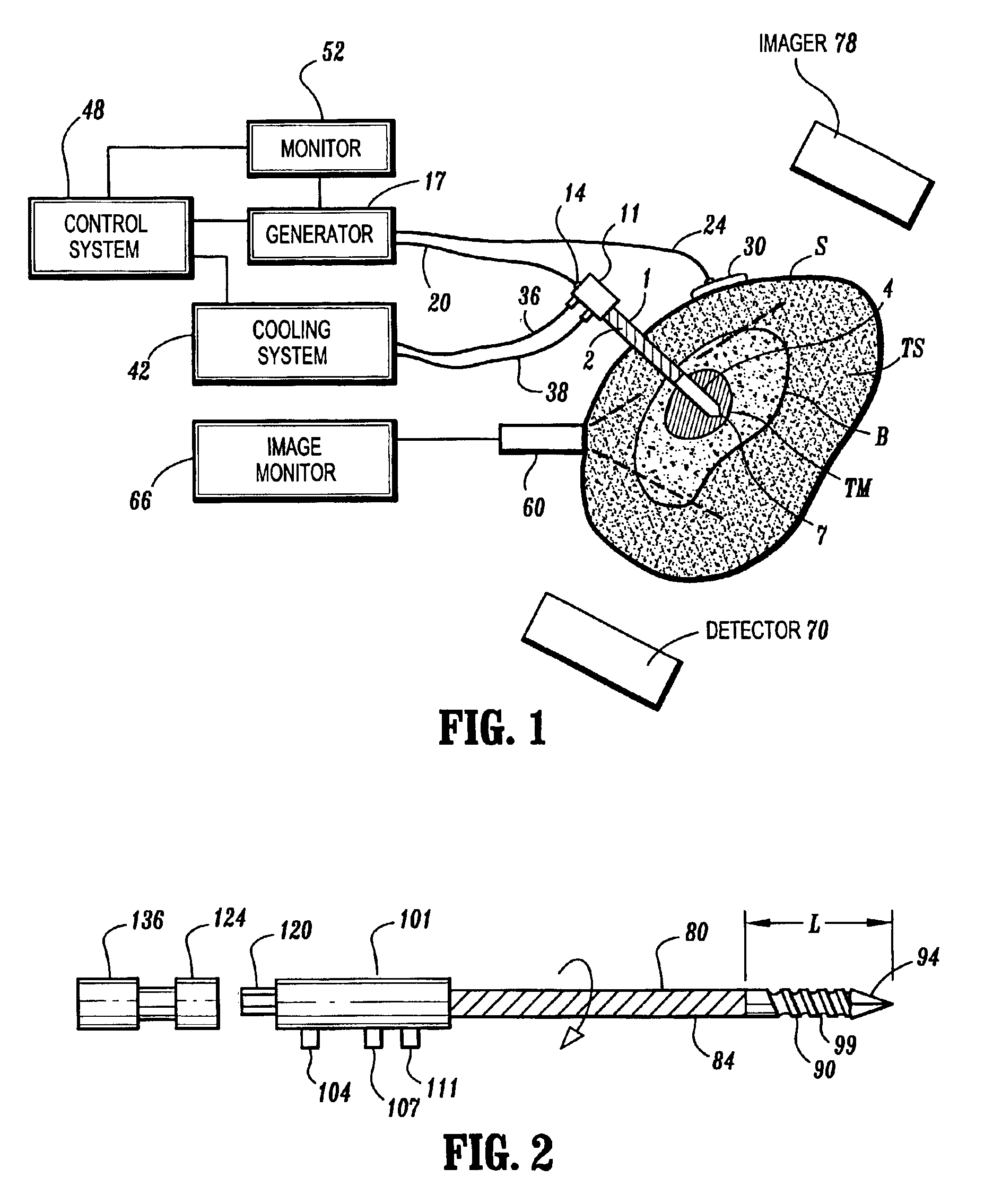

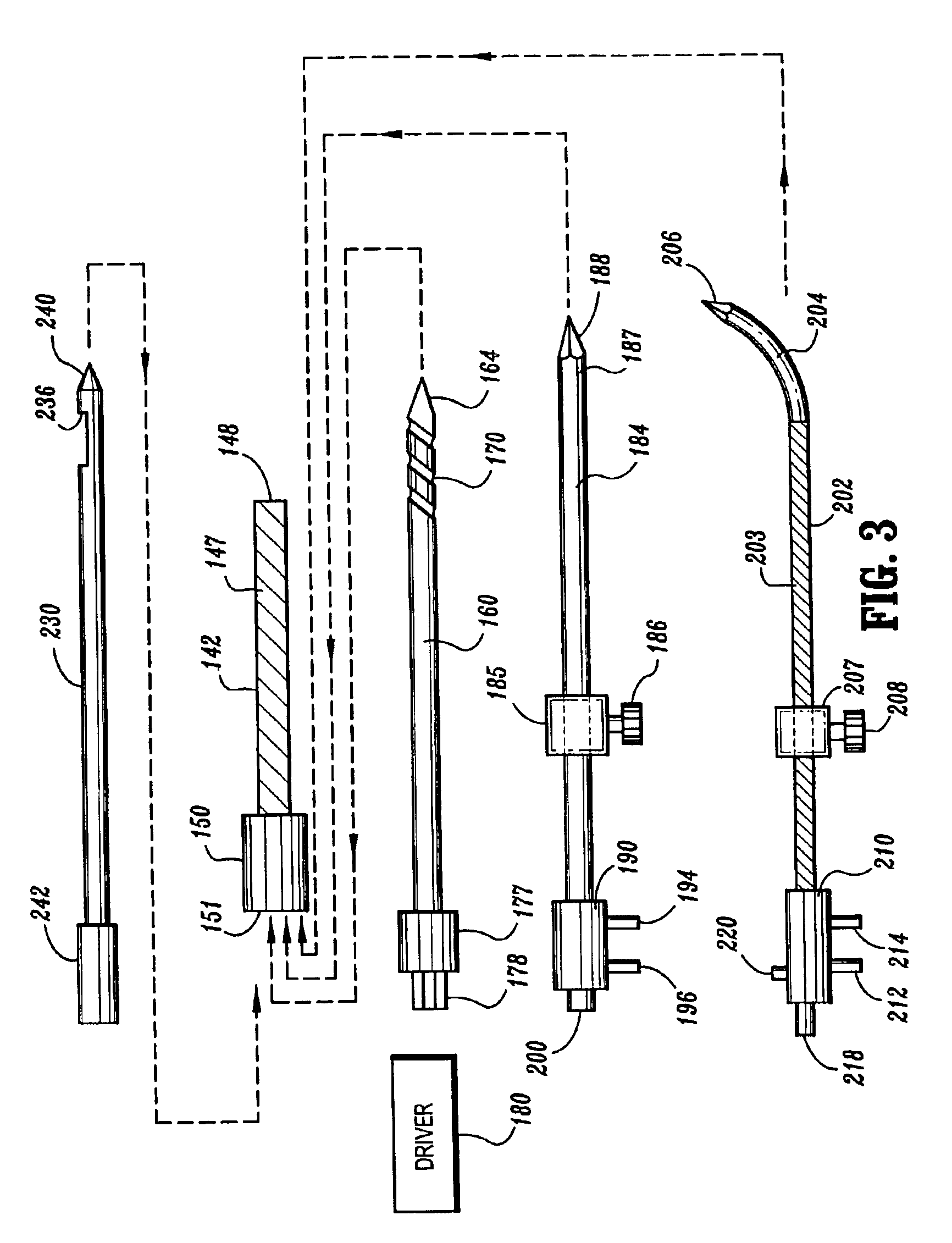

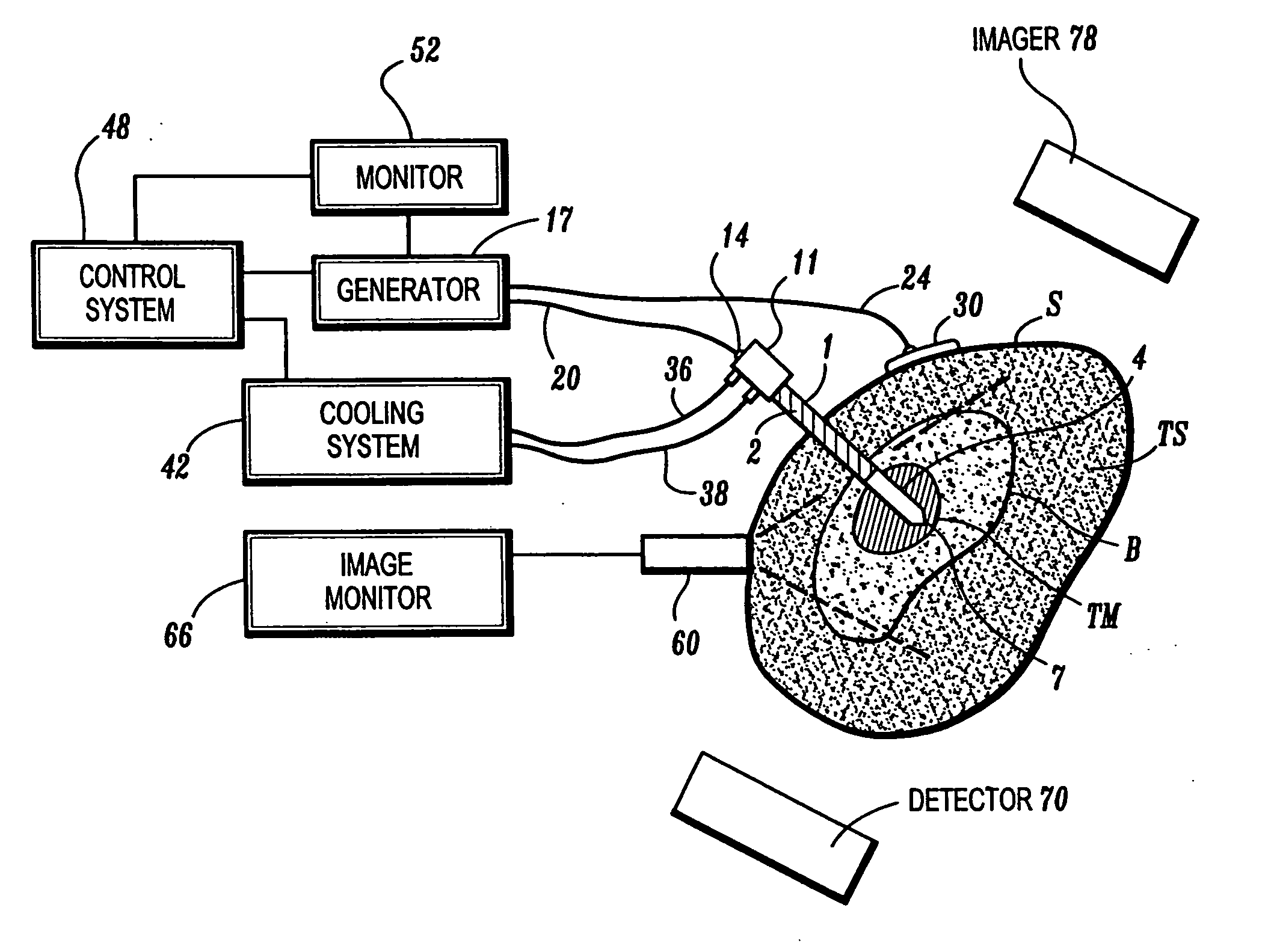

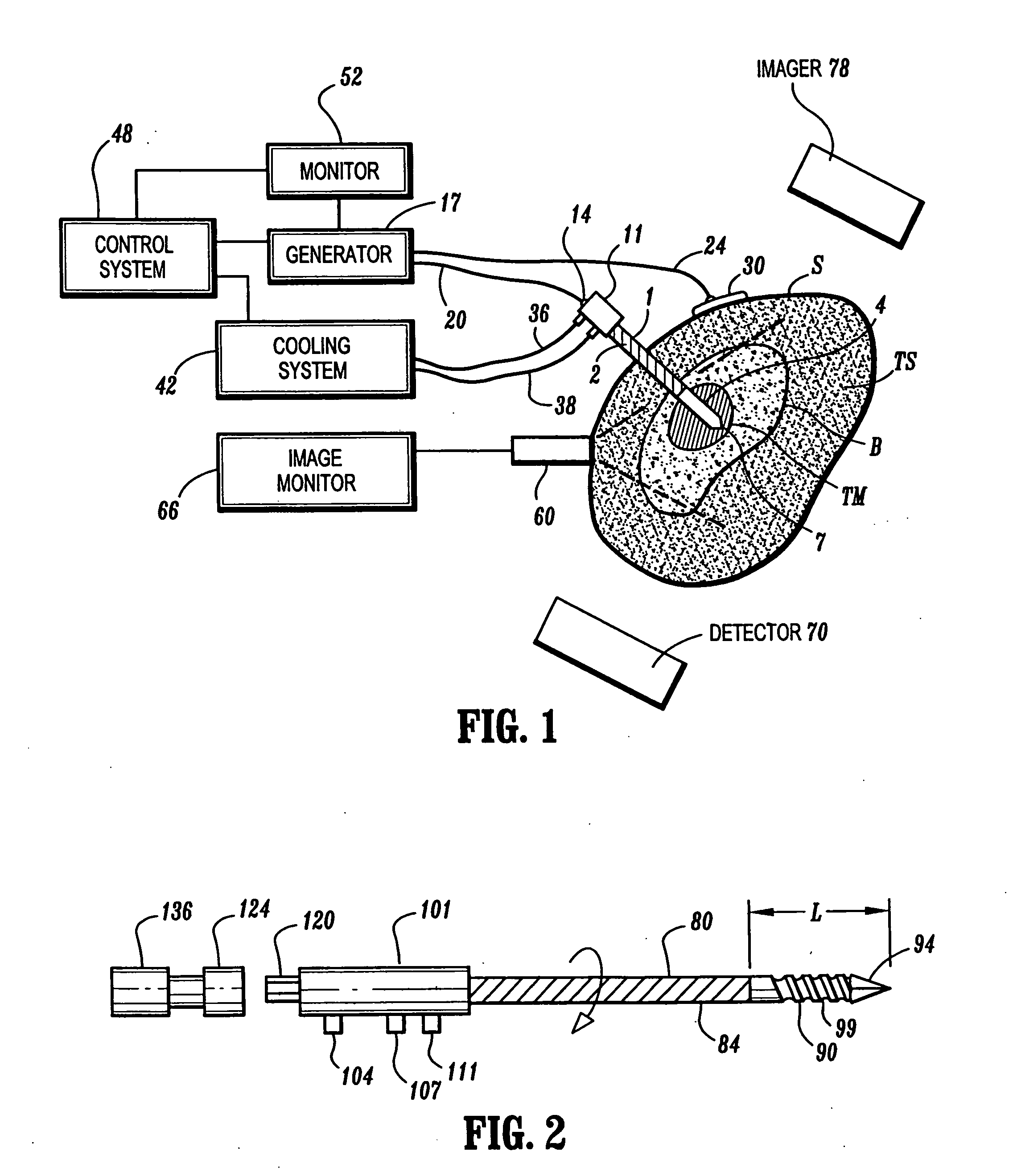

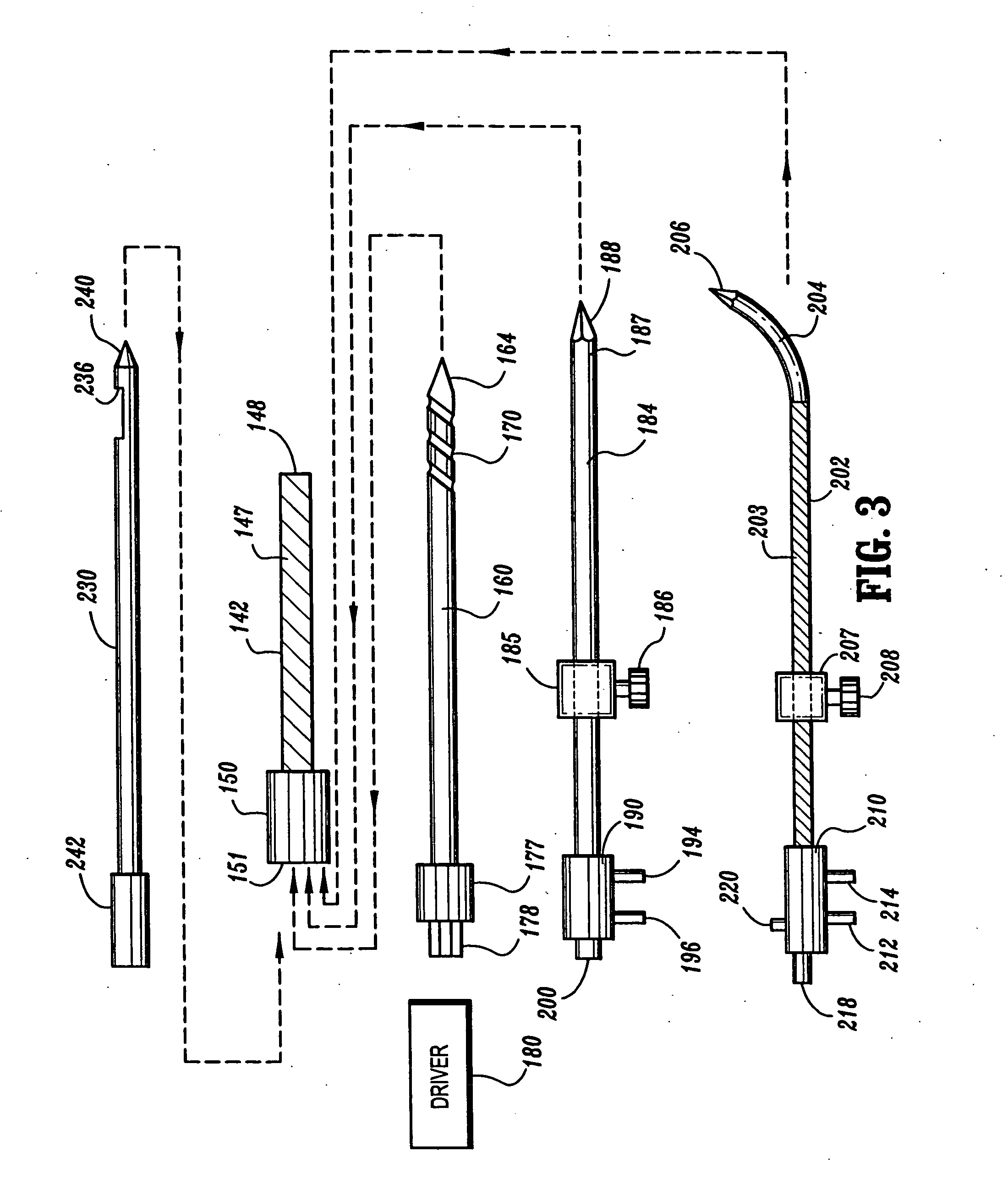

Ablation treatment of bone metastases

InactiveUS6881214B2Easily toleratedReduce the dependency of the patientDiagnosticsSurgical needlesElectrode placementHigh frequency power

Ablative treatment of metastatic bone tumors and relief of pain associated with metastatic bone tumors is achieved by heat ablation of the bone tumor or tissue near the bone tumor by an ablation probe. In one form the probe is an electrode coupled to a high frequency power supply to provide ablative heating of tissue proximate to an electrode that is placed in or near the bone tumor. Cooling of the electrode by fluid circulation from a cooling apparatus outside the patient's body may be used to enlarge the region of high frequency heating around the electrode. Image guidance of the electrode placement may be monitored by an imaging device. Tracking of the electrode by an image-guided navigator helps in placement of the electrode with respect to the configuration of the bone and bone metastasis. A set of tools accommodates biopsy and various shapes of electrodes according to clinical requirements. Several forms of electrodes, energy delivery and cooling apparatus and methods accommodate the specific objectives.

Owner:COVIDIEN AG

Ablation treatment of bone metastases

InactiveUS20050192564A1Easily toleratedReduce the dependency of the patientDiagnosticsSurgical needlesElectrode placementAbnormal tissue growth

Ablative treatment of metastatic bone tumors and relief of pain associated with metastatic bone tumors is achieved by heat ablation of the bone tumor or tissue near the bone tumor by an ablation probe. In one form the probe is an electrode coupled to a high frequency power supply to provide ablative heating of tissue proximate to an electrode that is placed in or near the bone tumor. Cooling of the electrode by fluid circulation from a cooling apparatus outside the patient's body may be used to enlarge the region of high frequency heating around the electrode. Image guidance of the electrode placement may be monitored by an imaging device. Tracking of the electrode by an image-guided navigator helps in placement of the electrode with respect to the configuration of the bone and bone metastasis. A set of tools accommodates biopsy and various shapes of electrodes according to clinical requirements. Several forms of electrodes, energy delivery and cooling apparatus and methods accommodate the specific objectives.

Owner:COVIDIEN AG

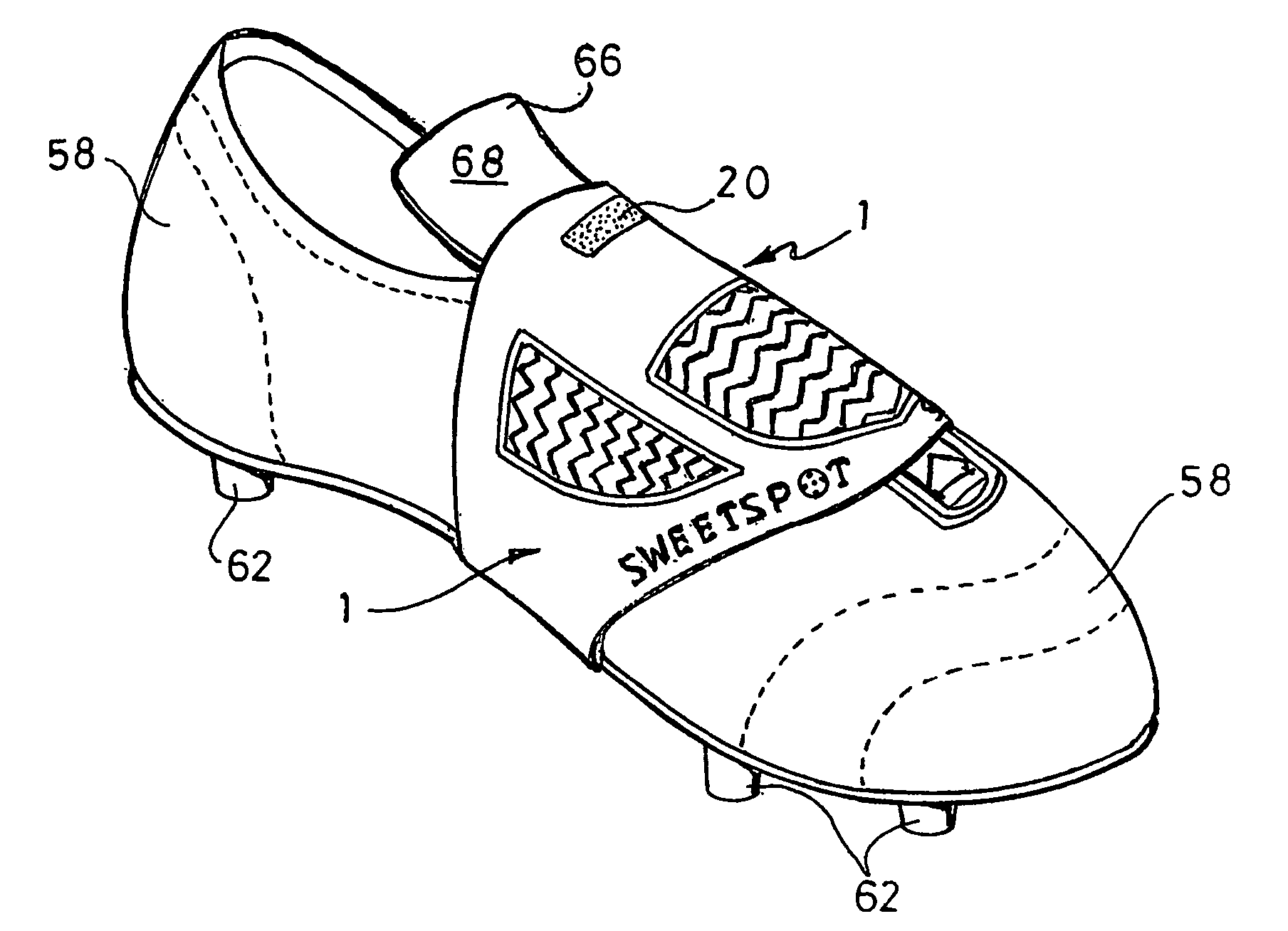

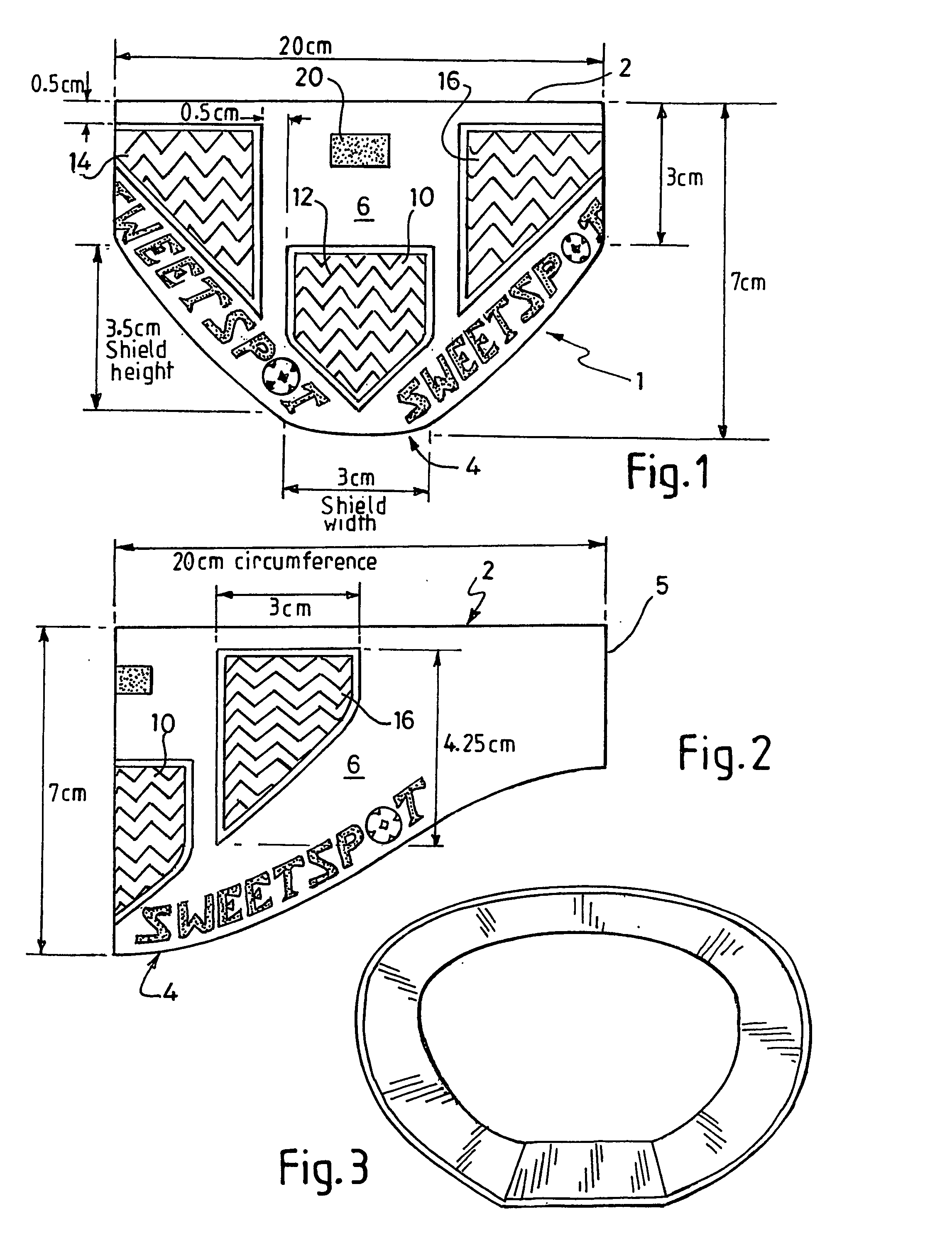

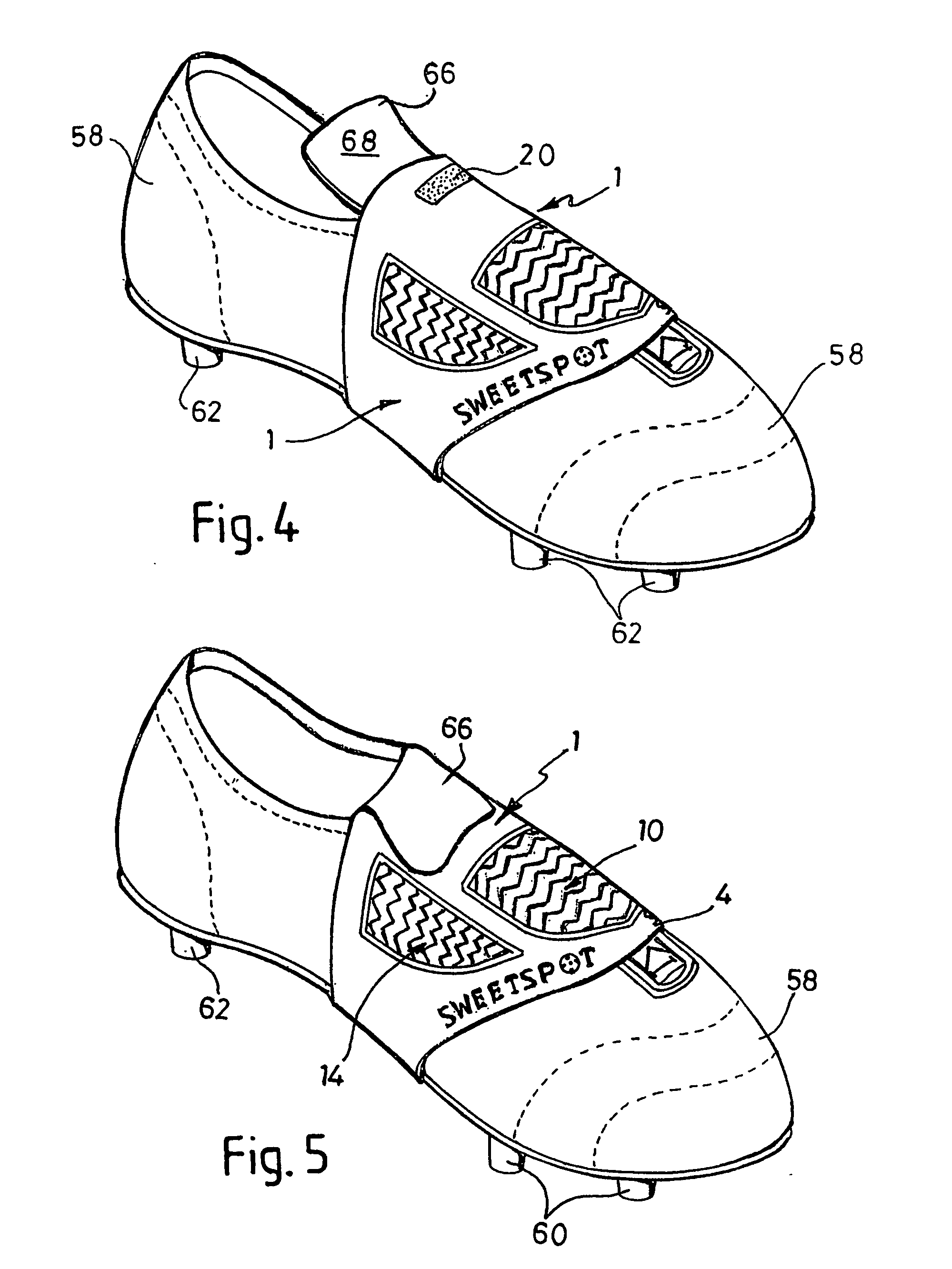

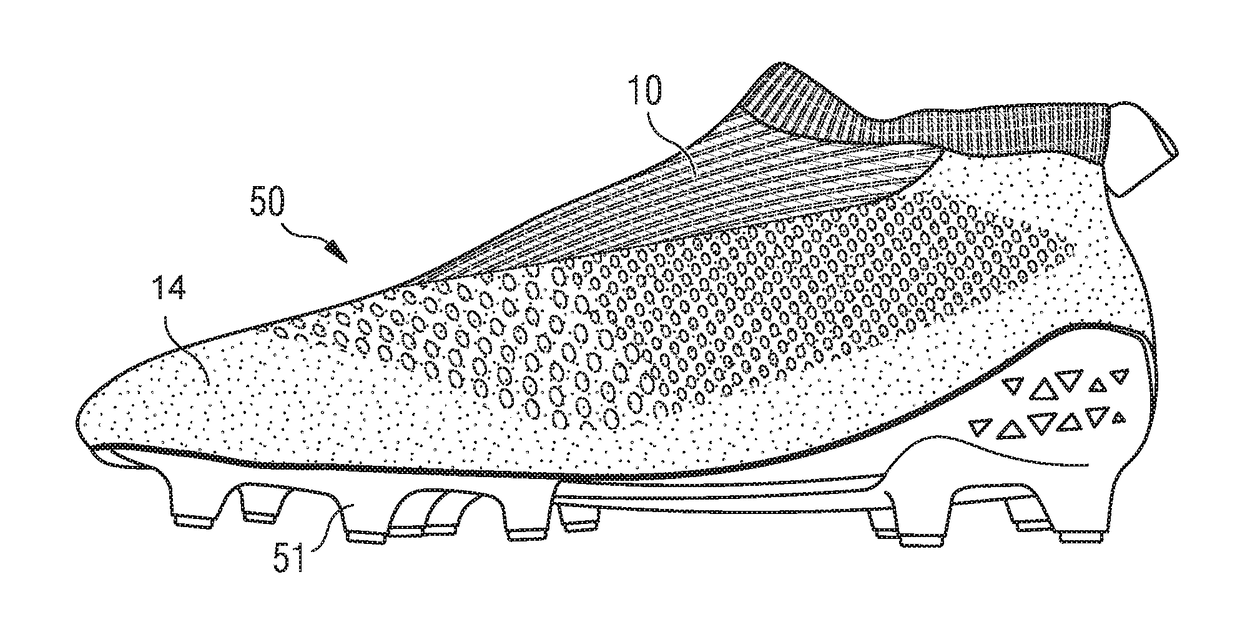

Sports shoe cover

InactiveUS20050144812A1Easily fitted (and removed)Accurate coverageShoe lace fasteningsUpperEngineeringArches of the foot

A cover for a lace-up football boot has a continuous, elastically expandable sleeve (1). The sleeve is, in use, stretched around the boot so that the latter extends through the sleeve with the toe of the boot protruding from the end of the sleeve, and that the underside of the sleeve engages the portion of the underside of the boot in a region between the heal and the toe (i.e. under the arch of the foot). This engagement between the sleeve and the boot is sufficient to hold the sleeve in position on the boot in use, the sleeve also covering the bootlaces to prevent the latter from untying. At least part of the cover may also be transparent so as to reveal ornamental features or indicia on the boot.

Owner:WHEELER JEFFREY DAVID

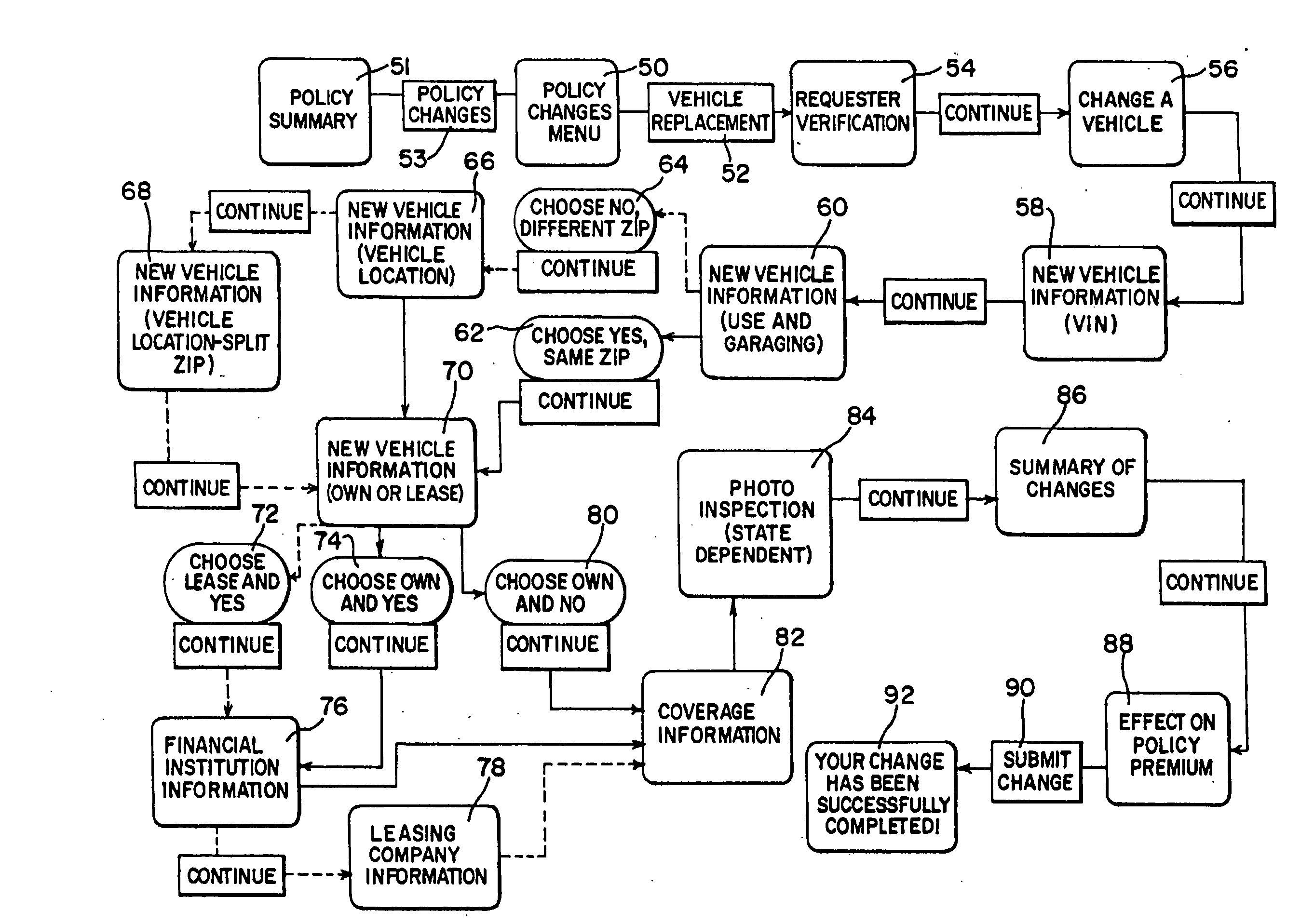

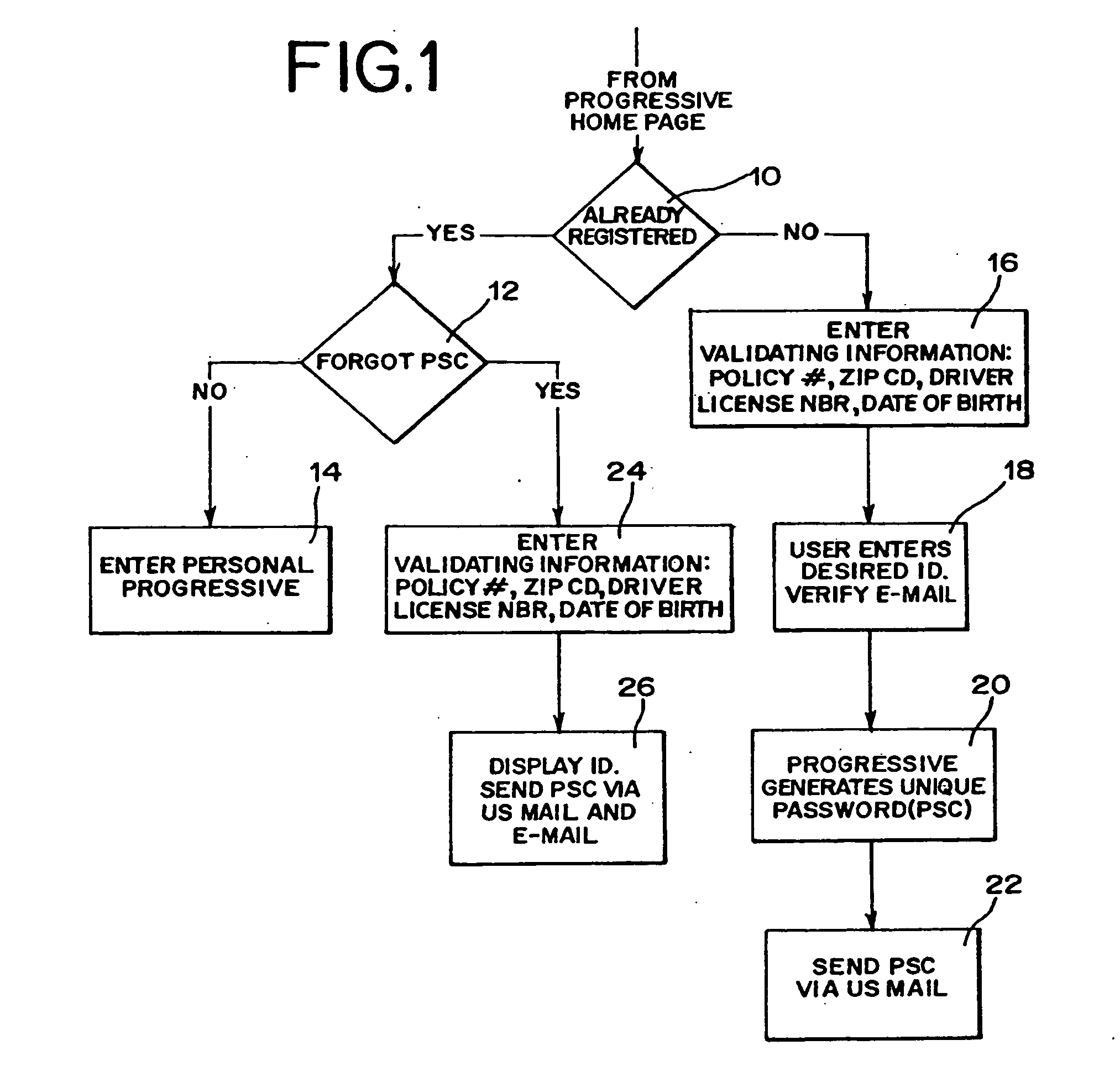

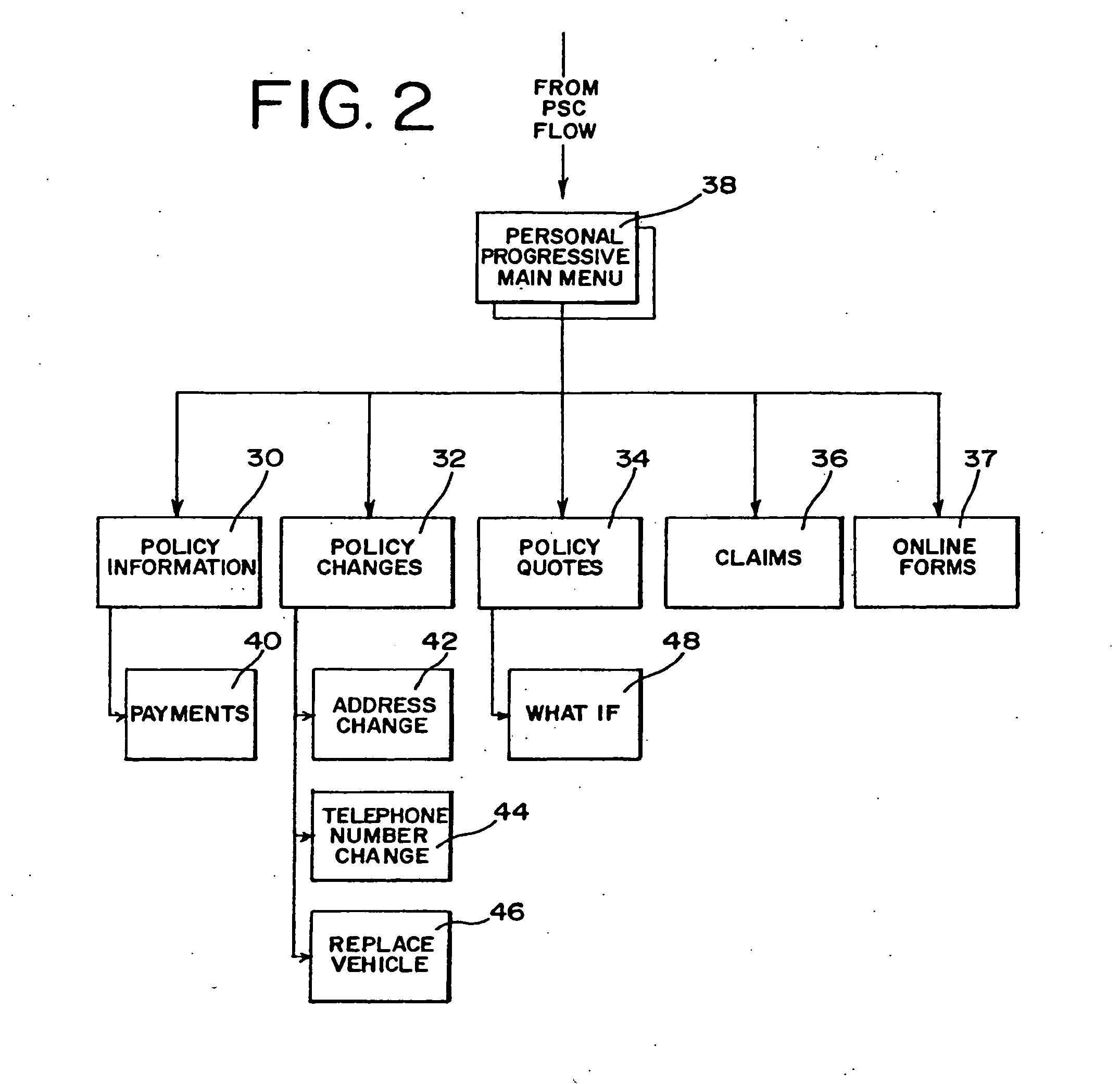

Method and apparatus for internet on-line insurance policy service

InactiveUS20070038488A1Easy to handleReduce inconvenienceFinanceOffice automationThe InternetComputer science

An Internet on-line insurance policy service system that facilitates real-time automated communication of policy information, adjustment of policy parameters, calculation and communication of resulting policy quotes, and implementation of policy changes, while obviating insurer personnel involvement and supervision of the communication. The system comprises a plurality of software modules relating to on-line real-time communication of existing policy information, testing of a wide range of variations in policy parameters, computing and communicating changes in policy premiums that would result from such variations, communicating desired changes in policy parameters and implementing desired policy changes. Other modules relate to communication of claims information and the providing of on-line forms.

Owner:PROGRESSIVE CASUALTY INSURANCE

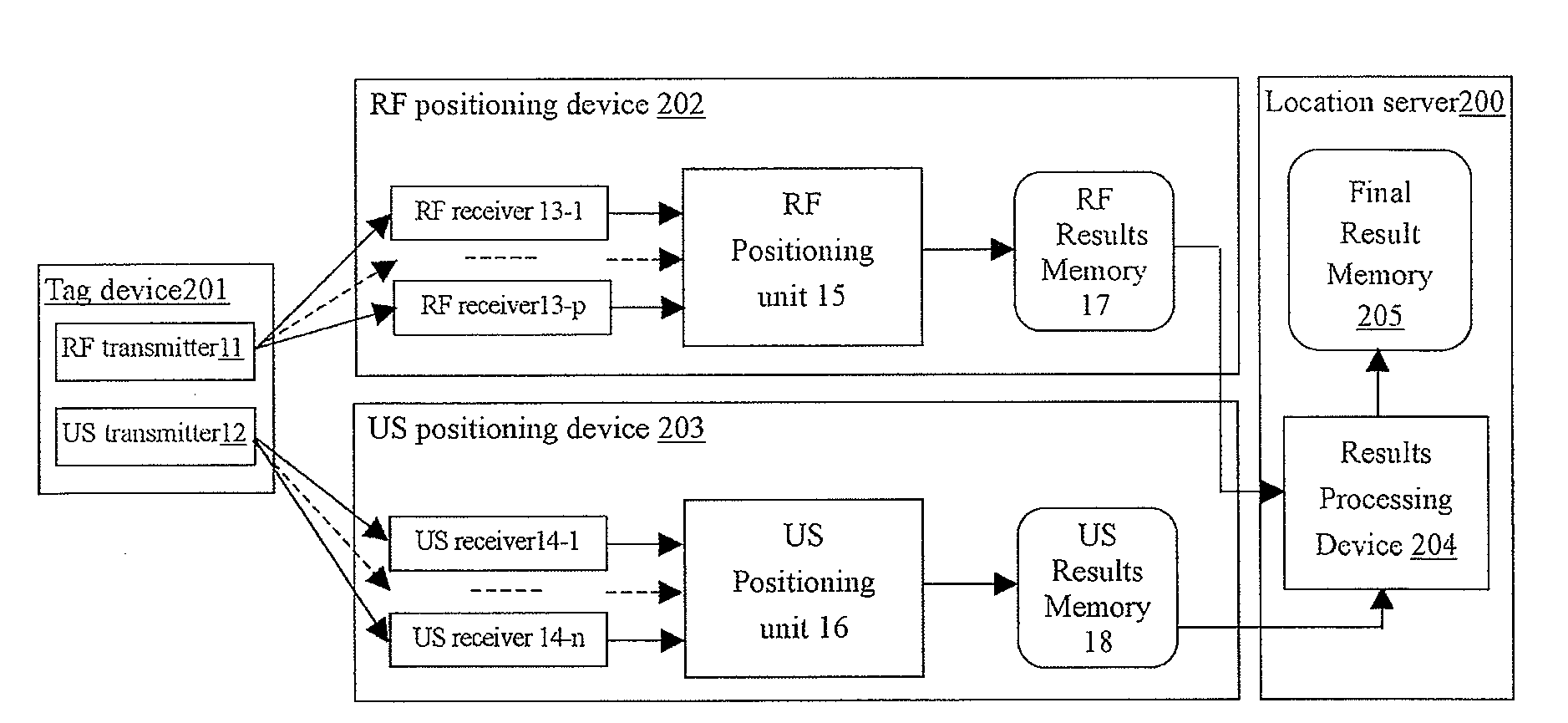

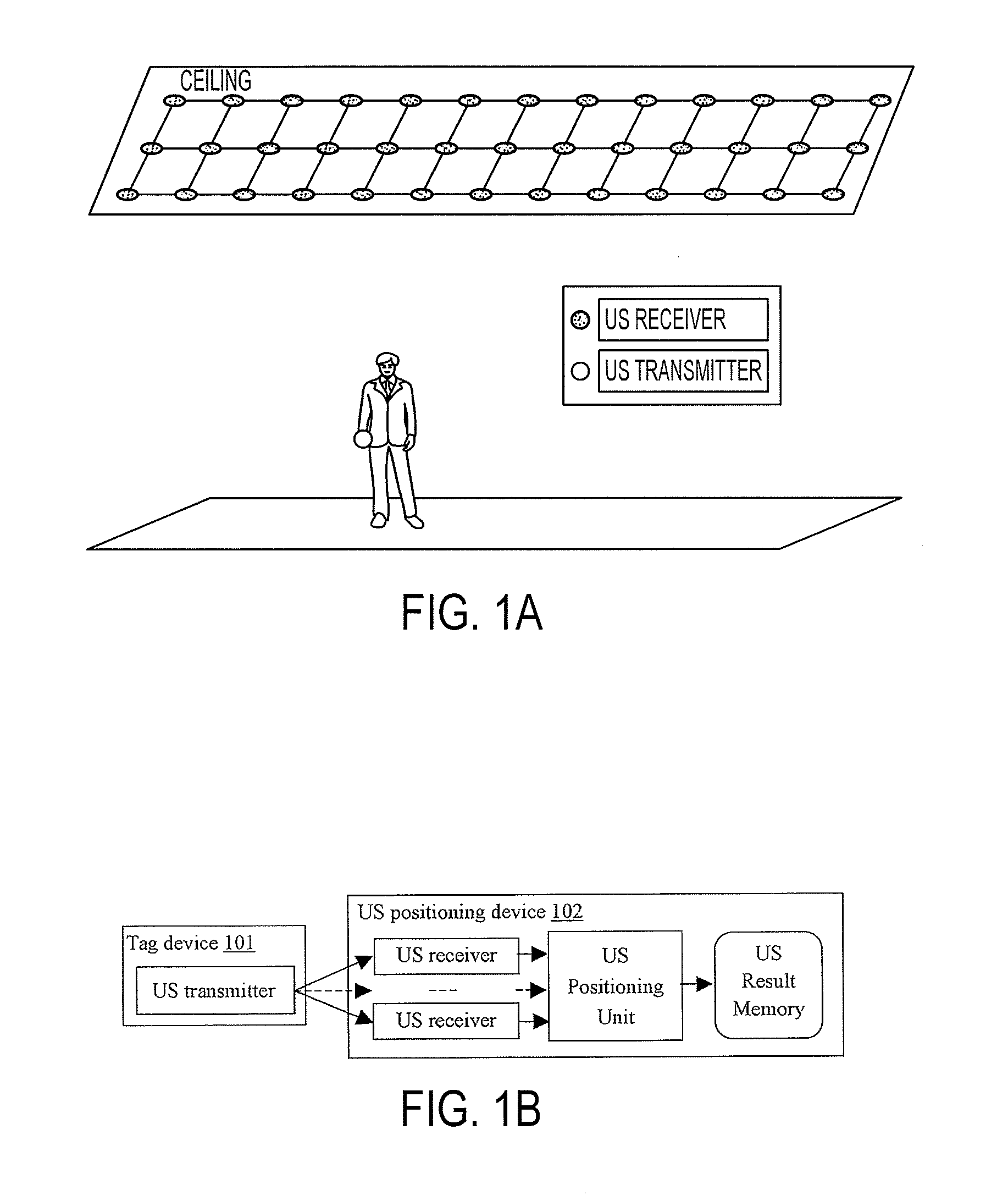

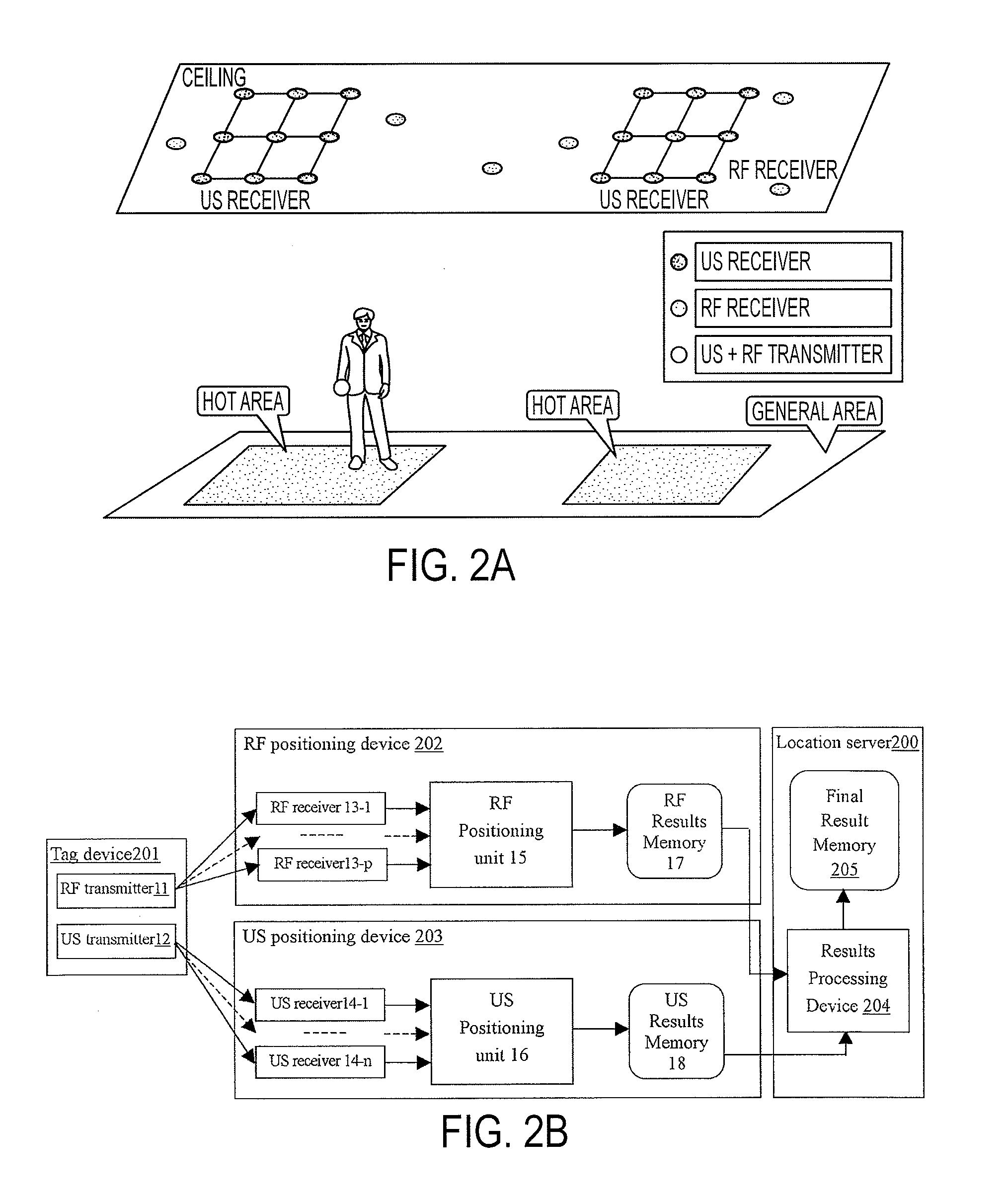

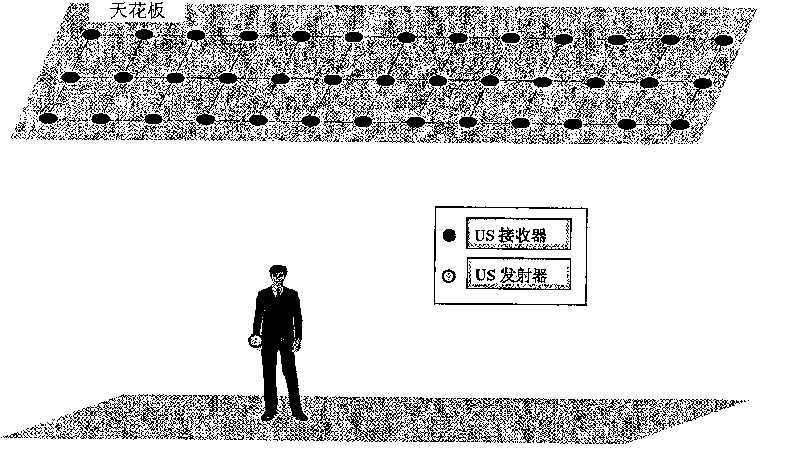

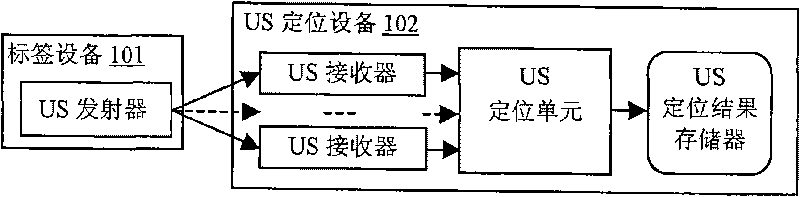

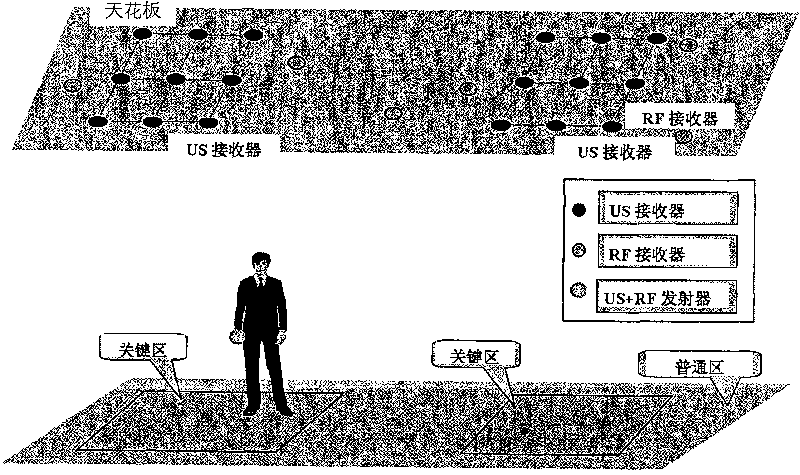

Method and system for positioning object with adaptive resolution

InactiveUS20100090899A1Precise positioningLow positioning accuracy requirementsDirection finders using radio wavesDirection finders using ultrasonic/sonic/infrasonic wavesHot zoneTransceiver

The present invention provides a method and system for positioning an object with adaptive resolution. The method comprises: dividing a space to be detected into Hot Area and General Area; arranging, according to the positions of Hot Area and General Area, high-resolution positioning signal (US) transceivers and low-resolution positioning signal (RF) transceivers, wherein the detection scope of the low-resolution positioning signal transceivers covers the space and the detection scope of the high-resolution positioning signal transceivers covers the Hot Area; and when the object moving in the space, fusing the detection results from the high-resolution positioning signal transceivers and the low-resolution positioning signal transceivers to determine the position of the object with adaptive resolution. With the system of the present invention, for different areas, the object can be positioned with different positioning resolutions (precisions or granularities). Also, since it is not necessary to use a great deal of high-precision positioning devices, the system cost can be reduced considerably.

Owner:NEC (CHINA) CO LTD

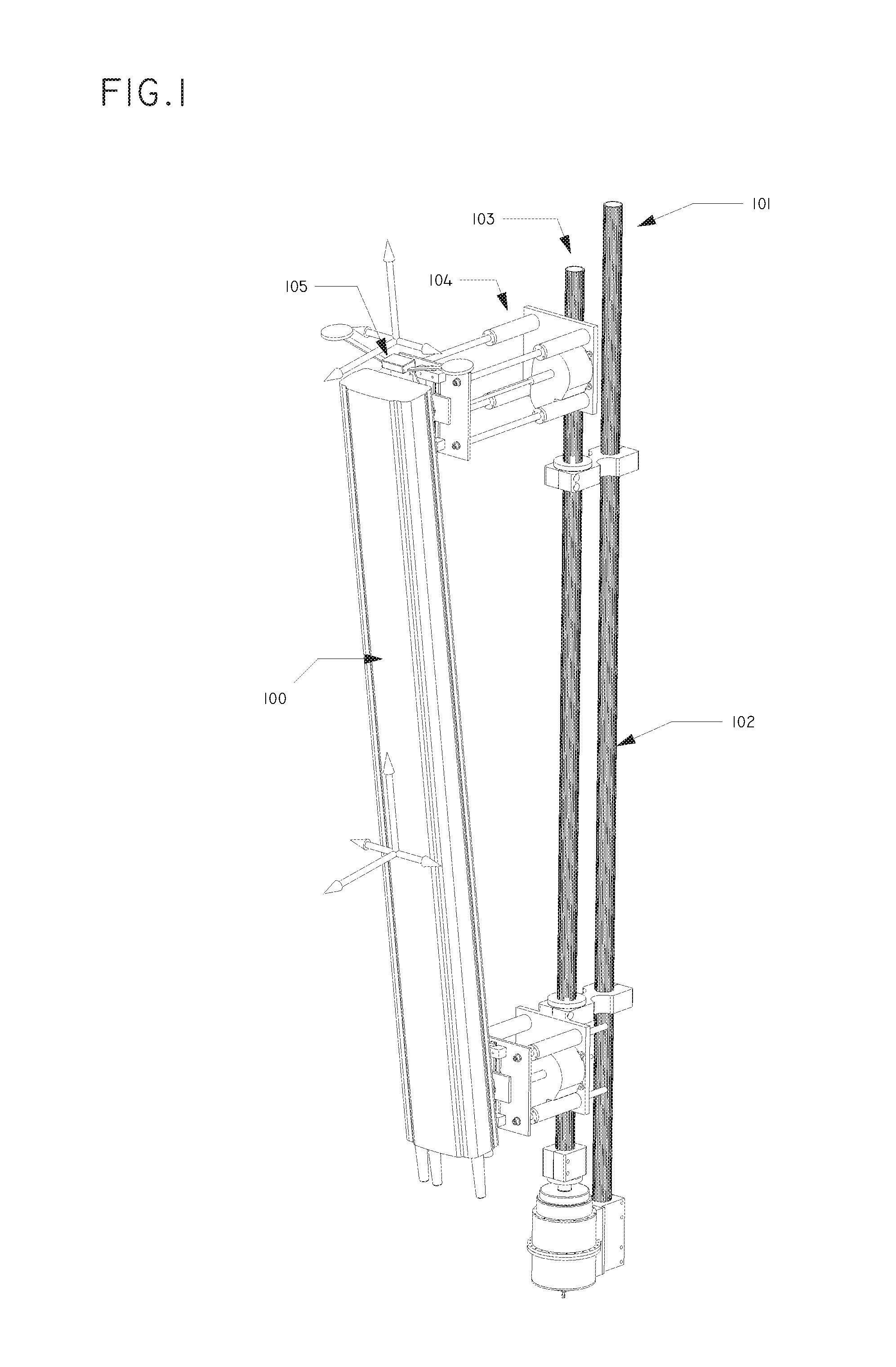

Two-way antenna mounting bracket and assembly with independently adjustable electromechanical antenna tilt and azimuthal steering for beam reshaping

InactiveUS20160211576A1Fast and reliable mobile broadband connectionAccurate network coverageAntenna supports/mountingsPump controlRemote controlControl signal

An assembly for a mobile communications antenna system includes a bracket assembly onto which an antenna array is mounted. The bracket assembly includes a steering arrangement configured to provide angular adjustment of an antenna beam azimuth, and an electromechanical tilting arrangement configured to adjust a tilt position of the antenna array. The steering arrangement and the electromechanical tilting arrangement are controllable in remote and manual operational modes to independently and variably adjust both azimuthal angle and tilt position of the antenna array. These operational modes ensure remote control of signal propagation and network coverage accuracy, and manual adjustment of the azimuth of the antenna beam and tilt position of the antenna array in case of field service or component failure.

Owner:OUTTHINK TECH LLC

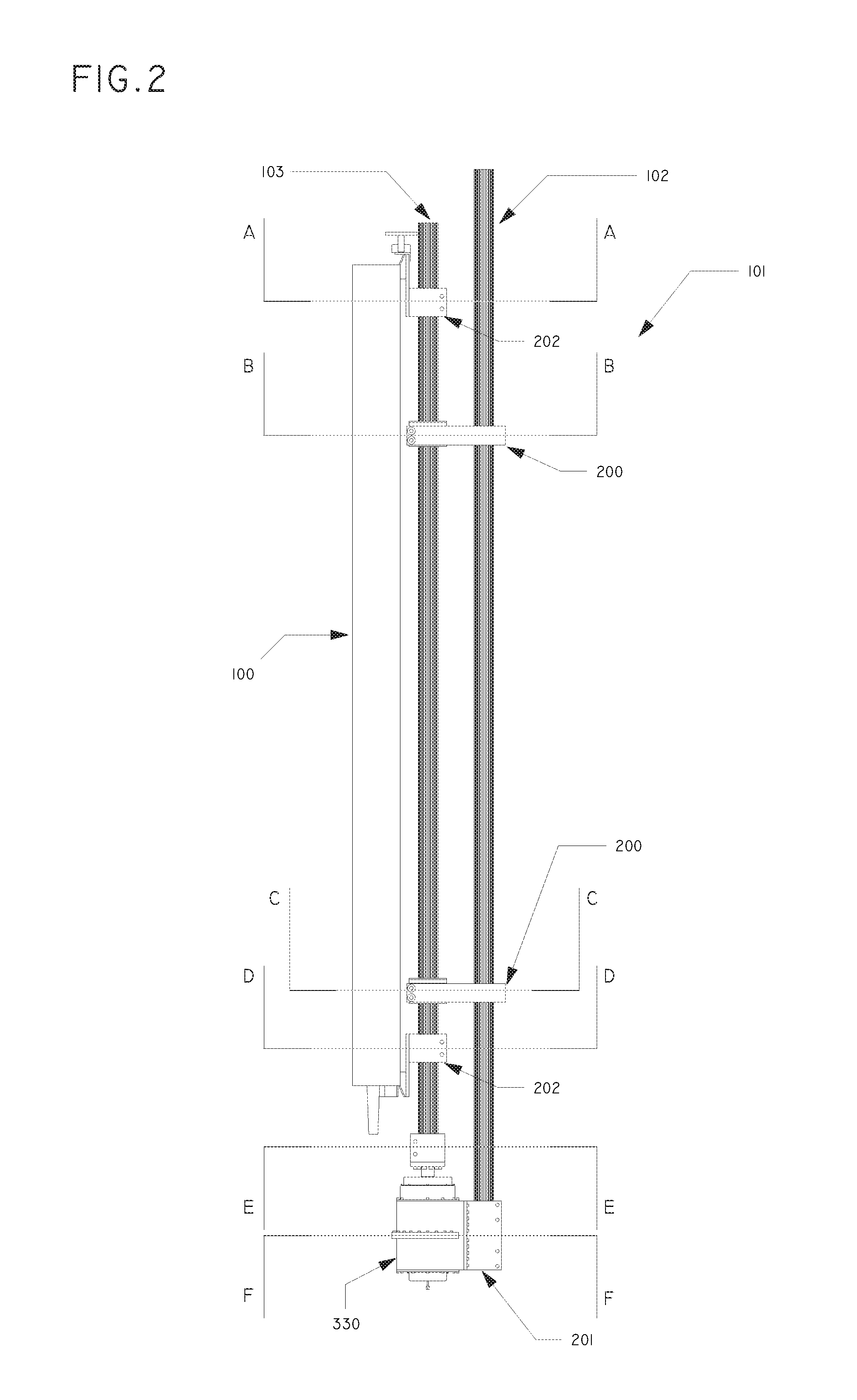

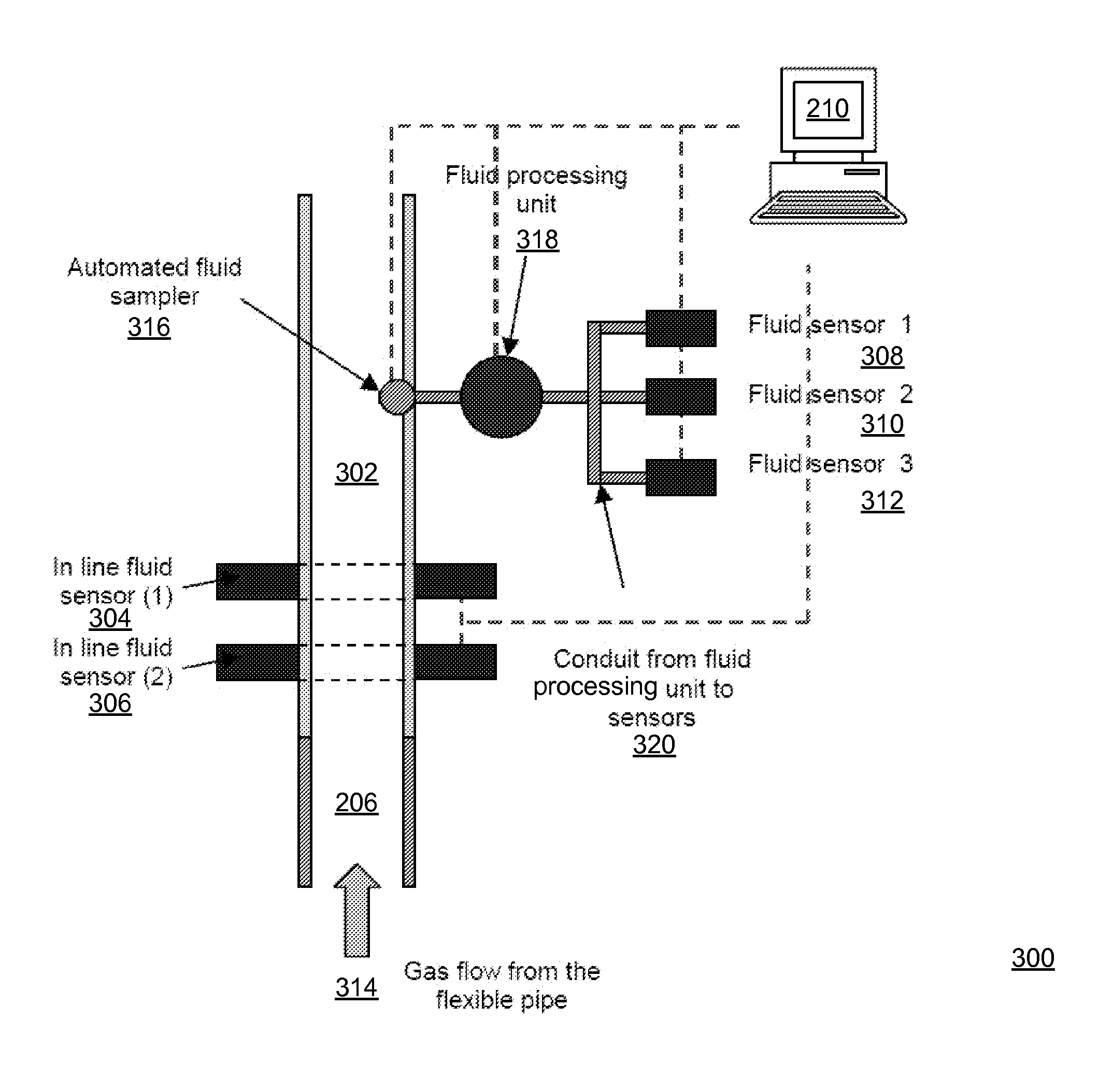

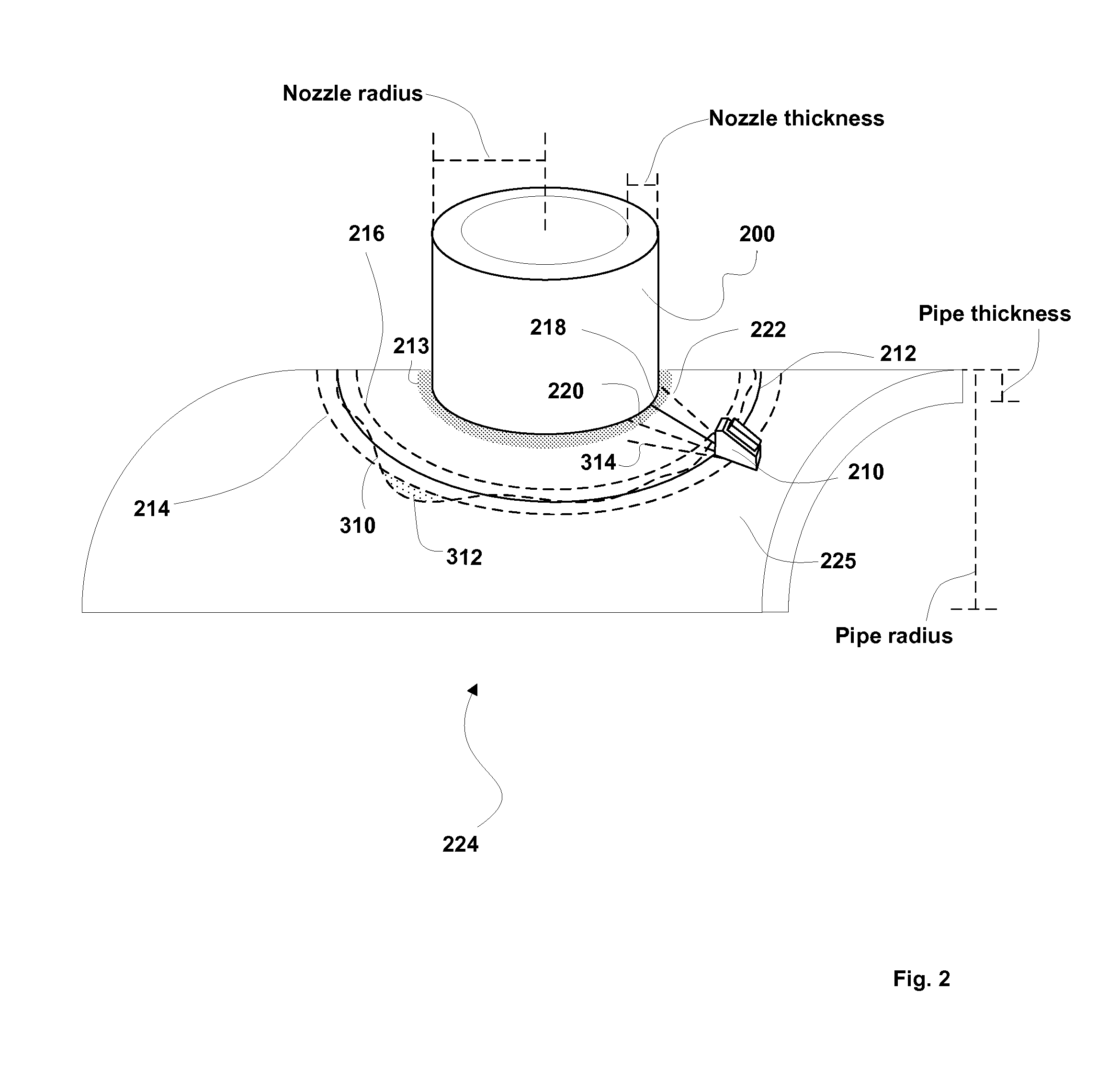

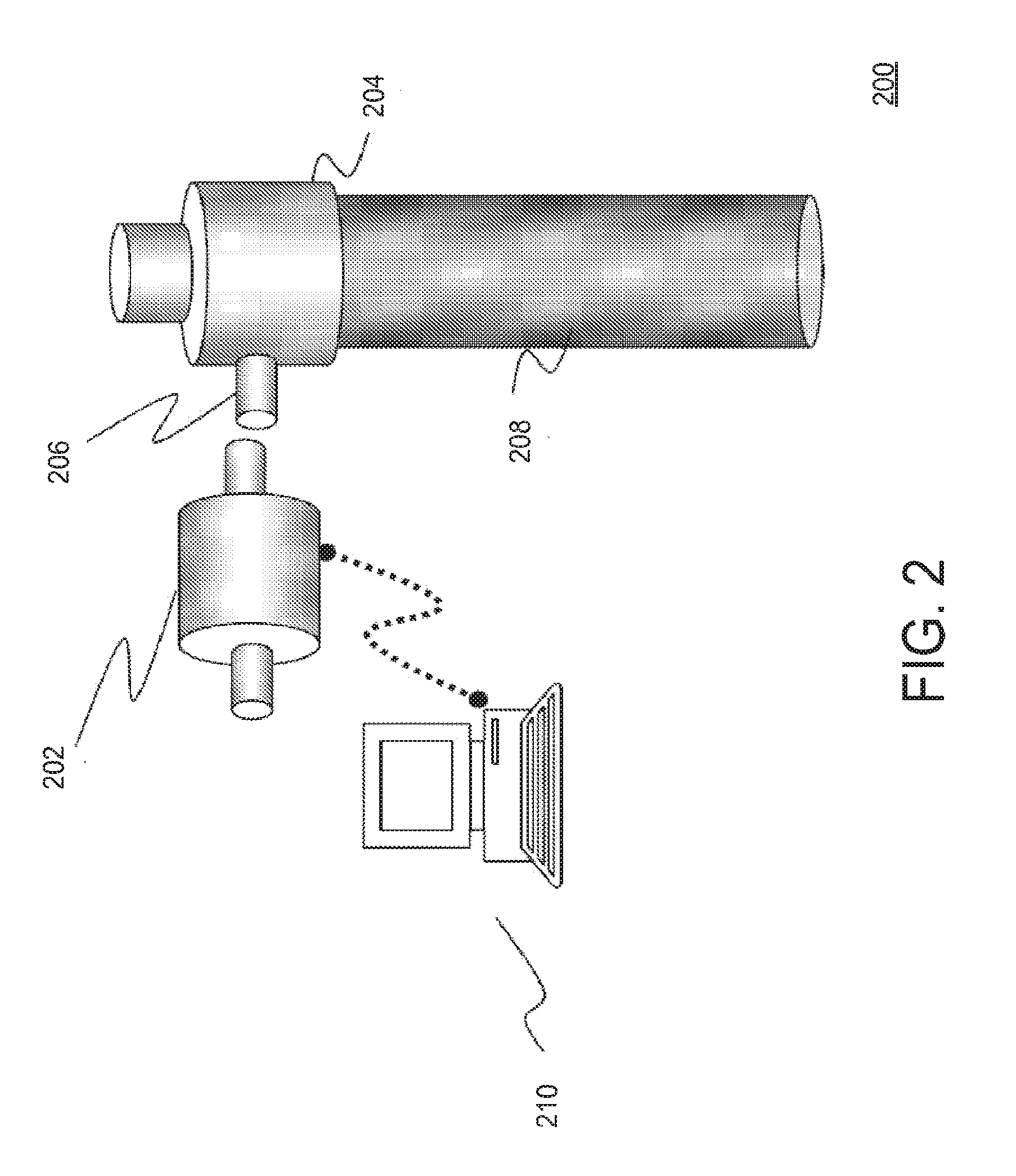

In-line composition and volumetric analysis of vent gases and flooding of the annular space of flexible pipe

InactiveUS20110153225A1High frequencyReduce in quantityPlug gaugesDrilling rodsExhaust valveVolume analysis

A method and system for monitoring a flexible pipe, including an inline sensor system coupled to the annulus of the flexible pipe to detect corrosion of the flexible pipe. Also disclosed are method and system for monitoring an amount of water being accumulated in an annulus of a flexible pipe, including locating a pressure measurement system proximate to the annulus for measuring pressure of gas inside the annulus; controlling a flow of vent gas with a vent gas valve; positioning a flow measurement system upstream or downstream of the vent gas valve for measuring the flow of the vent gas when the vent gas valve is opened; and collecting with a microprocessor pressure and flow measurement data from the pressure and the flow measurement systems for determining the amount of water accumulated in the annulus based on the collected pressure and flow measurement data.

Owner:SCHLUMBERGER TECH CORP

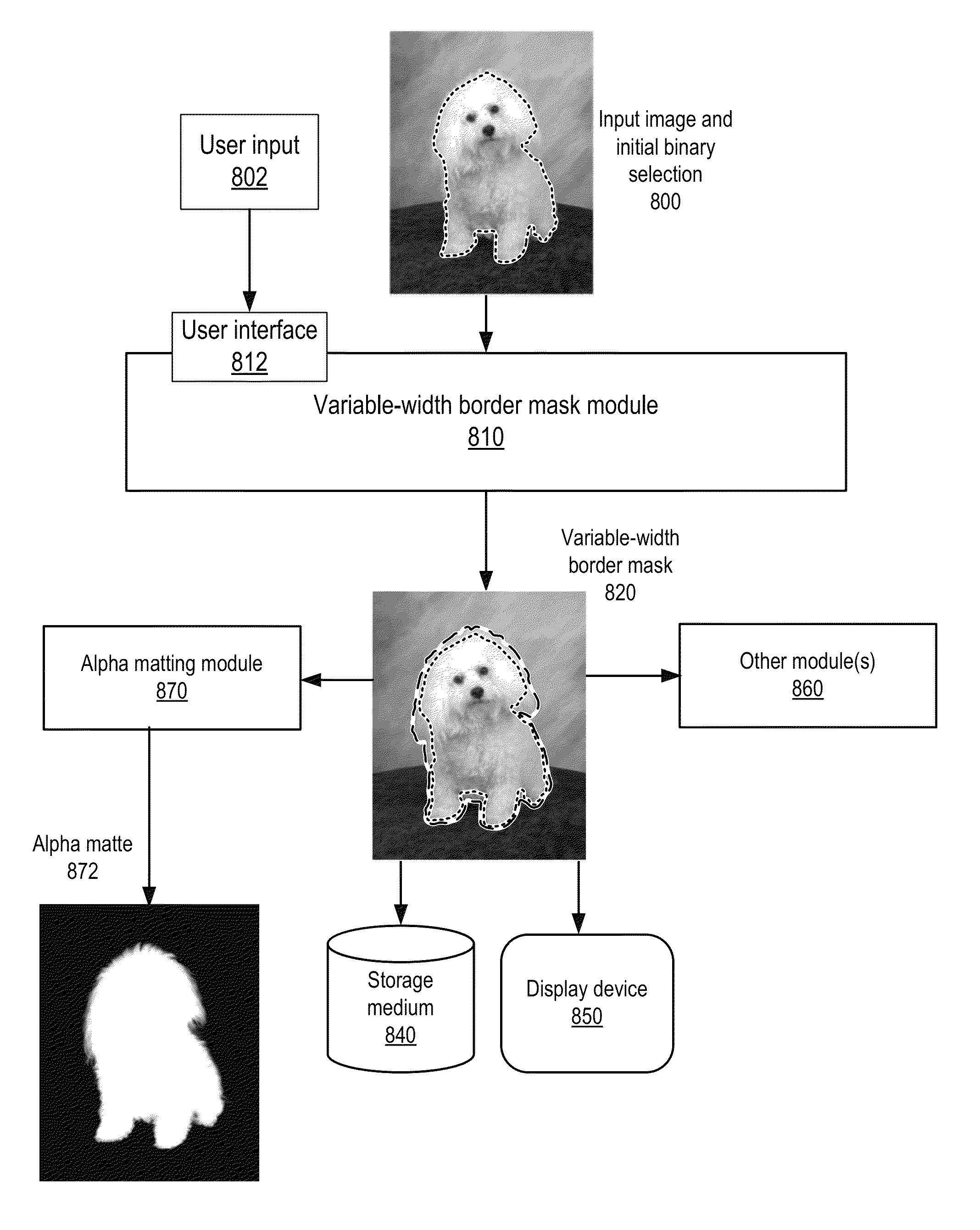

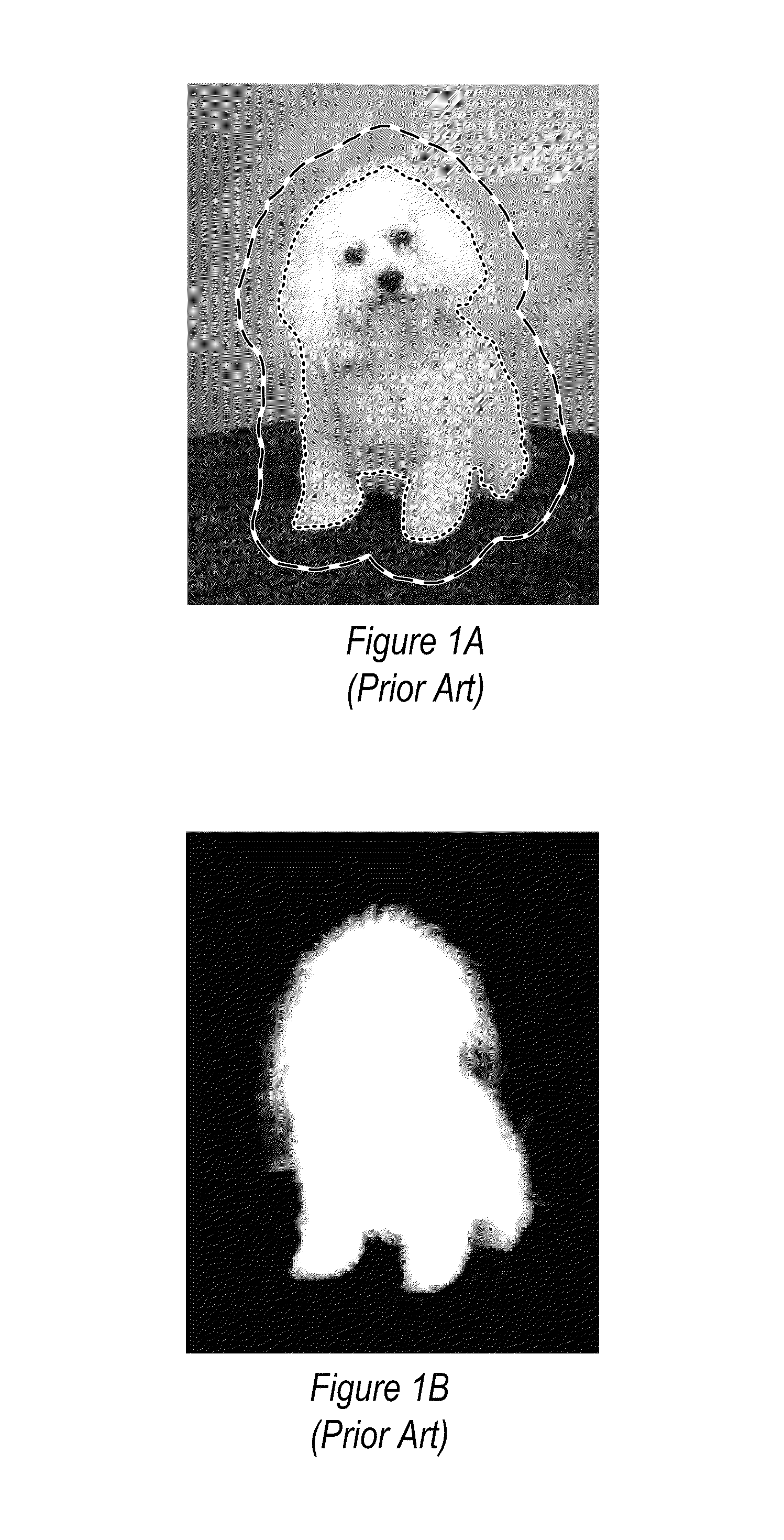

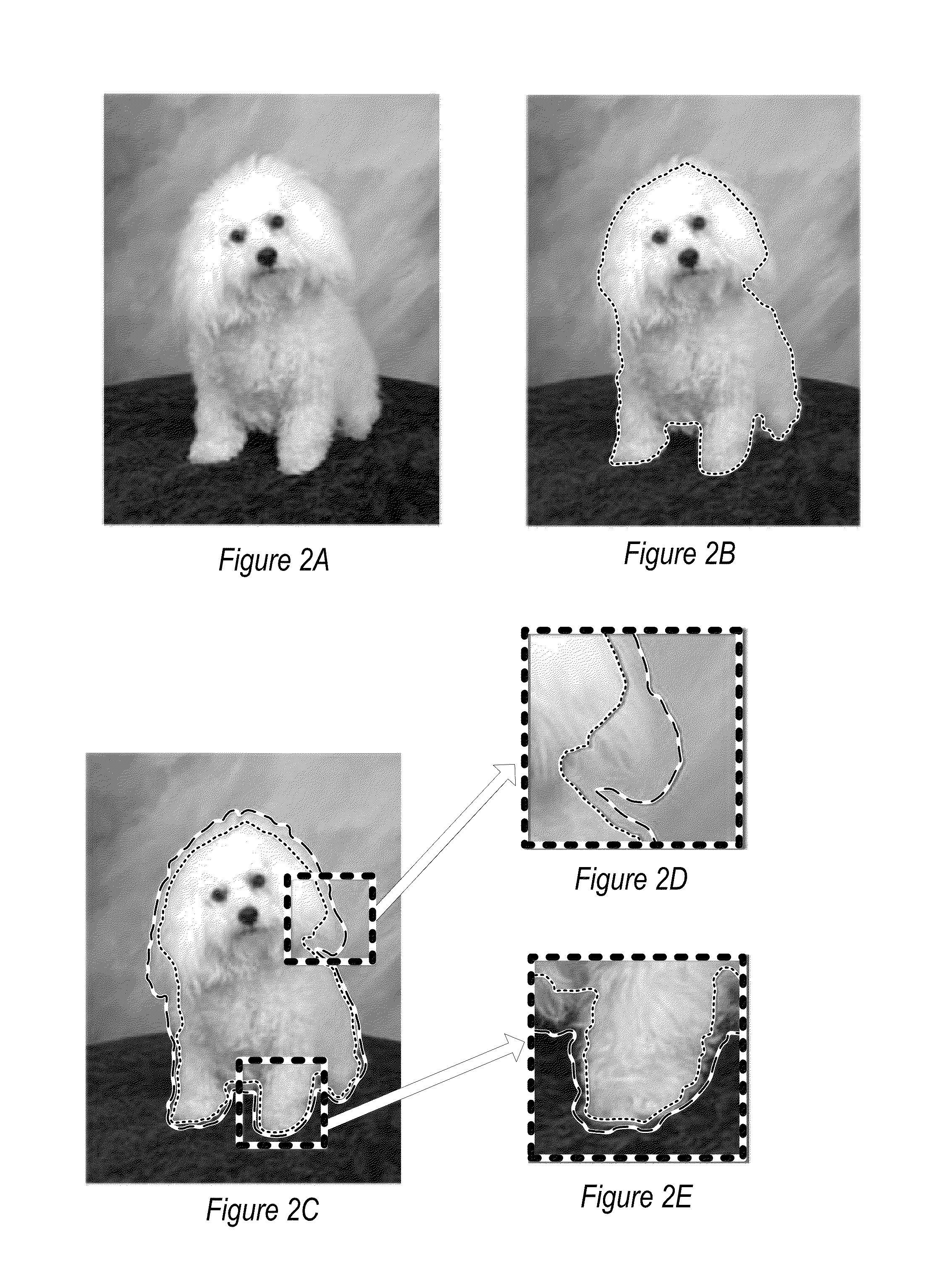

Method and apparatus for generating variable-width border masks

Methods and apparatus for generating variable-width border masks for objects in input images. Given an input image and an initial binary selection of an object in the image, a variable-width border mask method may be applied to automatically generate an accurate, variable-width border mask for the object. An initial border mask may be generated. An initial foreground probability map may be generated within the initial border mask using a Gaussian Mixture color modeling technique. A geodesic smoothing technique may be applied to the initial foreground probability map to reduce or remove noise. An optimization technique may be applied to optimize the foreground boundary, and a final variable-width border mask may be generated. The variable-width border mask may be used as input to image matting algorithms to generate an accurate alpha mask of the foreground object selected from the input image.

Owner:ADOBE SYST INC

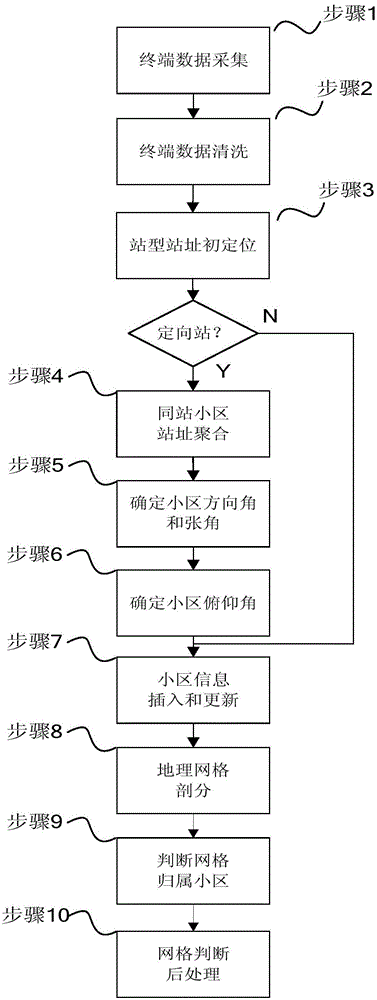

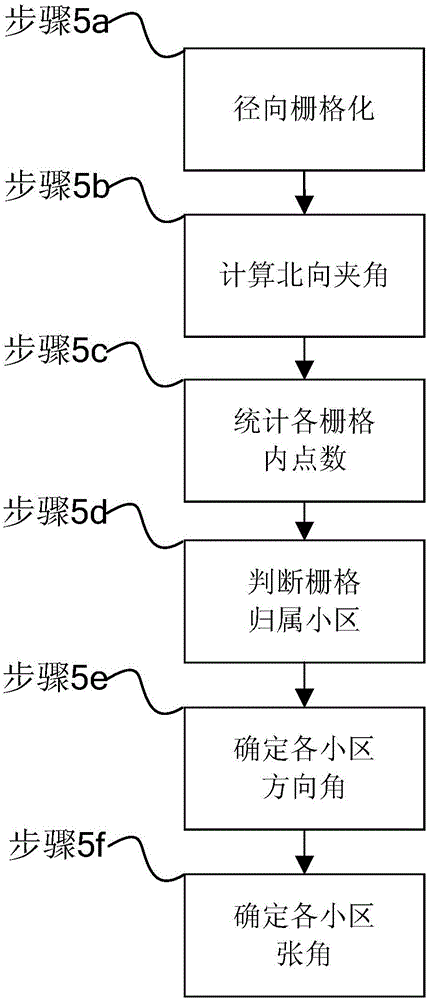

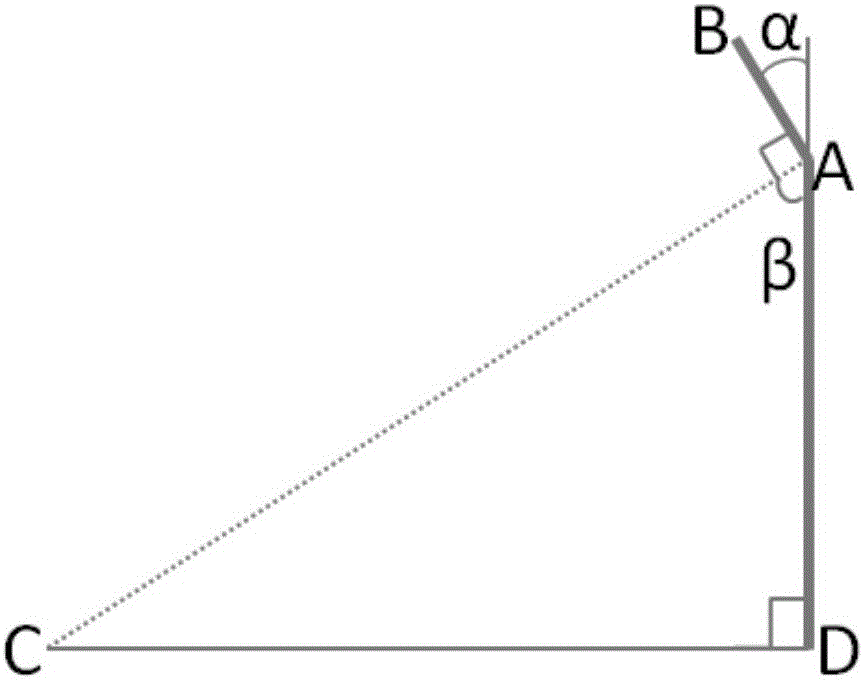

Cell information detection and cell coverage calibration method for mobile network

ActiveCN105744535AAvoid time delays and human errorsDelay the time of being blockedNetwork planningTime delaysMobile Web

The invention discloses a cell information detection and cell coverage calibration method for a mobile network, belongs to the field of mobile communication, and solves the problems that how to accurately acquire the cell key parameters of the mobile network and thereby to establish a base station information list, and how to accurately measure and calibrate the actual coverage range of each cell. According to the method, the user online information of the mobile network collected by a user terminal is used, and via the big data analysis means, the cell key parameters (cell identifiers, station location longitudes and latitudes, direction angles, station types, etc.) are determined, and the base station information list is established; and based on a large number of sampling data of the user online information collected by the terminal, the coverage boundary of each cell is accurately calibrated, and the cell coverage map of the whole network is established. According to the method, the cell key parameters of the mobile network can be accurately acquired, and thereby the base station information list can be established, the time delay and manual errors caused by maintaining the base station information list in a traditional manual collecting and step-by-step reporting manner can be effectively avoided, and the actual coverage range of the network can be accurately evaluated.

Owner:BEIJING UNION UNIVERSITY

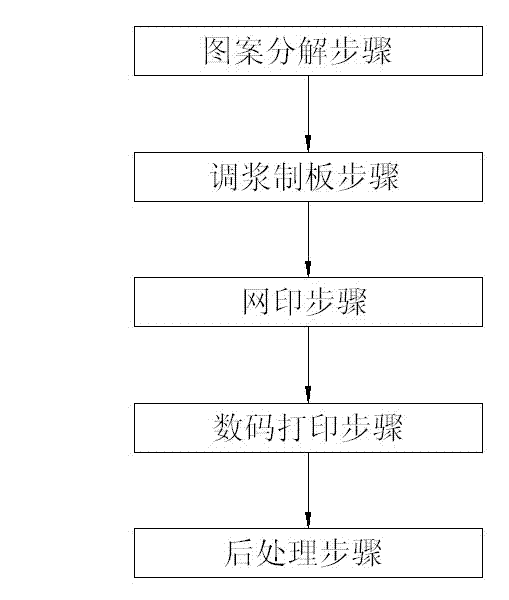

Printing method of combining conventional printing with digital printing

ActiveCN103171319AFlexible printingRich in colorDuplicating/marking methodsTypewritersDigital printingEngineering

The invention relates to a printing method of combining conventional printing with digital printing. At present, no printing method is capable of really and effectively combining conventional printing with digital printing. The printing method sequentially comprises the following steps of:1. decomposing a pattern, namely, decomposing a pattern needing being printed into a conventional printing pattern and a digital printing pattern; 2. mixing size and making plate, namely, carrying out dye blending and making a digital printing screen; 3. carrying out screen printing, namely, carrying out conventional printing and digital printing pretreatment; 4. carrying out digital printing, namely, carrying out digital jet printing on a printing medium by adopting a digital jet printing system with a pre-detection device according to the digital printing pattern, determining a digital printing position on the printing medium, printing the digital printing pattern on the printing medium to ensure that the digital printing pattern is coincident with the conventional printing pattern; and 5. carrying out post-treatment to prepare a finished product. The printing method is good in printing effect and low in production cost, and is capable of really and effectively combining the conventional printing with the digital printing.

Owner:HANGZHOU HONGHUA DIGITAL TECH

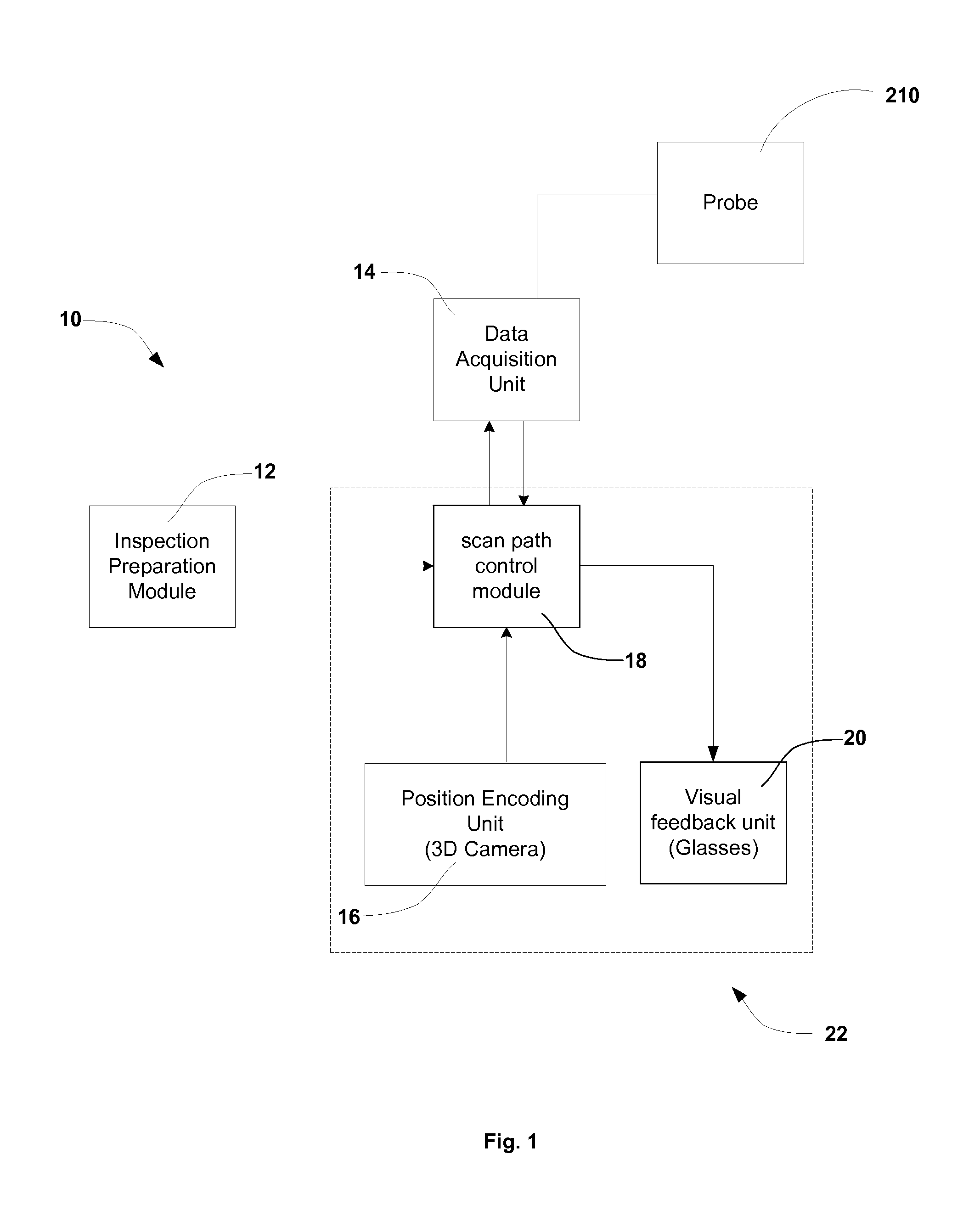

System and method of non-destructive inspection with a visual scanning guide

ActiveUS20150039245A1Accurate coverageReduce errorsMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansNon destructiveEyewear

Disclosed is an inspection device and method of guiding an inspection probe according to a predetermined inspection plan. The device is couple with a probe which is to be moved according to the inspection plan on the test object, the device including an inspection guide unit having a guide control unit, a position encoding such as a 3-D camera and visual feedback eyewear. The method including facilitating a virtual display of the inspection plan onto the visual feedback eyewear, moving the probe following the virtual display of the inspection plan, sensing sensed probe positions in real time of the inspection using the 3-D camera and validating the sensed probe position against the inspection plan using the control module. Then the information of the step of validating, such as those spots at which the probe is moved out of the tolerance of the inspection plan, is displayed on the feedback eyewear.

Owner:OLYMPUS AMERICA

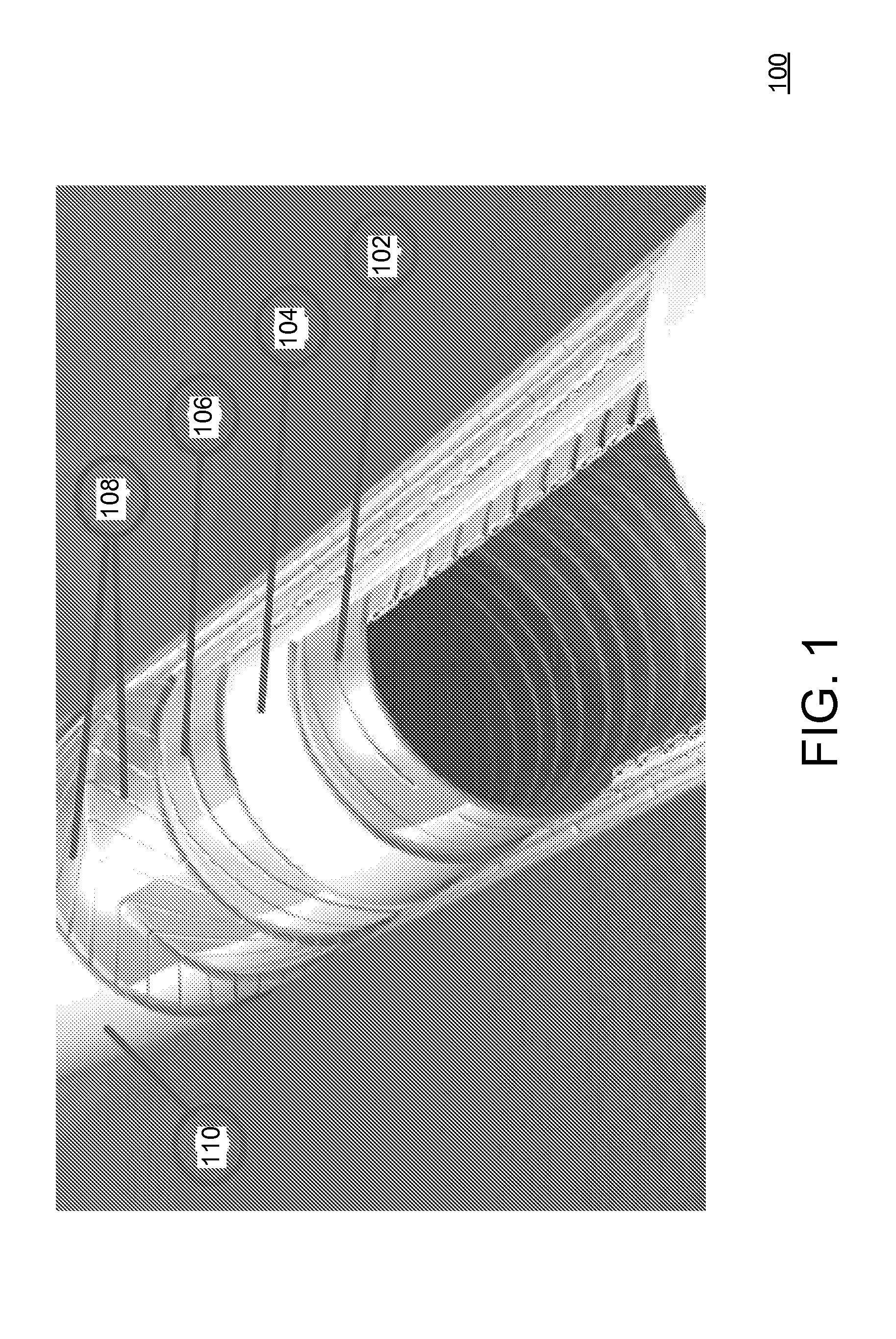

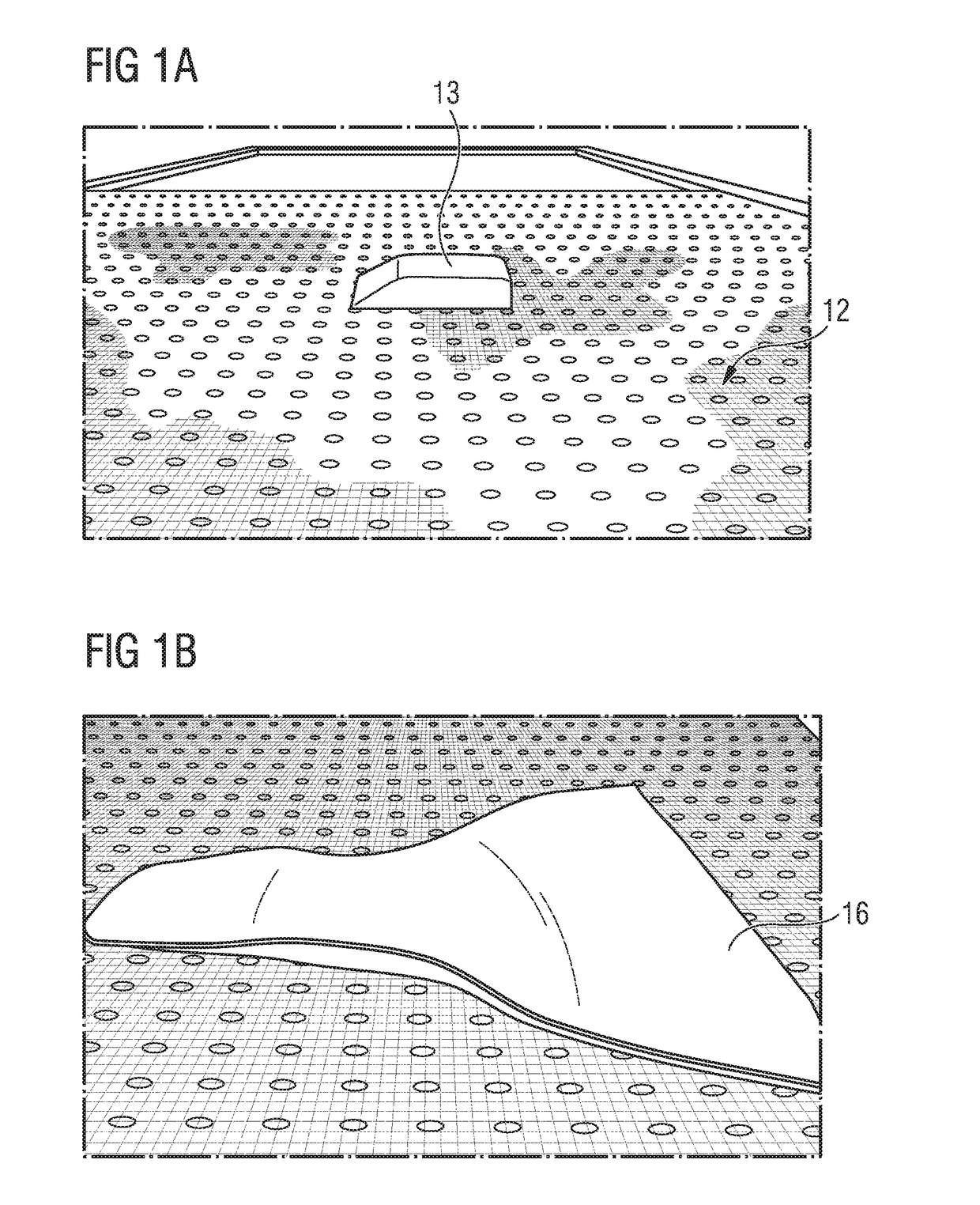

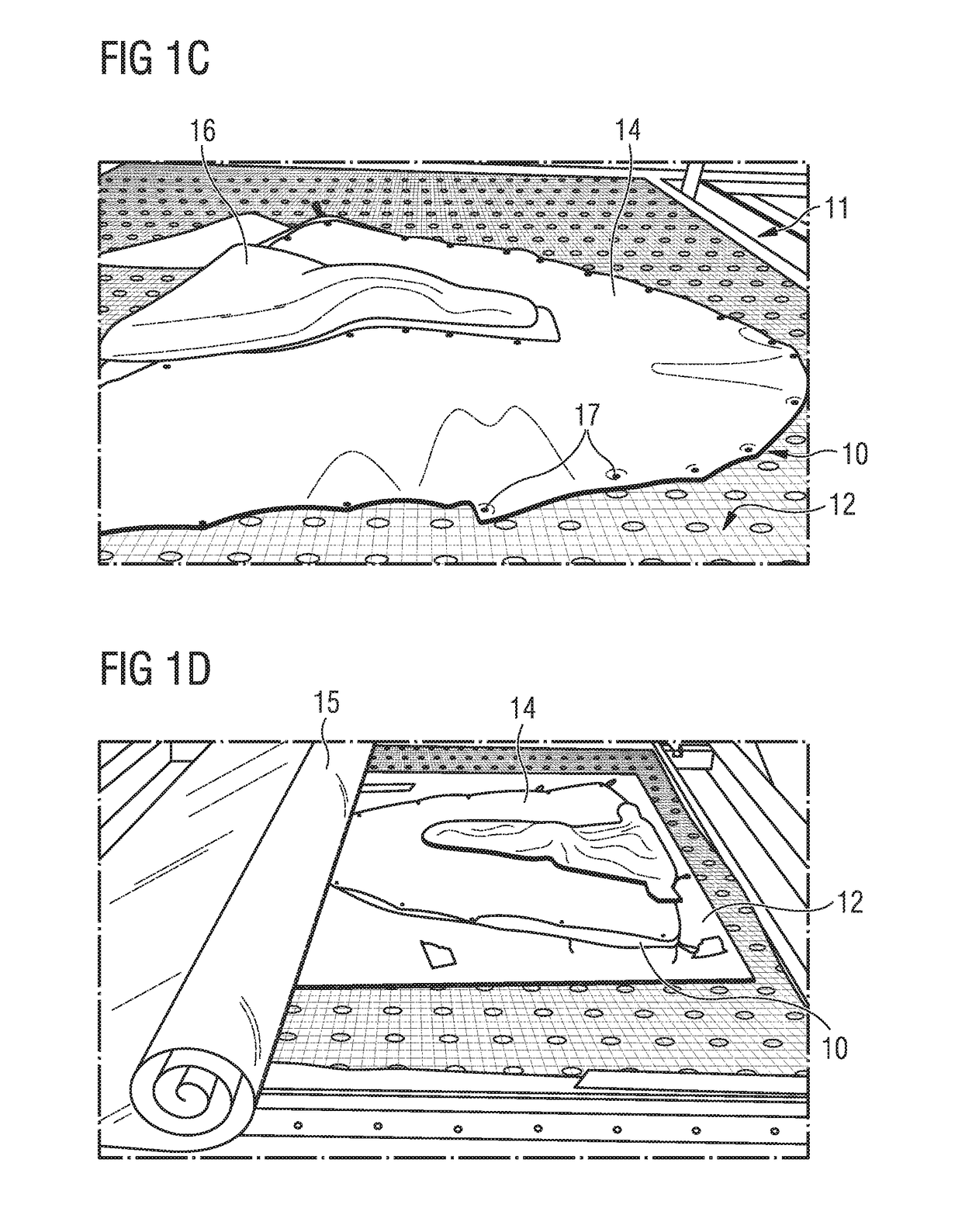

Manufacturing method for coating a fabric with a three-dimensional shape

ActiveUS20170099908A1Improve relationshipImprove protectionLastingDomestic footwearCoated surfaceThree dimensional shape

A method includes: (a.) providing a fabric comprising a first surface and a second surface; (b.) placing the fabric on a support structure adapted to permit gas circulation through at least a portion of a surface of the support structure, wherein the fabric is placed such that the first surface of the fabric faces the surface of the support structure and such that the fabric is arranged at least in part over a raised or embossed portion of the support structure; (c.) providing at least one coating comprising a first coating surface and a second coating surface opposite the first coating surface; (d.) placing the coating at least partially on the second surface of the fabric, such that the first coating surface faces the fabric; and (e.) applying a gas pressure differential between the second coating surface and the first surface of the fabric.

Owner:ADIDAS

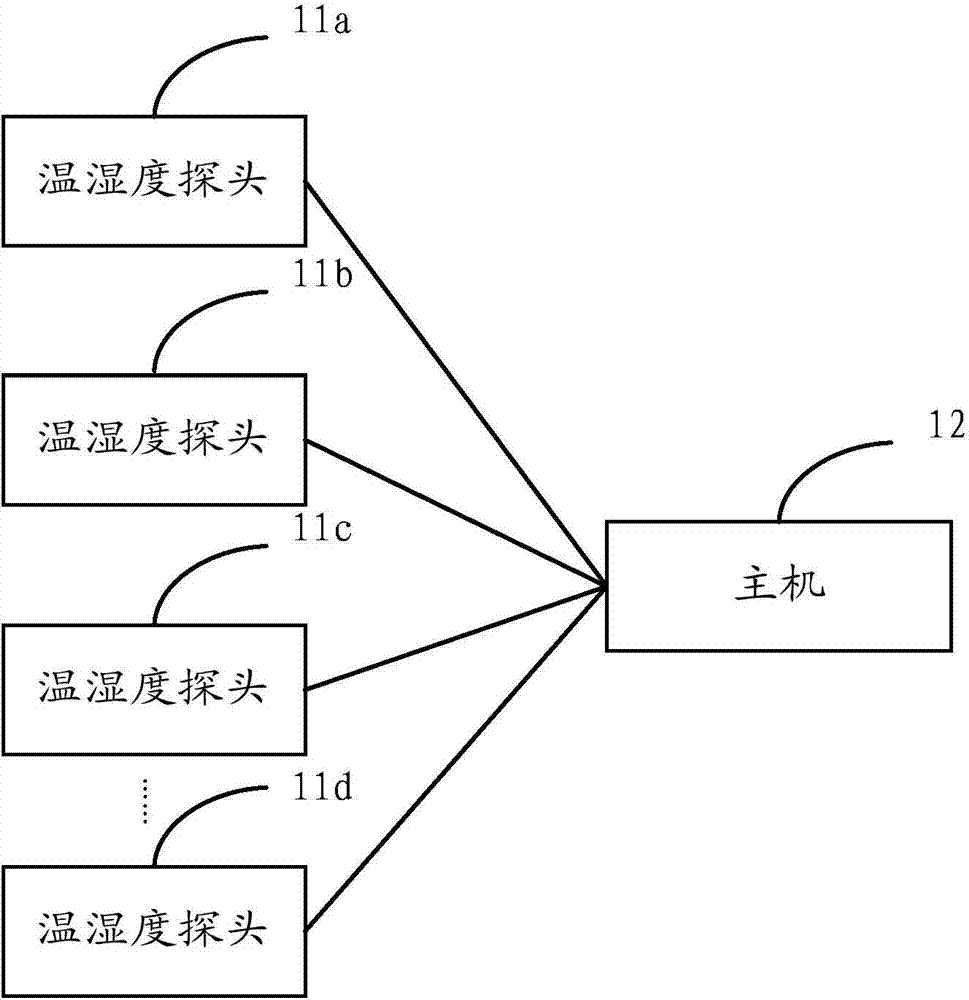

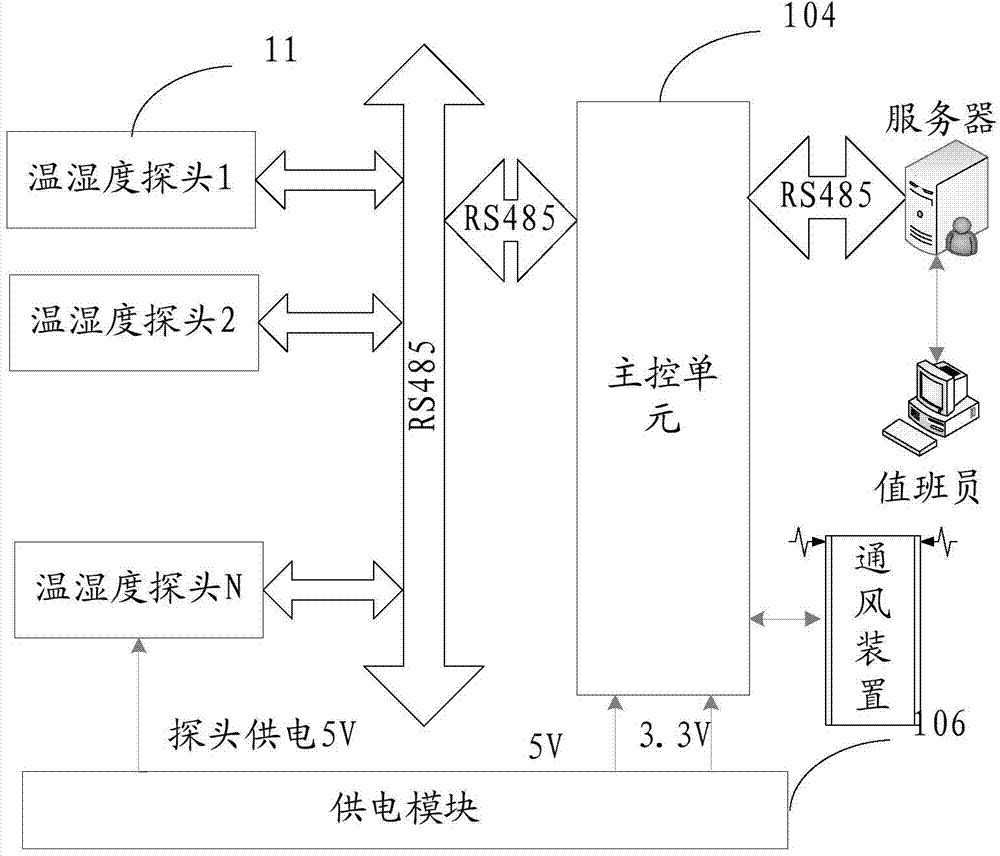

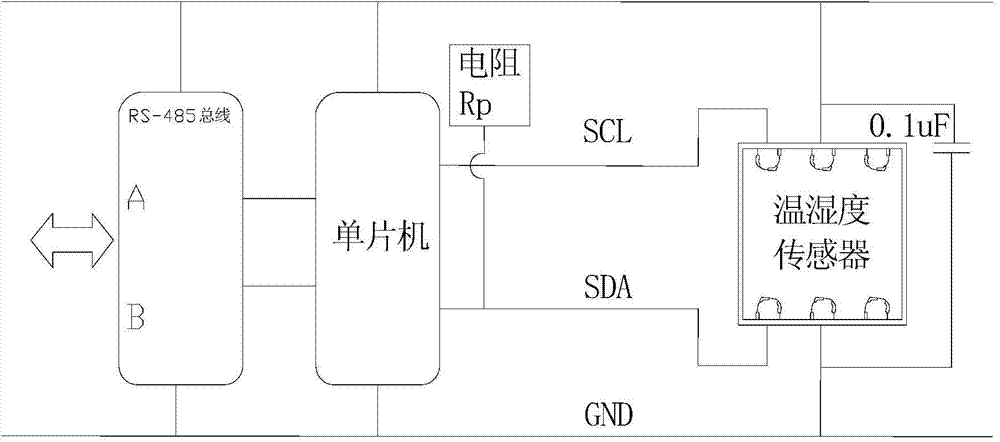

Temperature and humidity measuring and control device, system and method

ActiveCN104714577AAccurate coverageEasy networkingSimultaneous control of multiple variablesEngineeringHUMID WEATHER

The invention provides a temperature and humidity measuring and control device, system and method. Multiple temperature and humidity probes and a host are adopted, wherein the temperature and humidity probes are capable of being arranged at different positions and used for monitoring the temperature and humidity information of the environment where the probes are located, and the host is connected with the multiple temperature and humidity probes and used for obtaining the temperature and humidity information of all the temperature and humidity probes and conducting control processing according to the temperature and humidity information. The multiple probes are used for monitoring the environment of a warehouse, the host is used for processing the monitored environment of the warehouse, in this way, the whole environment can be accurately covered, multiple temperature and humidity measuring and control instruments are not needed, networking can be easy, and investment cost is greatly saved. Moreover, the environment parameters such as the temperature and the humidity and the like can be displayed and broadcast through voice. When the current environment parameters exceed a limit range, an alarm is given out, and / or the ventilation value of a ventilation device is controlled, the current environment parameters are changed, manual control is not needed, work efficiency is improved, and the real-time property is good.

Owner:BEIJING HANGYU JUNKE ELECTROMECHANICAL EQUIP

Method and system for positioning target by adaptive resolution

The invention provides a method and a system for positioning a target by adaptive resolution. The method comprises the following steps of: dividing a detected space into a key area and a common area; arranging a plurality of high-precision positioning signal (US) transceivers for high-precision positioning and a plurality of low-precision positioning signal (RF) transceivers for low-precision positioning according to the key area and the common area, wherein the detecting range of the low-precision positioning signal transceivers covers the detected space and the detecting range of the high-precision positioning signal transceivers only covers the key area; and determining the position of the target by integrating detecting results of the high-precision positioning signal transceivers and the low-precision positioning signal transceivers on the target by the adaptive resolution when the target moves in the detected space. By using the system, the target can be positioned according to different positioning resolutions (precision or granularity) in different areas and the cost of the system can be greatly reduced since plenty of high-precision positioning equipment is free from being used.

Owner:NEC (CHINA) CO LTD

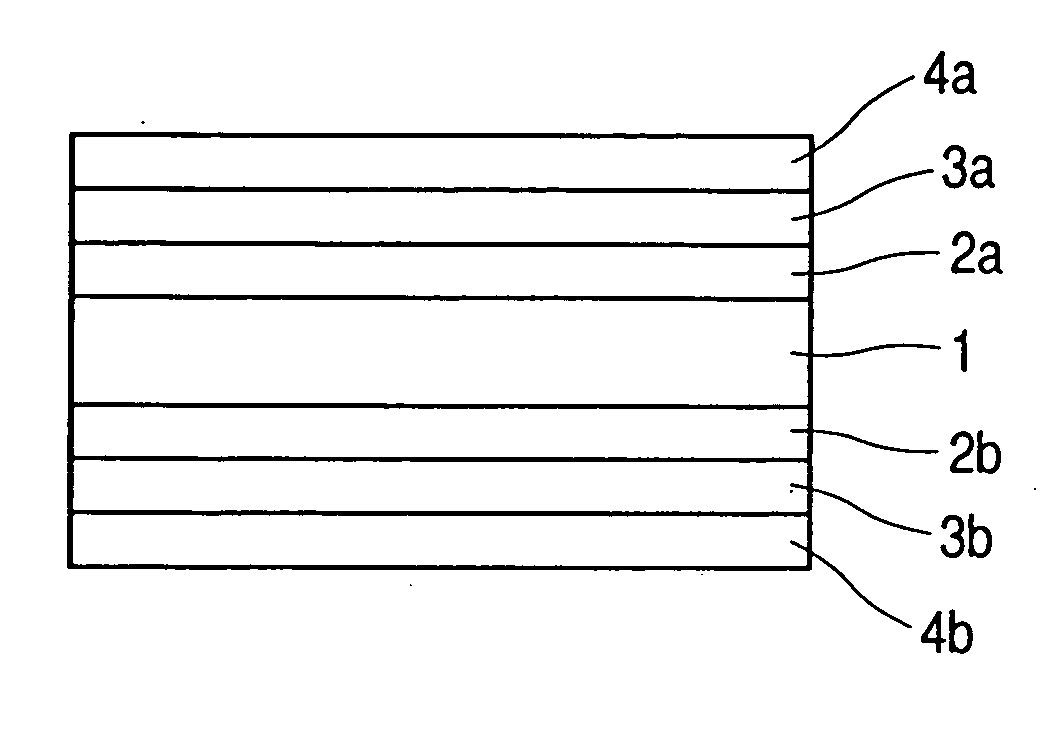

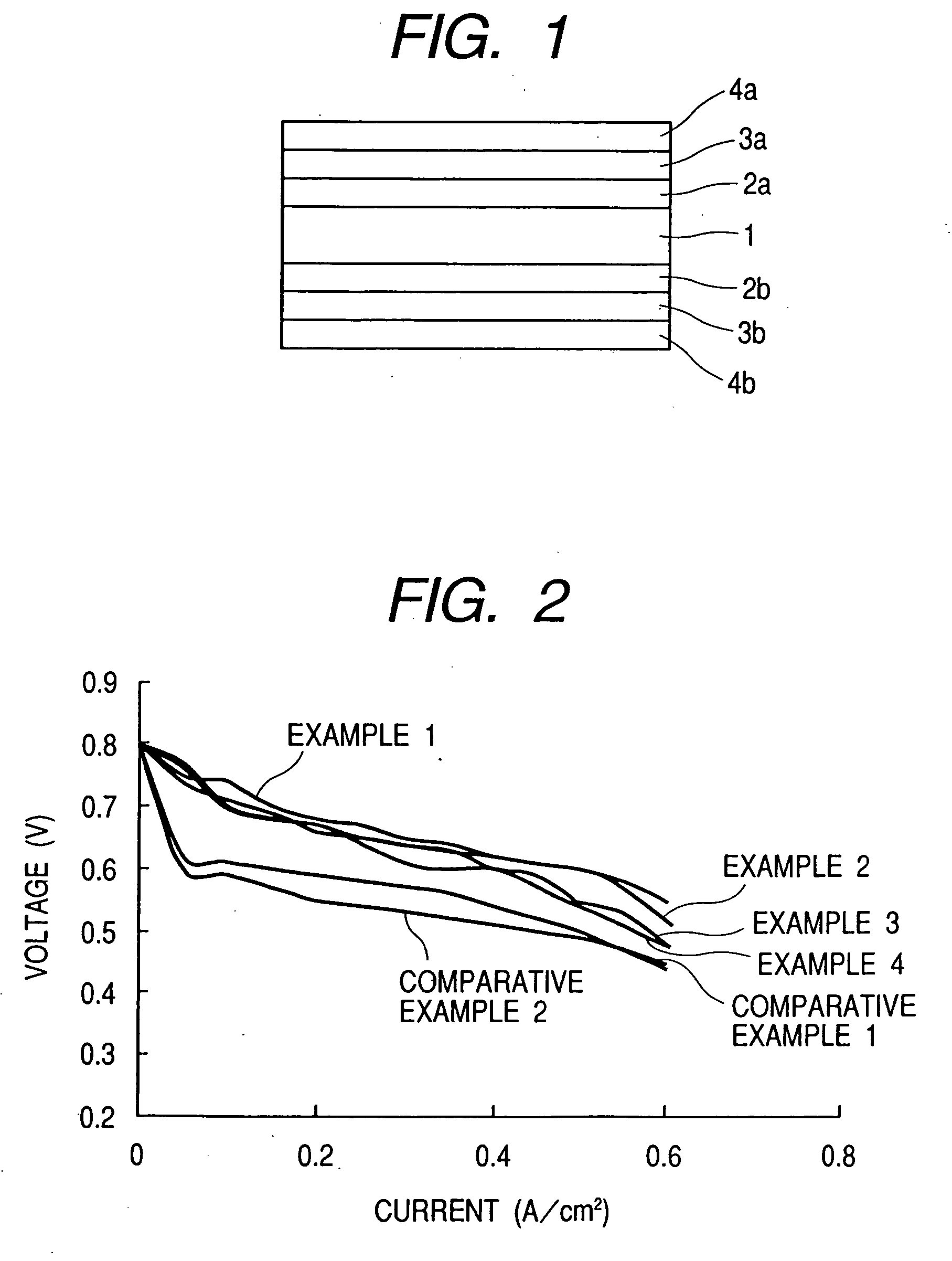

Manufacturing process for fuel cell, and fuel cell apparatus

InactiveUS20050272595A1Accurate coverageSimply provideActive material electrodesSolid electrolyte fuel cellsFuel cellsEngineering

In a manufacturing process for a fuel cell having a fuel electrode, an oxidizer electrode, and a polymer electrolyte membrane held between both the electrodes, and having electrode catalyst layers which are individually provided between both the electrodes and the polymer electrolyte membrane, the process has the step of ejecting an electrode catalyst composition containing conductive particles carrying thereon at least a catalyst, by an ink-jet process to form the electrode catalyst layers. This provides a fuel cell manufacturing process which can accurately control the coverage of catalyst layers and also can simply provide pores while controlling the same.

Owner:CANON KK

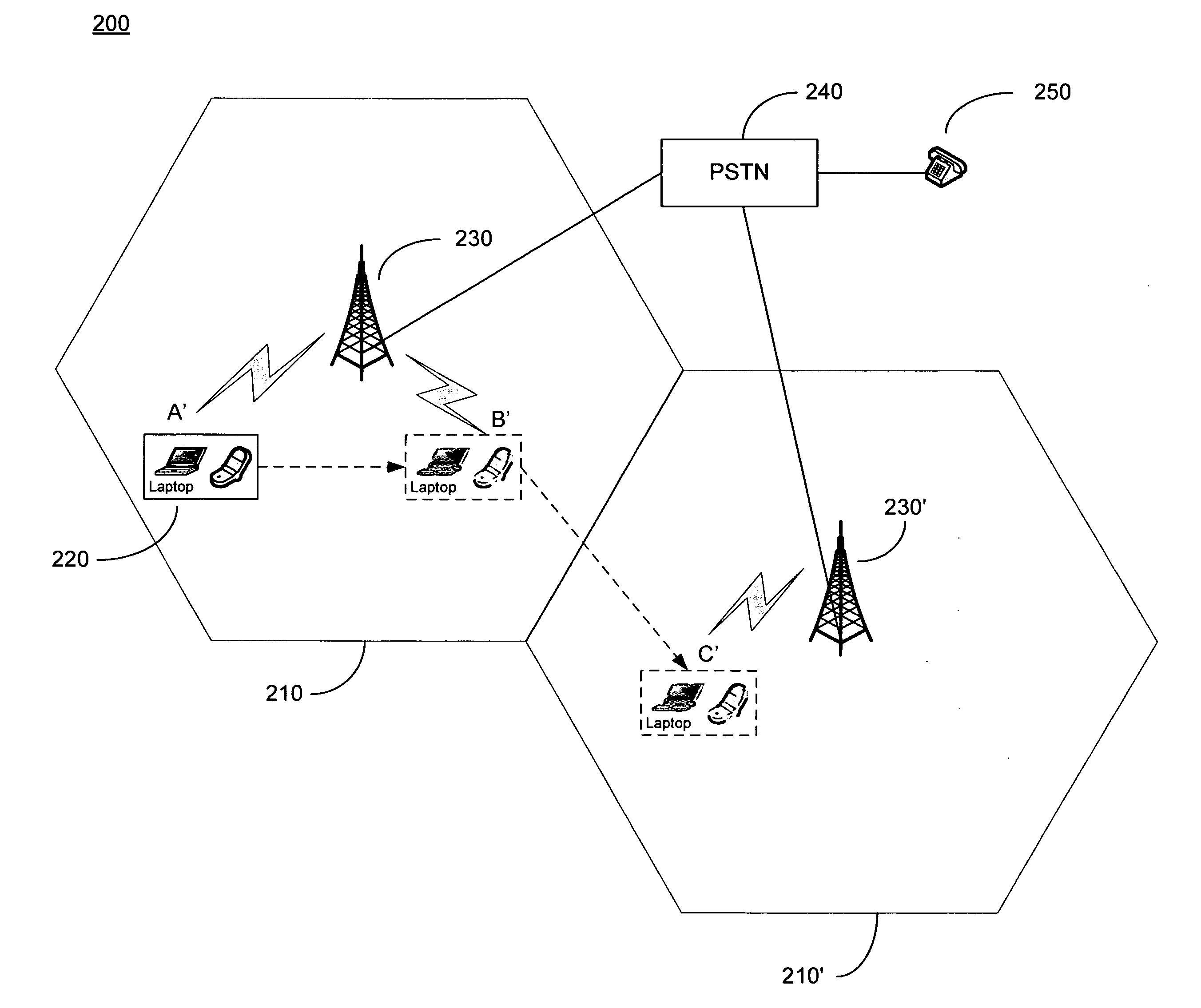

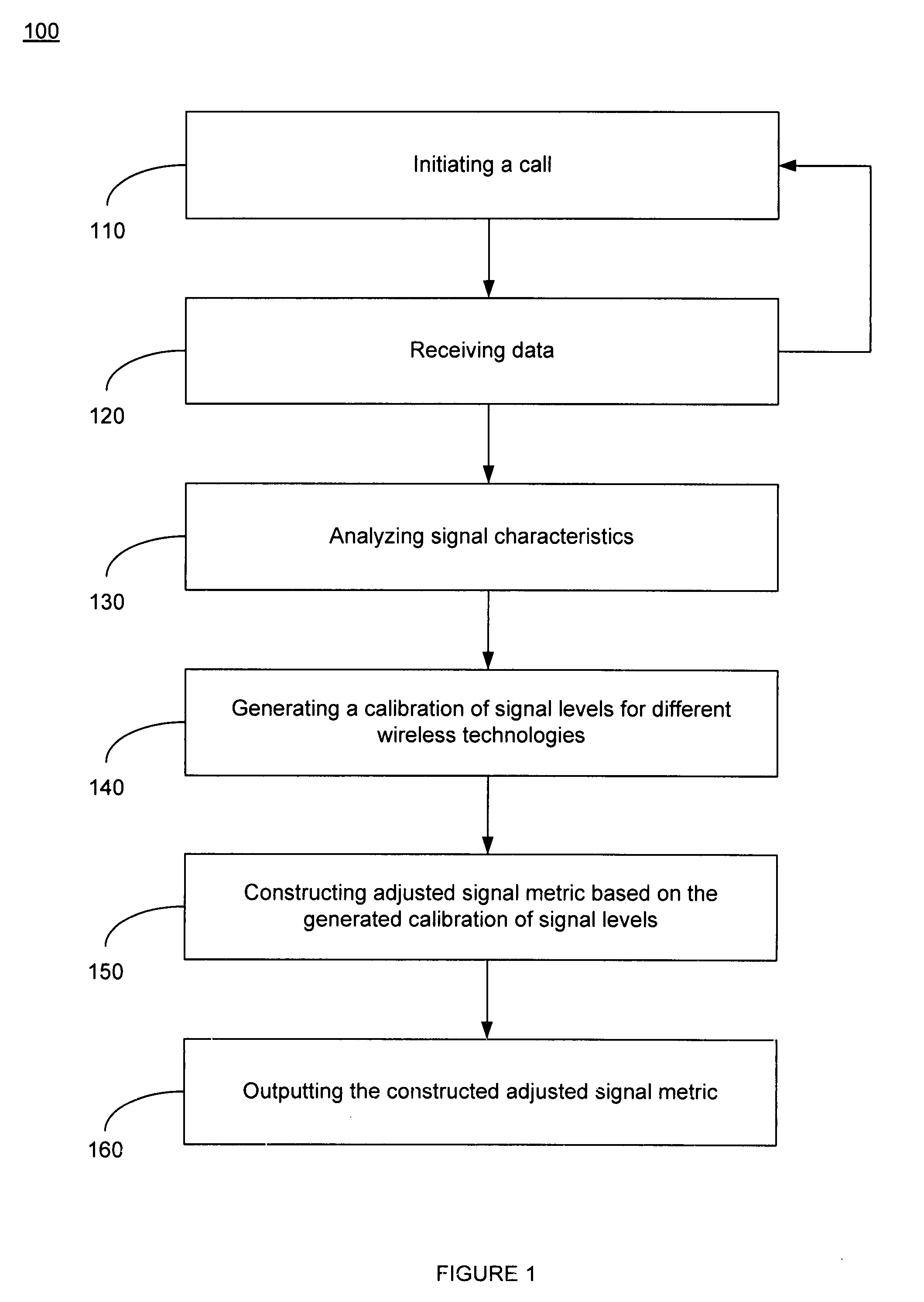

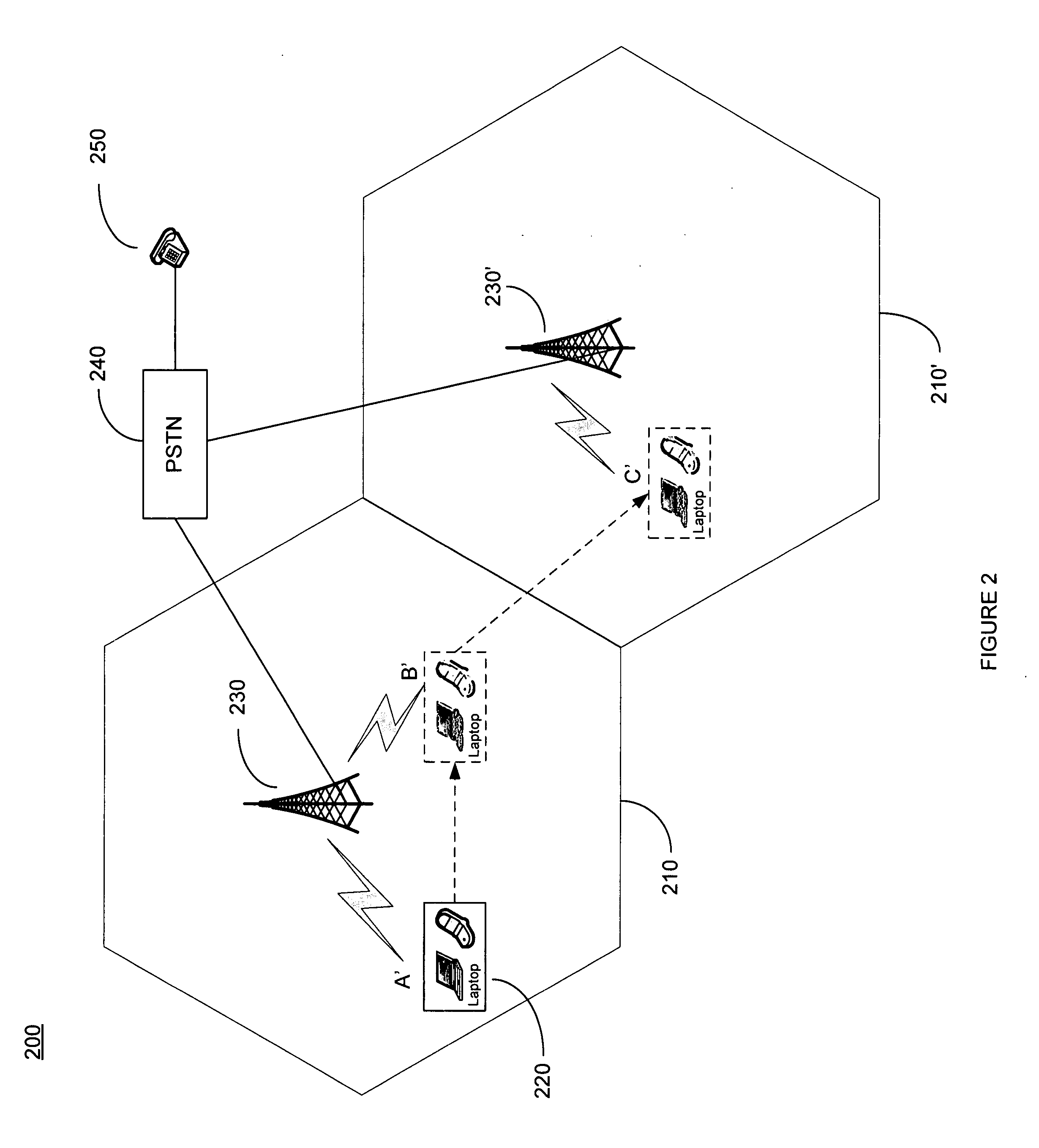

Method and system for measuring cross technology wireless coverage

InactiveUS20080299910A1Accurate coverageNetwork traffic/resource managementConnection managementFailure probabilityComputer science

A method of measuring wireless cross technology wireless coverage. The method includes initiating a call from a wireless device using a given wireless technology; in response to the initiating, receiving a plurality of data for the given wireless technology; in response to the receiving, analyzing the plurality of data; repeating the above steps for various wireless technologies; and generating a calibration for the analysis of the plurality of data for various wireless technologies. The adjusted data in response to the generated calibration is constructed and outputted. In one embodiment, the analysis includes determining the signal strength for the wireless device of the given wireless technology and determining the probability of call failure for the wireless device of the given wireless technology. Accordingly, at a given probability of call failure, signal strengths of the wireless device for various wireless technologies are corresponded and are equivalent to one another.

Owner:THE NIELSEN CO (US) LLC

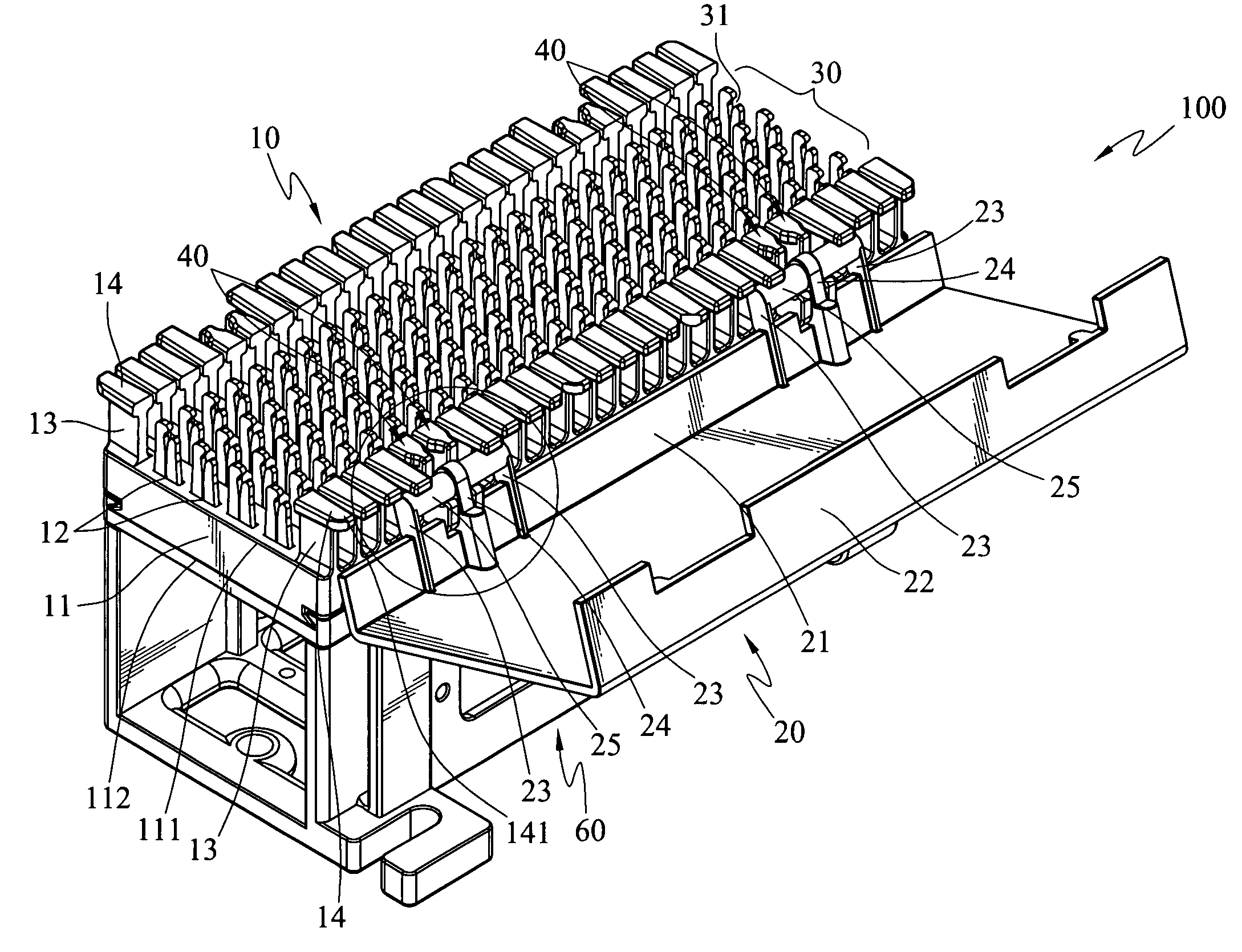

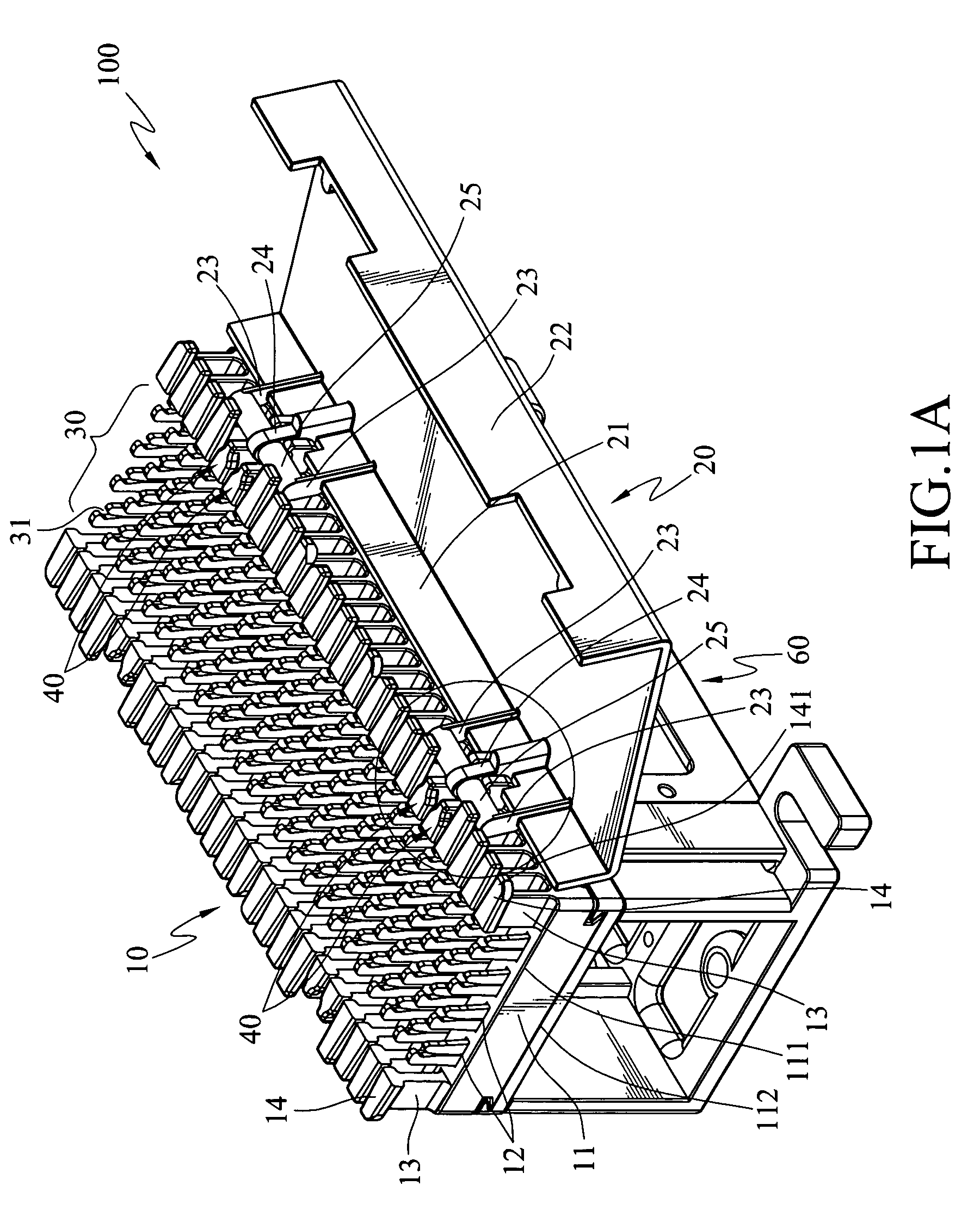

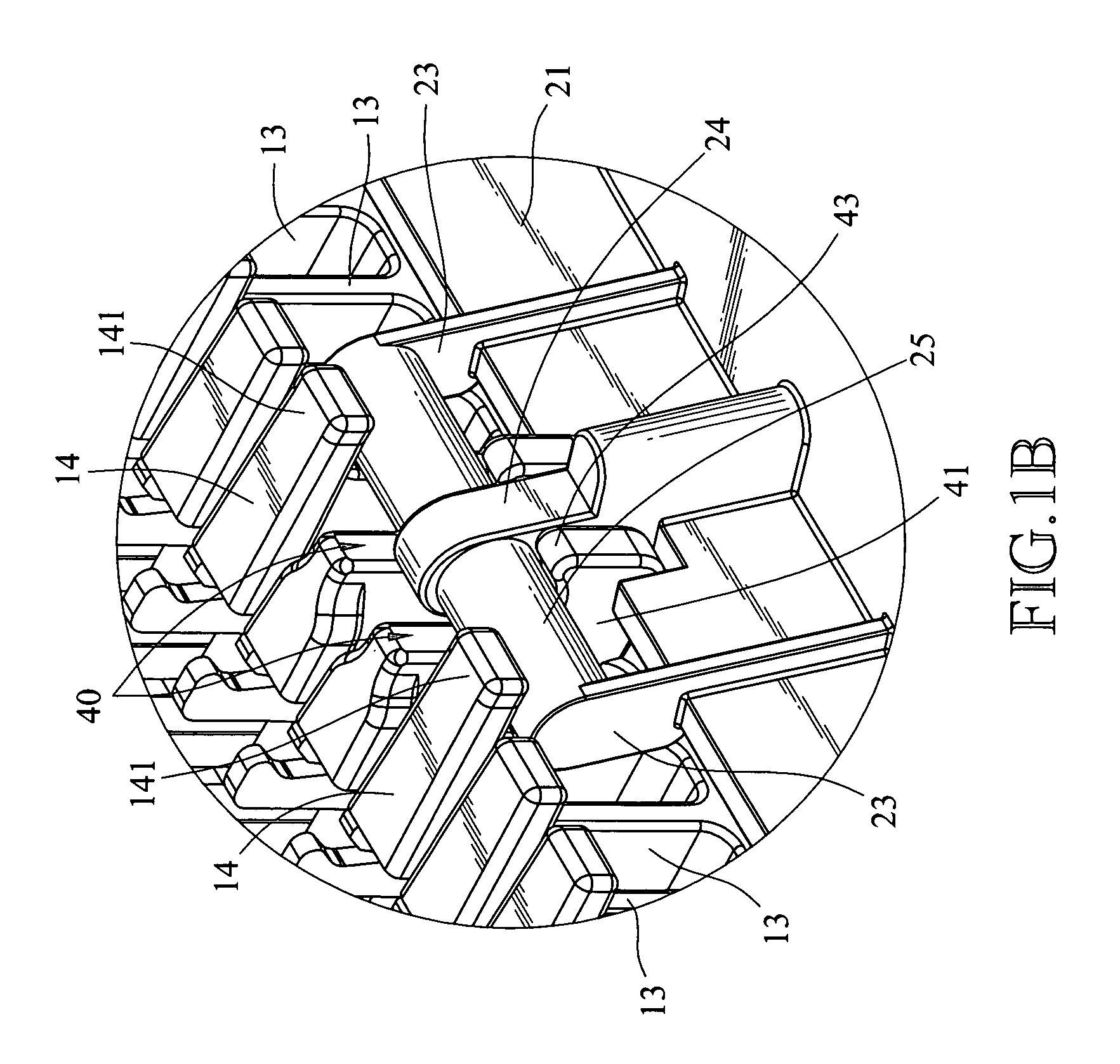

Terminal block equipped with a cover

InactiveUS7121901B1Easy wiringPromote repairElectrically conductive connectionsCouplings bases/casesCouplingJunction box

A terminal block equipped with a cover includes a cover and a terminal block. The terminal block has pivot plates on two sides. Each pivot plate has a coupling trough. The cover has an axle on one side, to be wedged in the coupling trough, so that the cover may be hinged on one side of the terminal block. The cover may be turned to shield the terminal block. Wedging of the axle in the coupling trough also forms an anchoring effect to position the cover on a correct location relative to the terminal block, so that the cover can fully shield the terminal block, to provide desired covering and protection.

Owner:SURTEC INDS

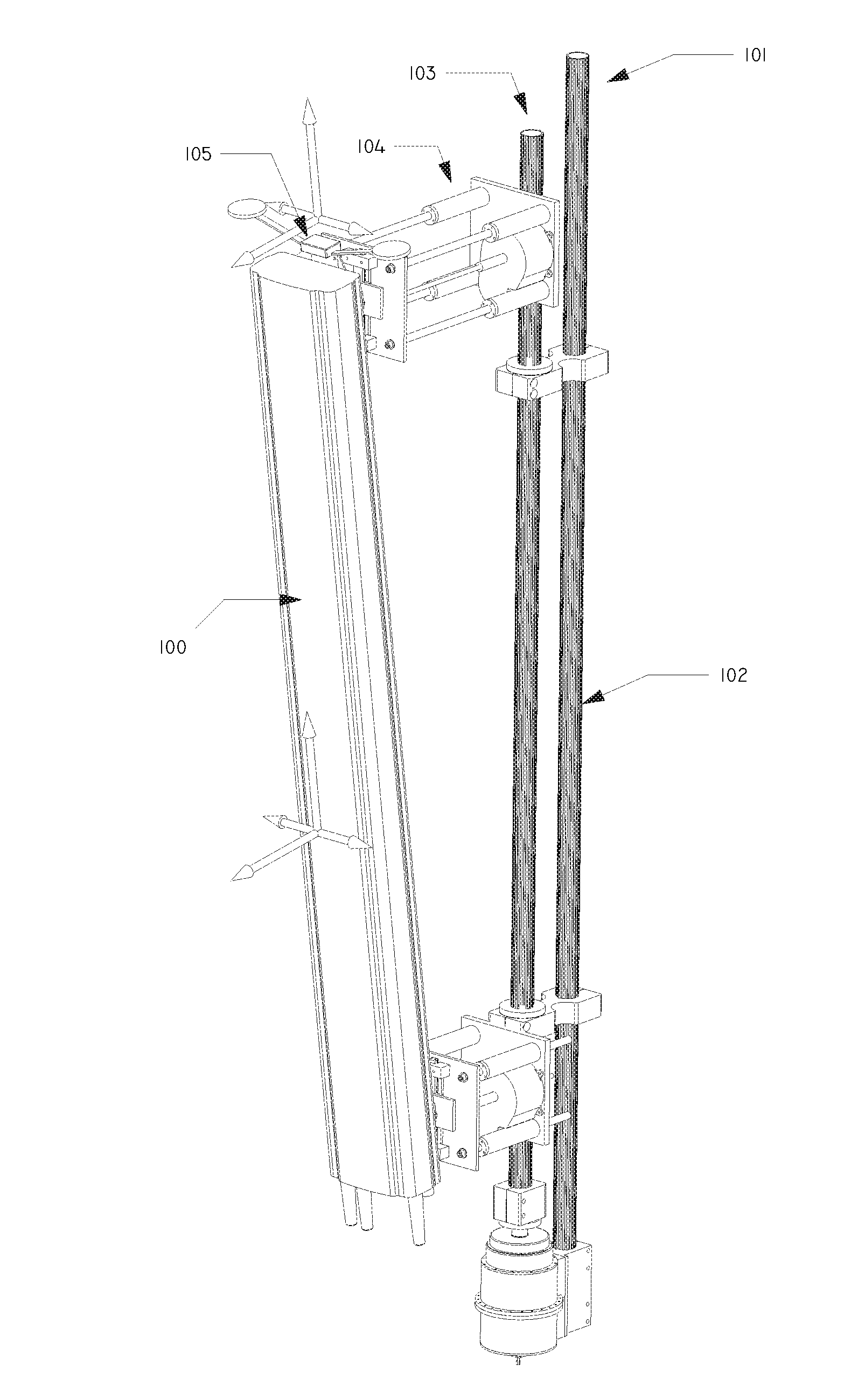

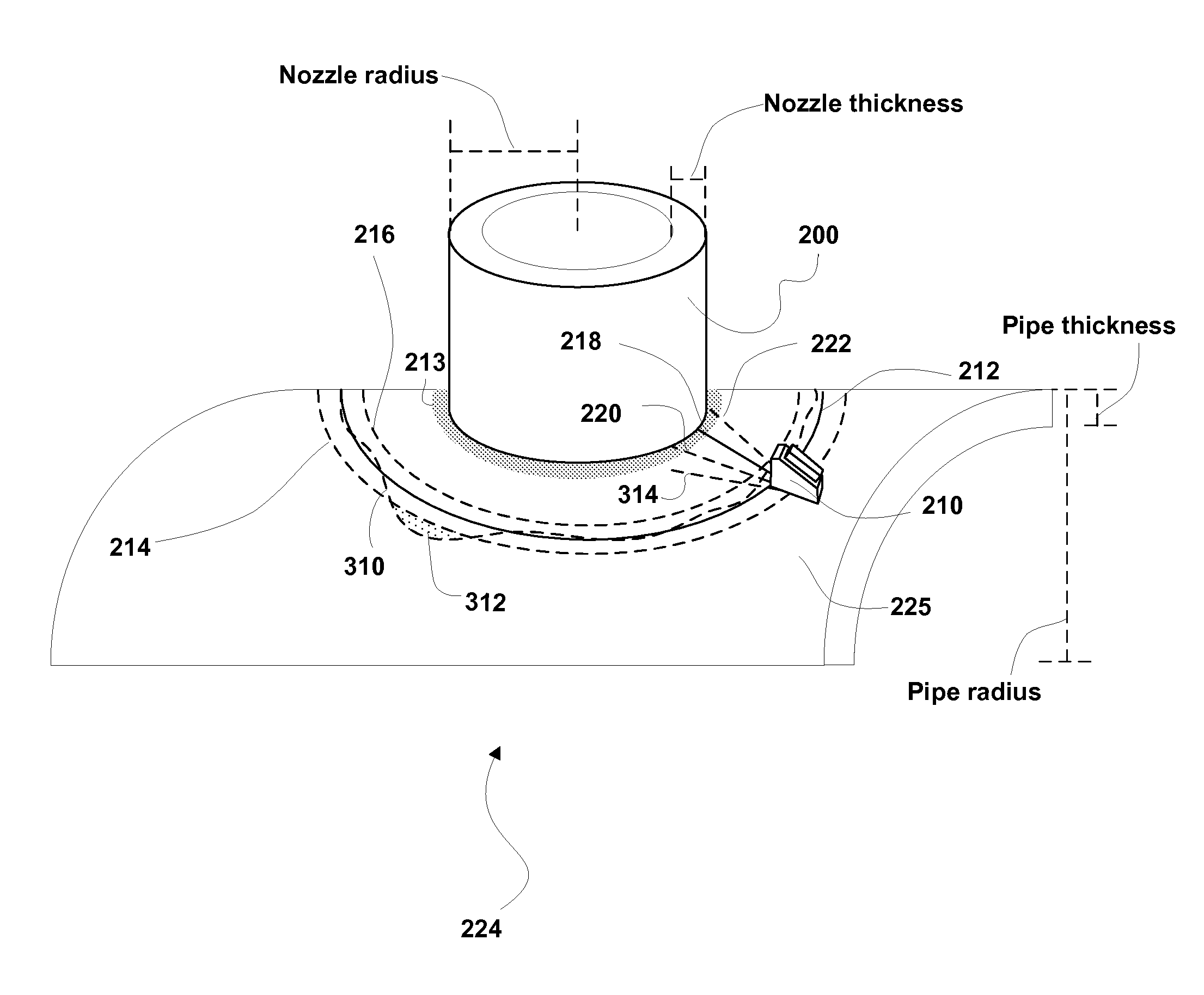

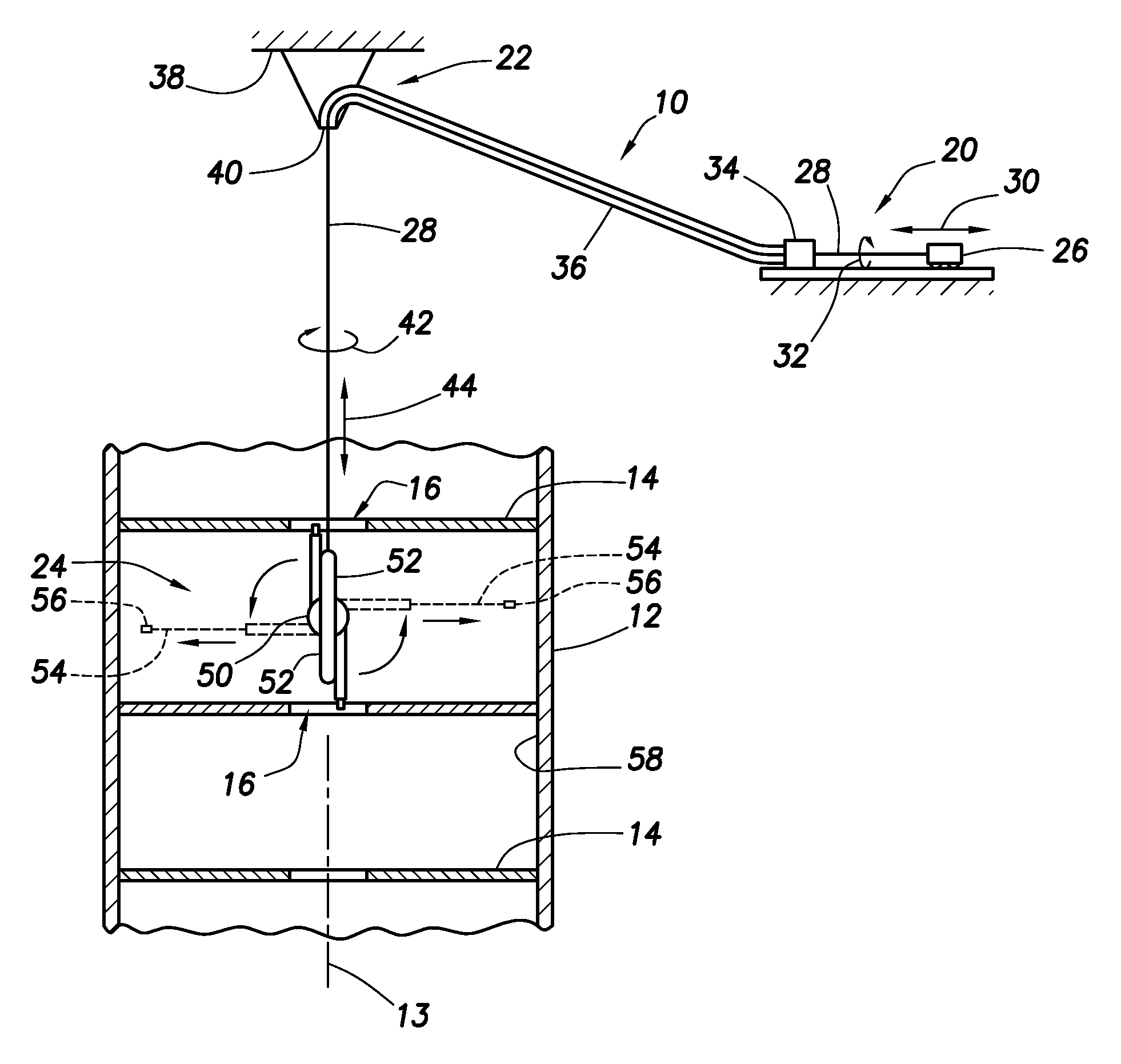

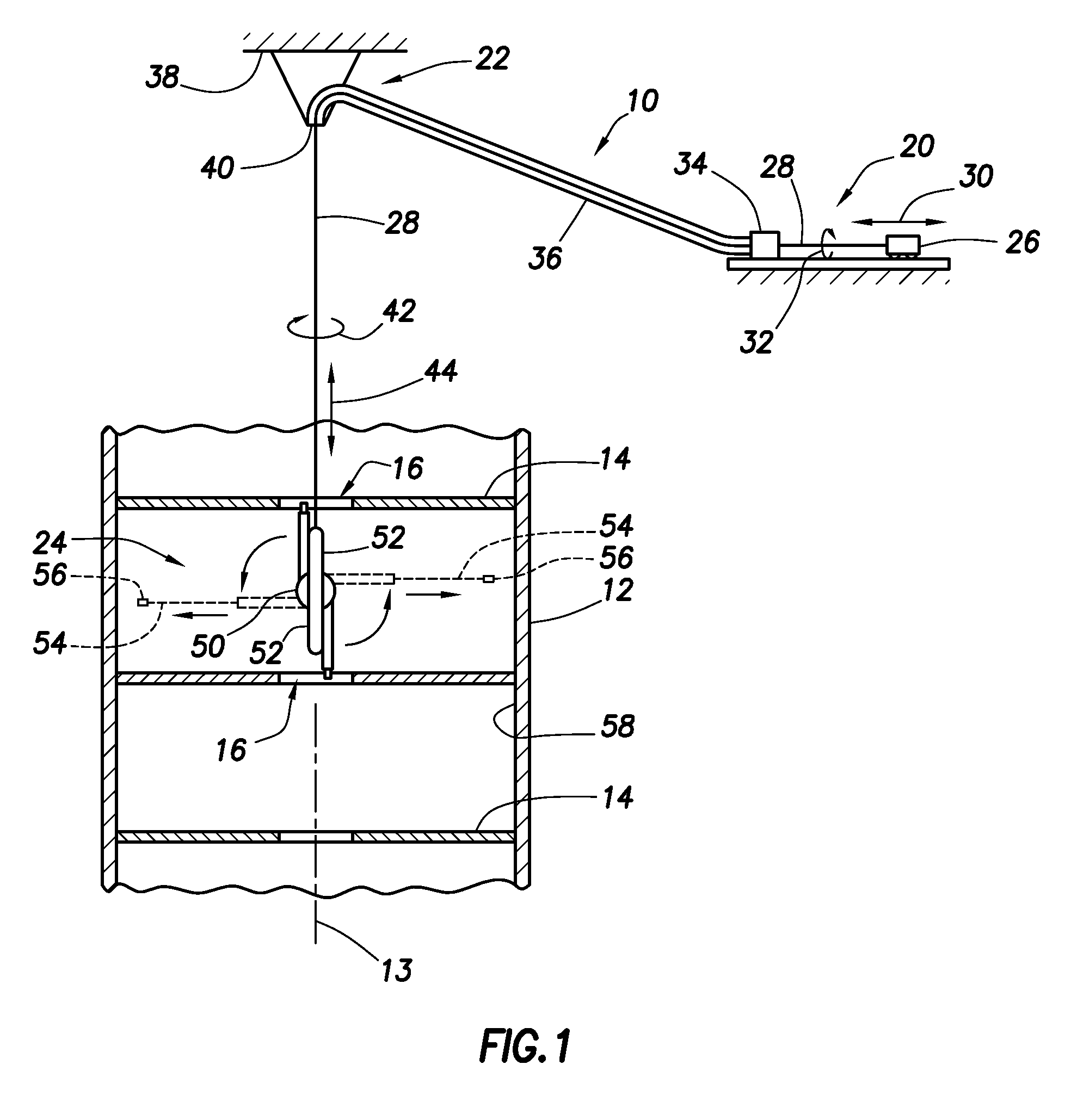

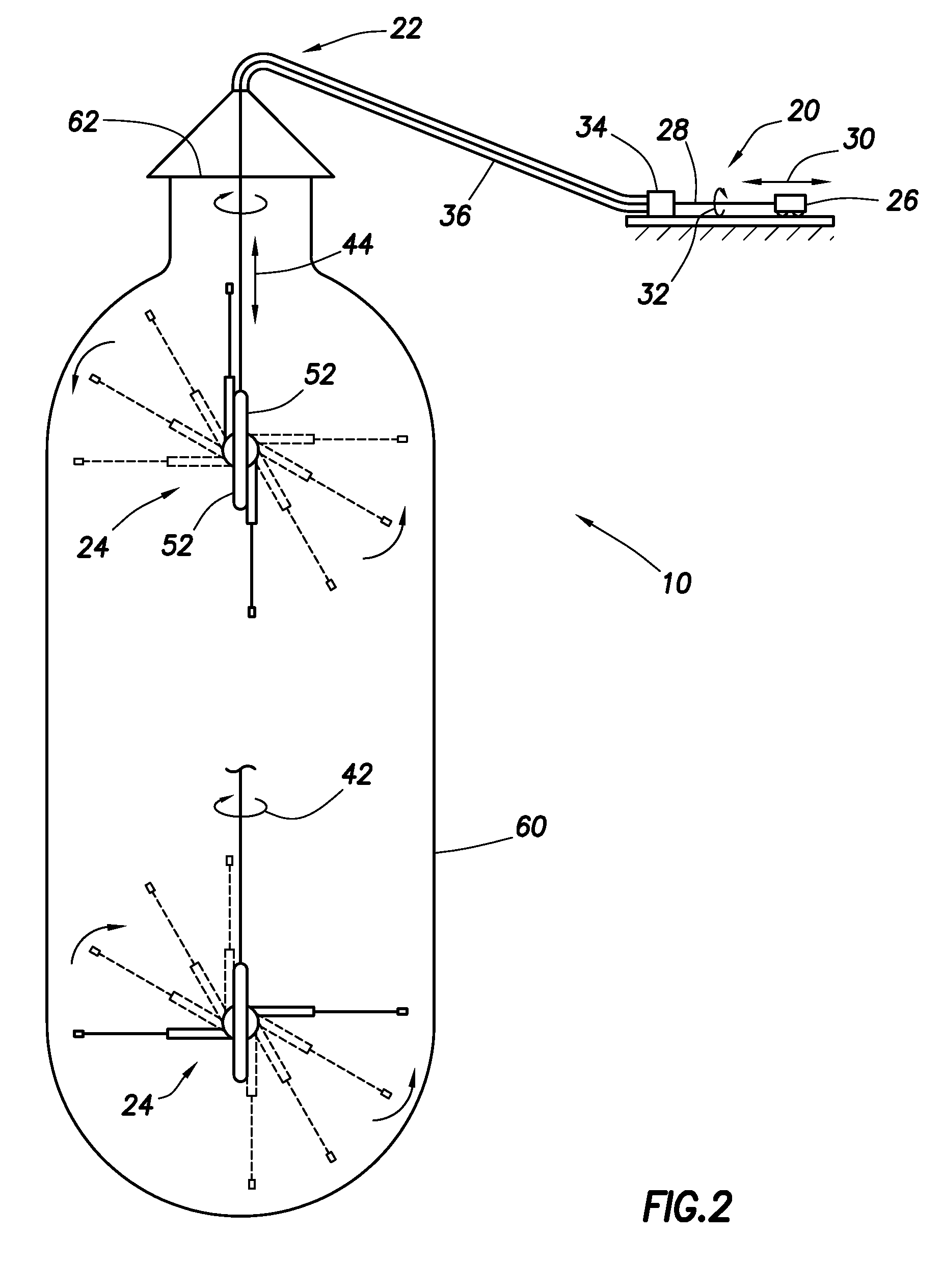

High-Pressure Apparatus and Method for Removing Scale from a Tank

ActiveUS20090235961A1Accurate coverageClean thoroughlyMovable spraying apparatusHollow article cleaningMarine engineeringHigh pressure water

A rotating and telescoping cleaning system improves high pressure water cleaning of the inner surfaces of vessels or tanks. Vessels can be vertically divided with dividing plates with centered through-holes. Synchronized and controlled transverse and rotary movements of water jets result in a controlled spiral or helical cleaning track along the vessel walls. The water jets are directed at a pre-adjusted distance from the vessel wall and the travel speed of the water nozzle jets is exactly controlled allowing the removal of very hard deposits. One pass with the tool carrier with operating water jets along the length axis of the vessel results in a thoroughly cleaned vessel wall. The tool unfolds and folds inside of the vessel powered by the flow of the high pressure cleaning water.

Owner:ACCONDA LLC

In-Line Composition and Volumetric Analysis of Vent Gases and Flooding of the Annular Space of Flexible Pipe

InactiveUS20170023435A1High frequencyReduce in quantityMeasurement of fluid loss/gain rateDrilling rodsLine sensorExhaust valve

A method and system for monitoring a flexible pipe, including an inline sensor system coupled to the annulus of the flexible pipe to detect corrosion of the flexible pipe. Also disclosed are method and system for monitoring an amount of water being accumulated in an annulus of a flexible pipe, including locating a pressure measurement system proximate to the annulus for measuring pressure of gas inside the annulus; controlling a flow of vent gas with a vent gas valve; positioning a flow measurement system upstream or downstream of the vent gas valve for measuring the flow of the vent gas when the vent gas valve is opened; and collecting with a microprocessor pressure and flow measurement data from the pressure and the flow measurement systems for determining the amount of water accumulated in the annulus based on the collected pressure and flow measurement data.

Owner:SCHLUMBERGER TECH CORP

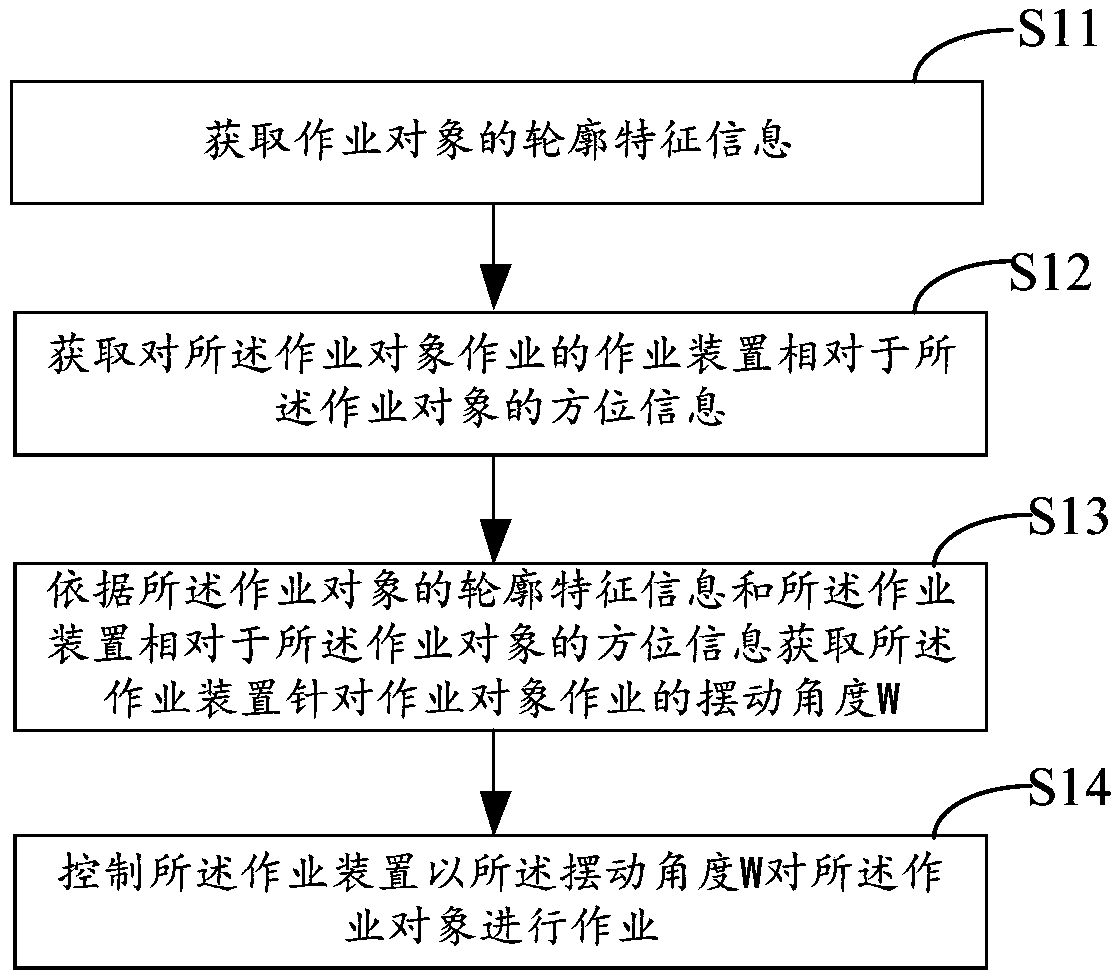

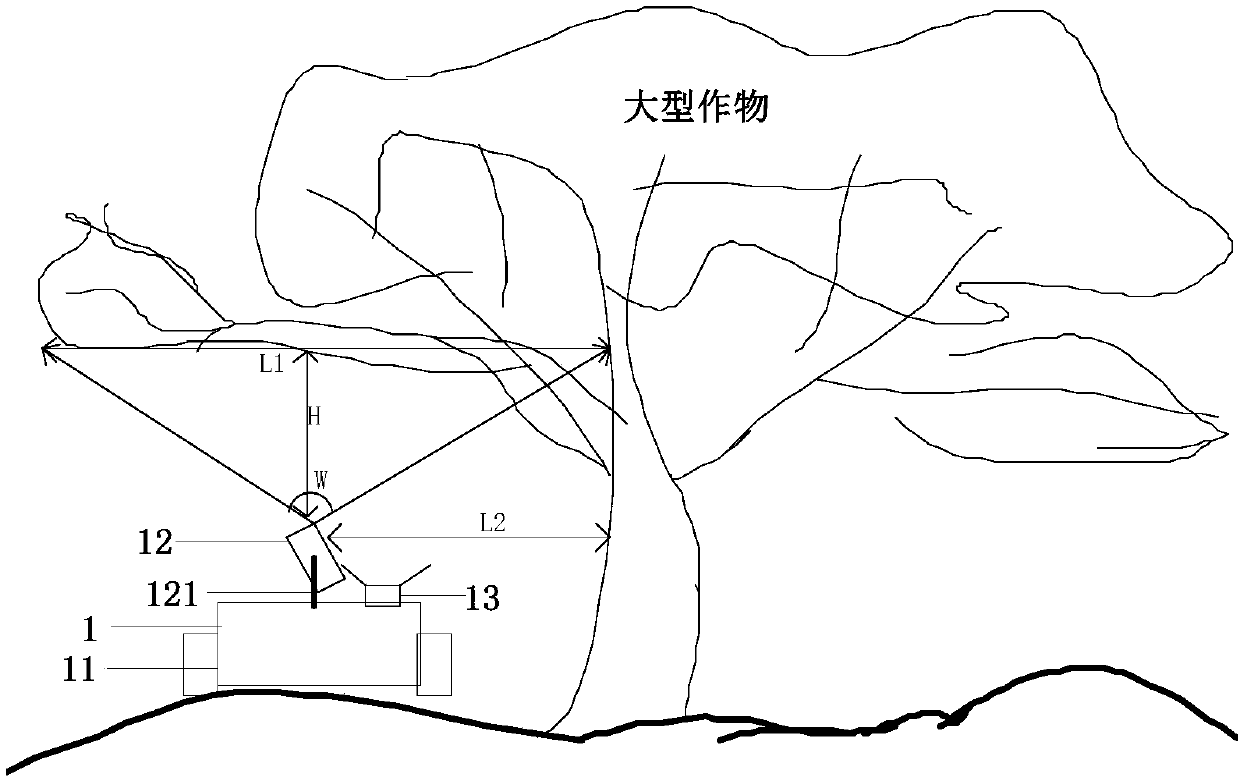

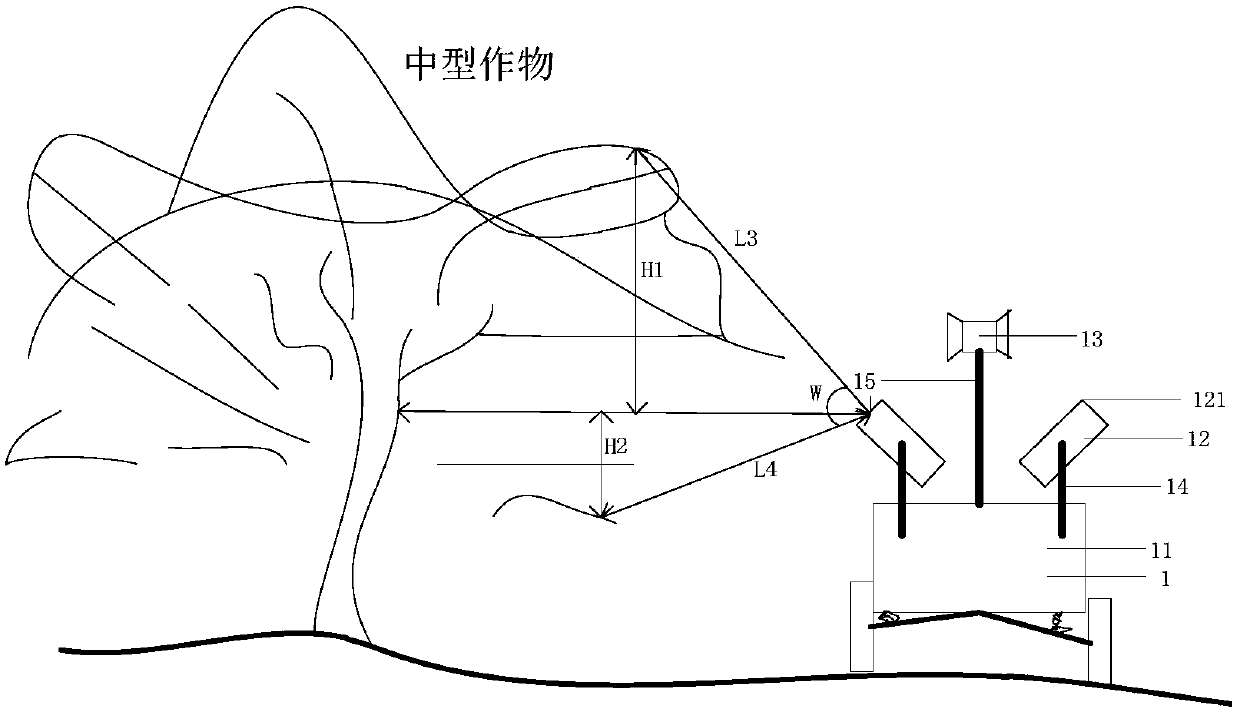

Working device, working control method and system thereof and unmanned vehicle

The invention provides a working control method of a working device. The working control method includes following steps: acquiring profile feature information of a worked object; acquiring azimuth information of the working device working on the operated object relative to the worked object; acquiring swing angle W of the working device for the worked object according to the profile feature information of the worked object and the azimuth information; controlling the working device to work on the worked object according to the swing angle W. By the method, when the working device works for spraying, accurate coverage of a sprayed material to branches and leaves of the worked object is realized, and the problem that vehicle-mounted spraying is prone to causing waste in the prior art is solved.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

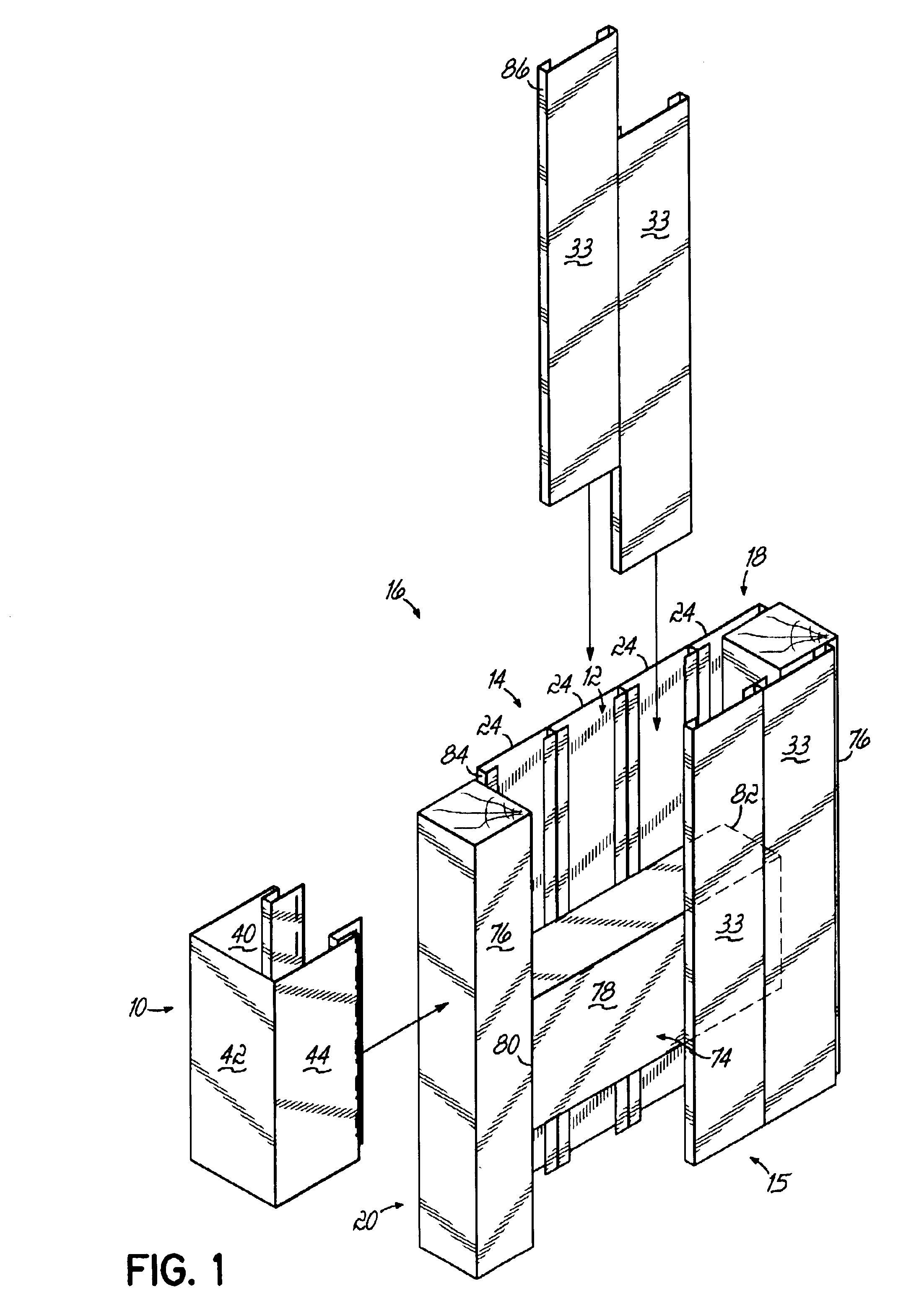

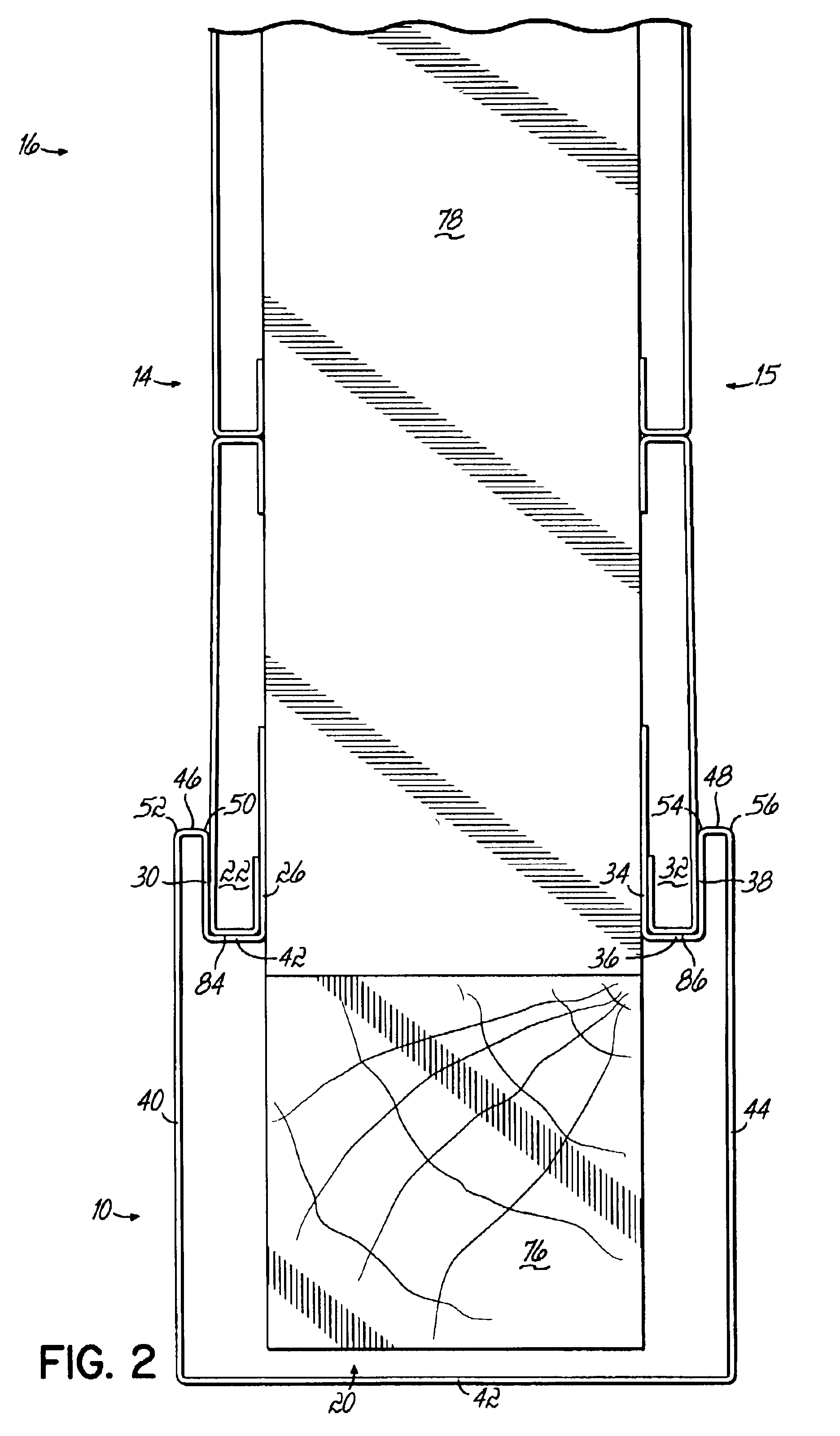

Fence caps for a fencing system

Owner:DIPASQUALE GIUSEPPE

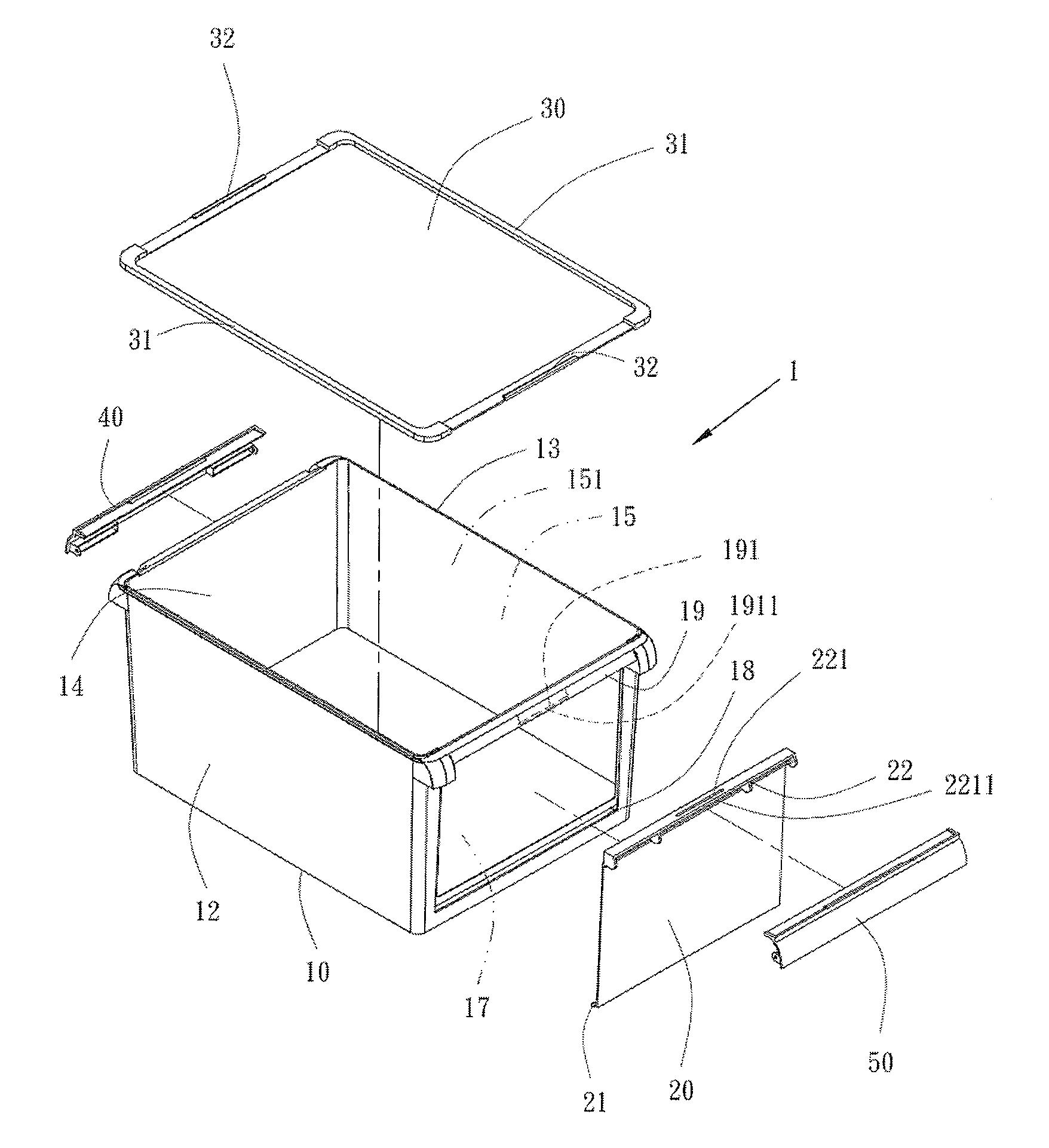

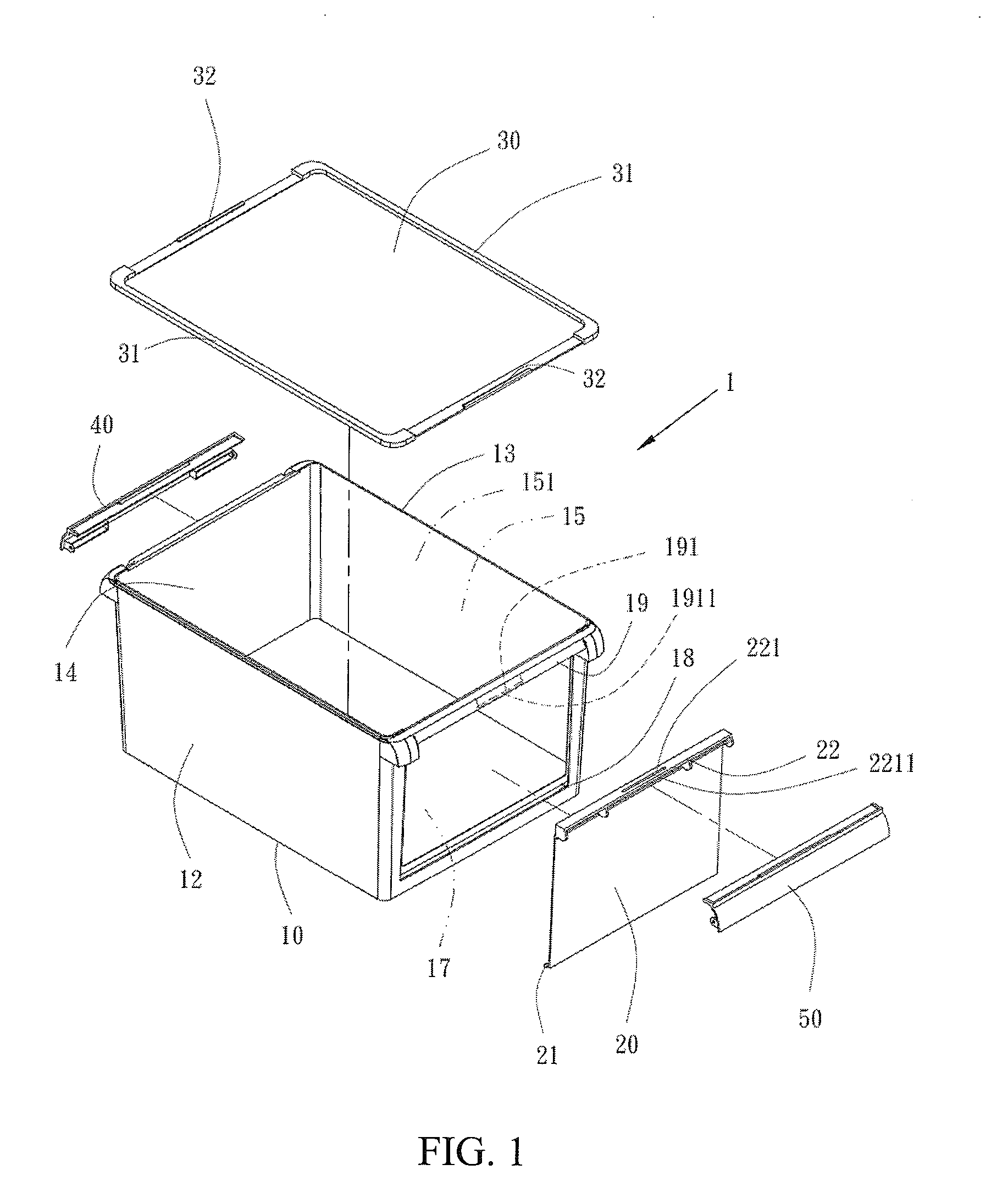

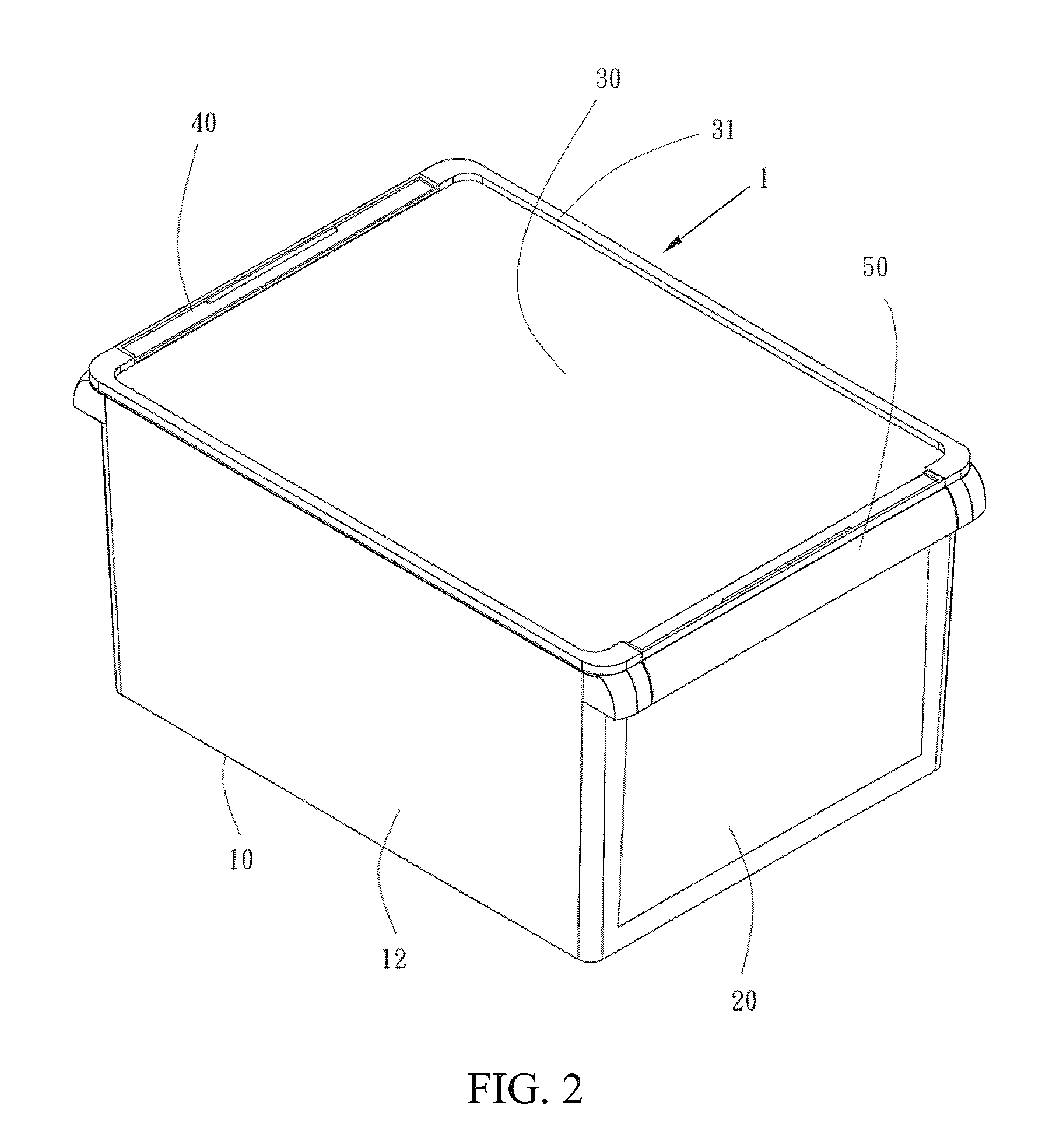

Versatile Storage Bin Structure

ActiveUS20150232238A1Improve usabilityEasy to operateRemovable lids/coversNon-removalbe lids/coversEngineering

Owner:SHUTER ENTERPRISE

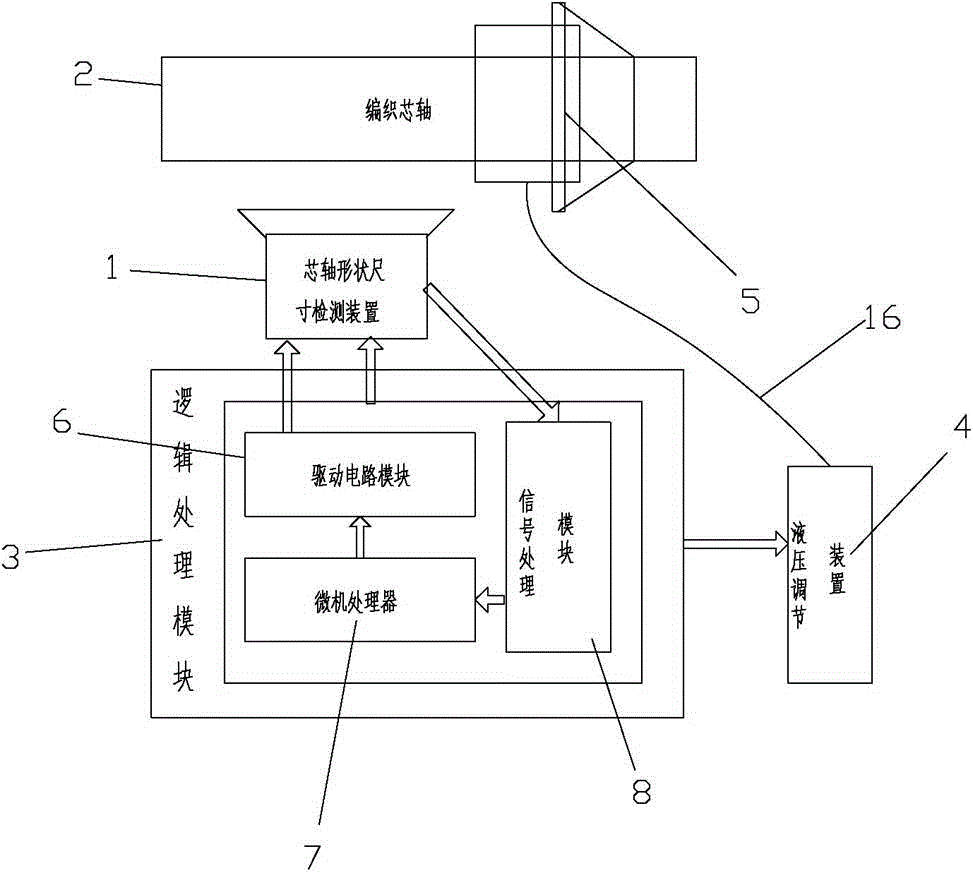

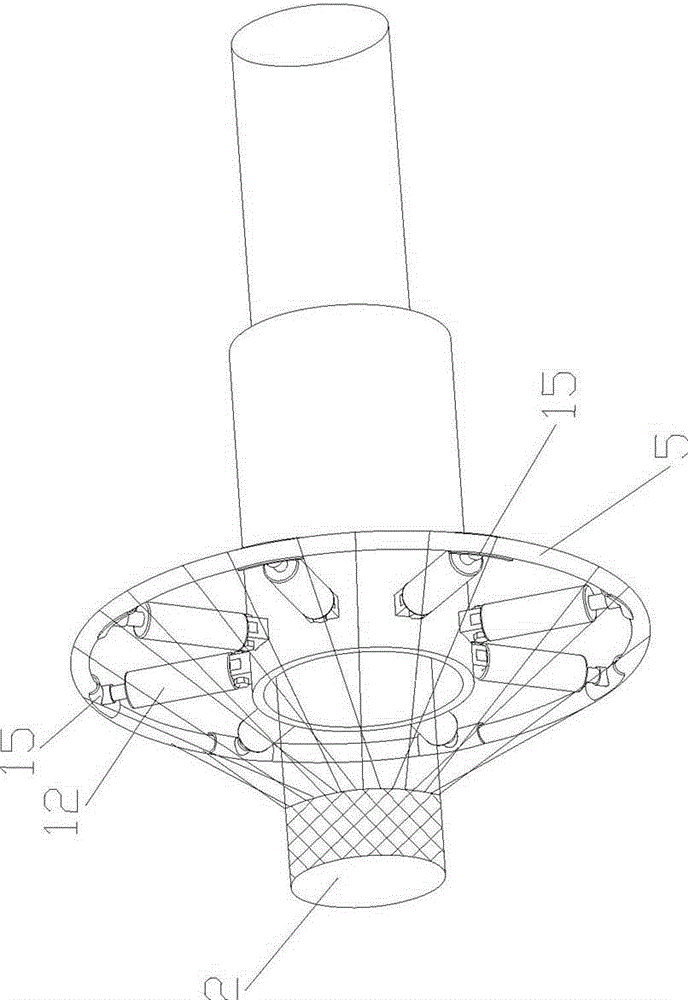

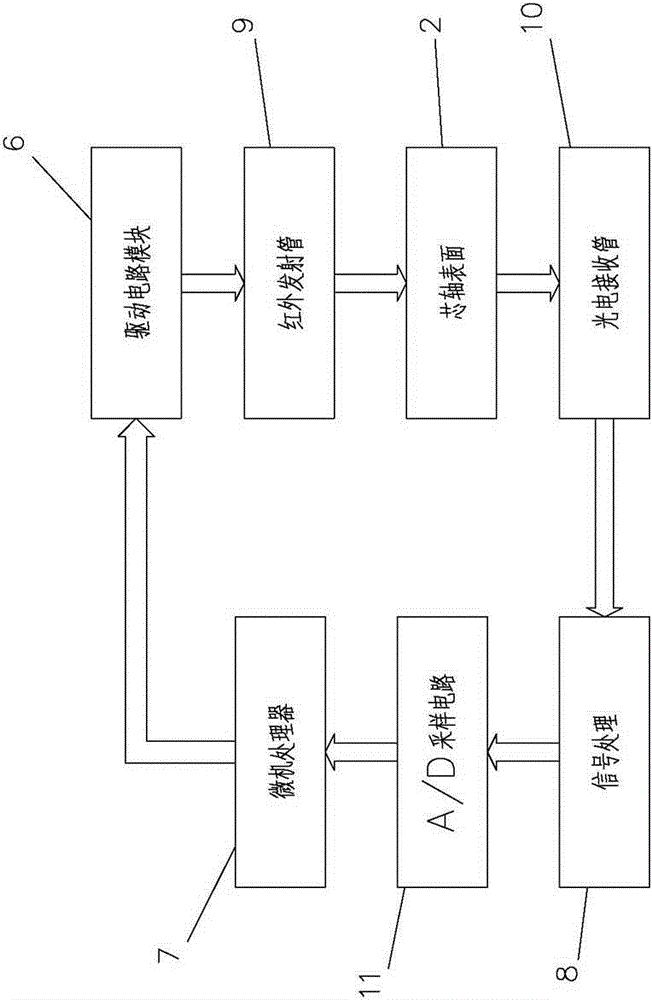

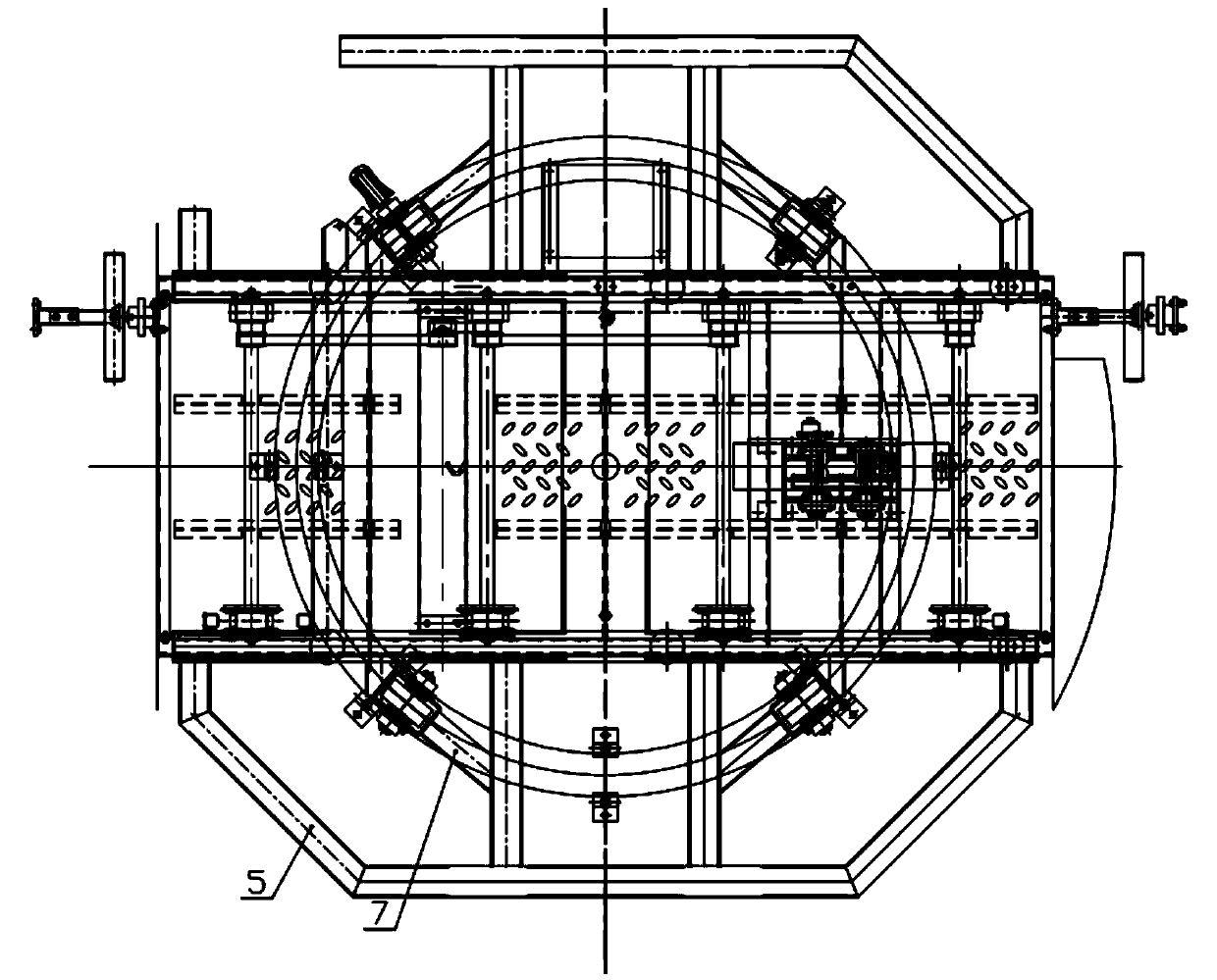

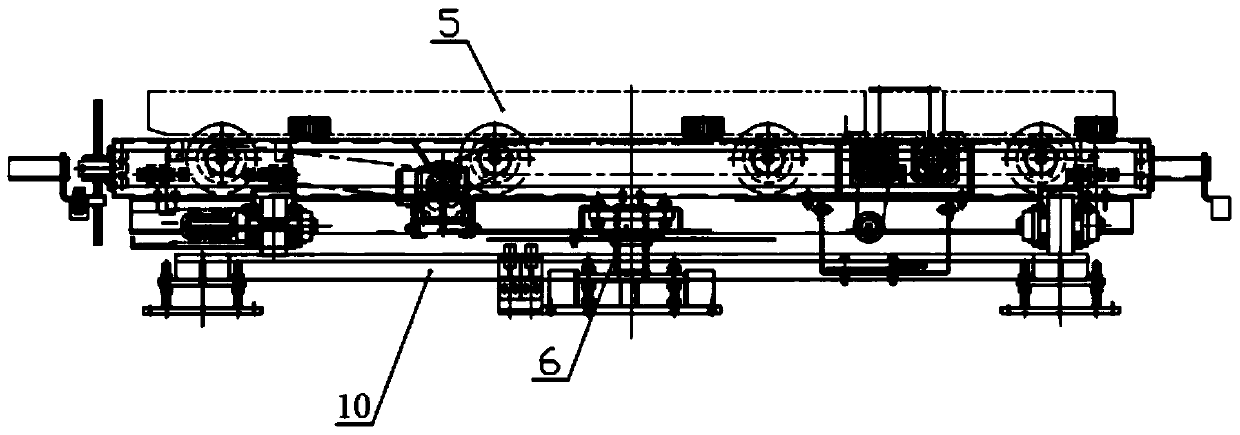

Fibre guide ring control system for annular three-dimensional knitting machine and adjustment method thereof

The invention relates to a fibre guide ring control system for an annular three-dimensional knitting machine and an adjustment method thereof. According to the fibre guide ring control system, a mandrel shape and dimension detection device and a knitting mandrel are oppositely arranged, in which an infrared transmitting tube and a photoelectric receiving tube are installed; a logical processing module is connected with a hydraulic adjustment device, and comprises a microcomputer processor, a drive circuit module and a signal processing module; the microcomputer processor is connected with the drive circuit module; the drive circuit module is connected with the infrared transmitting tube; the photoelectric receiving tube is connected with the signal processing module; the signal processing module is connected with the microcomputer processor through an AD sampling circuit; a hydraulic cylinder for adjusting the size of an adjustable fibre guide ring is installed on the guide ring; the hydraulic adjustment device is connected with the hydraulic cylinder through a pipeline. The fibre guide ring control system disclosed by the invention is capable of reducing the deformation degrees of fibres in a convergent area, thus the fibres are closer to straight lines in the convergent area and the basically constant taper angle of the convergent area is kept, the knitting angle of a fabric on the surface of the mandrel is closer to an ideal value, and the weaving quality is improved.

Owner:ZHEJIANG SCI-TECH UNIV

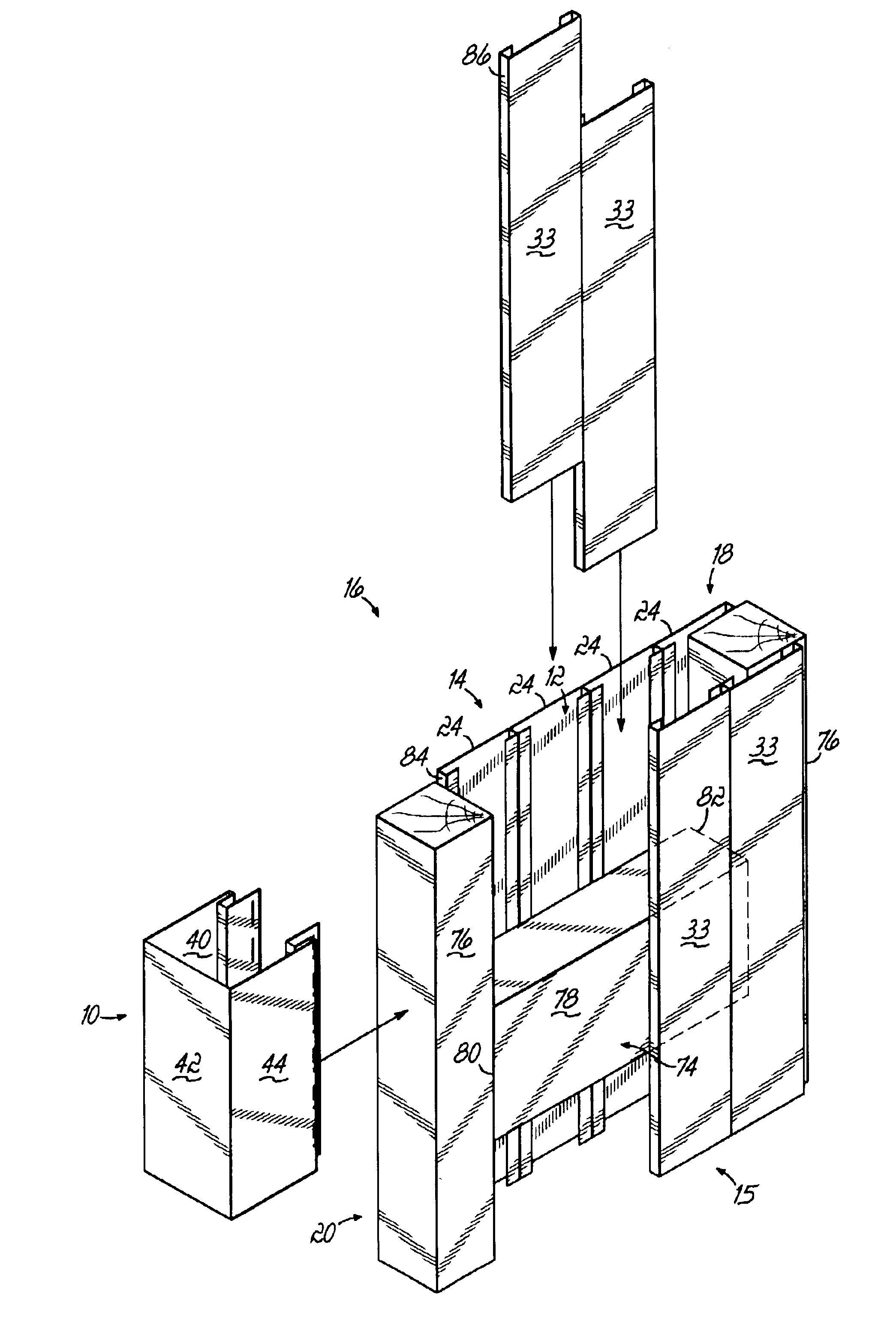

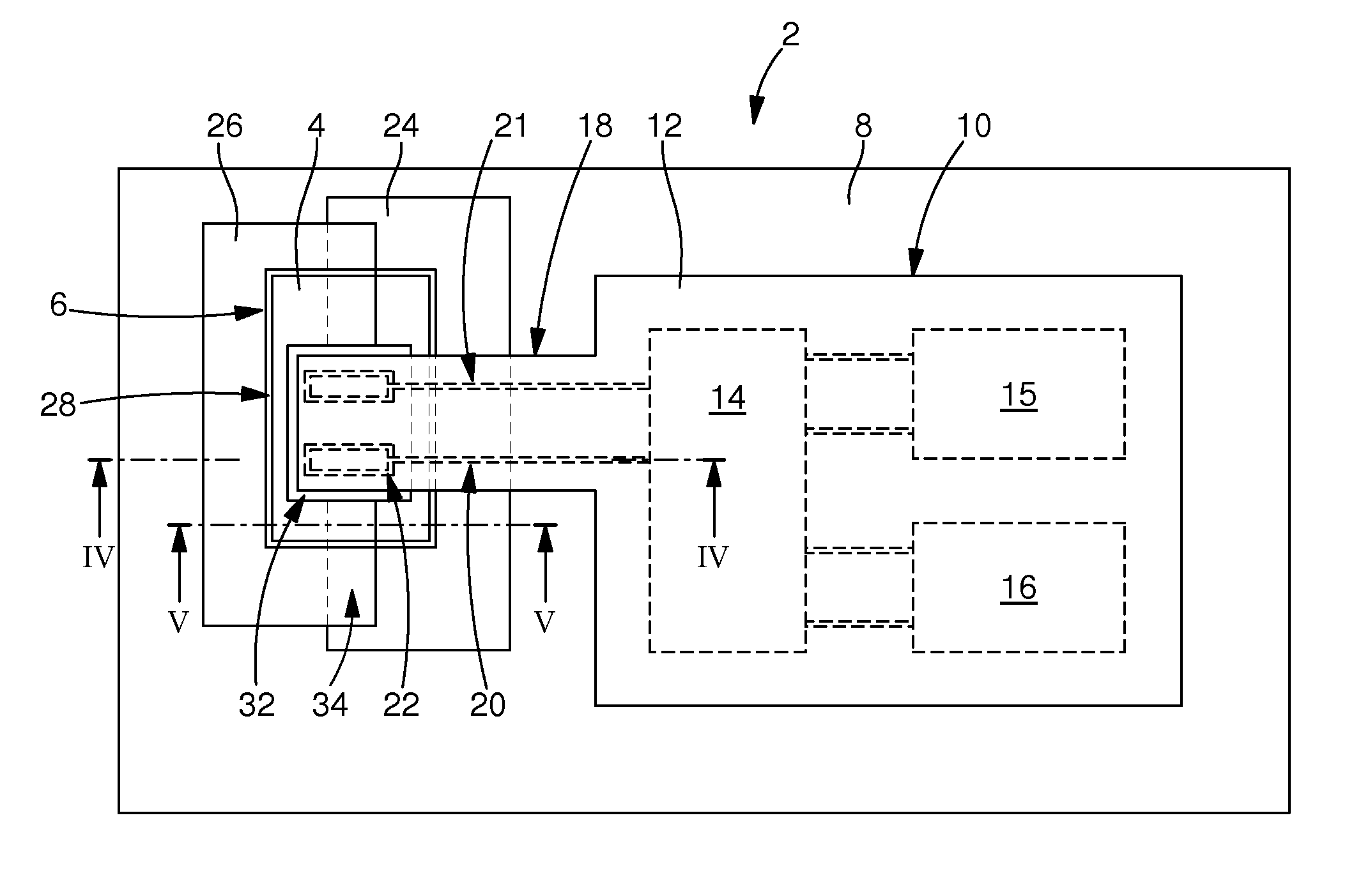

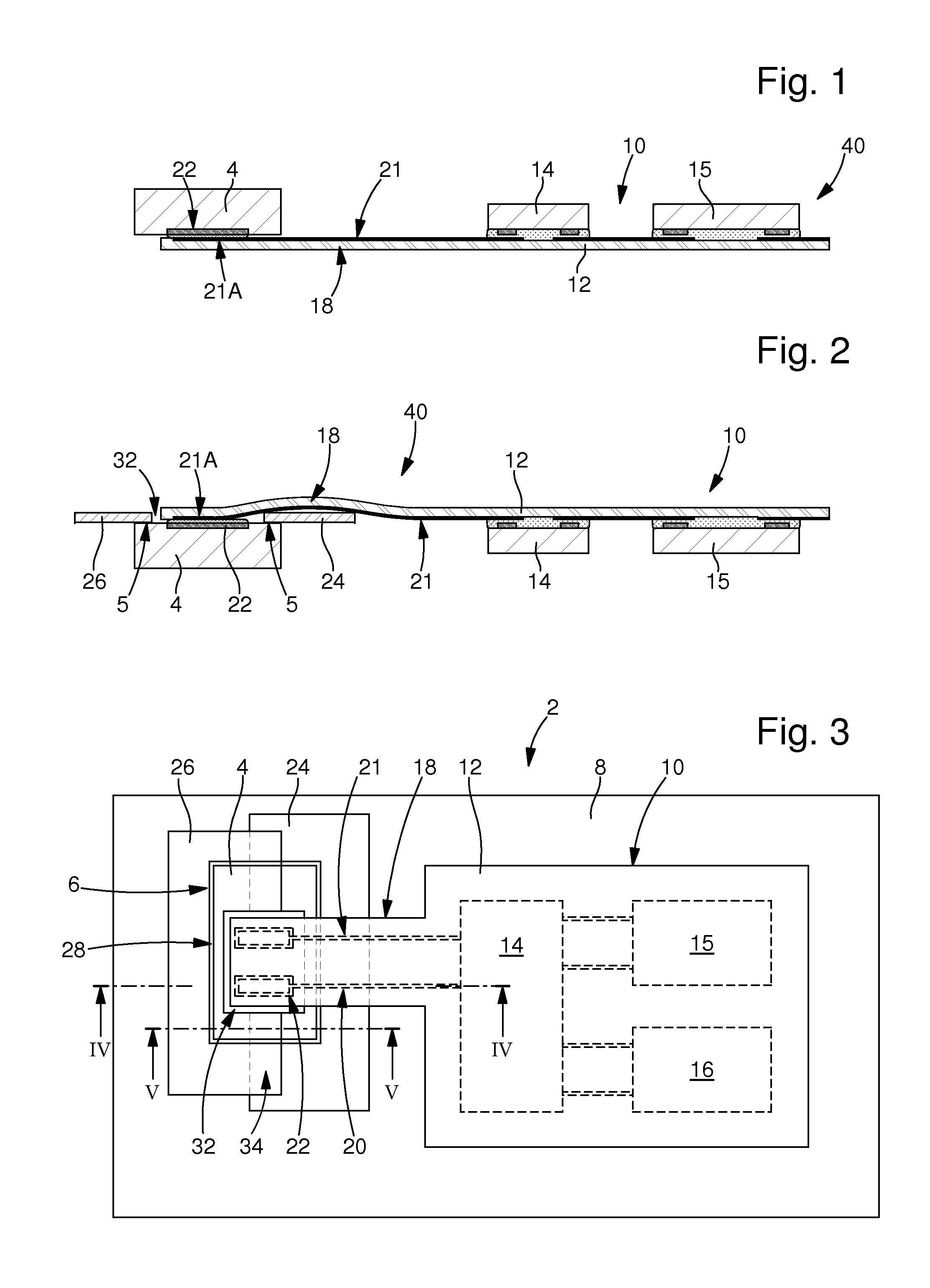

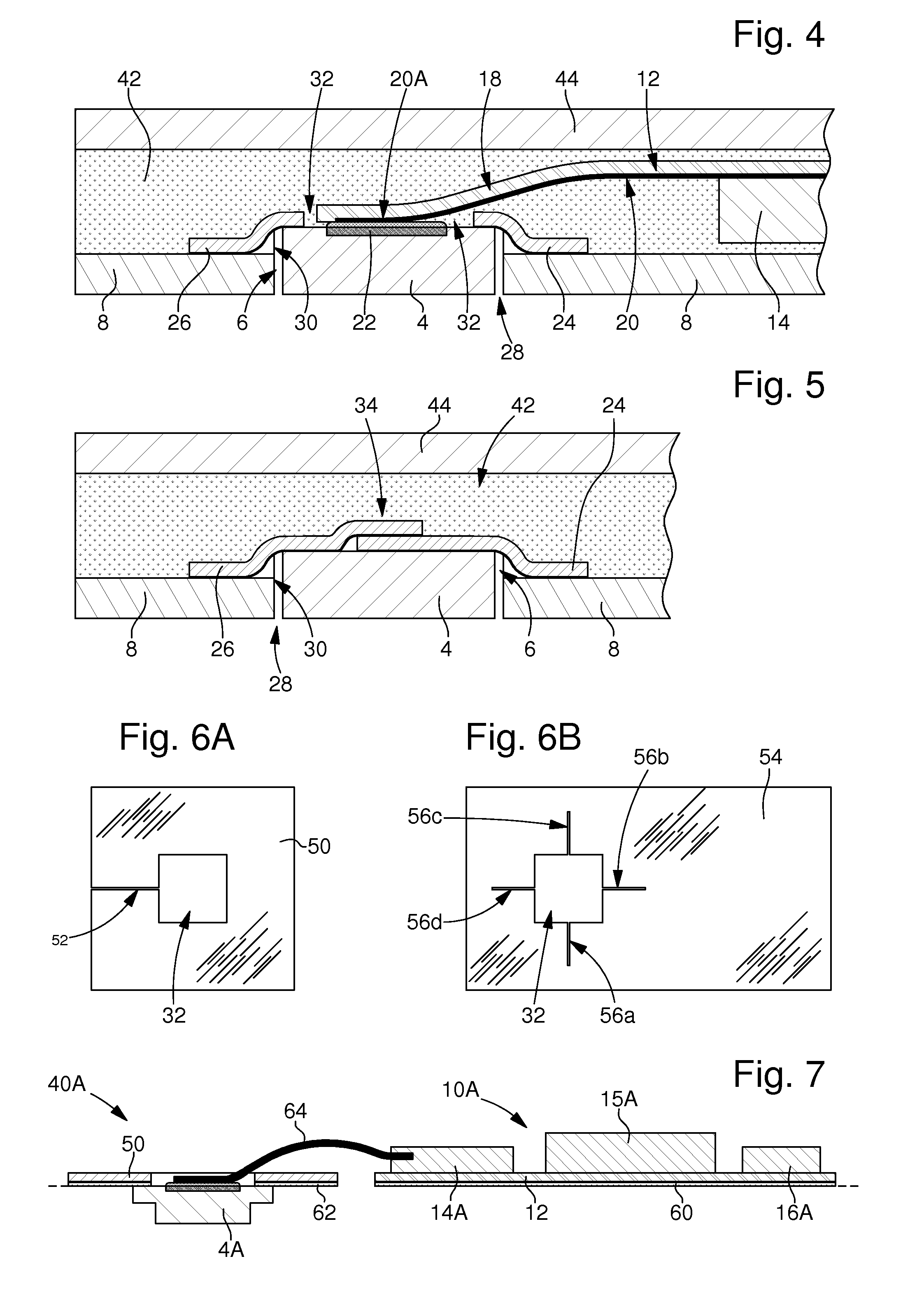

Method of manufacturing electronic cards

InactiveUS20110154662A1Prevent penetrationSmall dimensionPrinted circuit assemblingConductive pattern formationTectorial membraneElectrical connection

The present invention concerns a method of manufacturing complex electronic cards each including an electronic device or assembly (40) formed of a first electronic unit (4) at least partially arranged in a window in a solid bottom layer of the card and a second electronic unit (10), incorporated in the body of the card, at least partially formed by a resin provided on the solid bottom layer. In order to prevent the resin from flowing into a slit between the lateral wall of the window and the second unit inserted therein, a protective film is arranged to cover the edge of the rear face of the first unit and a zone peripheral to the aperture in the solid layer. According to the invention, the electronic device or assembly (40) is first formed and then placed on the bottom solid layer. The protective film is arranged between the two units after or when the electronic device or assembly is formed. Therefore according to the invention the protective film is formed, for example, of several parts (24, 26) having respective profiles that define an aperture into which the electrical connection (18) between the two electronic units (4, 10) passes. In another embodiment, the protective film is formed of a single part having at least one slit starting from an aperture (32) made in said part and provided to allow the electrical connection to pass therethrough. In another embodiment, the protective film has flaps at the edge of the aperture and is assembled to the solid bottom layer prior to addition of the electronic device or assembly.

Owner:NAGRAVISION SA

System and method for identifying and assessing topographical features using satellite data

ActiveUS20200279097A1Accurate and reliable and easy to useReduce mortalityImage enhancementInstruments for road network navigationSatellite dataSurface water

Disclosed herein are systems, media, and methods for identifying and assessing topographical features such as vegetation density and surface water using satellite data, comprising: a digital processing device; a database of digital maps, each indicative of grazing area(s); and a computer program to create an application comprising: a software module receiving a first set of satellite data indicative of a first topographical feature of the land; a software module calculating a normalized index array of the first topographic feature for the time period using the first set of satellite data; a software module generating a custom map indicative of density of the first topographical feature; a software module combining the custom map with one of the digital maps to generate a combined map indicative of the density of the first topographical feature within the grazing areas; and a software module allowing a user to visualize or print the combined map.

Owner:PROJECT CONCERN INT

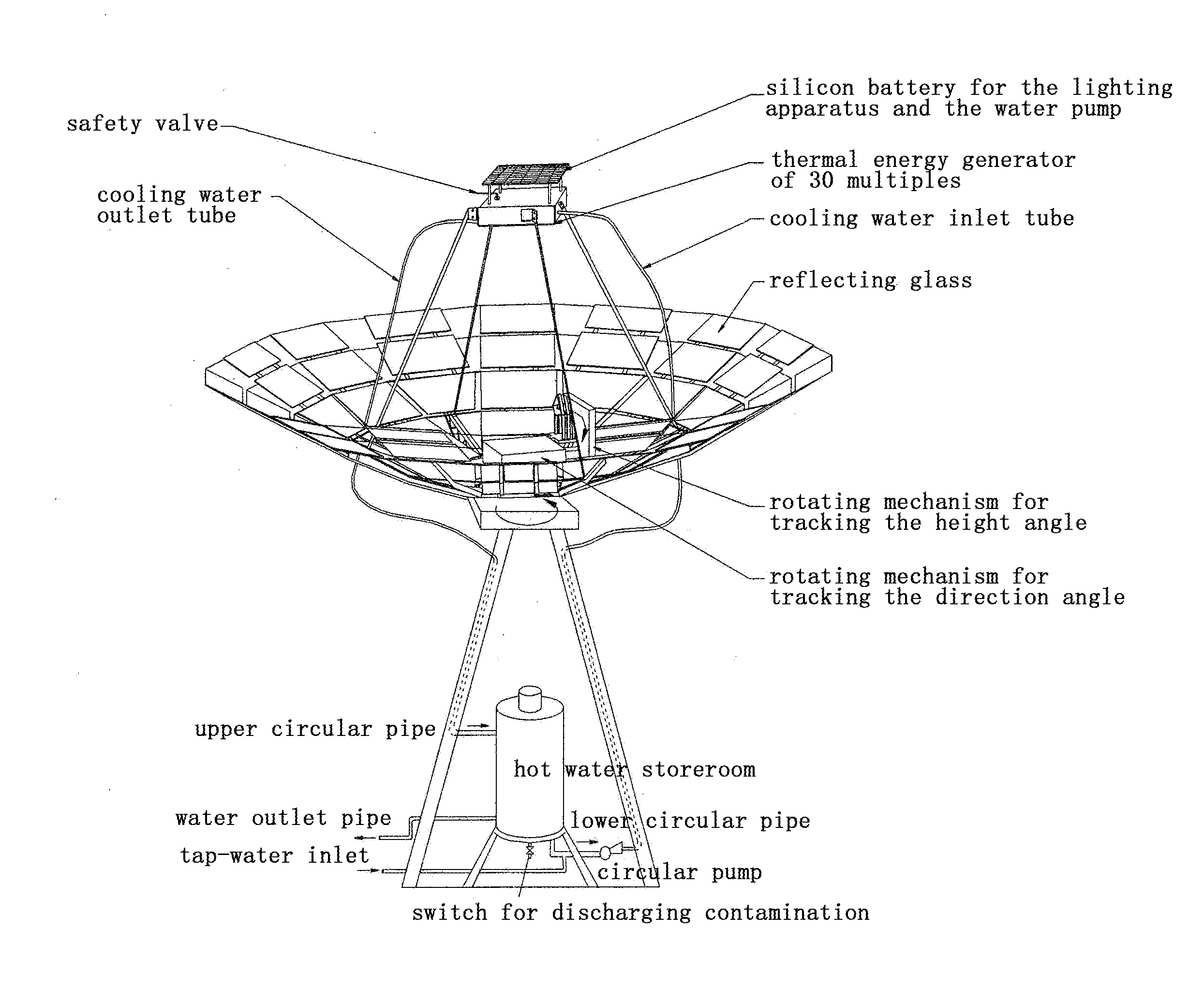

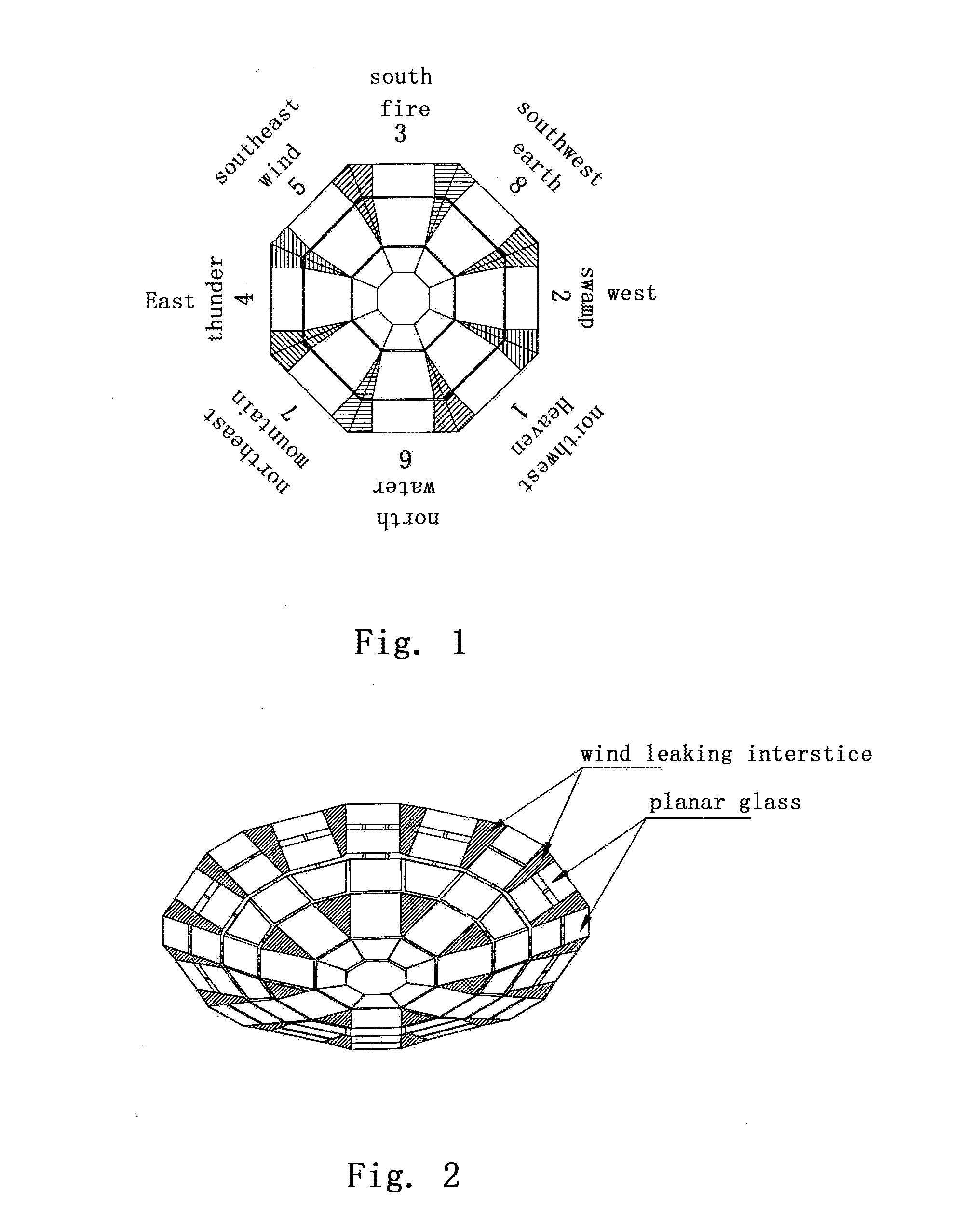

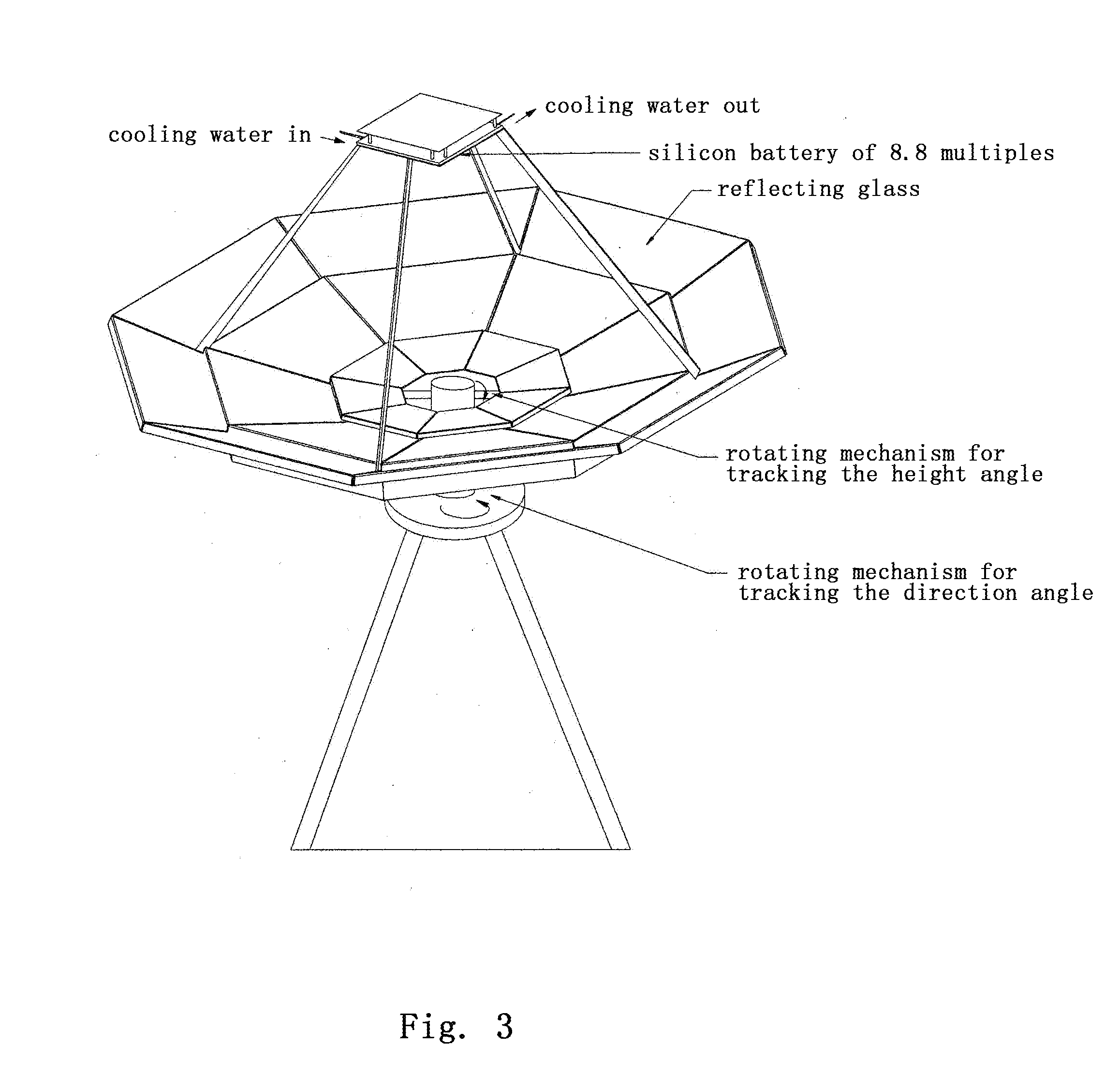

Solar energy generator

InactiveUS20130042903A1Reduce weightIlluminances of the sunlight are differentPhotovoltaic supportsSolar heating energyThermal energyCombustion

An auto-tracking sun solar energy power generator. The power generator includes an eight-diagram-shaped photovoltaic power generator of 8.8 multiples, an eight-diagram-shaped thermal energy generator of 30-50 multiples, a Striling external-combustion photothermal power generator of an eight-diagram-shaped thermal energy generator and a wind-light mutual complementing power generator with the power more than 20 kW. The first three devices are eight-diagram-shaped and of multiple sun structure. The fourth device is a wind-light mutual complementing planar silicon batteries power generator. The first three devices comprise a named multiple suns machine and a named tracking sun machine. The multiple suns machine comprises a metal bracket and planar glass. The tracking sun machine comprises a mechanical drive assembly for tracking sun and a counter-weight.

Owner:HENRY NG SHUN WU

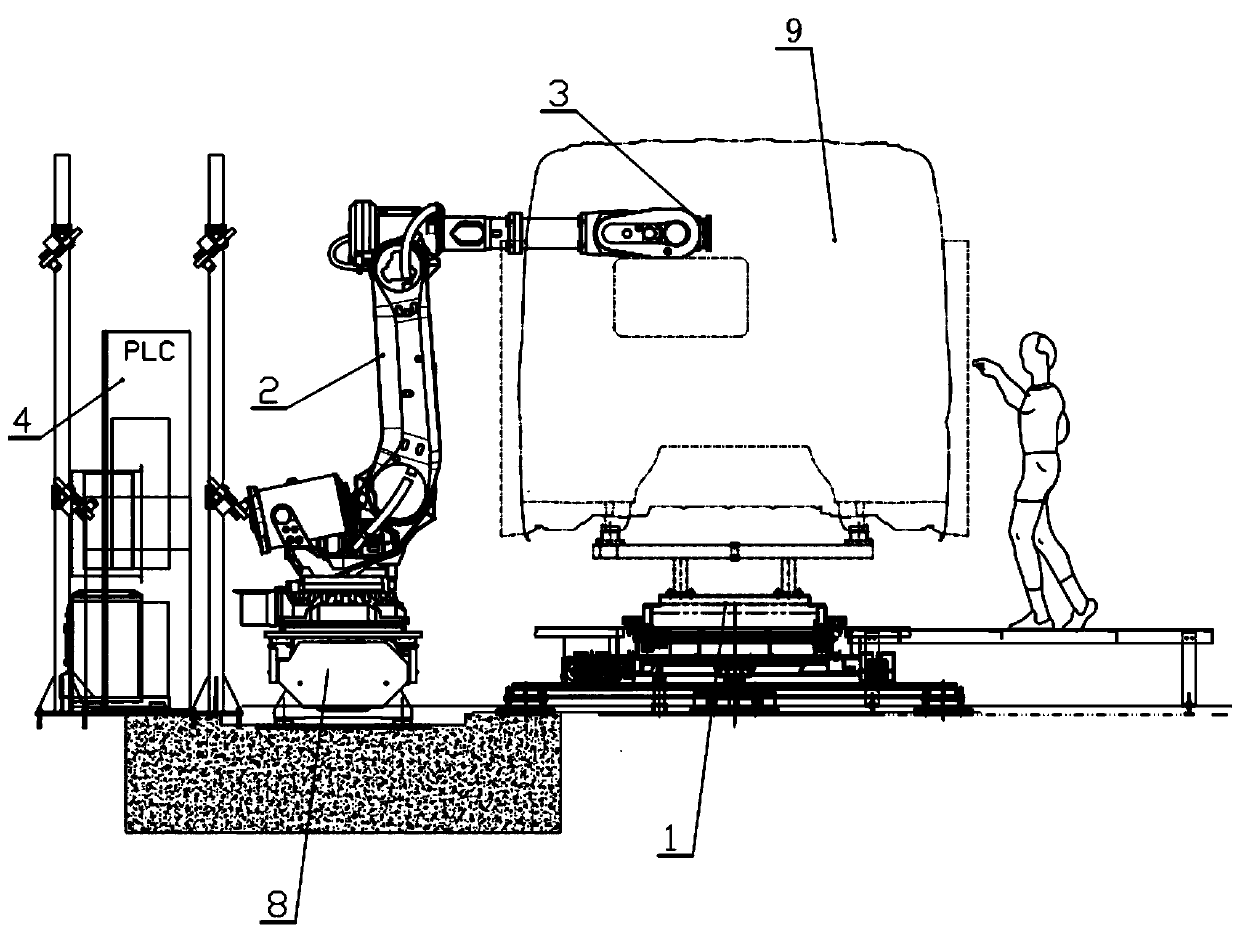

Truck whole vehicle automatic coating system and coating method

PendingCN110052349AReduce investmentReduce wasteLiquid surface applicatorsSpraying apparatusProduction lineCoating system

The invention discloses a truck whole vehicle automatic coating system and coating method. According to the system, a whole truck is carried by sliders to enter / leave the coating system. A code scanning gun, a rotatable rotary roll, a 3D visual system which is installed on the rotary roll and a spraying robot which is installed on a ground production line and in data transmission connection with the 3D visual system are included, a glue gun is installed on the spraying robot, the glue gun is provided with nozzles of different angles, and a PLC controlling system which controls all data signalsand a human-computer operation platform are included. The system has the advantages that the investment of labor force can be reduced, the waste of glue is reduced, the production efficiency is improved, and the demands of energy saving and emission reduction by existing enterprises are met; the advantages of high automation level, high repeating precision, stable technology and the like are achieved by adopting a robot coating technology, and the system and the method have higher using value on welding sealing glue coating working positions in truck industries.

Owner:济南希润自动化科技有限公司

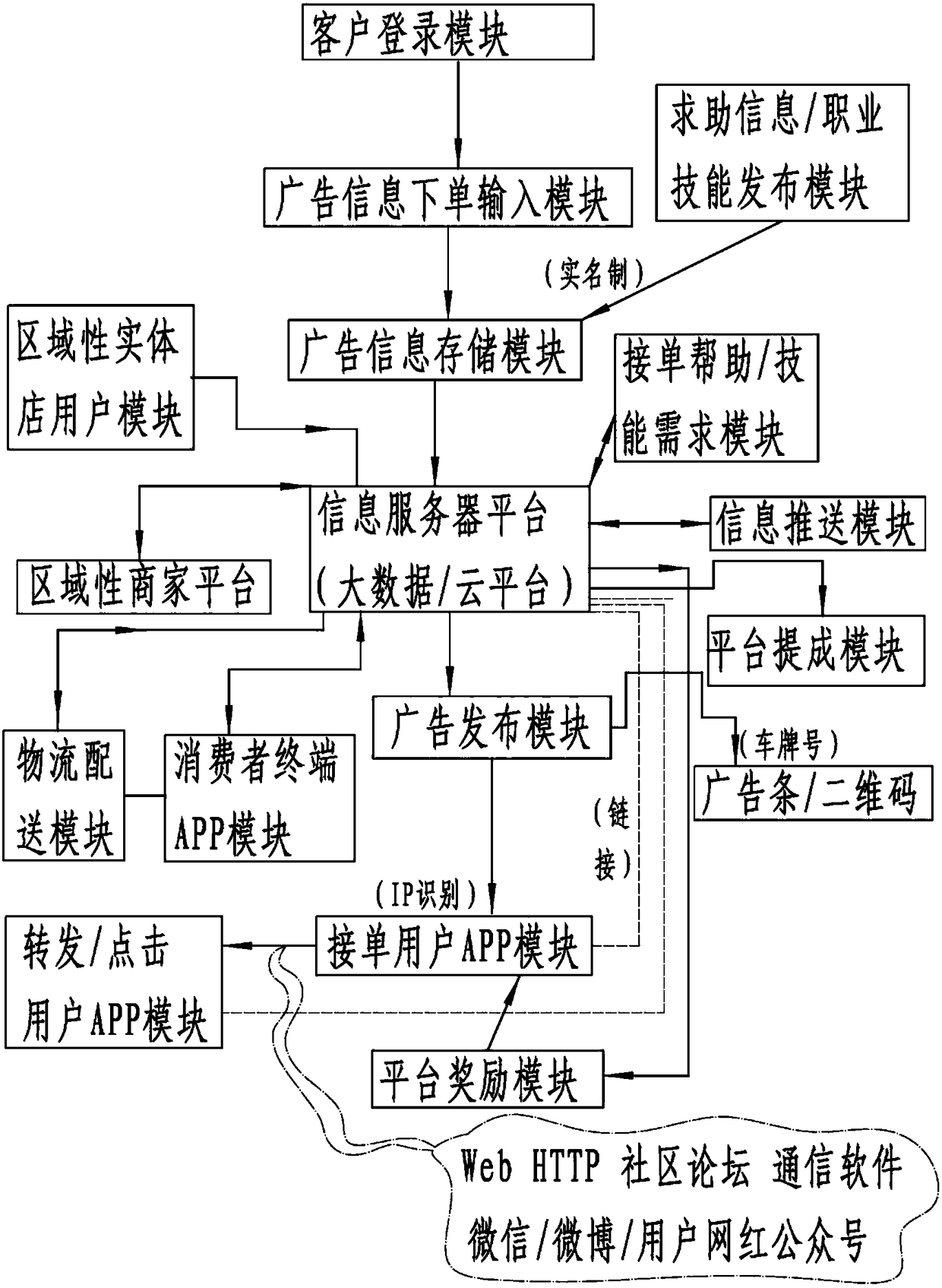

Sharing-type advertisement promotion system and method

InactiveCN108335145AAccurate coverageStrong coverageDiscounts/incentivesAdvertisementsCustomer informationWorld Wide Web

The invention discloses a sharing-type advertisement promotion system and method. The system includes a customer login module, which is a customer registration and login entrance, and submits advertisement promotion fees; an advertisement information order-placing input module, which is connected with the customer login module; an advertisement information storage module, which is connected with the advertisement information order-placing input module, and records customer information and the advertisement promotion fees; an information server platform, which is a big-data system / cloud platform / server, is connected with the advertisement information storage module, and has predetermined income of all advertisement information; an advertisement publishing module, which is connected with theinformation server platform; a platform percentage module, which is connected with information server platform, and extracts platform income from the advertisement promotion fees; and a platform reward module, which has an input end connected to the information server platform, and stores user sharing total-income, wherein the user sharing total-income = advertisement promotion fees - the platform income.

Owner:蒋严华

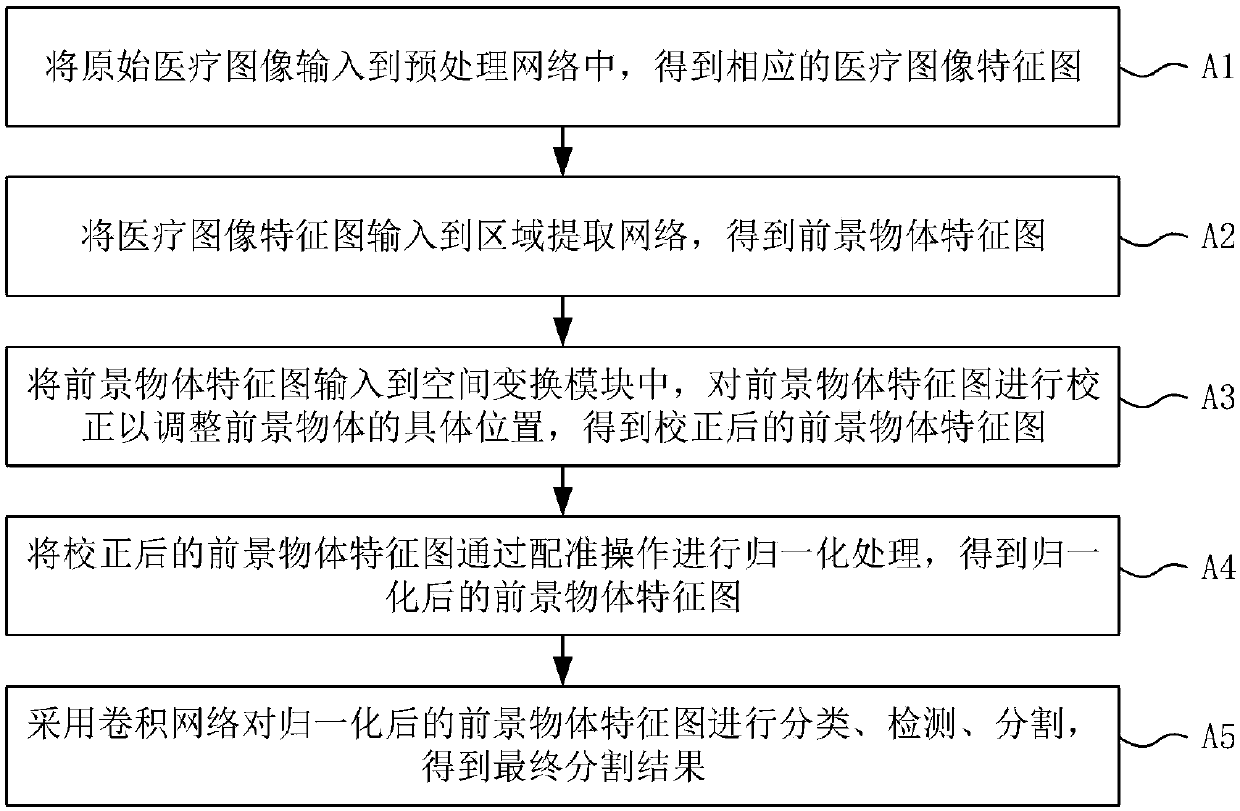

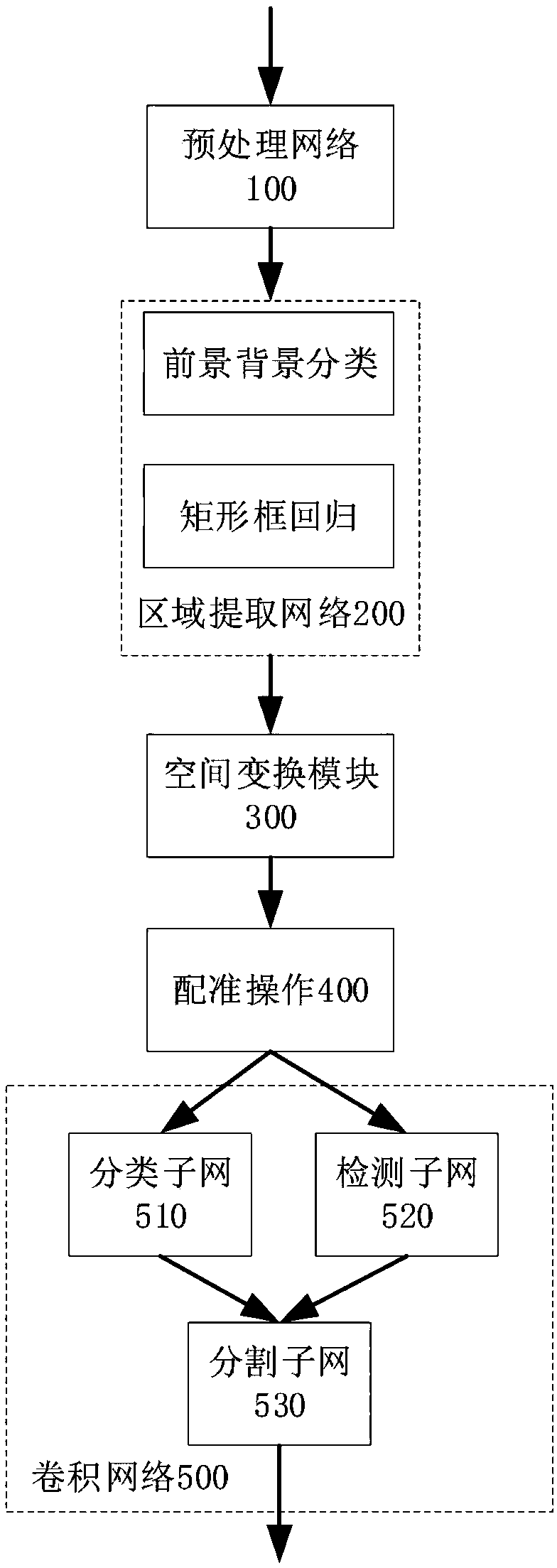

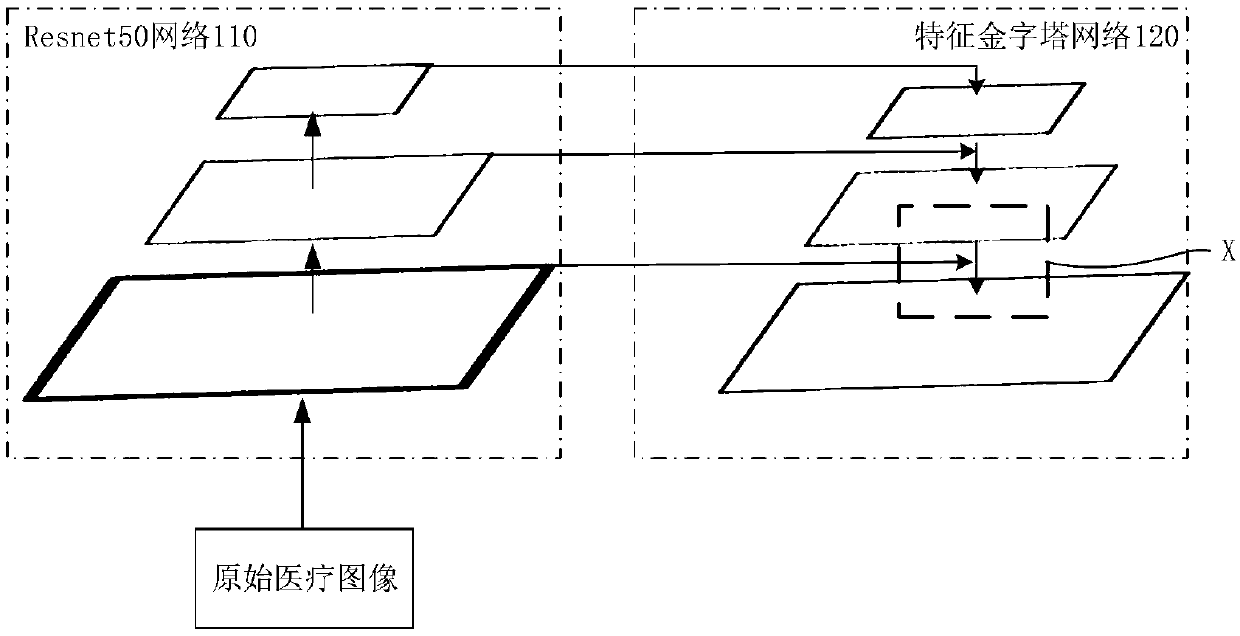

A medical image segmentation method

InactiveCN109544564AAccurate segmentationSolve mutual adhesionImage enhancementImage analysisPattern recognitionImaging Feature

The invention discloses a medical image segmentation method, comprising the following steps: A1, inputting an original medical image into a preprocessing network to obtain a corresponding medical image characteristic map; A2, inputting that medical image feature map to an area extraction network to obtain all foreground object feature maps; A5: adopting a convolution network to classify, detect and segment that feature map of the foreground object to obtain the final segmentation result. The medical image segmentation method provided by the invention realizes the accurate segmentation of eachregion of interest of the medical image by adopting an example segmentation, solves the problem that similar objects adhere to each other in the prior segmentation method, and has the advantages of simple and high efficiency.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

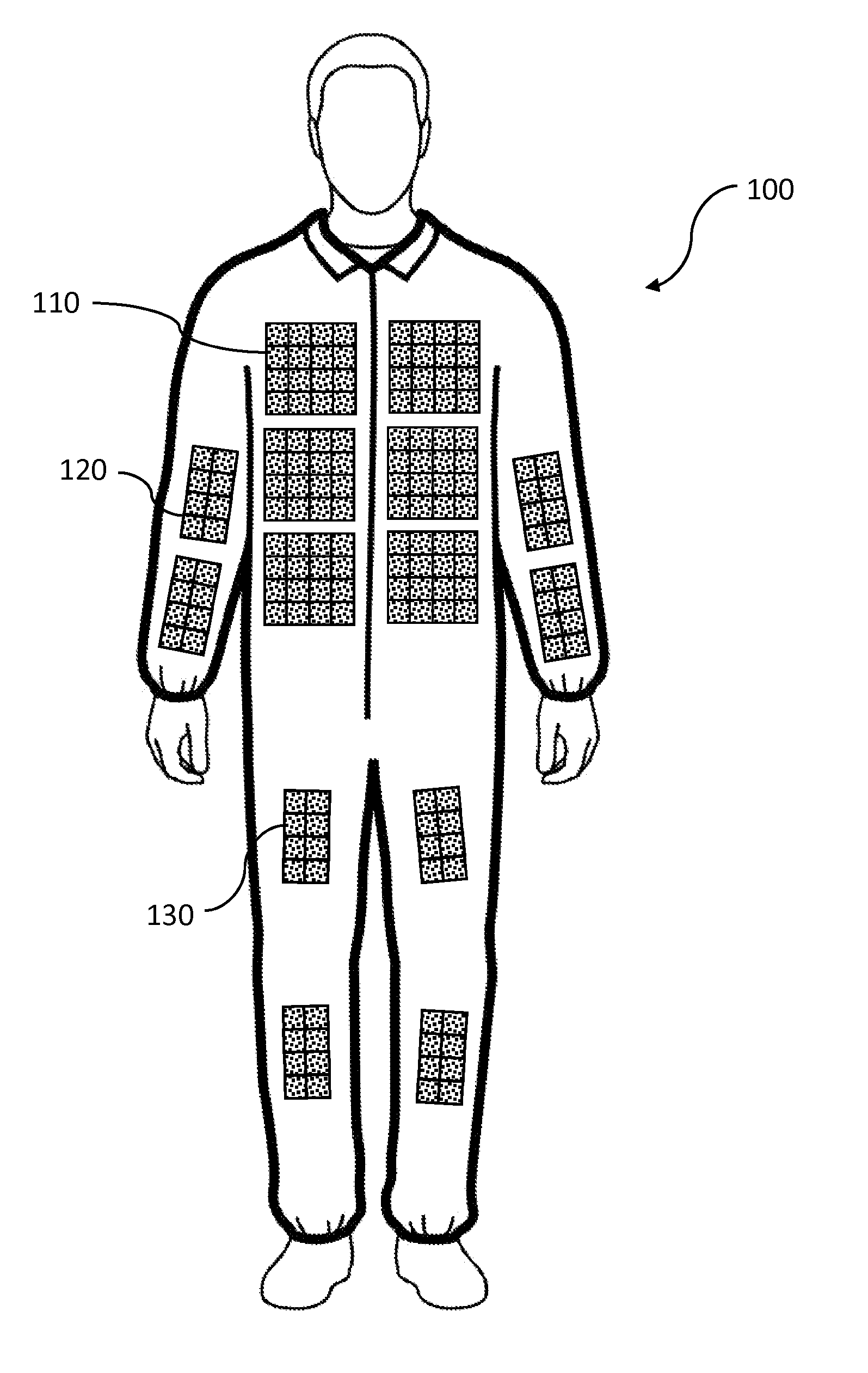

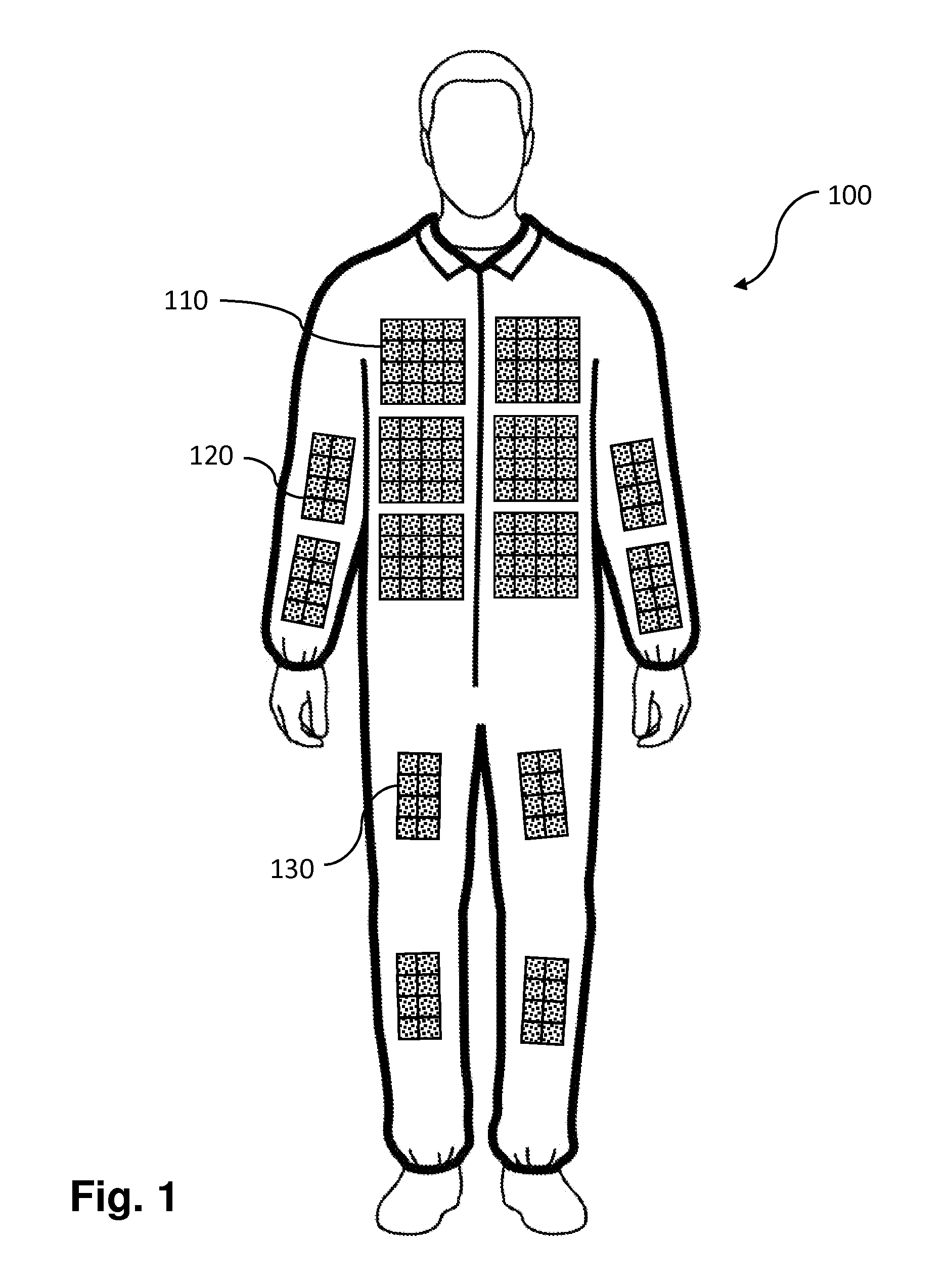

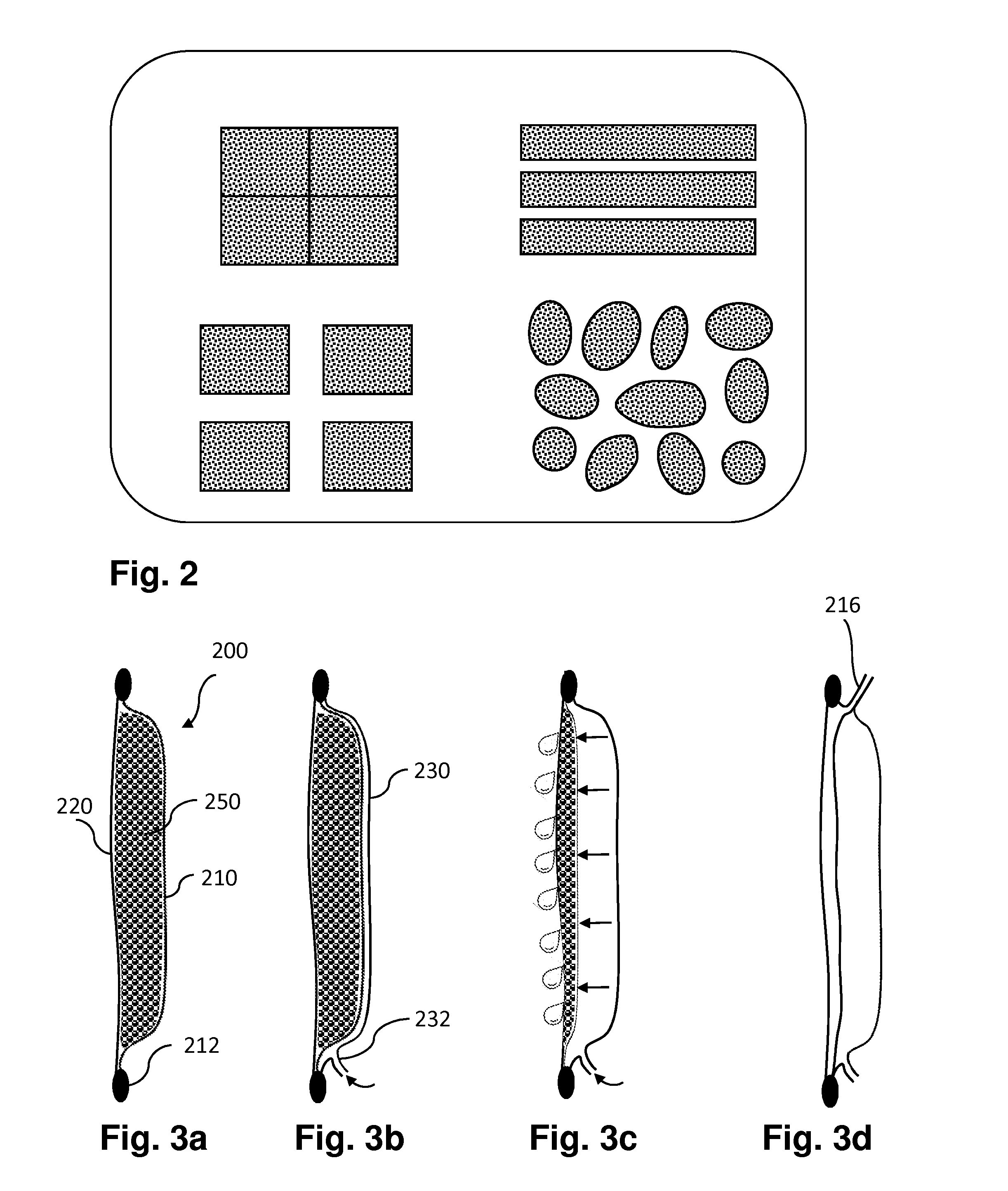

Self-Disinfecting Protective Garment

InactiveUS20160183605A1Extended use timeSimplified donningProtective garmentChemicalsEngineeringBiomedical engineering

A self-disinfecting personal protective garment comprises a plurality of pockets covered by a porous external layer. Each pocket contains (or can be filled with) a disinfecting solution. Applying compression to the flexible chamber of the pocket (such as by inflation of adjacent inflatable chambers) causes pressurization of the disinfecting solution and forces the solution to flow from the pockets across and through the porous external layer and ultimately to spread over the external surface of the protective garment—so as to eradicate the pathogens on the surface and disinfect the protective garment. Also described is a conversion kit configured to add a self-disinfecting feature to a conventional protective garment. The protective garment of the invention may be used by healthcare workers treating Ebola patients or patients with other highly contagious infections—to extend the time of garment usage, simplify garment removal procedure and increase their personal safety.

Owner:LESCHINSKY MARK DANIEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com